Production method of low-sulfur low-phosphorus steel

A production method and technology for low-phosphorus steel, applied in the field of iron and steel metallurgy, can solve the problems of increasing nitrogen in molten steel, difficult to meet the needs of the steel-making process, and not suitable for smelting of cold-rolled steel grades.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

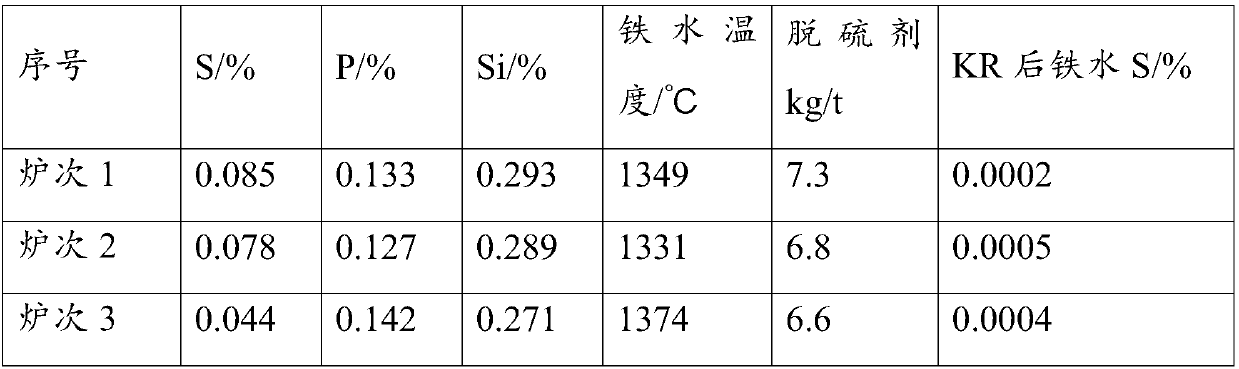

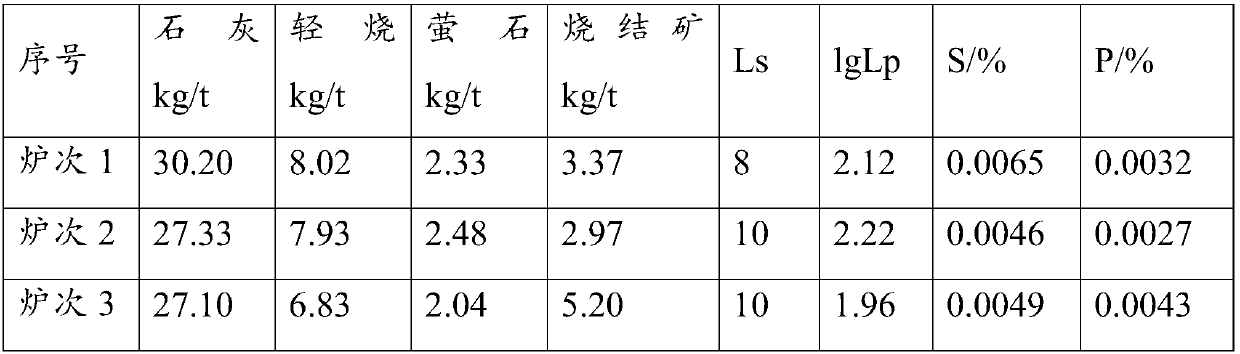

Examples

Embodiment Construction

[0027] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

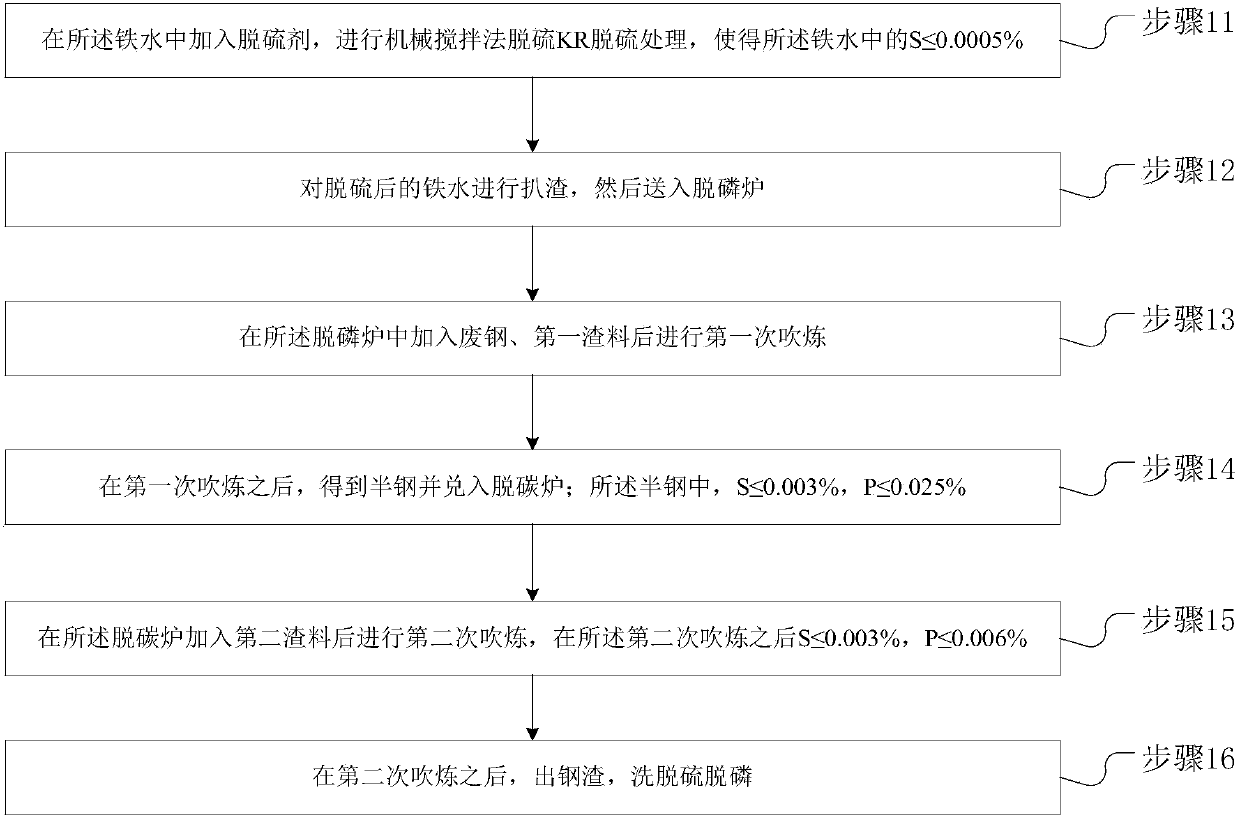

[0028] In the present invention, in order to solve the nitrogen increase problem brought by the existing converter + LF desulfurization process, this application adopts the double converter process to dephosphorize and decarburize the molten iron, and uses the mechanical stirring method for desulfurization and KR desulfurization before, so It can avoid the use of LF desulfurization process, thereby avoiding the problem of nitrogen increase caused by LF desulfurization process, and can achieve the problems of reducing sulfur, phosphorus and nitrogen.

[0029] The steelmaking and smelting process of the present invention includes: blast furnace, KR desulfurization, dephosphorization convert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com