Process for melting glass and glass

A technology for glass and glass raw materials, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as glass instability, achieve melting cost, excellent ductility and processability, and ensure heat resistance and resistance. Corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0068] Hereinafter, the present invention will be described in detail based on examples.

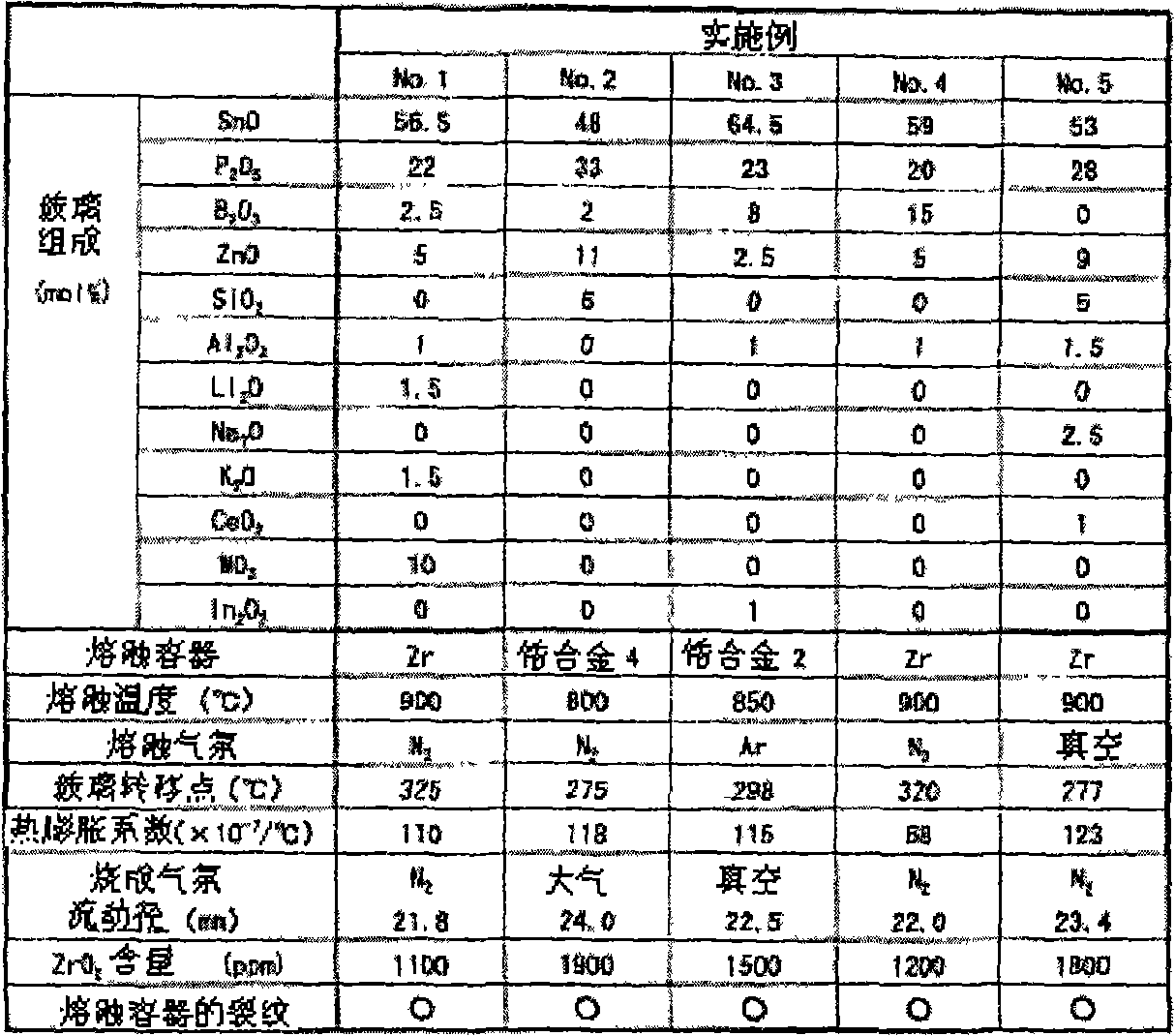

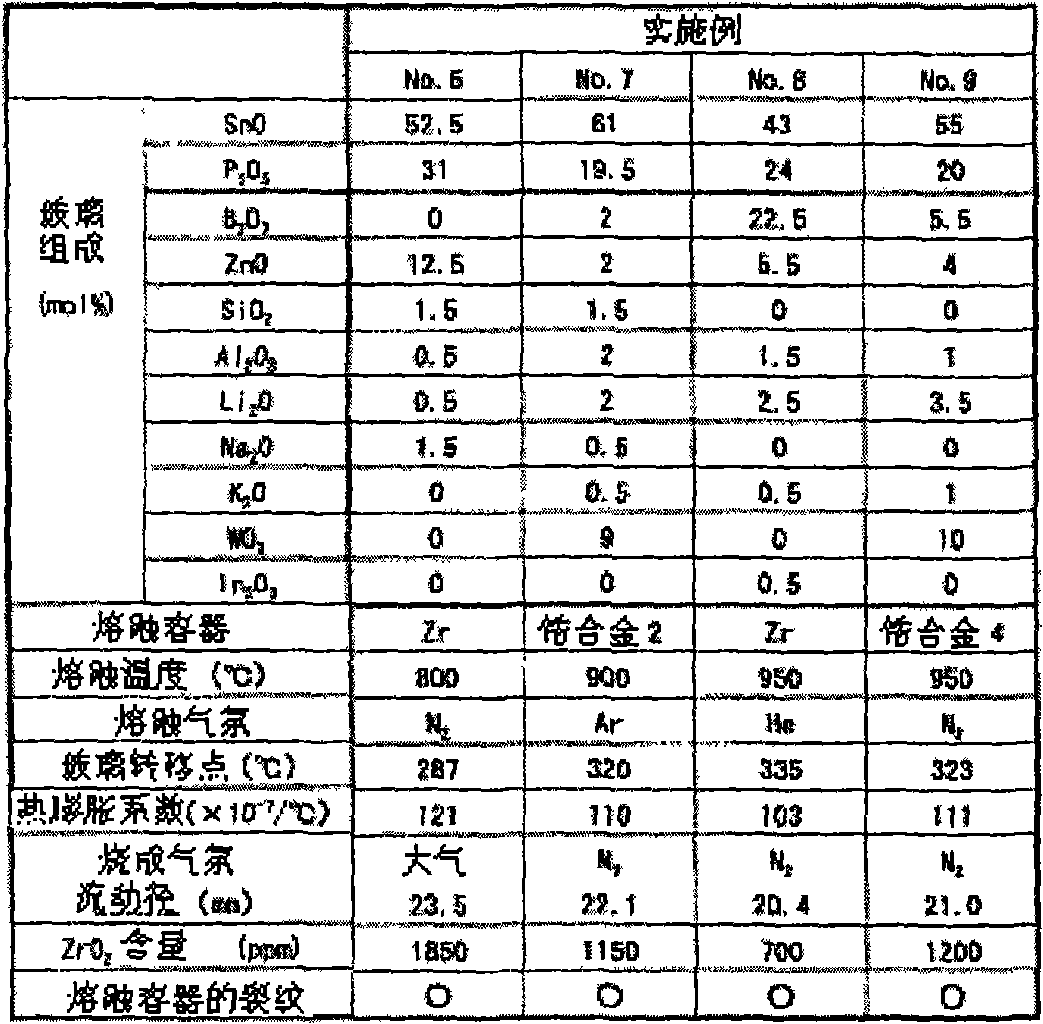

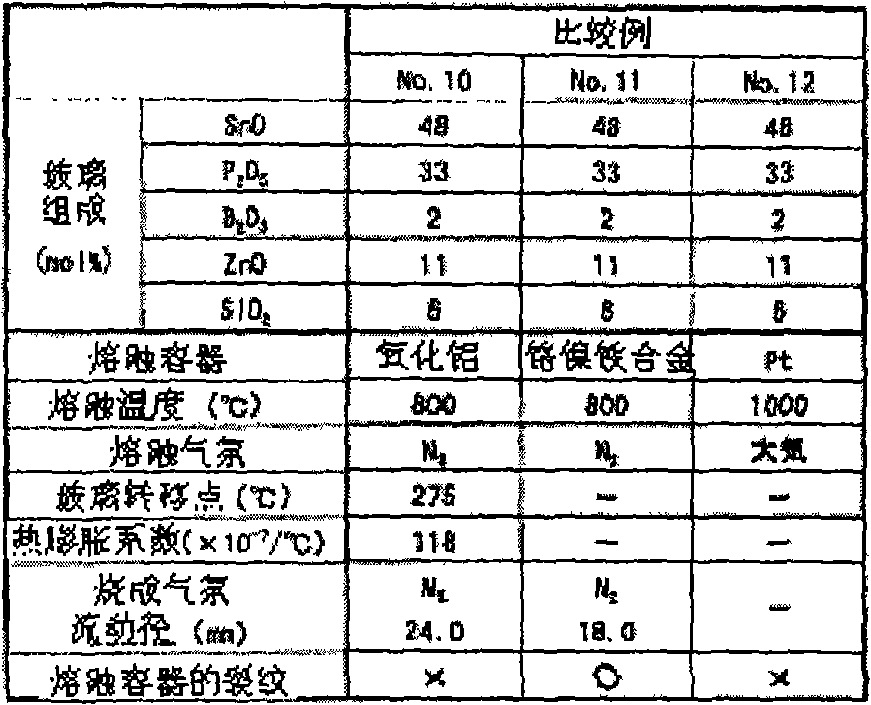

[0069] Tables 1 and 2 show examples (No. 1 to 9) of the present invention, and Table 3 shows comparative examples (No. 10 to 12).

[0070] [Table 1]

[0071]

[0072] (Note) Zirconium Alloy 2: Equivalent to ASTM Grade R60802

[0073] Zirconium Alloy 4: Equivalent to ASTM Grade R60804

[0074] [Table 2]

[0075]

[0076] (Note) Zirconium Alloy 2: Equivalent to ASTM Grade R60802

[0077] Zirconium Alloy 4: Equivalent to ASTM Grade R60804

[0078] [table 3]

[0079]

[0080] As shown in the glass composition in the table, various oxides, carbonate raw materials, etc. are blended to make glass raw materials. The glass raw materials shown in the table were charged into a melting container, and melted at the melting temperature shown in the table for 2 hours in the melting atmosphere shown in the table.

[0081] Next, the molten glass in the melting vessel flows out fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com