Method for forming carbon/metal double-layer structure and carbon/metal/carbon triple-layer structure on substrate

A manufacturing method and metal layer technology, applied in metal material coating process, coating, ion implantation plating, etc., can solve problems such as limiting the application of graphene, inability to completely remove it, and reducing the sensitivity of graphene.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In the following embodiments, the present invention discloses a low-temperature manufacturing (amorphous) crystalline carbon single-component layer, (amorphous) crystalline carbon / copper or nickel layer double-component layer, (amorphous) crystalline carbon / copper or nickel layer and (Amorphous) crystalline phase carbon / copper layer / (amorphous) crystalline phase carbon three-component layering method. The crystalline carbon (crystal carbon) refers to the regular arrangement of carbon atoms, and the amorphous carbon refers to amorphous carbon.

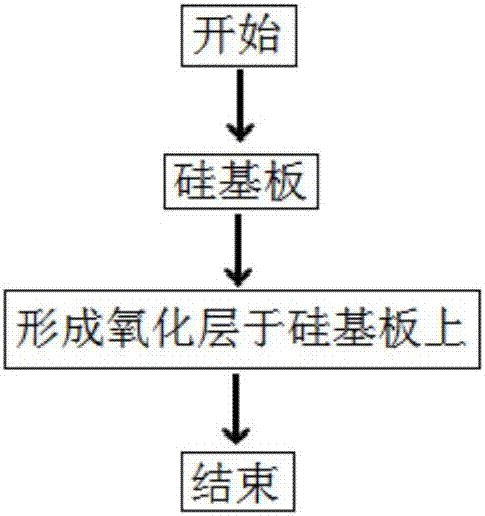

[0046] The substrate of the present invention may be a silicon substrate, a glass substrate, a quartz substrate, or a PET substrate, and the PET film here is a high-temperature-resistant (up to 350° C.) polyester film. Glass substrates are also substrates that can withstand high temperatures (up to 550°C).

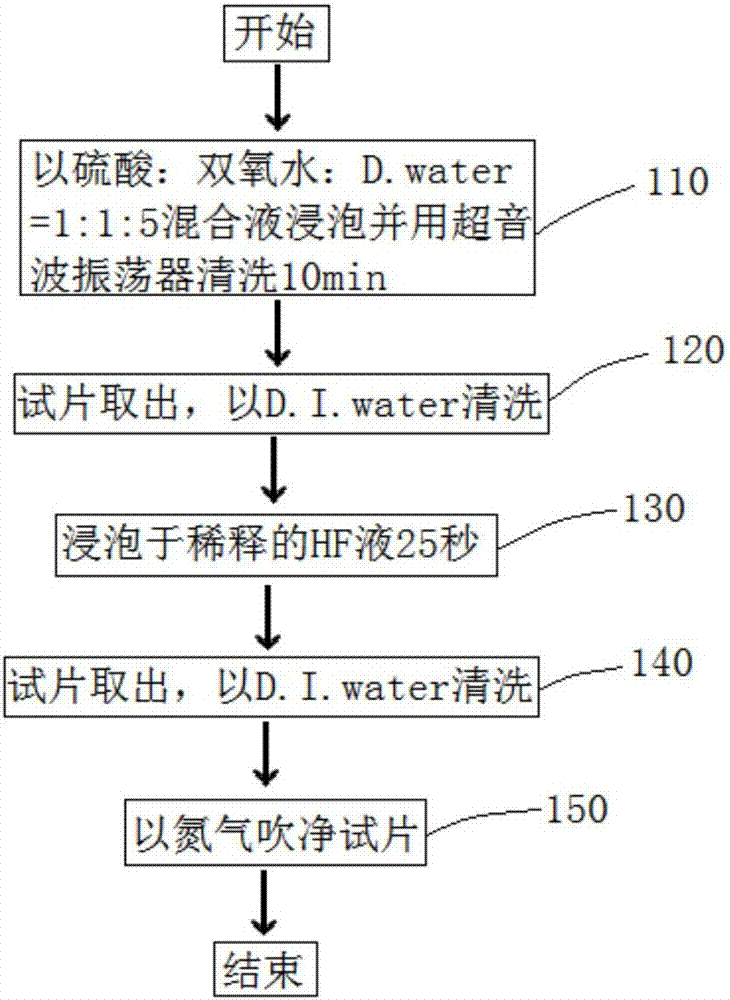

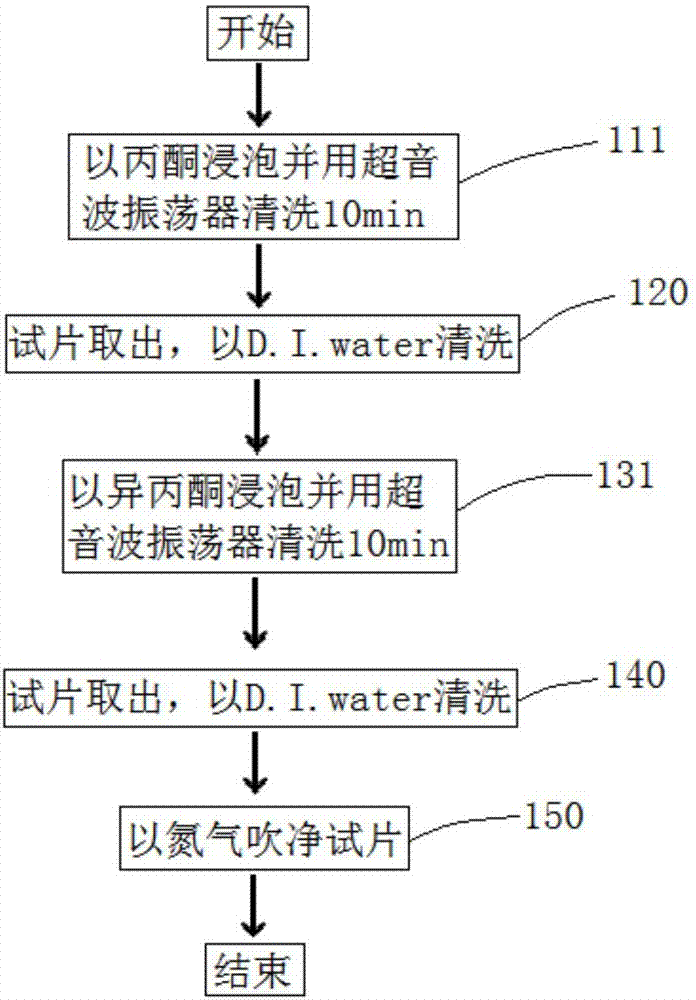

[0047] Silicon substrate pre-cleaning such as Figure 1A shown. As shown in step 100, the silicon substrate is soaked in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com