Patents

Literature

81results about How to "Prevent annealing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

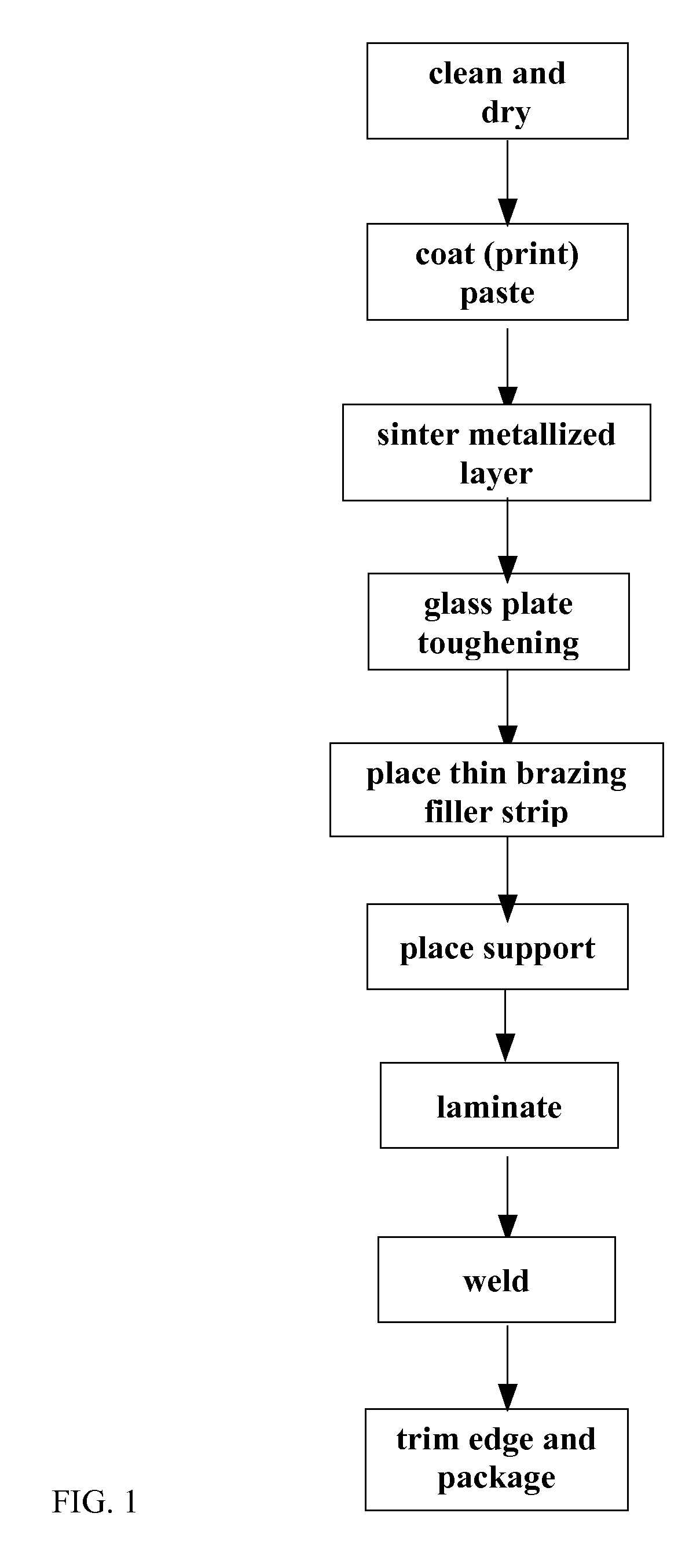

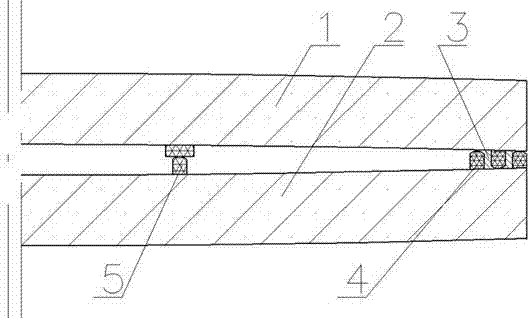

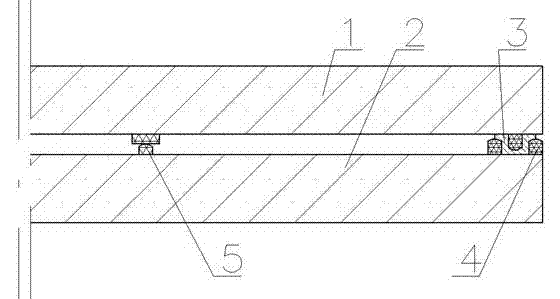

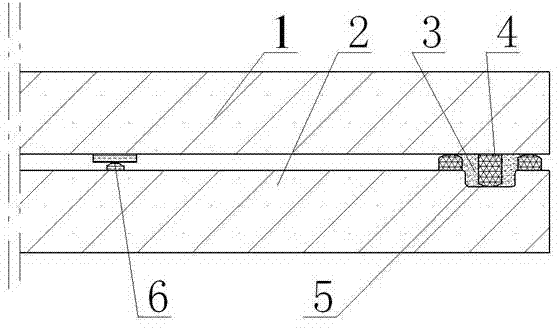

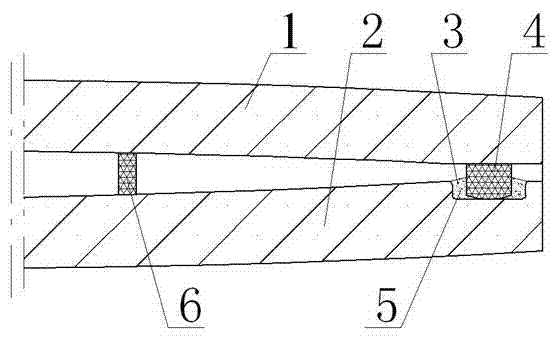

Compound Sealing Method for Vacuum Glass

ActiveUS20120321822A1Excellent brazeabilityPrevent annealingClimate change adaptationSoldering apparatusThermal shockBrazing

The invention relates to a compound sealing method for glass plates, which is characterized by realizing the air-tight joint between compounded glass plates in a preset position by using a metal brazing technology. The invention provides a brand new technological method for the compound sealing between glass plates. The method has the advantages of firm connection in sealing positions, high air tightness, favorable thermal shock resistance and the like, and the annealing of toughened glass are avoided because of a lower brazing temperature used, thereby providing convenience to the processing of toughened vacuum glass, toughened insulated glass and other toughened compound glass products

