High-yield-ratio hot-galvanized micro-carbo/aluminum killed steel plate and production method thereof

A production method and specific heat technology, applied in the direction of hot-dip plating process, coating, metal material coating process, etc., can solve the problems of limited load-carrying capacity, poor fatigue resistance, and increased cost of trucks, so as to reduce yield Strength, increase elongation, eliminate residual stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

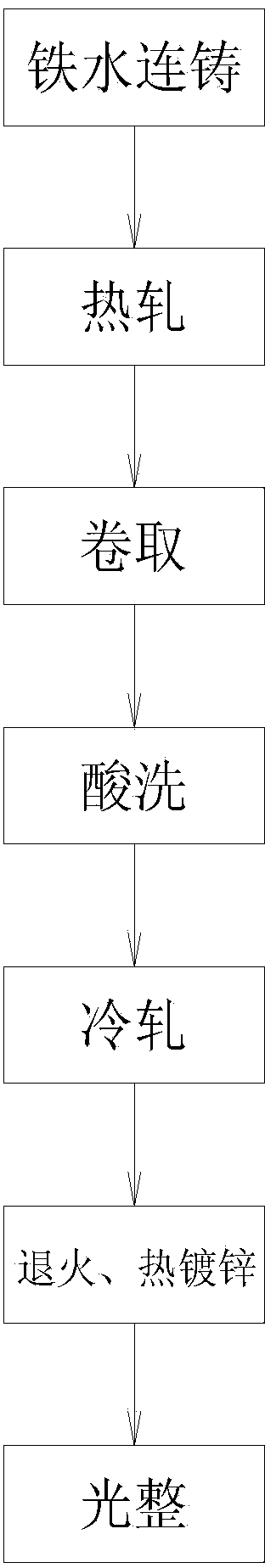

[0040] The flow process of the production method of the high yield strength hot-dip galvanized micro-carbon aluminum killed steel plate provided by the invention is:

[0041] According to the design of steel composition, C: 0.01~0.04%, Si≤0.03%, Mn: 0.23%, P≤0.013%, S≤0.010%, Als: 0.023%, N≤0.005%, B: 0.001~0.008% , the balance is Fe and unavoidable impurities, using molten iron desulfurization, converter blowing, RH vacuum refining, continuous casting to obtain continuous casting slabs.

[0042] The continuous casting slab is heated by a heating furnace, rolled on a continuous hot rolling mill, cooled under control, and then coiled. The coiling temperature after hot rolling is controlled at 716°C to produce qualified hot-rolled steel coils.

[0043] The hot-rolled steel coil is re-coiled and pickled to wash off the oxide scale on the surface, and then cold-rolled on a cold tandem rolling mill, and the cold-rolling reduction rate is controlled to be 75.4% to obtain a cold-roll...

Embodiment 2

[0047] The flow process of the production method of the high yield strength hot-dip galvanized micro-carbon aluminum killed steel plate provided by the invention is:

[0048] According to the design of steel composition, C: 0.01~0.04%, Si≤0.03%, Mn: 0.25%, P≤0.013%, S≤0.010%, Als: 0.028%, N≤0.005%, B: 0.001~0.008% , the balance is Fe and unavoidable impurities, using molten iron desulfurization, converter blowing, RH vacuum refining, continuous casting to obtain continuous casting slabs.

[0049] The continuous casting slab is heated by a heating furnace, rolled on a continuous hot rolling mill, cooled under control, and then coiled. The coiling temperature after hot rolling is controlled at 732°C to produce qualified hot-rolled steel coils.

[0050] The hot-rolled steel coil is re-coiled and pickled to wash off the oxide scale on the surface, and then cold-rolled on a cold tandem rolling mill, and the cold-rolling reduction rate is controlled to be 76.2% to obtain a cold-roll...

Embodiment 3

[0054] The flow process of the production method of the high yield strength hot-dip galvanized micro-carbon aluminum killed steel plate provided by the invention is:

[0055] According to the design of steel composition, C: 0.01~0.04%, Si≤0.03%, Mn: 0.24%, P≤0.013%, S≤0.010%, Als: 0.031%, N≤0.005%, B: 0.001~0.008% , the balance is Fe and unavoidable impurities, using molten iron desulfurization, converter blowing, RH vacuum refining, continuous casting to obtain continuous casting slabs.

[0056] The continuous casting slab is heated by a heating furnace, rolled on a continuous hot rolling mill, cooled under control, and then coiled. The coiling temperature after hot rolling is controlled at 722°C to produce qualified hot-rolled steel coils.

[0057] The hot-rolled steel coil is re-coiled and pickled to wash off the oxide scale on the surface, and then cold-rolled on a cold tandem rolling mill to control the cold-rolling reduction rate to 78.3% to obtain a cold-rolled steel pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com