Process for low-carbon silicon-controlled aluminum killed clean steel

一种洁净钢、镇静的技术,应用在低成本生产高成型性低碳铝镇静洁净钢的生产领域,能够解决限制薄板坯连铸生产效率、影响钢板成型性能、CaS夹杂等问题,达到满足洁净度和可浇性要求、省却钙处理成本、吸附效果明显的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

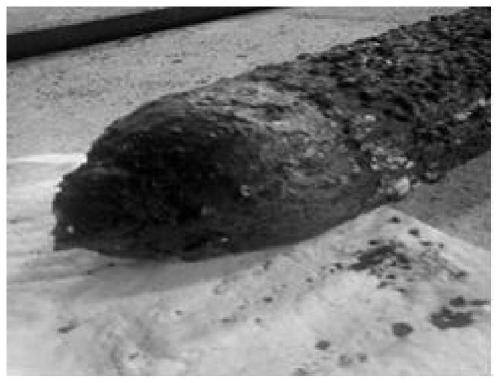

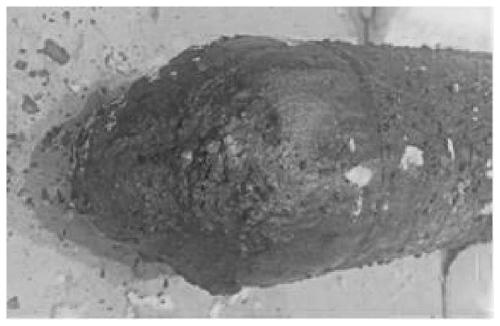

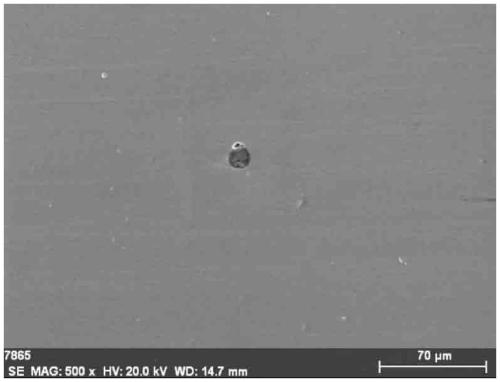

Image

Examples

Embodiment 1

[0042] (1) Molten iron: reduce the sulfur content of the molten iron to less than 0.02% by means of pretreatment of the molten iron;

[0043] (2) Oxygen top-bottom double-blown converter: adopt sub-lance technology and bottom-blown argon technology to control the molten steel [O] at the end of the converter 2 o 3 The total amount of deoxygenated inclusions.

[0044] (3) LF refining: Refining incoming molten steel [Al] 0.020-0.03%, molten steel temperature ≥ 1550°C; adding lime at 6-7Kg / ton, controlling slag composition to be CaO 55-60%; Al 2 o 3 25-30%; SiO 2 7~8%; MgO 5~7%, alkalinity CaO / SiO 2 The value is 7-8; white slag is produced by refining; the aluminum composition of molten steel is adjusted, and the number of times of aluminum distribution is strictly controlled to be less than 3 times, specifically twice in this embodiment; the mass percentage of molten steel composition is controlled as follows: C: 0.038-0.045%, Si: 0.15-0.25%, Mn: 0.50-0.60%, P≤0.015%, S≤0.003...

Embodiment 2

[0050] (1) Molten iron: reduce the sulfur content of the molten iron to less than 0.02% by means of pretreatment of the molten iron;

[0051] (2) Oxygen top-bottom combined blowing converter: adopt sub-lance technology, bottom blowing argon technology, control the molten steel [O] at the end of the converter 2 o 3 The total amount of deoxygenated inclusions.

[0052] (3) LF refining: Refining incoming molten steel [Al] 0.035-0.050%, molten steel temperature 1550-1650°C; adding lime at 6-7Kg / ton, controlling slag composition to CaO 54-58%; Al 2 o 3 26-28%; SiO 2 7~8%; MgO 5~6%, alkalinity CaO / SiO 2 The value is 6-8; refining produces white slag; the aluminum composition of molten steel is adjusted, and aluminum is fed 3 times, and the aluminum-iron rare earth cored wire is fed; the silicon content of molten steel is 0.15-0.25%; : C: 0.038~0.045%, Si: 0.15~0.25%, Mn: 0.50~0.60%, P≤0.015%, S≤0.003%, Alt: 0.008~0.020%, the balance is iron and trace unavoidable impurities . T...

Embodiment 3

[0057] (1) Molten iron: reduce the sulfur content of the molten iron to less than 0.02% by means of pretreatment of the molten iron;

[0058] (2) Oxygen top-bottom double-blown converter: adopt sub-lance technology and bottom-blown argon technology to control the molten steel at the end point of the converter [O] 2 o 3 The total amount of deoxygenated inclusions.

[0059] (3) LF Refining: Adjust refining incoming molten steel [Al] 0.02-0.04%, molten steel temperature ≥ 1550°C; add lime at 6-7Kg / ton, control slag composition to be CaO 54-56%, Al 2 o 3 25-30%; SiO 2 6~7%; MgO 5~7%, alkalinity CaO / SiO 2 The value is 8-9; white slag is produced by refining; the aluminum composition of molten steel is adjusted, the number of times of aluminum blending is 2 times, and the limestone cored wire is fed 400 meters; the silicon content of molten steel is 0.15-0.25%; the mass percentage of molten steel composition out of refining is controlled as: C : 0.038~0.045%, Si: 0.15~0.25%, Mn:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| process yield | aaaaa | aaaaa |

| alkalinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com