Owner:LUOYANG LANDGLASS TECH CO LTD

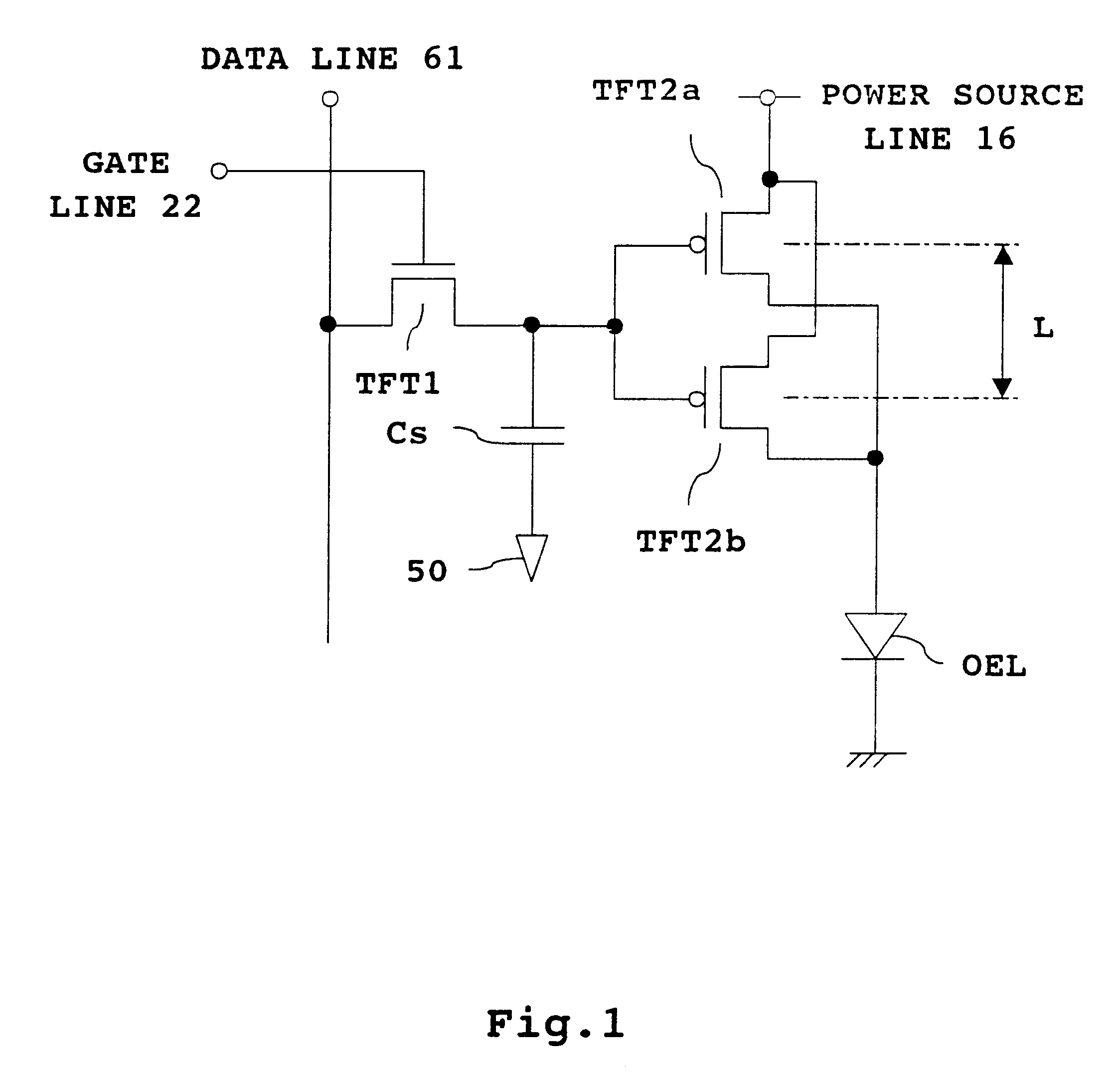

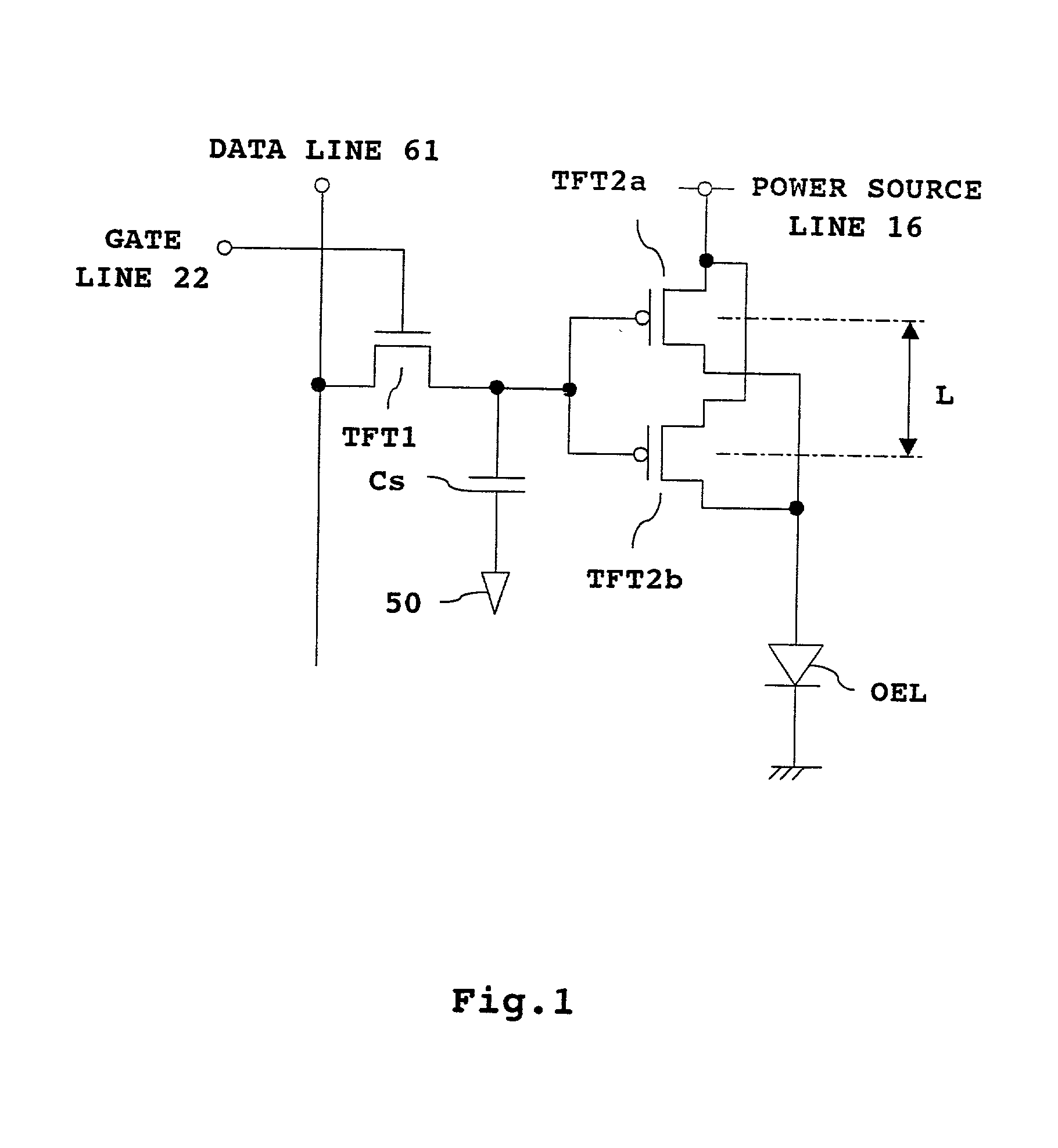

Semiconductor device having thin film transistor for supplying current to driven element

InactiveUS6469318B2Avoid problemsReduce Brightness VariationsTransistorSolid-state devicesActive layerDriven element

