Control method for titanium nitride inclusion of gear steel bar material

A control method, titanium nitride technology, applied in the manufacture of converters, etc., can solve problems such as excessive nitride inclusions, achieve the effects of reducing the precipitation concentration product, preventing nitrogen increase, and inhibiting precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

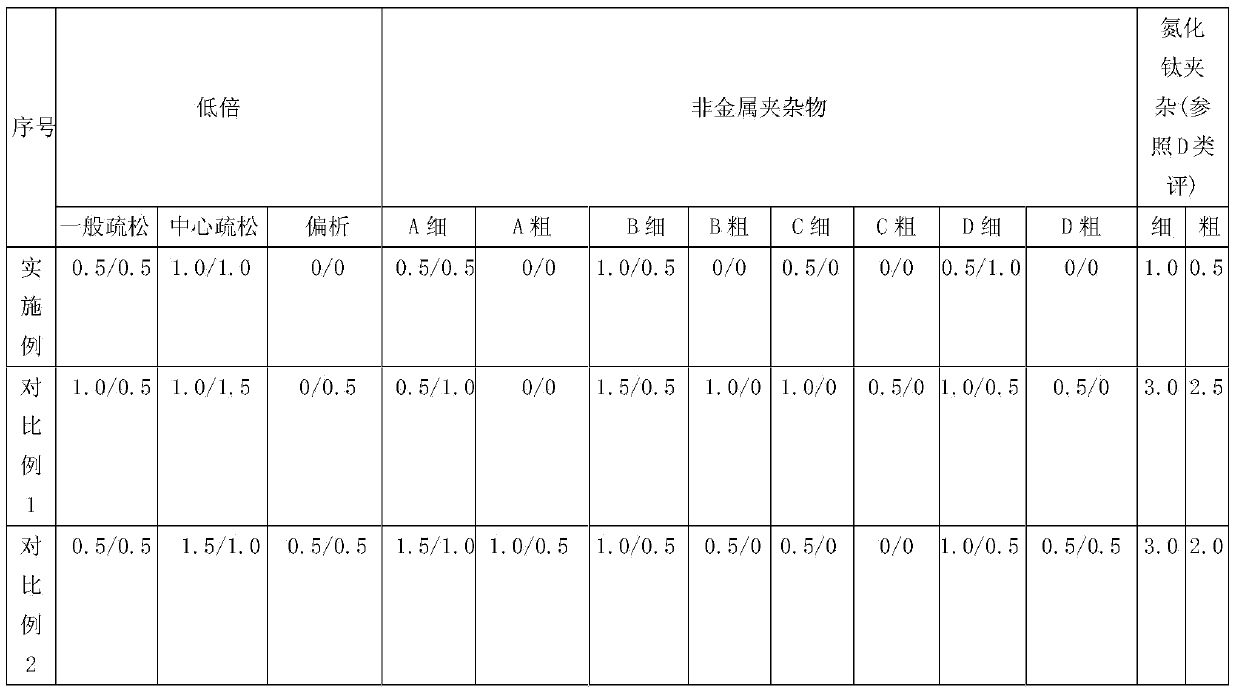

Examples

Embodiment 120

[0018] Embodiment 1 is illustrated with the production process control of 20CrMnTiH gear round steel.

[0019] (1) Converter smelting, using a 130t converter for smelting, adding molten iron and scrap steel to the converter, the ratio of molten iron to scrap steel (weight ratio Wt%) is greater than 15:1, preferably, the ratio of molten iron to scrap steel (weight ratio Wt%) 15:1, use high-quality steel scrap, add low-nitrogen low-carbon ferrochromium, silicon-manganese, and ferromanganese alloys during the smelting process, and do not supplement blowing in the later stage of smelting; try to use bottom blowing argon during the smelting process, and add aluminum-ferroalloys from 1 / 3 of the tapping Perform pre-deoxidation to obtain a molten steel ladle. The said tapping 1 / 3 means that the molten steel in the converter furnace is poured into the ladle, and the molten steel in the furnace is poured into 1 / 3 of the total weight.

[0020] (2) Refining outside the furnace. After the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com