Oblate bag type dust collector

A bag-type dust collector, oblate technology, applied in the field of dust removal and environmental protection, can solve the problems of not using air flow organization, increasing equipment one-time investment, increasing dust cleaning air volume, etc., to meet environmental protection and industrial hygiene, and reduce primary investment costs , the effect of reducing steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

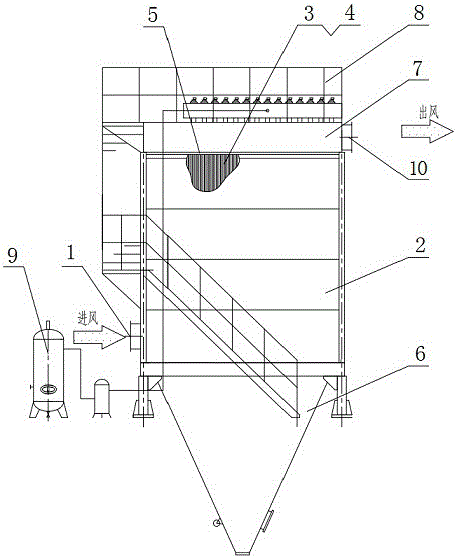

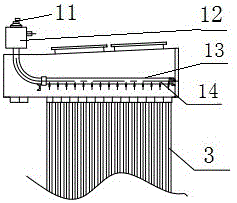

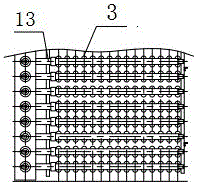

[0035] An oblate bag-type dust collector, including an inlet air duct 1, an outlet air duct 10, an upper box body 7, a middle box body 2, a flower plate 5, an injection device 8, an ash hopper 6, a filter bag frame 4, a filter The bag frame 4 supports the oblate filter bag 3; the blowing device 8 includes an air bag 12, a pulse valve 11, and a blowing pipe 13, and the blowing pipe 13 has a blowing hole 14, and the compressed air system 9 is connected with the air bag 12. Circular filter bags 3 and blowing pipes 13 are arranged in fixed rows. The blowing pipes 13 are fixed in the clean air chamber of the upper box body 7. The blowing pipes 13 correspond to the oblate filter bags 3 row by row. The spray holes 14 are installed in one-to-one correspondence with the oblate filter bags 3 in the same row.

[0036] The dust at each dust removal point is captured and enters th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com