Owner:SANYO ELECTRIC CO LTD

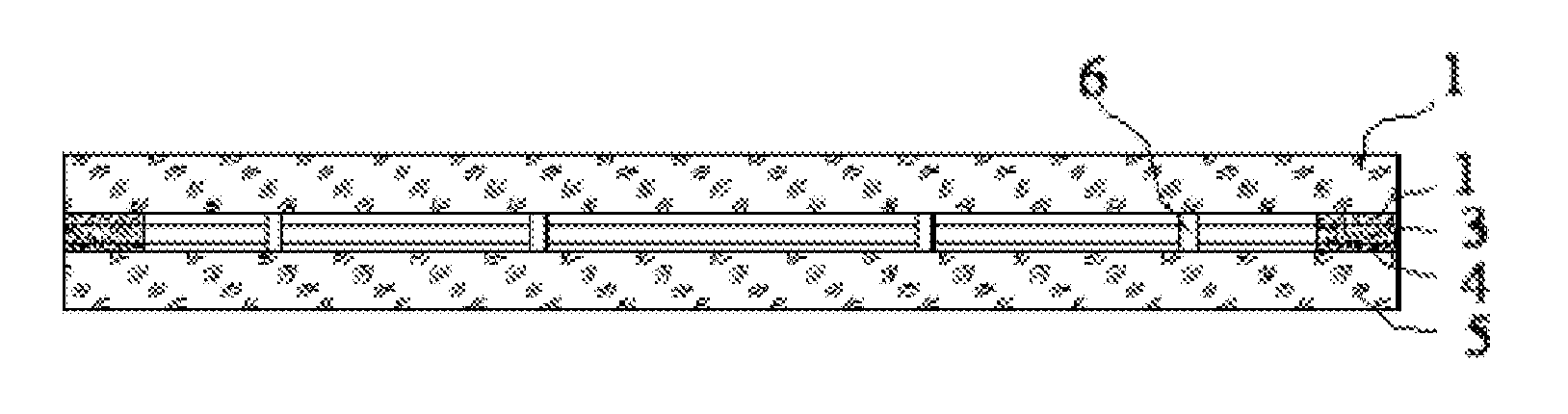

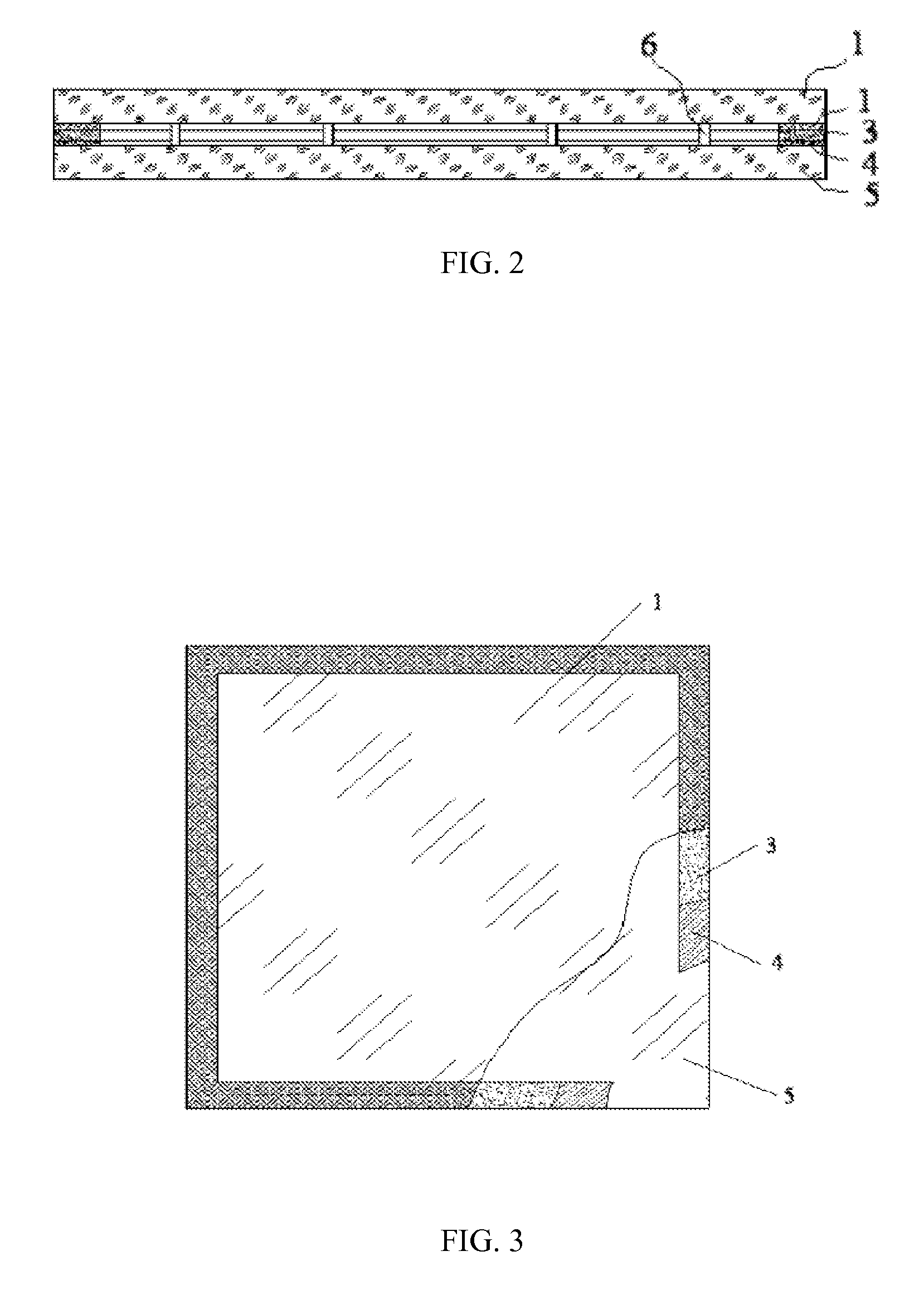

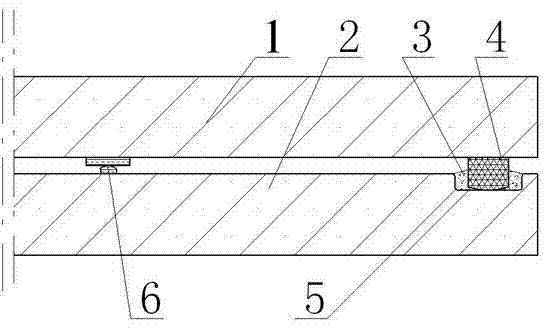

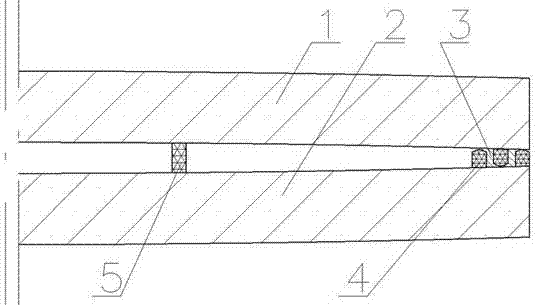

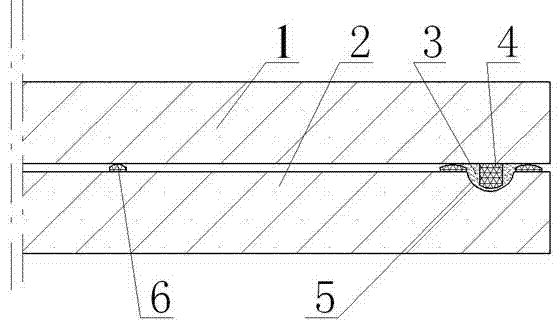

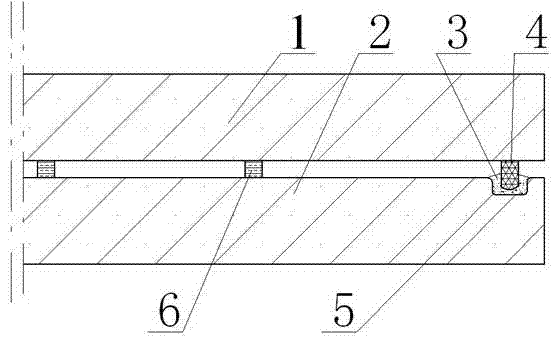

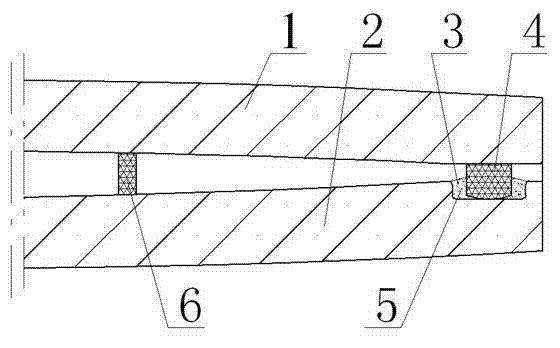

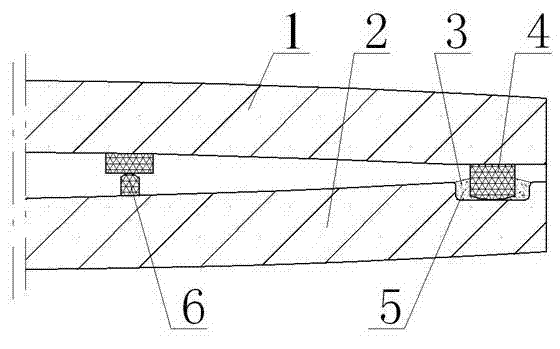

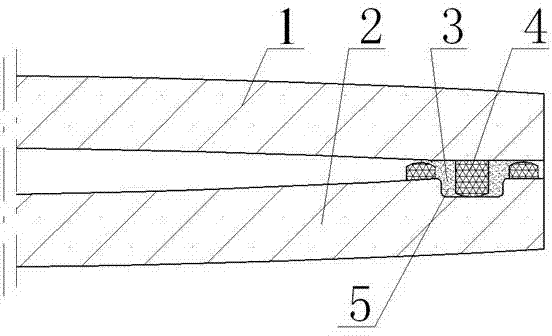

