High-concentration salt water nano-filtration membrane bidirectional separating device and method

A two-way separation, concentrated brine technology, applied in chemical instruments and methods, water/sewage treatment, water/sewage treatment equipment, etc., can solve the problems of complicated operation and high investment and operation cost of evaporation and salt separation, to simplify the process, reduce The effect of one-time investment and operating costs, and overall low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

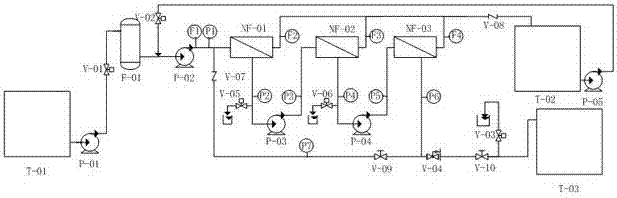

Image

Examples

Embodiment 1

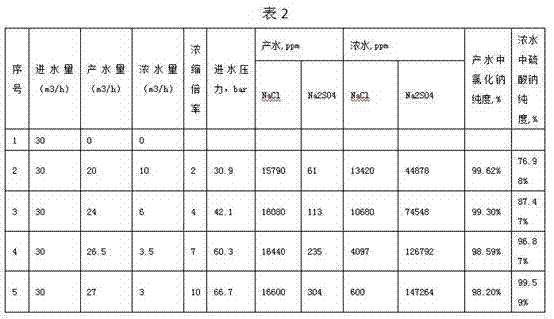

[0026] The water volume is 30m 3 / h, the influent salt content (TDS) is 4%, the sodium chloride content is 2.5%, the sodium sulfate content is 1.5%, and the high-concentration brine with impurities 2 SO 4 Separation results of mixed brine with NaCl.

[0027]

Embodiment 2

[0029] The water volume is 30m 3 / h, the influent salt content (TDS) is 3%, among which the sodium chloride content is 1.5%, the sodium sulfate content is 1.5% as an example, and the high-concentration brine with impurities 2 SO 4 Separation results of mixed brine with NaCl.

[0030]

[0031] Examples 1 and 2 show that the product purity of two-way concentration is artificially controlled by adjusting the concentration ratio. When the concentration ratio is about 7, the purity of sodium chloride on the product water side reaches more than 95% ("Industrial Salt GBT5462-2015" Industrial Dry Salt Superior Grade product requirements), and at the same time, the purity of sodium sulfate on the concentrated water side reaches more than 95% ("GBT 6009-2014 Industrial Anhydrous Sodium Sulfate" three qualified products); and the reverse migration of sodium chloride is greater than the residual sodium sulfate, making the product water The concentration of sodium chloride increases. ...

Embodiment 3

[0033] The water volume is 30m 3 / h, the salt content (TDS) of the influent water is 4%, among which the sodium chloride content is 1.5%, the sodium sulfate content is 2.5% Control different concentration ratios, measure salt content and component purity in its concentrated water tank and product water tank by sampling titration, test result is as shown in table 3, and table 3 is the present invention under different concentration ratios to Na 2 SO 4 Separation results of mixed brine with NaCl.

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com