Technique for rolling multiple-variety multiple-station spline threaded shaft

A multi-station, multi-variety technology, applied to threaded products, metal rolling, and other household appliances, can solve the problems of unallowable design and low output from the perspective of cost, and achieve low investment cost and equipment investment cost , Adjust the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

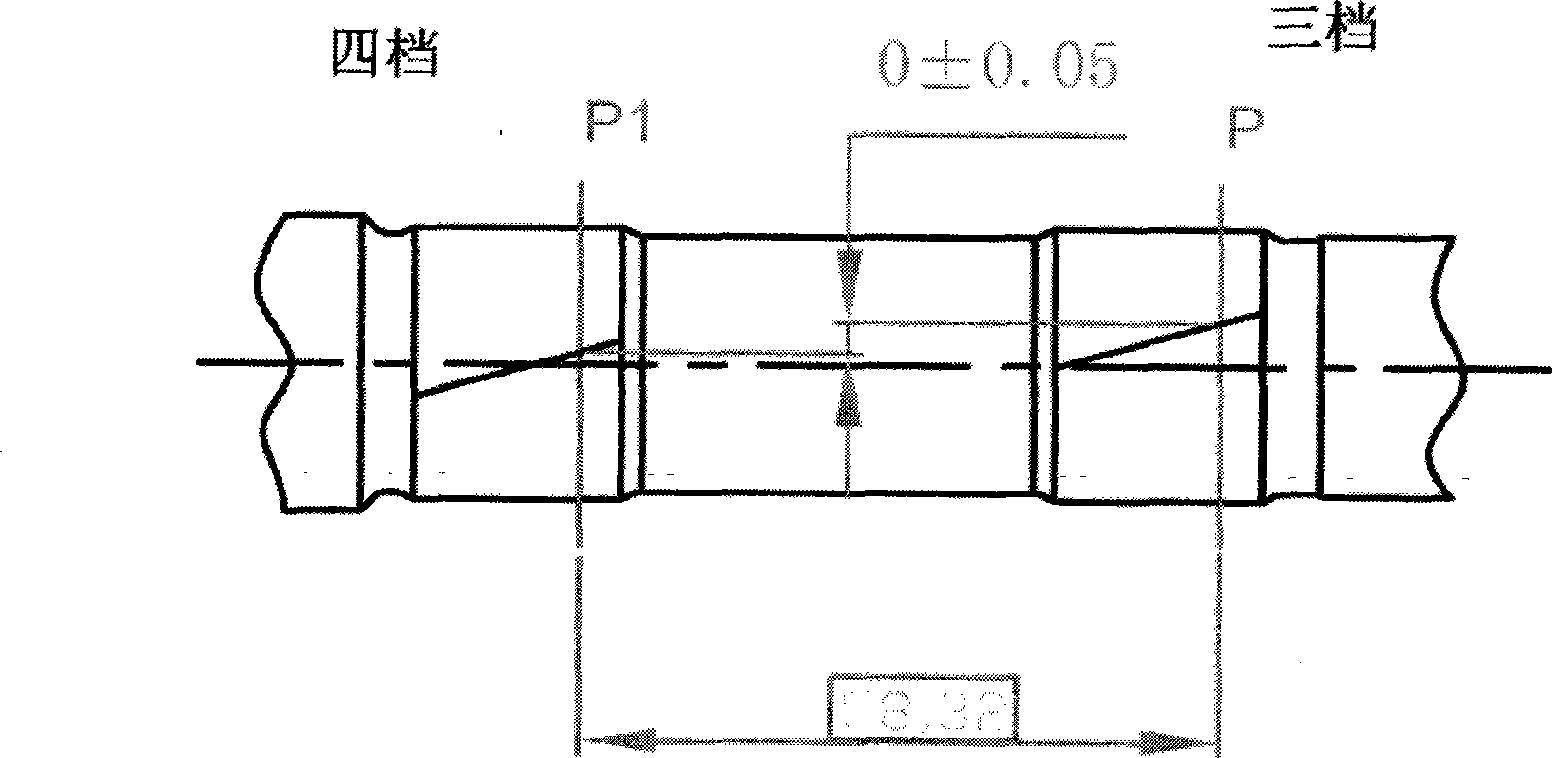

[0024] BE two-axis 3rd gear, 4th gear spline consistency requirements data such as figure 1 shown. The P1-P distance of the 3rd and 4th splines is 58.32, and the spline consistency deviation requirement is ≤0.05, which is a special requirement for the BE 2-axis 3rd and 4th splines.

