Raw material preparation process based on heating non-combustible cigarette

A heat-not-burn, preparation process technology, applied in the preparation of tobacco, tobacco, tobacco processing and other directions, can solve the problems of long production process, high processing cost, and high equipment investment, reducing equipment investment costs, saving steam energy consumption, The effect of reducing steam energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

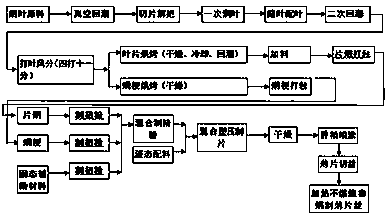

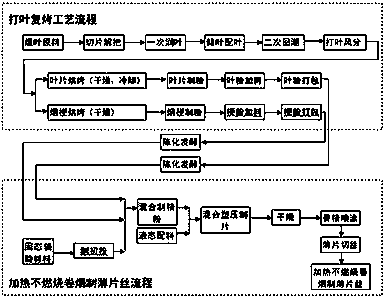

[0044] The raw material preparation process based on heat-not-burn cigarettes includes the following steps:

[0045] 1. Pre-processing:

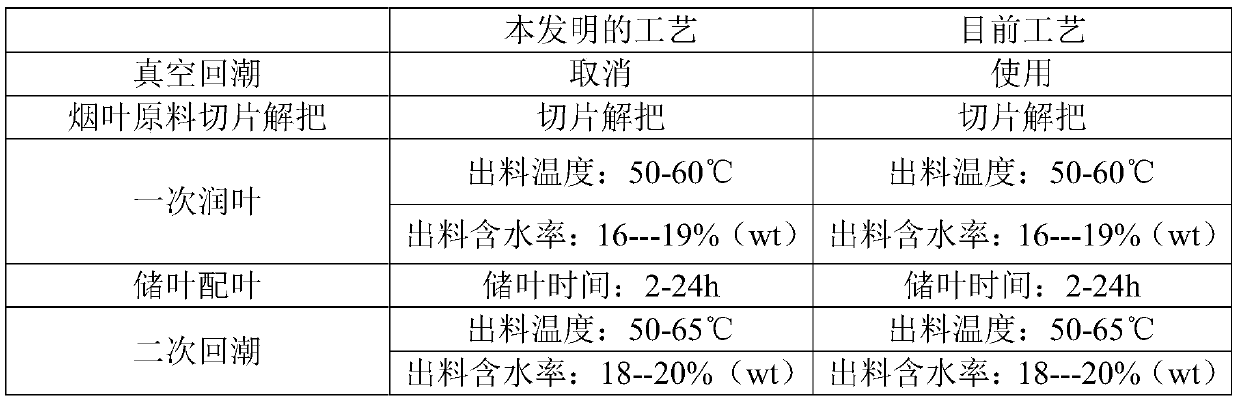

[0046] The pre-treatment mainly includes: slice and unhook the tobacco leaf raw material; moisten the leaves once; store and match the leaves; remoisturize the second time; compared with the current process, the differences are as follows:

[0047]

[0048] 2 Leaves and tobacco stems are processed separately after threshing air:

[0049] Leaf treatment: three-stage threshing and air separation; leaf baking and cooling; leaf powdering; leaf powder feeding; leaf powder packaging; leaf powder aging and fermentation;

[0050] Tobacco stem processing: tobacco stem baking; tobacco stem powder milling; stem powder feeding; stem powder packaging; stem powder aging and fermentation;

[0051] (1) Compared with the current process of blade treatment, the difference is as follows:

[0052]

[0053] (2) Compared with the current process, the tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com