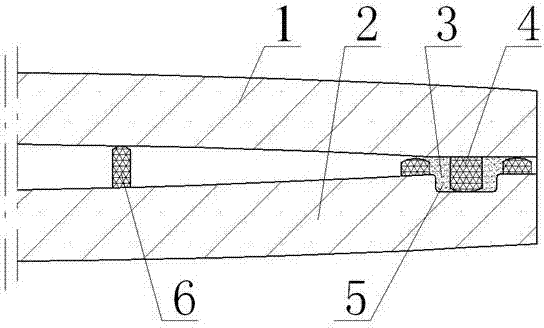

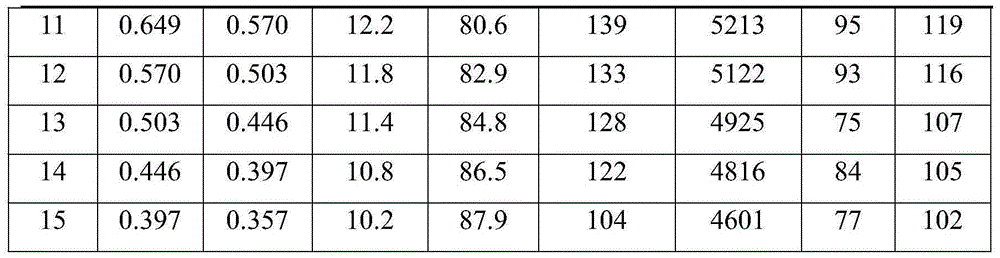

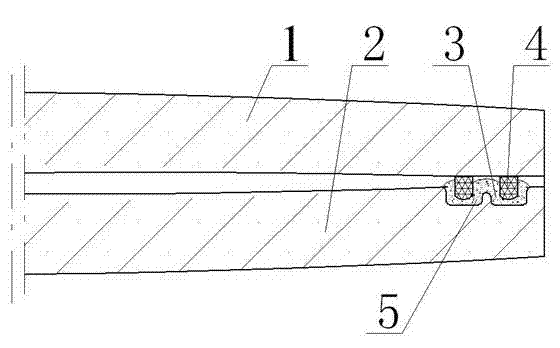

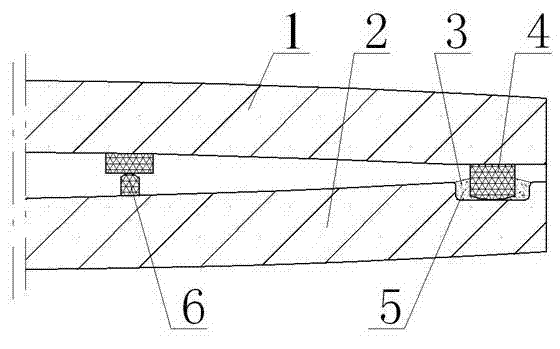

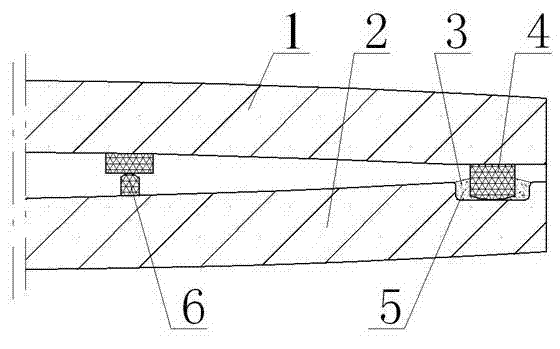

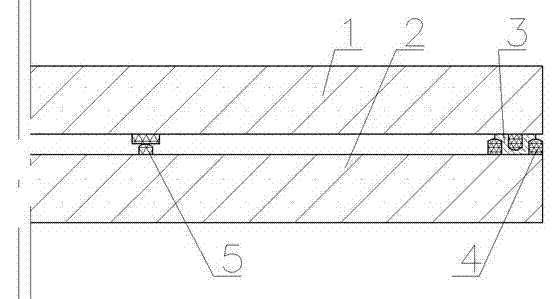

Method for sealing vacuum glass and vacuum glass product

ActiveCN102249560APrevent annealingImprove high temperature resistanceDoors/windowsClimate change adaptationHermetic sealMetallurgy

