Amorphous annealing furnace

An annealing furnace, amorphous technology, applied in the direction of furnace, furnace type, heat treatment furnace, etc., can solve the problems of affecting the working effect of the annealing furnace, waste of resources, low cooling rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

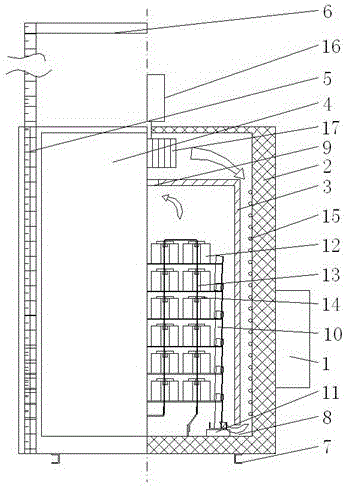

[0020] like figure 1 As shown, a kind of amorphous annealing furnace of the present invention comprises instrument box 1, furnace body and iron frame group, and furnace body comprises outer furnace wall 2, inner furnace wall 3 and door 4, and door 4 moves up and down through slide rail 5, The slide rail 5 is located on the outer furnace wall 2, and the top of the furnace body is provided with a door bracket 6, which replaces the opening of the double doors in the prior art, and the door is directly opened upward without occupying space. The bottom of the outer furnace wall 2 is provided with an external support 7, The inner furnace wall 3 is set inside the outer furnace wall 2, and a sealed chamber is formed between the outer furnace wall 2 and the door 4, and the chamber is sealed and filled with nitrogen gas. The addition of nitrogen gas can make the iron core bright, and the bottom of the inner furnace wall 3 has no bottom cover. A gap 8 is provided between the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com