Lubricant composition for cold spinning of zirconium alloy pipe

A technology of lubricant composition and zirconium alloy tube, which is applied in the direction of lubricating composition, additives, petroleum industry, etc., can solve the problems of reduced processing performance, pollution, easy adhesion, etc., and achieve reduced oil film strength, easy degreasing, and good cooling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

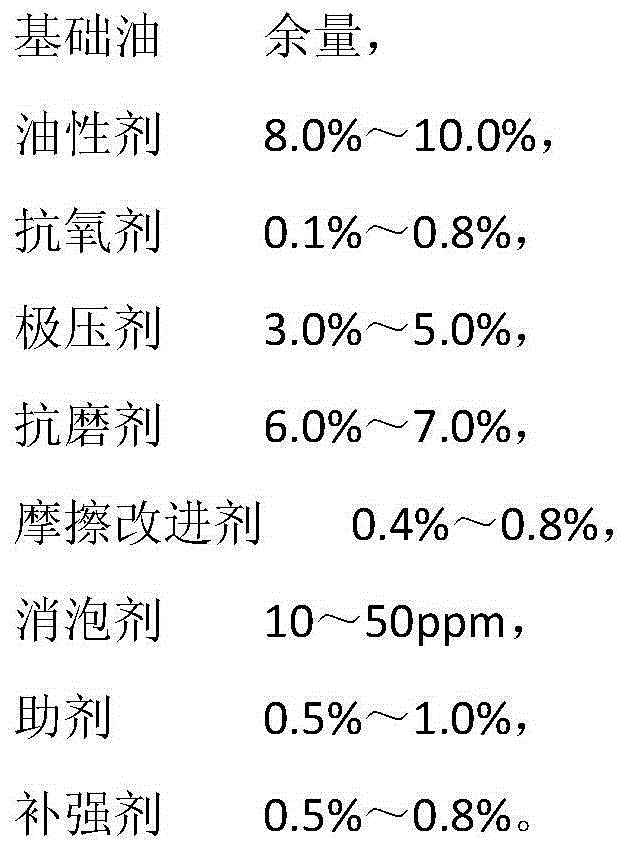

[0018] It is formed by blending the following components in mass percentage:

[0019] components

[0020] The sum of the mass percentages of the above components is 100%.

Embodiment 2

[0022] It is formed by blending the following components in mass percentage:

[0023] components

[0024] The sum of the mass percentages of the above components is 100%.

Embodiment 3

[0026] It is formed by blending the following components in mass percentage:

[0027] components

Mass percentage content

HVIS 650 base oil

margin

vulcanized lard

10.0%

Liquid high molecular weight phenol (IrganoXL135)

0.6%

4.0%

The mass ratio is 67% sulfurized tripolybutylene and 33% high alkali value synthetic calcium sulfonate compound

7.0%

Organic copper molybdenum (MD-3011)

0.6%

30ppm

Tungsten dialkyldithiocarbamate

0.8%

0.6%

[0028] The sum of the mass percentages of the above components is 100%.

[0029] The main physical and chemical index of embodiment 3 products:

[0030] project

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com