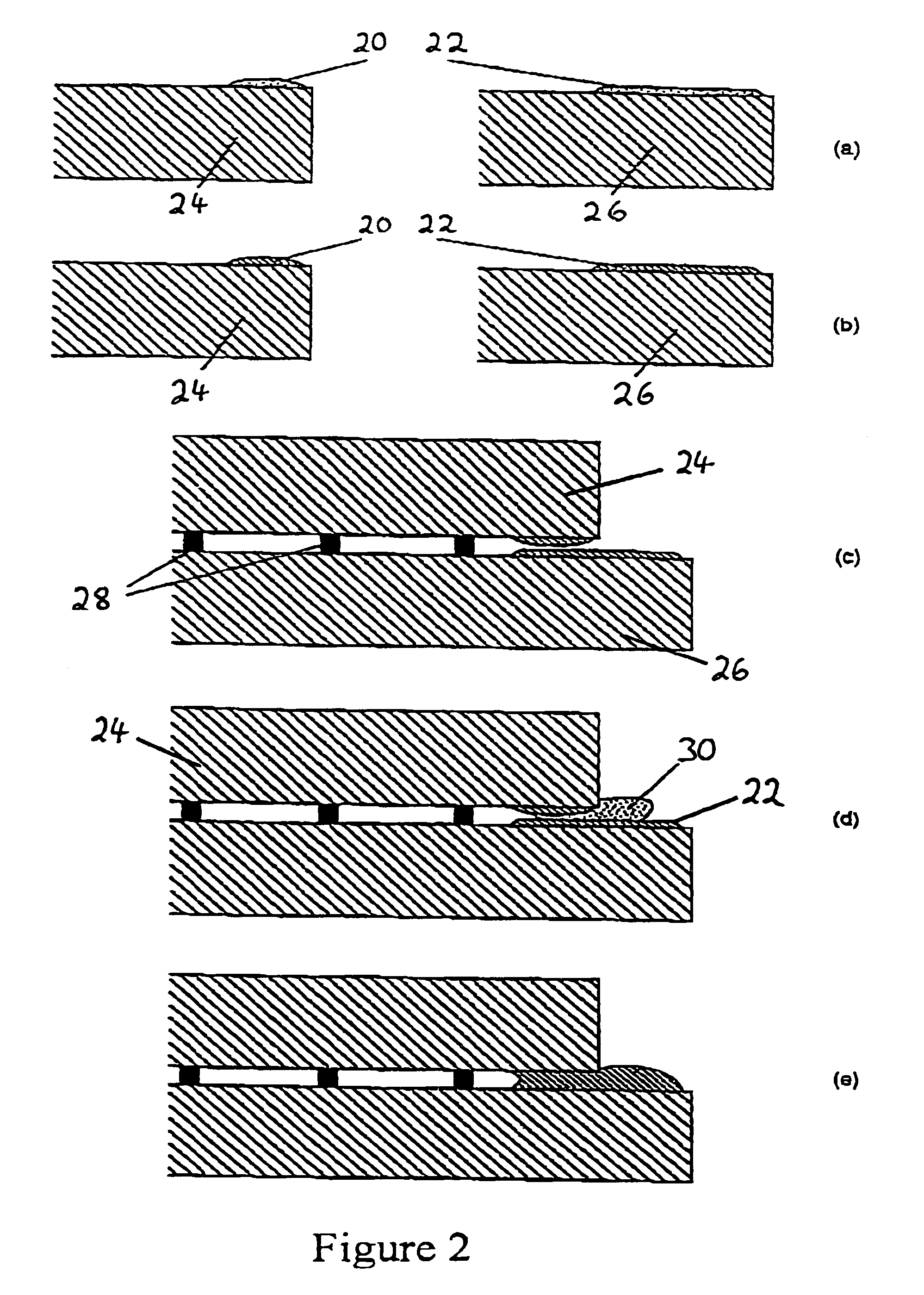

The invention discloses a method for sealing vacuum glass and a vacuum glass product thereby. The method comprises the following specific steps: preparing a metallized layer solidified together with a glass plate by the sintering technology on a surface to be sealed at the edge of the glass plate; and hermetically welding and connecting a metal sealing sheet between the metallized layers of two glass plates to realize the hermetic seal of the edges of the two glass plates. In the method, the metallized layer is sintered on the surface of each glass plate, the metallized layers and the metal sealing sheet are used for hermetically sealing the edges of the glass plates, and the method provides a brand-new technical means for manufacturing vacuum glass. The method disclosed by the invention has the advantages of firm connection of sealing parts, high air tightness, good heat shock resistance and the like. In addition, because of the use of the metal sheet, the vacuum glass product can better adapt to temperature deformation generated by temperature difference between an inner glass plate and an outer glass plate in the vacuum glass, and the vacuum glass can be guaranteed to be used safely.

