Zirconium alloy having excellent corrosion resistance and creep resistance and method of manufacturing the same

a zirconium alloy and creep resistance technology, applied in the field of zirconium alloys, can solve the problems of mechanical properties of conventional zirconium alloys, corrosion and creep properties in severe operating conditions may deteriorate, and achieve the effects of maximizing corrosion resistance and creep resistance, and increasing corrosion resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

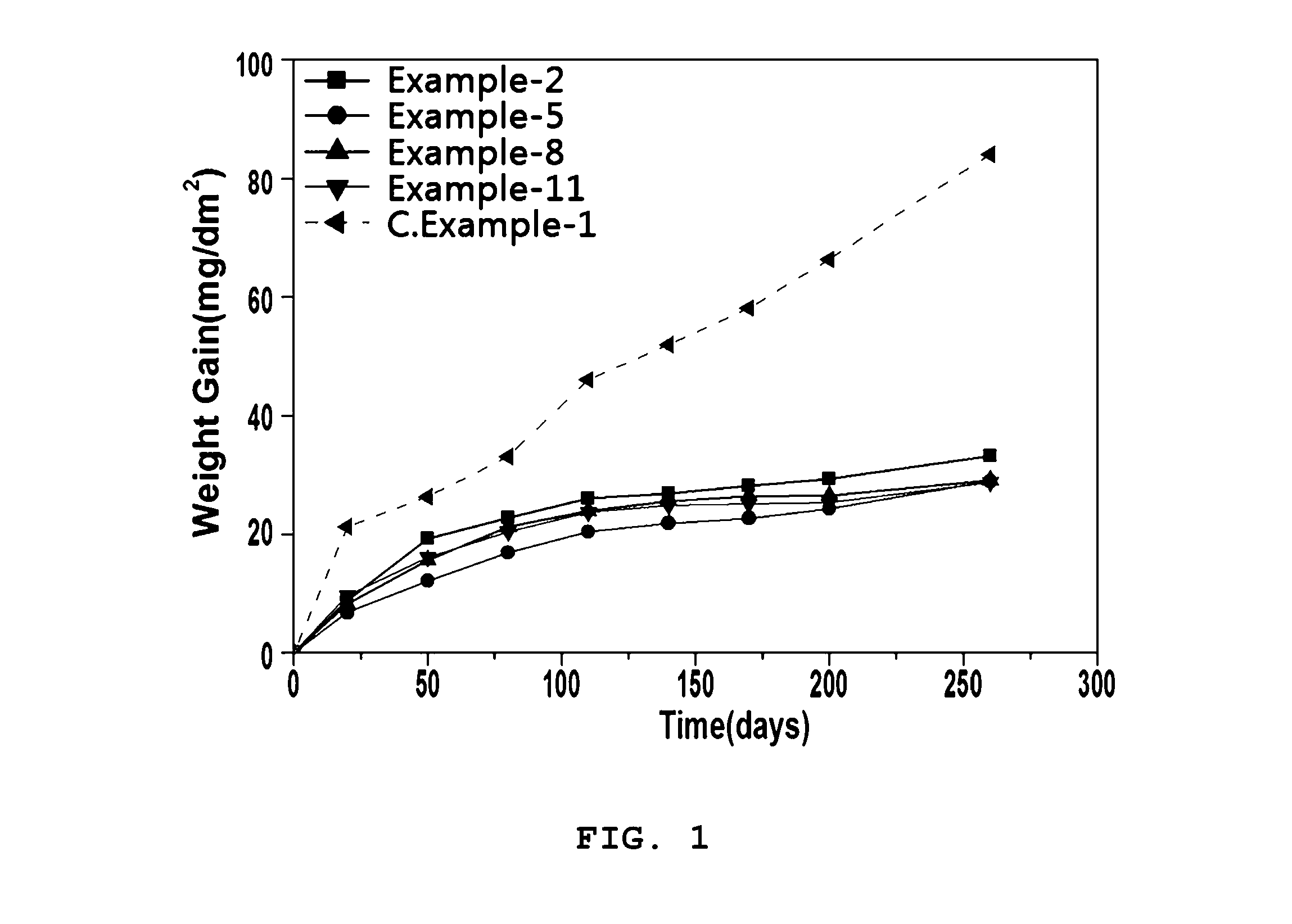

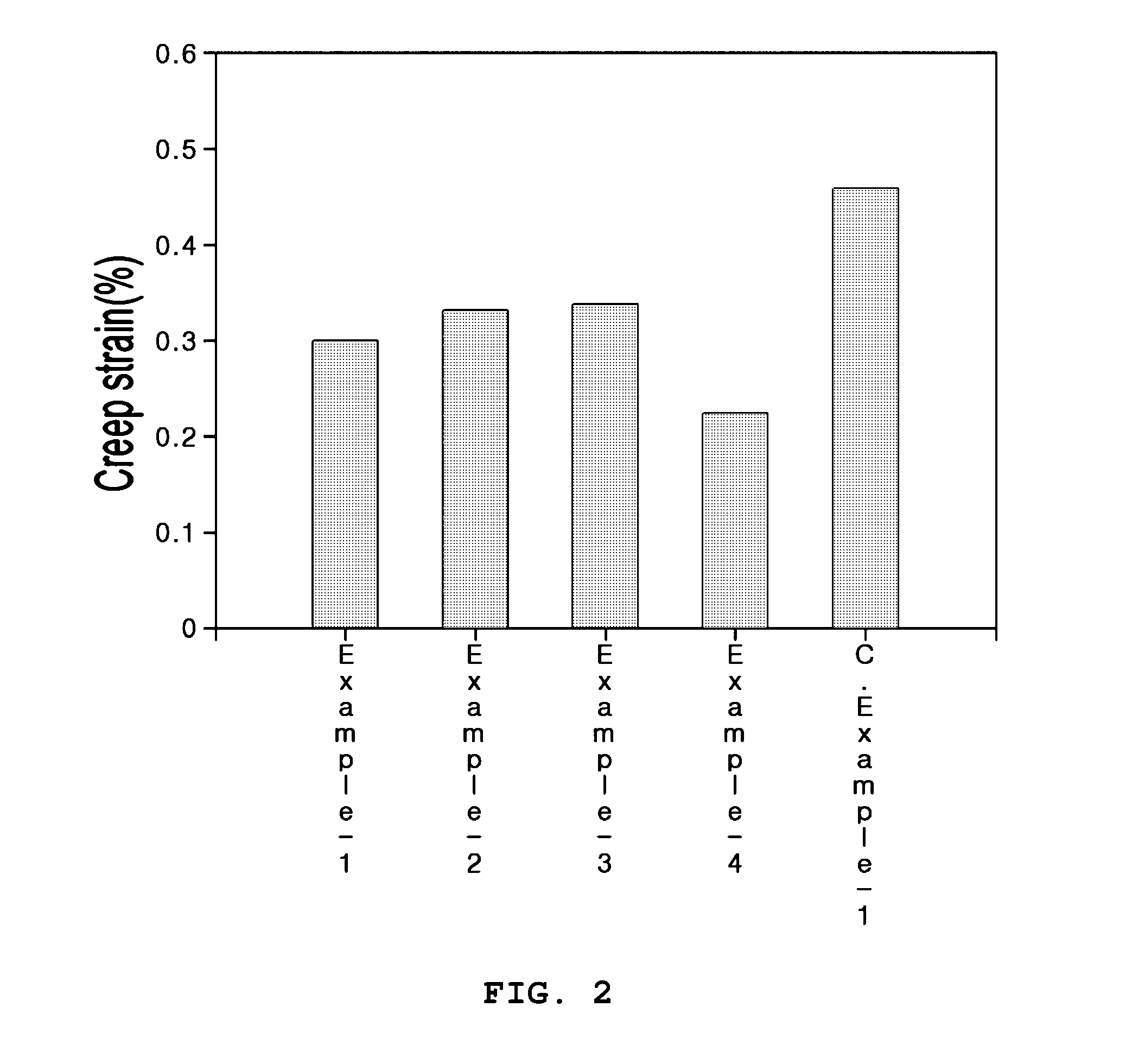

examples 1 to 12

Preparation of Zirconium Alloys

[0043](1) Formation of Ingot

[0044]In step (1), 1.2 wt % of Nb, 0.02 to 0.05 wt % of P, 0.03 to 0.1 wt % of Ta, 0.2 wt % of Fe, and the balance of Zr were subjected to VAR (Vacuum Arc Remelting), thus forming an ingot.

[0045]The Zr that was used is zirconium sponge (Reactor Grade ASTM B349), and the added elements, such as Nb, P, Ta, Fe and the like, have a high purity of 99.99% or more.

[0046]In order to prevent the segregation of impurities and the non-uniform distribution of the alloy composition, this process was repeated about three times, and the alloy was melted under the condition that the chamber for VAR was maintained at a vacuum level of 10−5 torr or less, thus forming an ingot. Unlike the other alloy elements, P was melted after being compacted, in order to prevent precipitation and segregation.

[0047]To prevent the surface of the sample from being oxidized during the cooling, cooling was carried out inert gas environment such as argon.

[0048](2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| wt % | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com