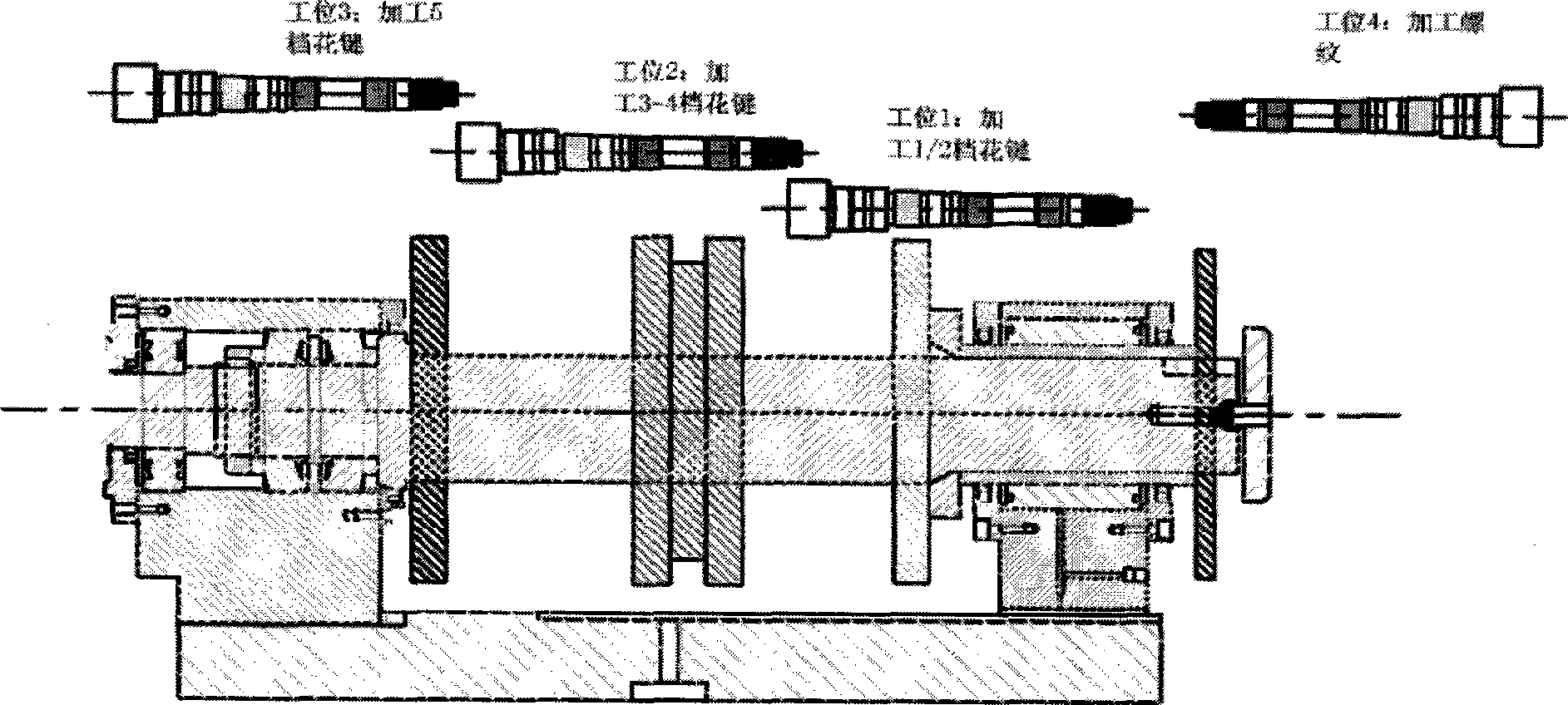

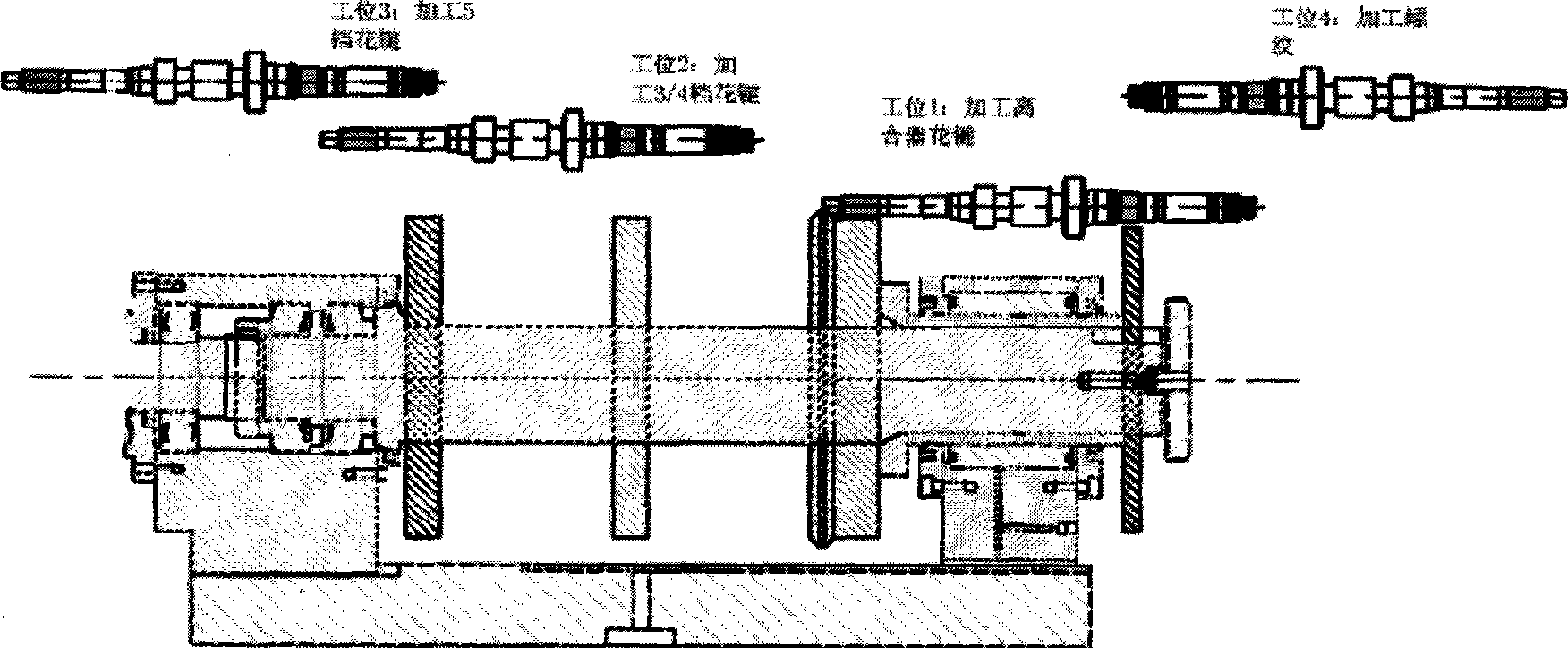

[0025] BE two-axis cloth knife such as figure 2 , Figure 5 shown. One set of Italian MS5 rolling mill is adopted, which is five-axis CNC. BE two-axis 5-speed rolling wheel, 3-4 gear rolling wheel, 1 / 2-speed rolling wheel, and thread rolling wheel are distributed in BE two-axis station 3, two-axis station 2, two-axis station 1, On the two-axis station 4 four stations. The processing method of the 3-4 gear rolling wheel is: 1. Processing the rolling wheel and adding a circle; 2. Assembling two rolling wheels together to process the spline; 3. Disassembling the assembled rolling wheel; 4. 1. Add pads between the two rolling wheels, and adjust the angle of the two rolling wheels; (the straight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com