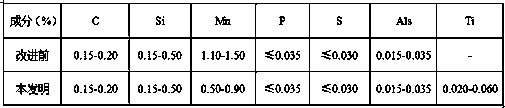

Low-cost manufacturing method of flaw-detection-ensured Q345B stage steel plate

A manufacturing method and low-cost technology, applied in the field of low-cost manufacturing of Q345B grade steel plates for flaw detection, can solve the problems of large addition of manganese alloy, long production process and high production cost, and achieve lower alloy costs, lower costs per ton of steel, The effect of increasing machine-time output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

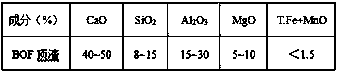

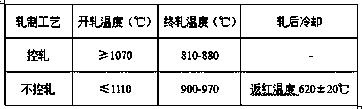

Method used

Image

Examples

Embodiment 130

[0045] A low-cost manufacturing method for flaw detection Q345B grade steel plate in this embodiment, the chemical composition and mass percentage content of the Q345B grade steel plate are: C 0.16%, Si 0.35%, Mn 0.75%, P 0.025%, S 0.012 %, Als 0.020, Ti0.025%, the rest is Fe and unavoidable impurities. The present embodiment takes 130 tons of converters as an example, and its manufacturing method comprises the following steps:

[0046] (1) Hot metal KR desulfurization treatment

[0047] Add molten iron with mass fraction P≤0.150%, S≤0.050% and temperature T≥1280°C in the molten iron tank, and then pretreat the molten iron with KR heavy desulfurization. After treatment, S≤0.005% in molten iron, and add Remove at least 2 / 3 of the desulfurization slag from the molten iron tank before the converter;

[0048] (2) Converter smelting

[0049] ①Smelting the desulfurized molten iron into the top-bottom combined blowing converter, adding dephosphorization agent to reduce the phospho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com