Desulfurization system and method for flue gas of cement kiln furnace

A cement kiln and desulfurization system technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of low desulfurization efficiency of cement kilns, achieve improved desulfurization effect, high desulfurization efficiency, and convenient operation and management Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

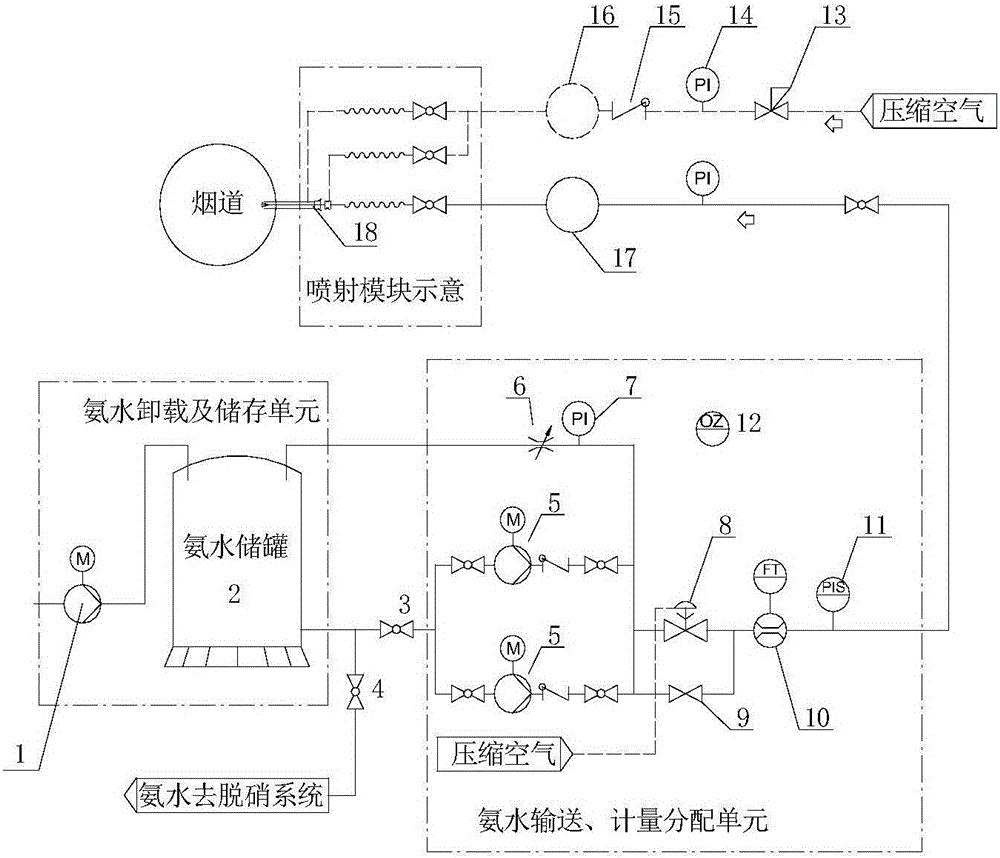

[0045] Such as figure 1 As shown, a cement kiln flue gas desulfurization system, the ammonia water in the tank car is transferred to the ammonia water storage tank 2 through the ammonia discharge pump 1, and the SNCR denitrification system will be built in the cement plant, using ammonia water as the reducing agent for denitrification The system will be equipped with an ammonia discharge pump and an ammonia water storage tank, so the present invention generally does not additionally provide an ammonia discharge pump 1 and an ammonia water storage tank 2 to save investment. At the outlet of the ammonia water storage tank, there is a main valve 3 for opening / stopping the ammonia water supply of the desulfurization system and a second main valve 4 for opening / stopping the ammonia water supply of the denitrification system, so as to switch the ammonia water supply of different systems at any time.

[0046] In this embodiment, the desulfurization system uses two centrifugal deliver...

