Method for reducing nitrogen content in steel

A technology of nitrogen content and molten steel, applied in the field of steelmaking, can solve the problems affecting the plasticity and toughness of high-strength steel, high nitrogen content of high-strength steel slabs, and long process steps, so as to prevent nitrogen increase, suppress nitrogen absorption, and reduce nitrogen content. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

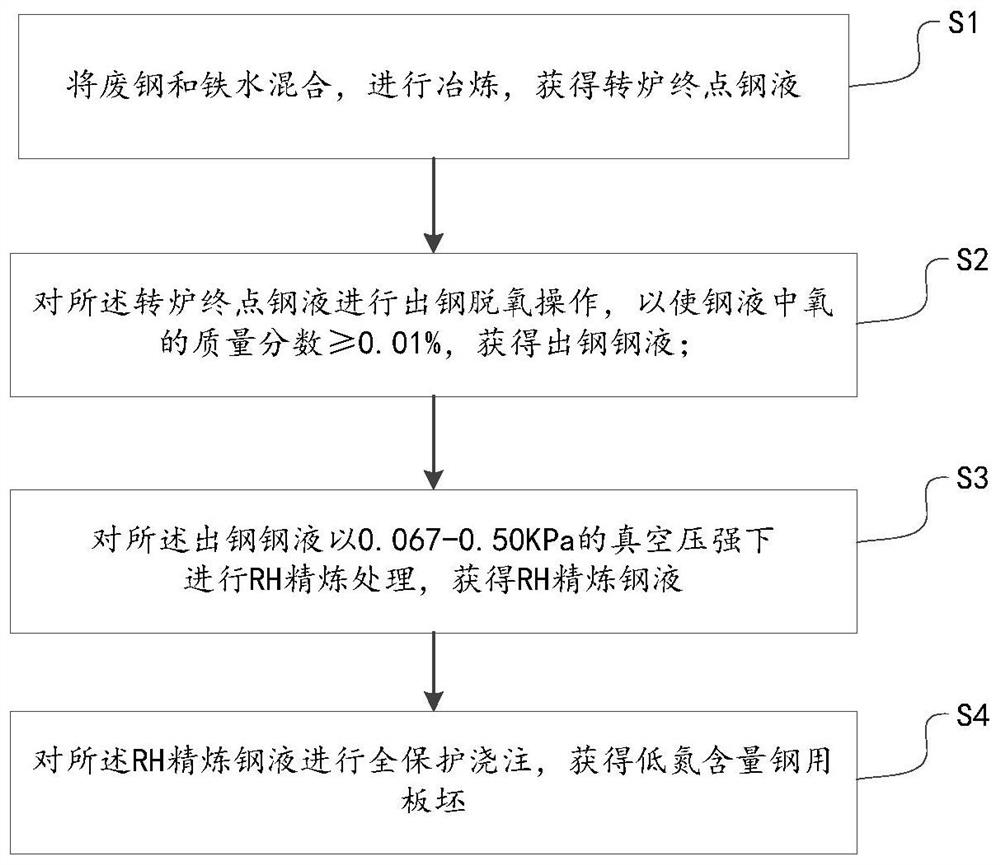

Method used

Image

Examples

Embodiment approach

[0032] As an implementation manner of the embodiment of the present invention, the loading amount of the scrap steel is 8-15% of the total loading amount.

[0033] In the present invention, steel scrap and molten iron are loaded into a converter for smelting. The converter is the most important link in controlling the nitrogen content of molten steel. Especially in the later stage of converter blowing, due to the weakening of the carbon-oxygen reaction, it is very easy to cause nitrogen increase in molten steel. Therefore, the present invention proposes to control The loading amount of scrap steel is 8-15% of the total loading amount, which ensures that the converter has sufficient heat. At the end of the converter, the molten steel will not be overoxidized due to insufficient heat, which will cause the molten steel to absorb nitrogen; on the other hand, it can also ensure the end temperature of the converter. Avoid the problem that the temperature of molten steel in the tundis...

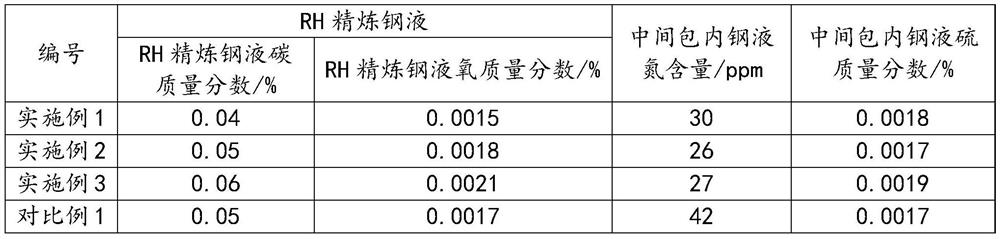

Embodiment 1

[0058] Embodiment 1 provides a method for reducing the nitrogen content in steel. The method adopts the process route of 210t converter → RH → continuous casting, and adopts the following smelting process, specifically:

[0059] 1. Put the molten iron and steel scrap into the converter for converter oxygen blowing smelting to obtain converter smelting molten steel. Specifically, the total charging amount is 235t, wherein the charging amount of scrap steel is 8% of the total charging amount, when the oxygen supply in the converter smelting process is 85%, the adding amount of converter pellets is 8kg / t steel; The carbon content of the end point molten steel is 0.045%, the oxygen content is 0.04%, and the temperature is 1640°C.

[0060] 2. Tapping the converter smelting molten steel obtained in step 1 into a ladle to obtain tapping molten steel; adding a deoxidizer to deoxidize during the tapping process, and adding an alloy for alloying. Specifically, Si deoxidation is used to...

Embodiment 2

[0065] Embodiment 1 provides a method for reducing the nitrogen content in steel. The method adopts the process route of 300t converter → RH → continuous casting, and adopts the following smelting process, specifically:

[0066] 1. Put the molten iron and steel scrap into the converter for converter oxygen blowing smelting to obtain converter smelting molten steel. Specifically, the total charging amount is 328t, of which the charging amount of scrap steel is 11% of the total charging amount. When the oxygen supply in the converter smelting process is 87%, the adding amount of converter pellets is 11kg / t steel; The carbon content of the end point molten steel is 0.04%, the oxygen content is 0.04%, and the temperature is 1638°C.

[0067] 2. Tapping the converter smelting molten steel obtained in step 1 into a ladle to obtain tapping molten steel; adding a deoxidizer to deoxidize during the tapping process, and adding an alloy for alloying. Specifically, Si deoxidation is used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com