Steel for heavy-truck super-thick steel-made spokes and manufacturing method of steel

A manufacturing method and steel technology, applied in the field of steel rolling, can solve problems such as complex spinning deformation, affecting production rhythm, and large thickness reduction, and achieve the effects of refining grains, increasing nucleation rate, and increasing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

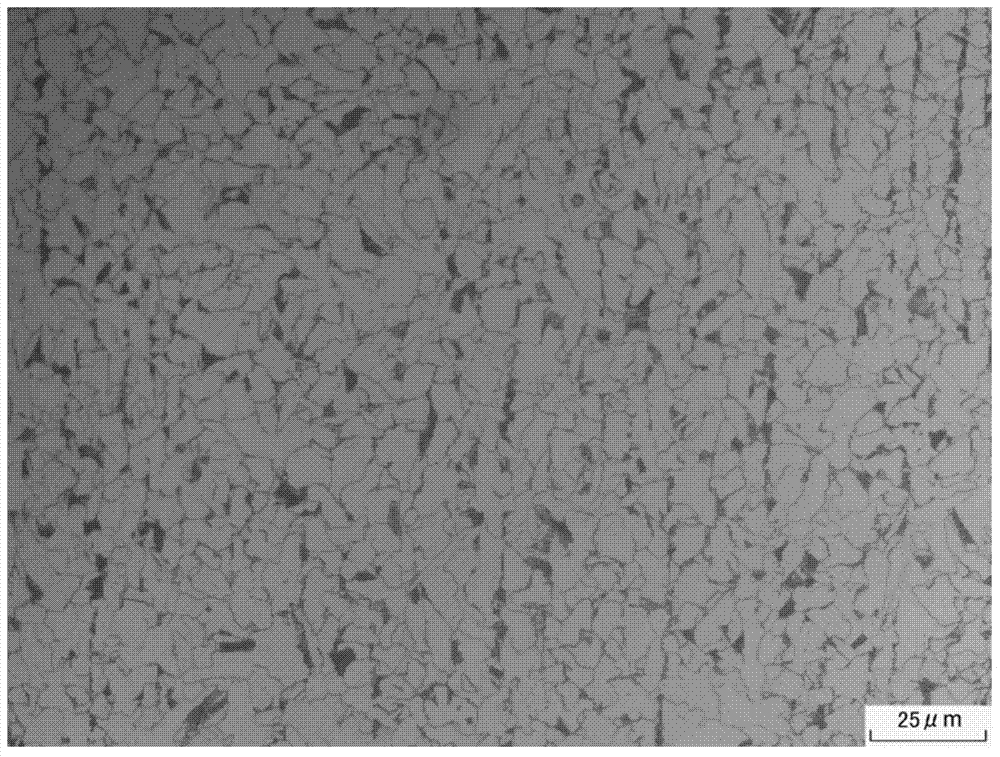

[0024] The invention provides a heavy-duty truck ultra-thick steel wheel spoke steel, including the following chemical components in mass percentage: carbon: 0.07-0.12%; silicon: 0.05-0.15%; manganese: 0.7-1.1%; niobium: 0.01-0.03% ; Titanium: 0.01-0.03%; Phosphorus: ≤0.015%; Sulfur: ≤0.005%; Aluminum: 0.02-0.05%; Nitrogen: ≤0.006%; Others are iron and unavoidable trace impurities.

[0025] Among them, although carbon (C) no longer plays a major role in solid solution strengthening in steel, it still significantly affects the process of each phase transformation and controls the final formed structure, thus roughly determining the corresponding structure of the structure. mechanical properties. Carbon can significantly improve the strength of steel, but too high carbon is not good for the toughness of steel. Therefore, in order to improve the cold formability of steel for heavy truck ultra-thick steel spokes, the carbon content should be controlled below 0.12%. The carbon con...

