Calcium treatment method of ultra-low-carbon and high-aluminum steel

A carbon-high-aluminum steel and calcium treatment technology, applied in the field of steelmaking process, can solve the problems of large inclusion content, difficulty in precise control of the addition of calcium-iron alloy ingots, and reduction in the purity of molten steel, so as to improve yield and reduce molten steel. The effect of churning, reducing vacuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

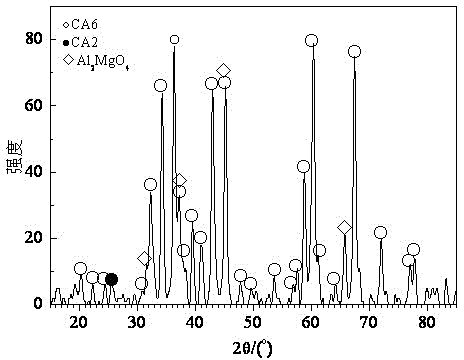

Image

Examples

Embodiment Construction

[0023] The present invention will be further illustrated below in conjunction with specific embodiments, and it should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0024] The grade is 50W800 non-oriented electrical steel, its chemical composition mass percentage is: C ≤ 0.005%, Si: 0.8% ~ 1.4%, Mn: 0.1% ~ 0.4%, P ≤ 0.05%, S ≤ 0.005%, Alt: 0.1 %~0.4%, the balance is Fe and unavoidable impurity elements. The smelting process is as follows: hot metal desulfurization pretreatment-converter smelting-bottom blowing argon at the argon blowing station-RH furnace vacuum degassing and refining-RH furnace adding calcium-iron alloy Calcium treatment of blocks - continuous casting of slabs.

[0025] The molten steel entering the RH furnace is degassed for 5 minutes, and the vacuum degree is 270Pa for decarburization for 18 minutes. After decarburization, the molten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com