Owner:洛阳兰迪真空玻璃科技有限公司

Glass panel

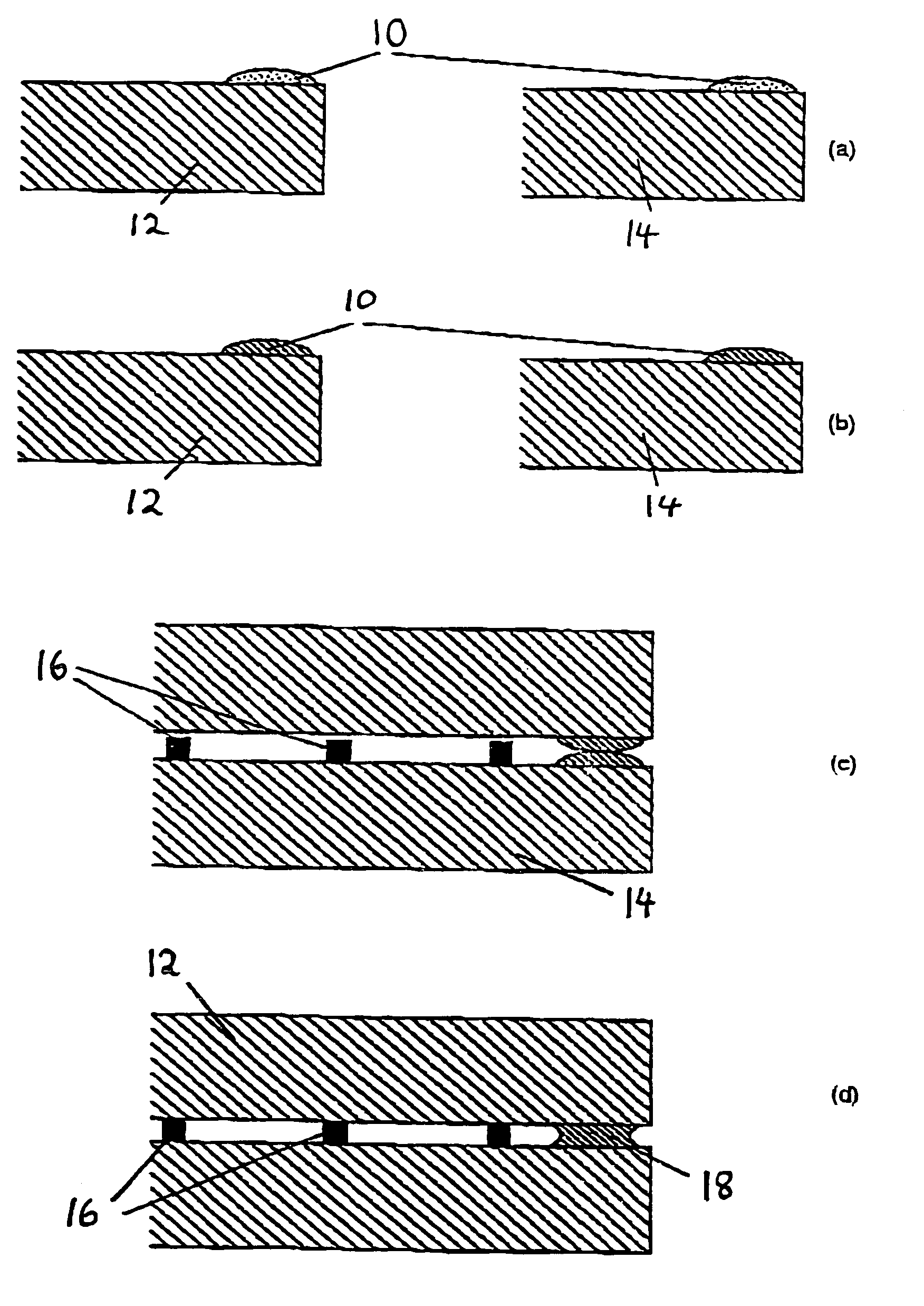

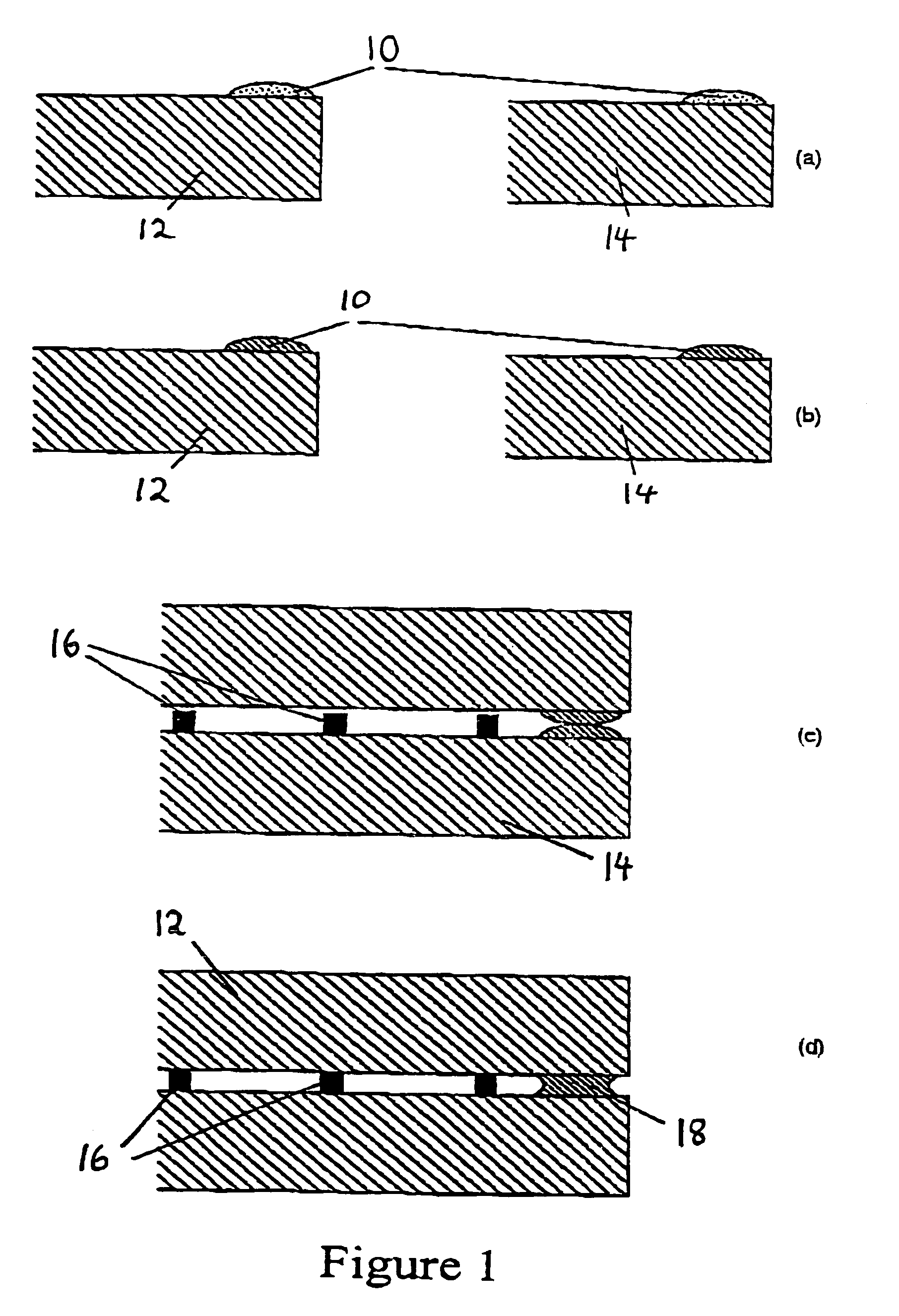

A method of constructing a glass panel which comprises two confronting edge sealed glass sheets, the method comprises the steps of providing a solder glass band around the margin of one surface of each glass sheet, forming, at a first temperature, an hermetic bond between the solder glass band and the associated surface of each glass sheet, positioning the glass sheets in spaced-apart confronting relationship, forming, at a second temperature which is lower than the first temperature, an hermetic seal between the two solder glass bands whilst maintaining the spaced apart relationship between the glass sheets.

