Electrical charging coagulation method for dust in flue gas transfering pipeline

A dust charging and coagulation method technology, applied in chemical instruments and methods, electrode structure, power supply technology, etc., can solve the problems of low dust efficiency, high energy consumption, and bulky volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

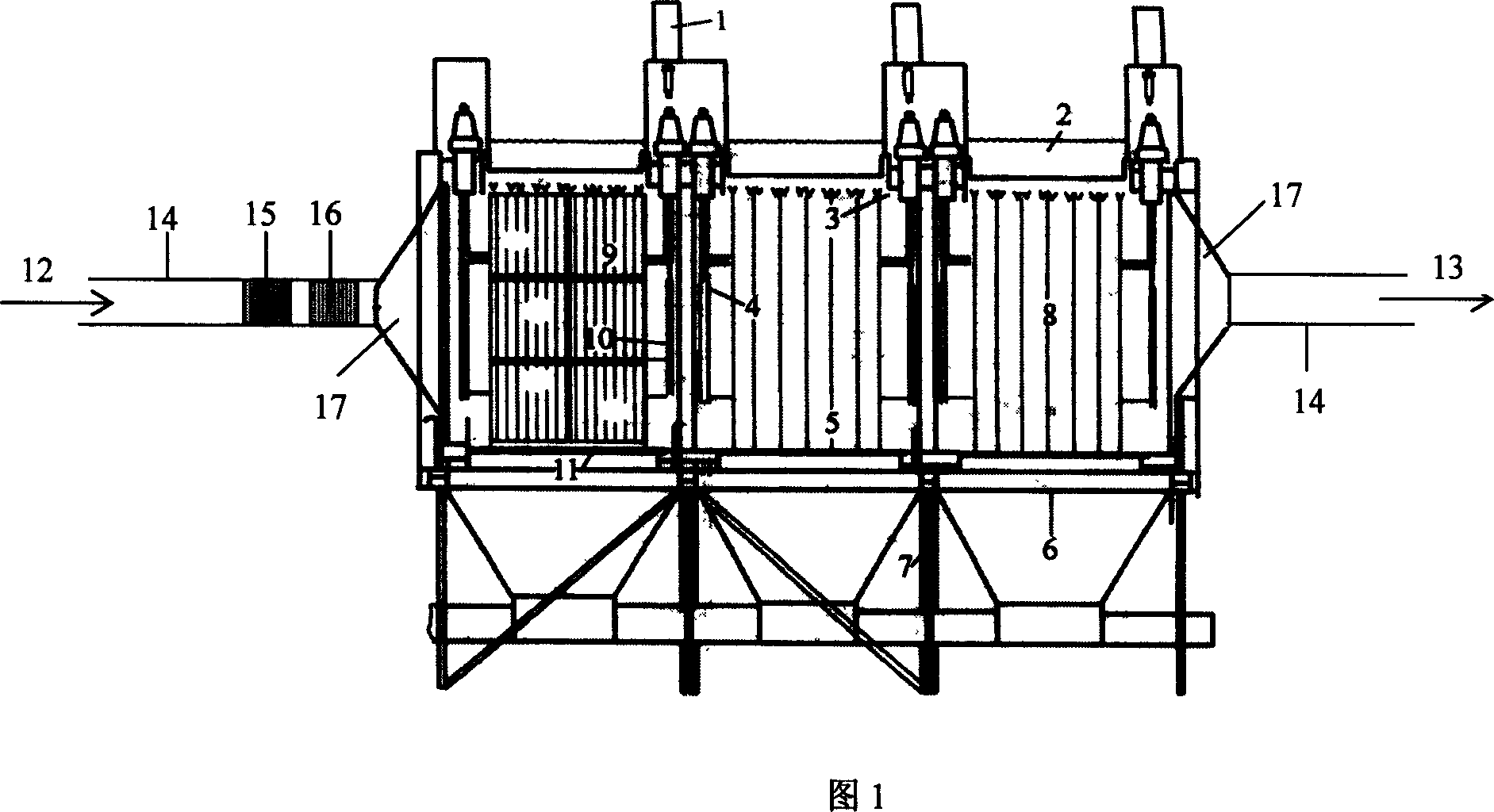

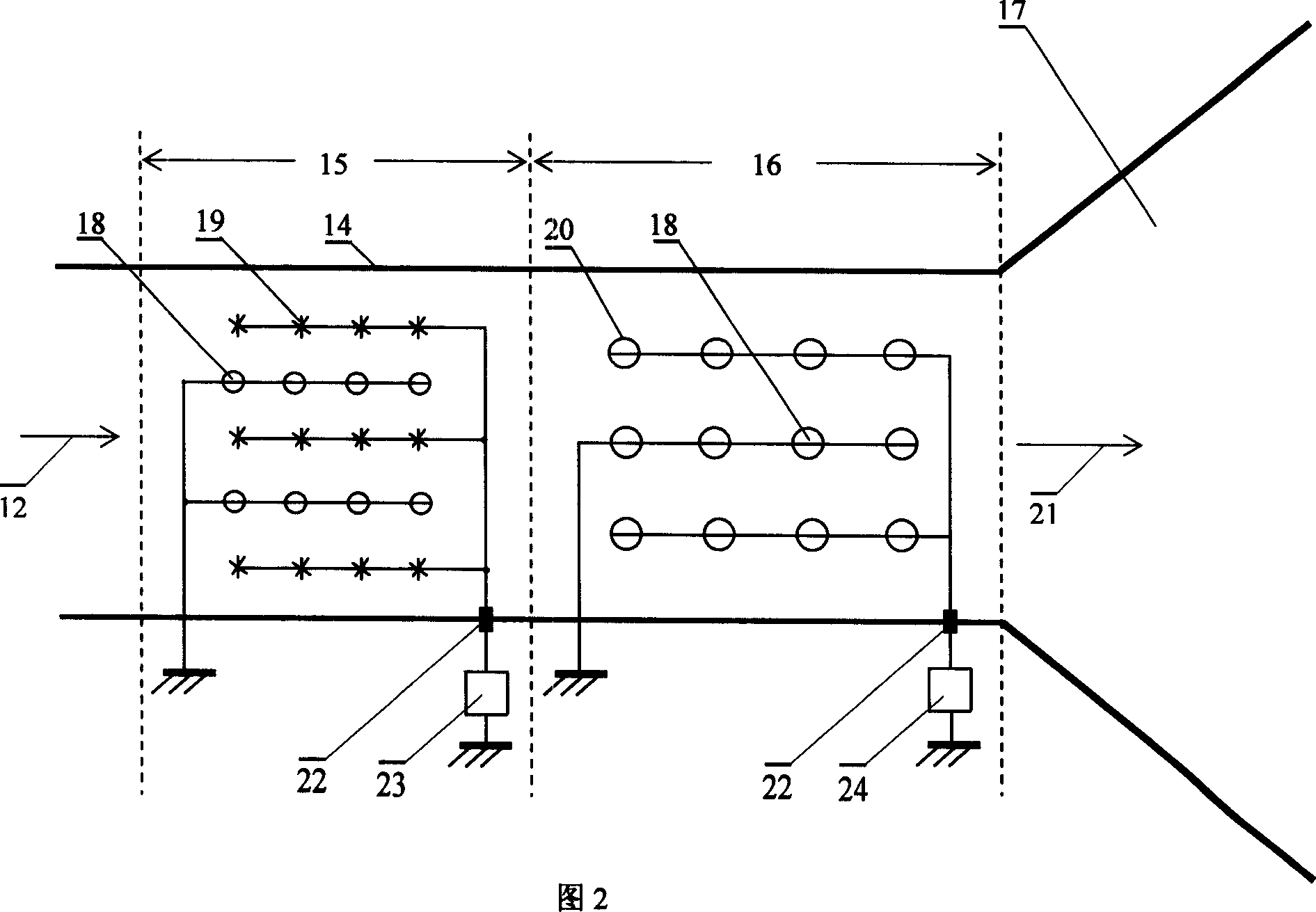

[0031] Specific embodiments of the present invention will be described in detail below in conjunction with the technical solution and the drawings.

[0032] step 1.

[0033] In the flue gas conveying pipe 14 of the inlet flue gas 12 in Fig. 1, a dust charging device 15 and a dust condensing device 16 are provided. The dust condensing device should be placed near the front end of the inlet air hopper 17 of the electrostatic precipitator. Place it at the front of the dust flocculating device. According to requirements, 1 to 4 sets of dust charging and condensing treatment devices can be installed in the flue gas conveying pipeline at the entrance of the electrostatic precipitator.

[0034] Step 2.

[0035] In Fig. 2 the discharge electrode 19 of the pre-charging device 15 is composed of metal circular, star, zigzag or fishbone electrodes; the ground electrode 18 is a narrow metal plate, cylindrical, elliptical or It is composed of round wire and other electrodes. The discharge elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com