Method for cooling hydrogen in front of hydrogenation machine

A hydrogen refueling machine and hydrogen technology, applied in the field of hydrogen refueling stations, can solve the problems of high operation and maintenance costs, safety risks, and complexity, and achieve the effects of eliminating operation and maintenance costs, easy operation and high cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

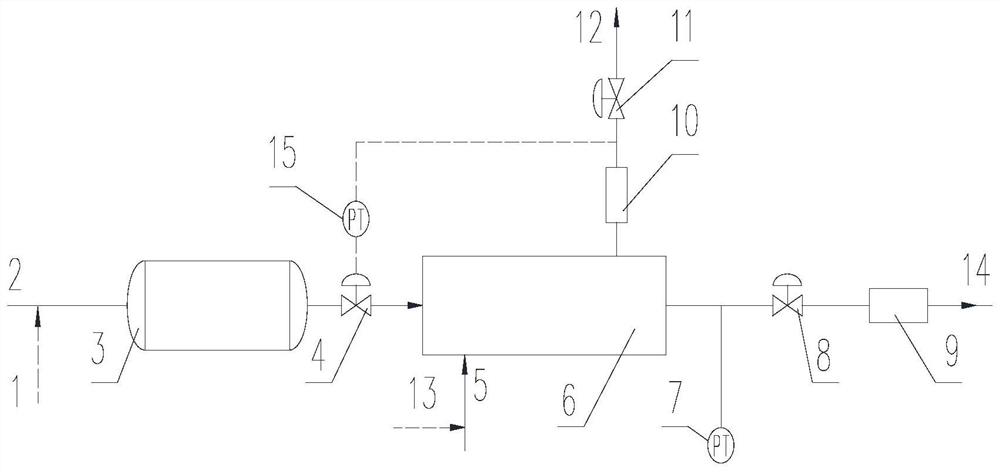

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] Such as figure 1 As shown, when the hydrogen cooling system in front of the hydrogenation machine is put into use for the first time or is used again after a long period of idleness:

[0030] First, carry out normal temperature nitrogen purging steps:

[0031] Open the coolant inlet valve 4 and the coolant outlet valve 8, and use room temperature nitrogen 1 to purge and replace the coolant delivery pipeline and cooler, etc., to discharge the air and water vapor therein; open the hydrogen outlet valve 11, and use room temperature nitrogen 13 to The hydrogen delivery pipeline is purged and replaced, and the air and water vapor in it are also discharged; after the cooler 6 completes the nitrogen replacement at normal temperature, the coolant inlet valve 4 and the coolant outlet valve 8 connected to the cooler 6 are closed at the same time; the hydrogen delivery pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com