Owner:THE UNIV OF SYDNEY

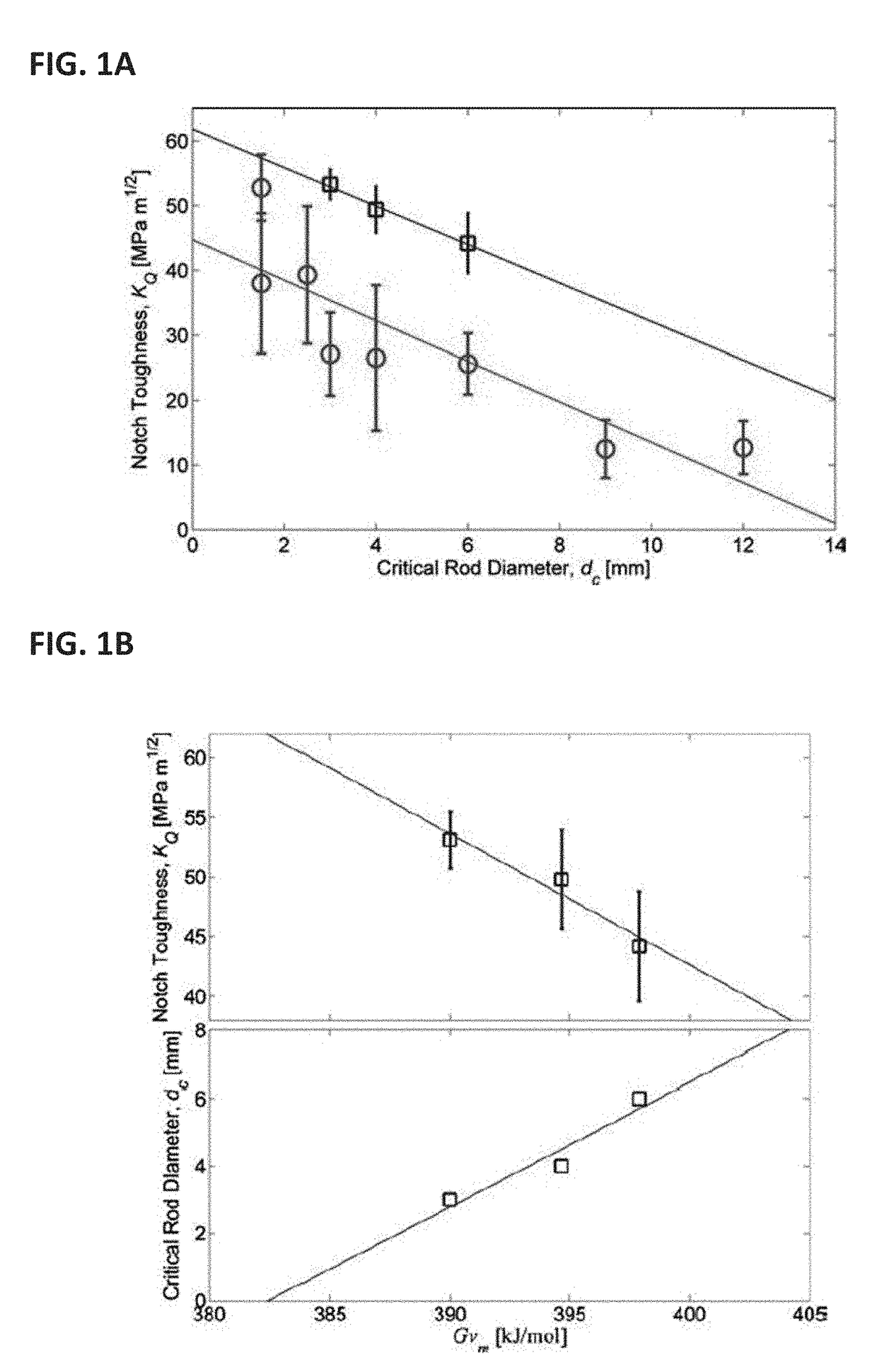

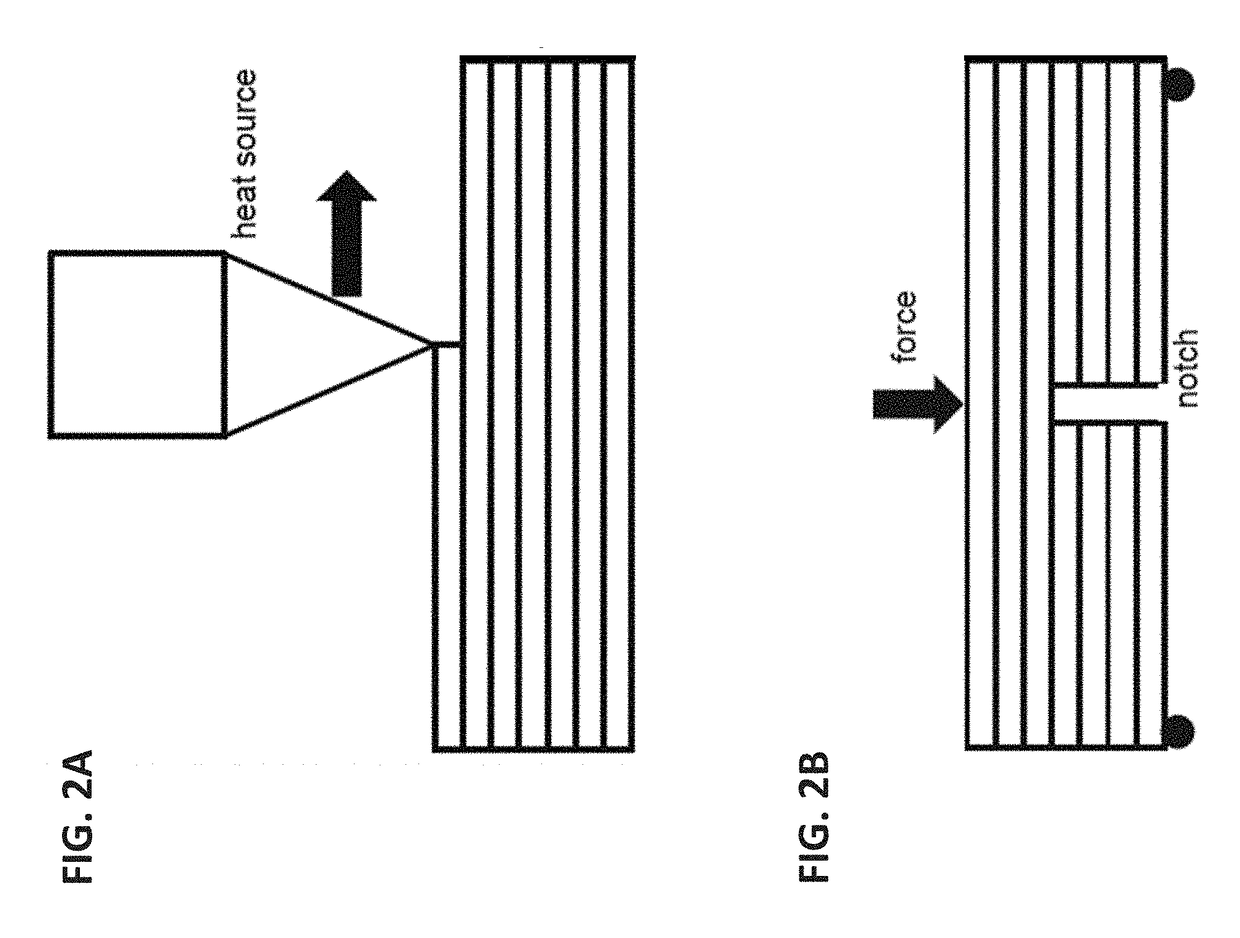

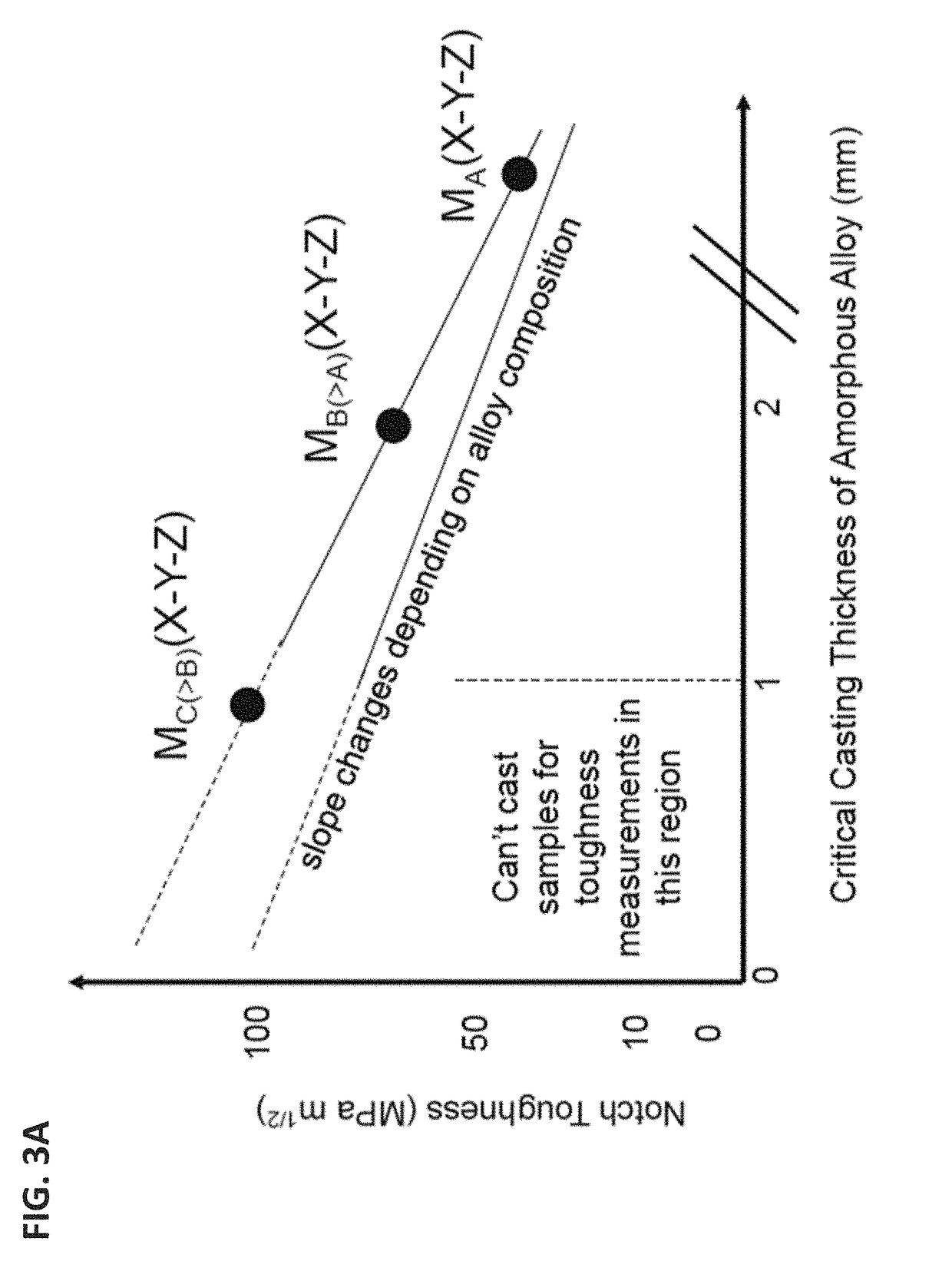

Hypoeutectic Amorphous Metal-Based Materials for Additive Manufacturing

ActiveUS20180339338A1Improve cooling effectExtension of timeAdditive manufacturing apparatusIncreasing energy efficiencyThin layerToughness

Systems and methods for developing tough hypoeutectic amorphous metal-based materials for additive manufacturing, and methods of additive manufacturing using such materials are provided. The methods use 3D printing of discrete thin layers during the assembly of bulk parts from metallic glass alloys with compositions selected to improve toughness at the expense of glass forming ability. The metallic glass alloy used in manufacturing of a bulk part is selected to have minimal glass forming ability for the per layer cooling rate afforded by the manufacturing process, and may be specially composed for high toughness.