Embodiment approach 2

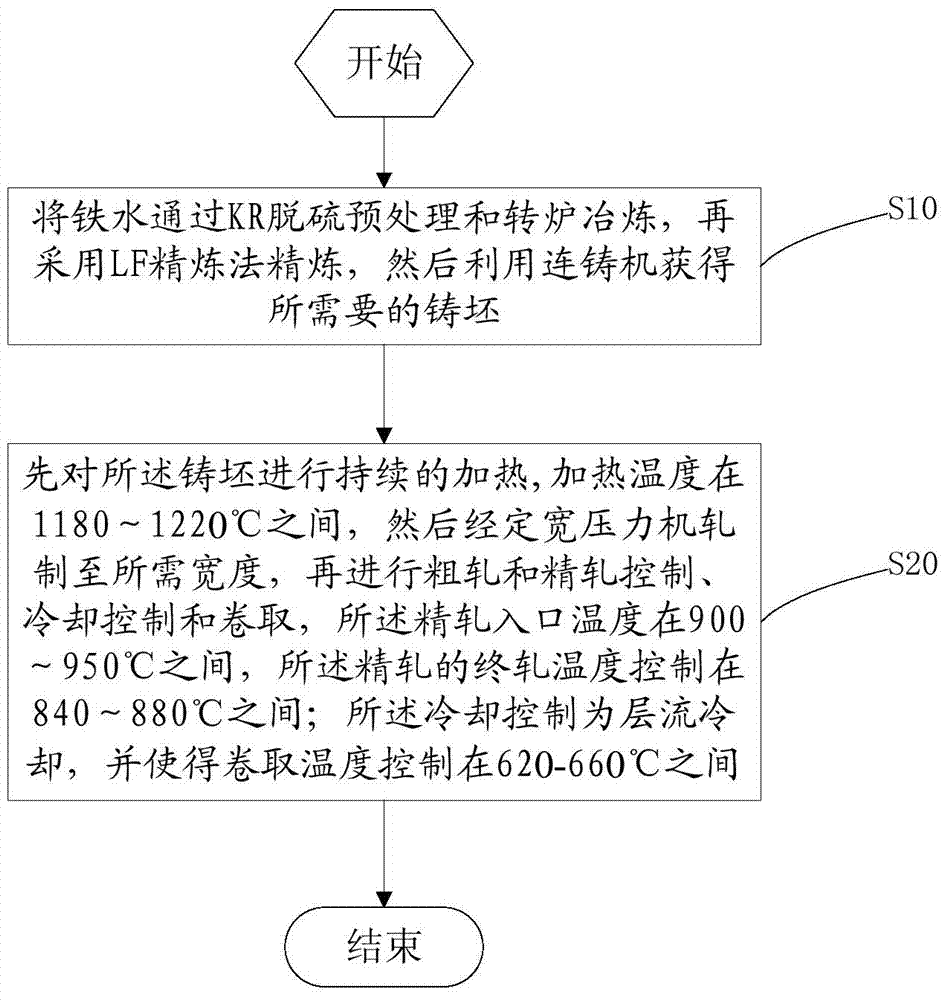

[0033] like figure 2 as shown, figure 2 It is a schematic flowchart of a method for manufacturing heavy truck ultra-thick steel spoke steel provided in Embodiment 2 of the present invention.

[0034] Step S10: the molten iron is subjected to KR desulfurization pretreatment and converter smelting, and then refined by LF refining method, and then a continuous casting machine is used to obtain the required casting slab. In this example, the molten iron is subjected to desulfurization pretreatment and full three desulfurization converter smelting process by the KR method to control the content of harmful elements such as sulfur and phosphorus in the molten steel. During the converter smelting process, pig iron blocks are not allowed, and LF Refining treatment, in order to accurately control the content of various chemical components in molten steel, so that the aluminum content of the refined station accounts for the mass percentage of molten steel between 0.02 and 0.05%, creat...

Embodiment approach 3

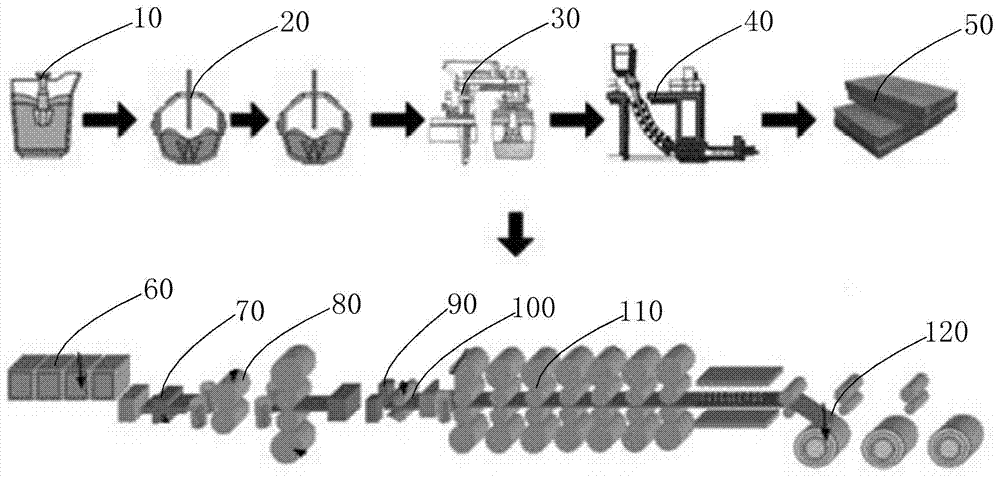

[0039] like image 3 , image 3 Another schematic flowchart of a method for manufacturing heavy truck ultra-thick steel spoke steel provided in Embodiment 3 of the present invention.

[0040] Wherein, step 10: desulfurize the molten iron by the KR method.

[0041] Step 20: Smelting the molten steel desulfurized by the KR method in a converter. In this embodiment, no pig iron block is added during the converter process, and the percentage of aluminum element refined to the station in the molten steel is controlled to be between 0.02% and 0.05% by mass. And in the process of converter smelting, de-Si, de-P and de-C treatment are carried out.

[0042] Step 30: Transfer the molten steel smelted in the converter to a refining furnace for LF refining treatment. In this embodiment, the mass percentage of each component in the molten steel after refining by the LF method is as follows: carbon: 0.07-0.12%; silicon: 0.05-0.15%; manganese: 0.7-1.1%; niobium: 0.01-0.12% 0.03%; titani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com