Method for preparing reverse osmosis antisludging agent

A scale inhibitor and reverse osmosis technology, applied in the field of industrial water supply treatment and advanced water treatment, can solve the problems of low scale inhibition rate and large performance difference, and achieve the effect of high scale inhibition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

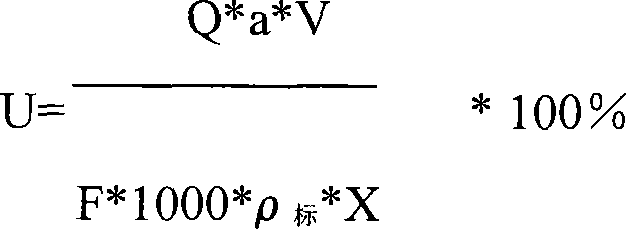

Method used

Image

Examples

Embodiment 1

[0021] The method embodiment 1 of the present invention, its steps are:

[0022] (1) Add 50kg of melamine, 150kg of 40% hydrolyzed maleic anhydride, 150kg of ammonium chloride, and 150kg of formaldehyde into a container with a volume of 2000L, stir and dissolve, and react at 80±5°C for 0.5 hours;

[0023] (2) Add 150kg of urea, 150kg of ammonium chloride, and 150kg of formaldehyde, and react at 90±5°C for 2 hours;

[0024] (3) Add 150kg of 30% polyacrylic acid and 150kg of 2% cationic polyacrylamide, and react at 70±5°C for 0.5 hours;

[0025] (4) After cooling to room temperature, the multi-component polymeric reverse osmosis scale inhibitor can be prepared.

Embodiment 2

[0026] The method embodiment 2 of the present invention, its steps are:

[0027] (1) Add 50kg of melamine, 100kg of 30% hydrolyzed maleic anhydride, 100kg of ammonium chloride, and 100kg of formaldehyde into a constant temperature reaction kettle with a volume of 2000L and a stirrer. After stirring and dissolving, react at 80±5°C for 1 hour ;

[0028] (2) Add 50kg of urea, 50kg of ammonium chloride, and 65kg of formaldehyde, and react for 3 hours at 90±5°C;

[0029] (3) Add 50kg of 15% polyacrylic acid and 60kg of 0.5% cationic polyacrylamide, and react for 0.5 hours at 70±5°C;

[0030] (4) After cooling to room temperature, the multi-component polymeric reverse osmosis scale inhibitor can be prepared.

Embodiment 3

[0031] Embodiment 3 of the inventive method, its steps are:

[0032] (1) Add 50kg of melamine, 50kg of 40% hydrolyzed maleic anhydride, 50kg of ammonium chloride, and 50kg of formaldehyde into a container with a volume of 2000L, stir and dissolve, and react at 80±5°C for 2 hours;

[0033] (2) Add 50kg of urea, 50kg of ammonium chloride, and 50kg of formaldehyde, and react at 90±5°C for 4 hours;

[0034] (3) Add 50kg of 30% polyacrylic acid and 50kg of 2% cationic polyacrylamide, and react for 1 hour at 70±5°C;

[0035] (4) After cooling to room temperature, the multi-component polymeric reverse osmosis scale inhibitor can be prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com