Embodiment 1 comparative example 1

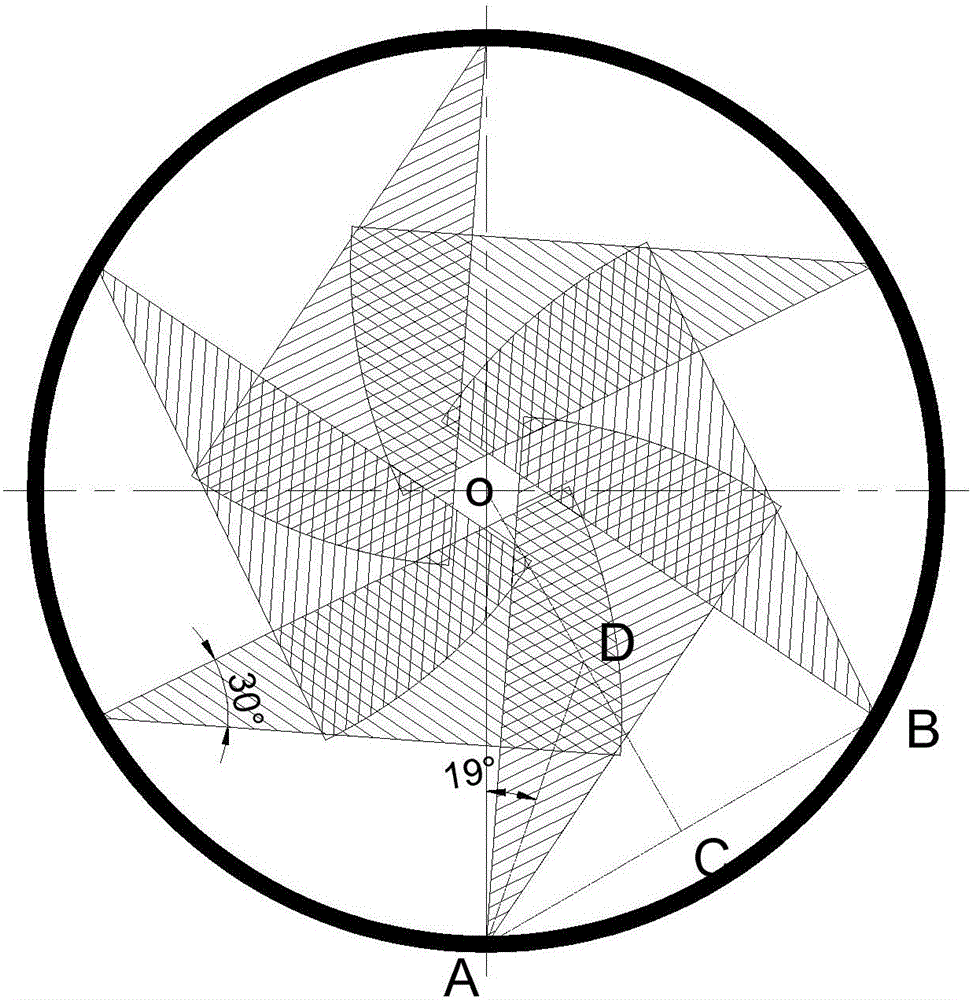

[0053] Embodiment one and comparative example one compare:

[0054] By comparison, the side-spray spray gun is compared with the direct-spray spray gun, and the coverage rate is increased by 9.71% compared with the direct-spray spray gun, so as to achieve the purpose of improving the efficiency of desulfurization reaction and reducing the consumption of ammonia water.

Embodiment 2

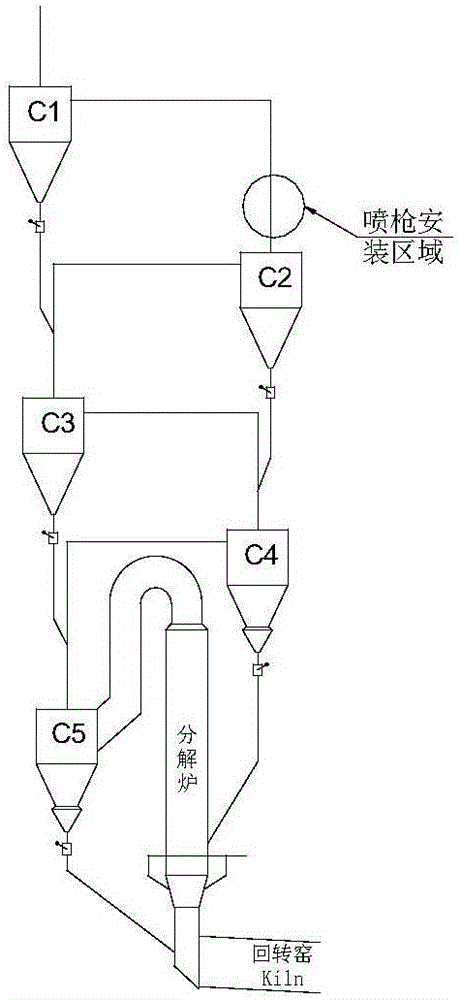

[0056] A method for desulfurization using a cement kiln flue gas desulfurization system, comprising the steps of:

[0057] Step 1, configuring 15%-25% ammonia water and transporting it to the ammonia water storage tank;

[0058] Step 2. Set the SO through the automatic control system 2 The concentration preset value, the detection device detects SO in the flue gas of the cement kiln pre-decomposition system in real time 2 Concentration, and the measured value is sent to the automatic control system, the automatic control system calculates and adjusts the injection amount of ammonia water in real time according to the deviation between the preset value and the measured value;

[0059] Step 3. According to the amount of ammonia water injection calculated in step 2, the ammonia water is pressurized by the delivery pump and then injected into the spray gun and then sprayed in the cement kiln pre-decomposition system. At the outlet, the temperature at the outlet of the second-sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com