Chimney type desulfurization, denitrification and dust removal integrated device and working method thereof

A technology for desulfurization, dust removal, desulfurization and denitrification, which is applied in the field of coke oven flue gas purification, can solve the problems of many types of pollutants, many process links, large equipment occupation, etc., and achieves the effect of short process flow, convenient maintenance and space saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

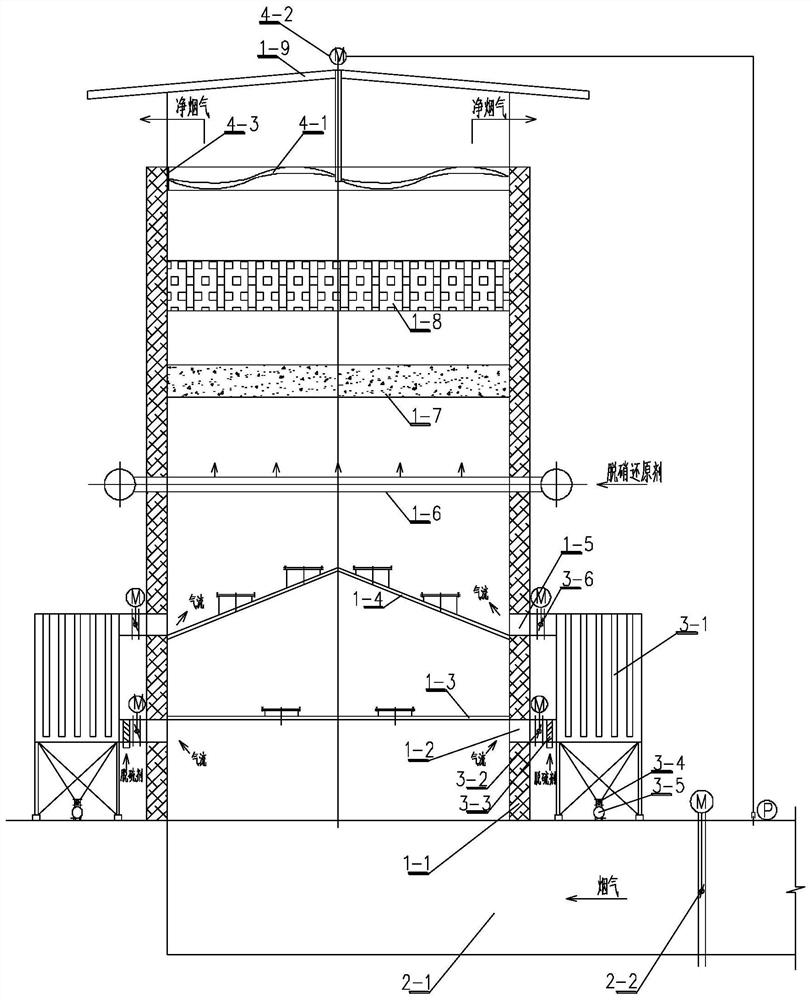

[0029] Such as figure 1 As shown, a chimney-type desulfurization, denitrification and dust removal integrated device of the present invention includes a main treatment tower 1-1 and a desulfurization and dust removal reactor 3-1; the top and bottom of the main treatment tower 1-1 are open structures , the bottom of the main treatment tower 1-1 is directly connected with the coke oven main flue 2-1, and a rainproof roof 1-9 is set above the top opening; the desulfurization and dust removal reactor 3-1 is located at the top of the main treatment tower 1-1 Outside the lower part, the desulfurization and dedusting reactor 3-1 is provided with a filter bag; the main treatment tower 1-1 is provided with a bottom interlayer board 1-3, a lower interlayer board 1-4, a denitrification reducing agent sprayer in sequence from bottom to top. Inlet pipe 1-6, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com