High-temperature washing and deacidifying system

A high-temperature, washing tower technology, applied in the field of high-temperature flue gas treatment, can solve the problems of no anti-corrosion of dilute acid, increase one-time investment, increase operating cost, etc. Corrosion and alkali corrosion resistance, the effect of reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

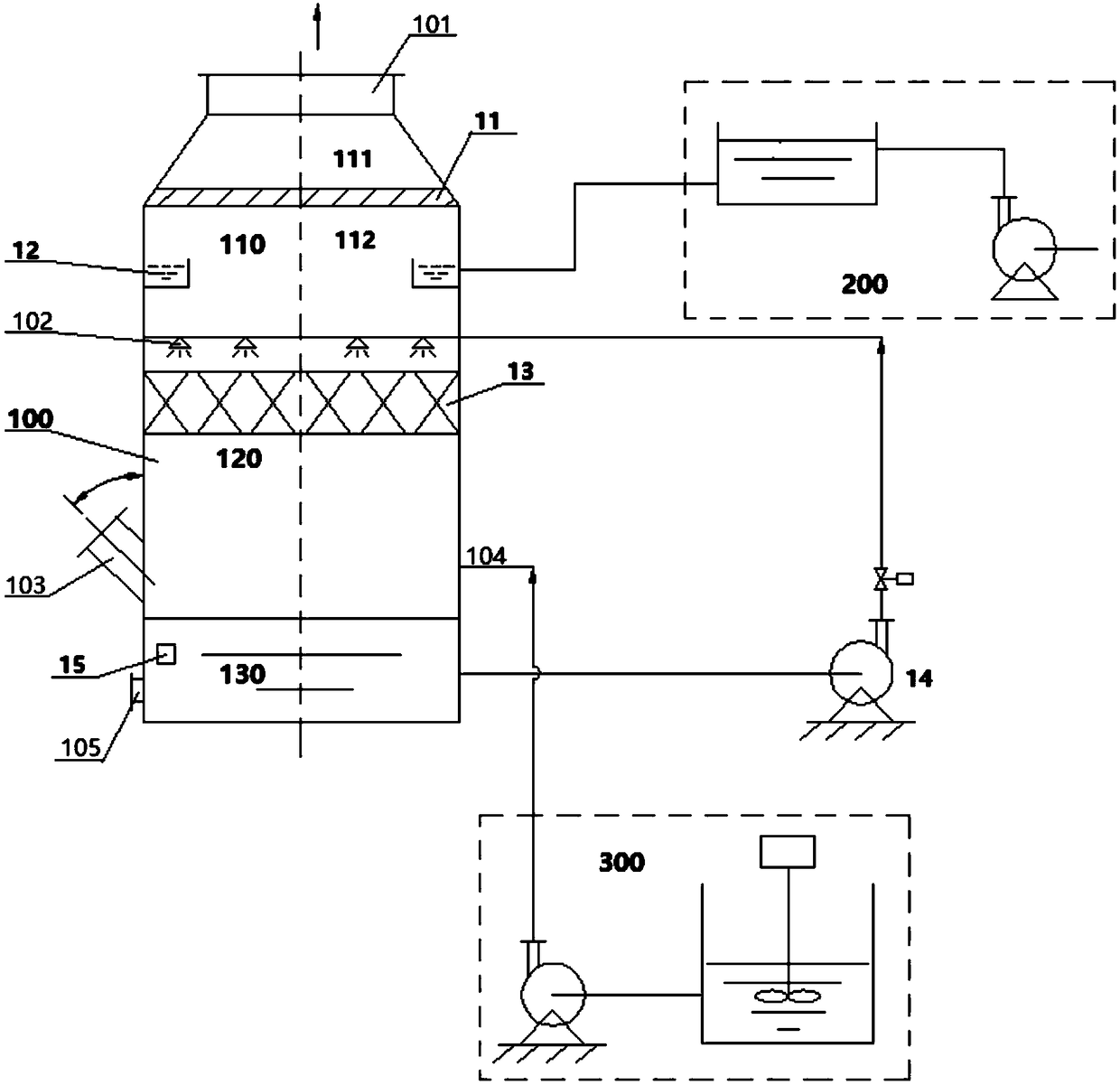

[0054] The height ratio of the defogging area, the spraying area, and the reaction area in the FRP washing tower is 1:4:6, and the distance between the bottom of the high-temperature flue gas inlet and the upper end of the alkali liquid level in the reaction area is 1.0m. The angle between the intake direction of the high-temperature flue gas inlet and the central axis of the FRP scrubber is 55°

[0055] The flue gas containing harmful components at a temperature of 80°C-250°C is introduced into the reaction zone of the FRP washing tower through the high-temperature flue gas inlet, and the flue gas rushes into the lye in the reaction zone at a speed of 12m / s-15m / s, and the The action of lye realizes preliminary dust removal, deacidification and temperature reduction, and then the flow direction of the flue gas is changed from downward to upward, and the temperature of the flue gas is reduced by 10°C to 20°C. At the same time, the lye is sprayed evenly through the circulating l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com