Vacuum temperature measurement sampling system and operation method thereof

A sampling system and operation method technology, applied in the field of liquid metal processing in the metallurgical field, can solve the problems of poor operating environment, difficult to grasp the state of the metal, difficult temperature measurement and sampling, etc., to save process time, reduce thermal radiation damage and other problems. Possibility of scalding, effect of improving the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

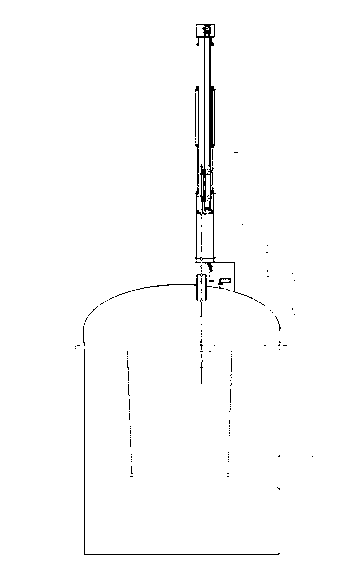

[0018] Embodiment, a kind of vacuum temperature measurement and sampling system, figure 1 The vacuum temperature measurement and sampling system configured for the 120t VOD vacuum refining furnace is shown, including the automatic opening and closing vacuum chamber system 1, the automatic temperature measurement sampling gun system 2 and the vacuum metallurgical container 3. The automatic sealing passage chamber 7 of the automatic sealing passage chamber system 1 is welded on the shell 5 of the tank lid of the 120tVOD vacuum refining furnace, and the fixed sealing chamber 9 is installed on the outer wall 5 of the tank lid through the bracket 14 . The movable sealing cover 8 is hung outside the sealing conduit 10 by three sets of cylinders I11. The automatic temperature measurement sampling gun system 2 is installed inside the fixed sealing chamber 9. The automatic temperature measurement system sampling gun 18 includes a paper tube probe 4, a lifting trolley 19, Track 20, freq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com