Owner:CALIFORNIA INST OF TECH

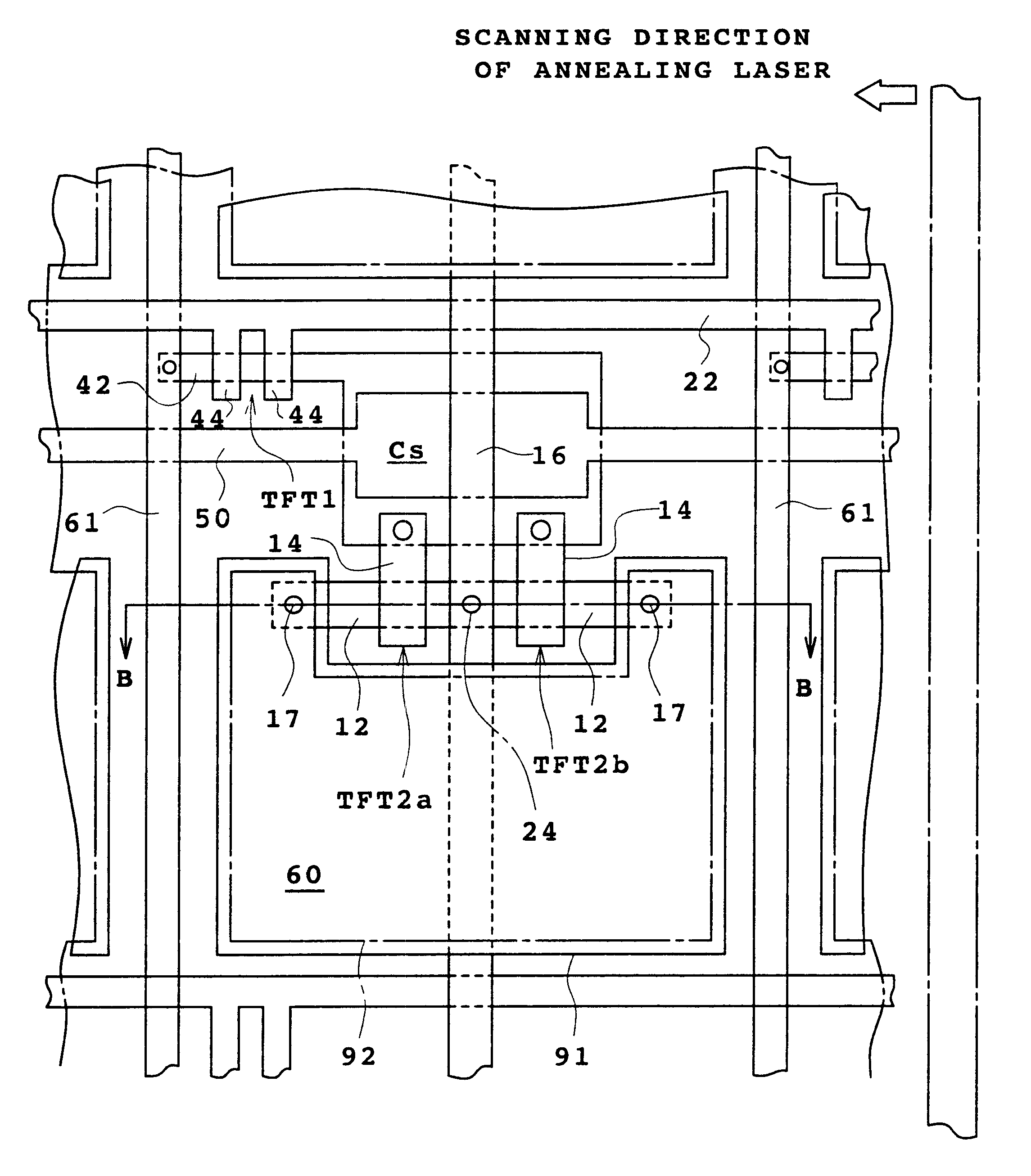

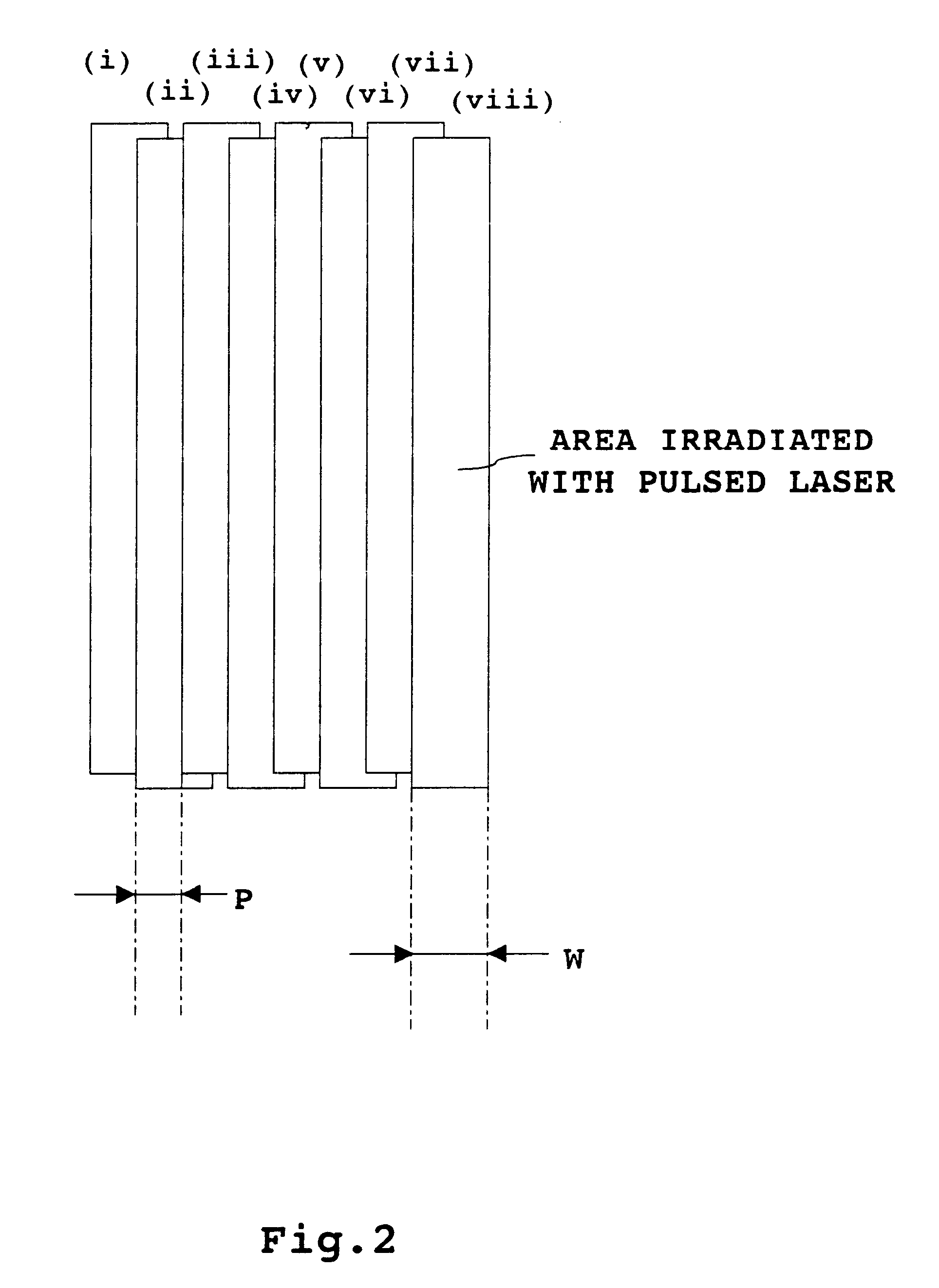

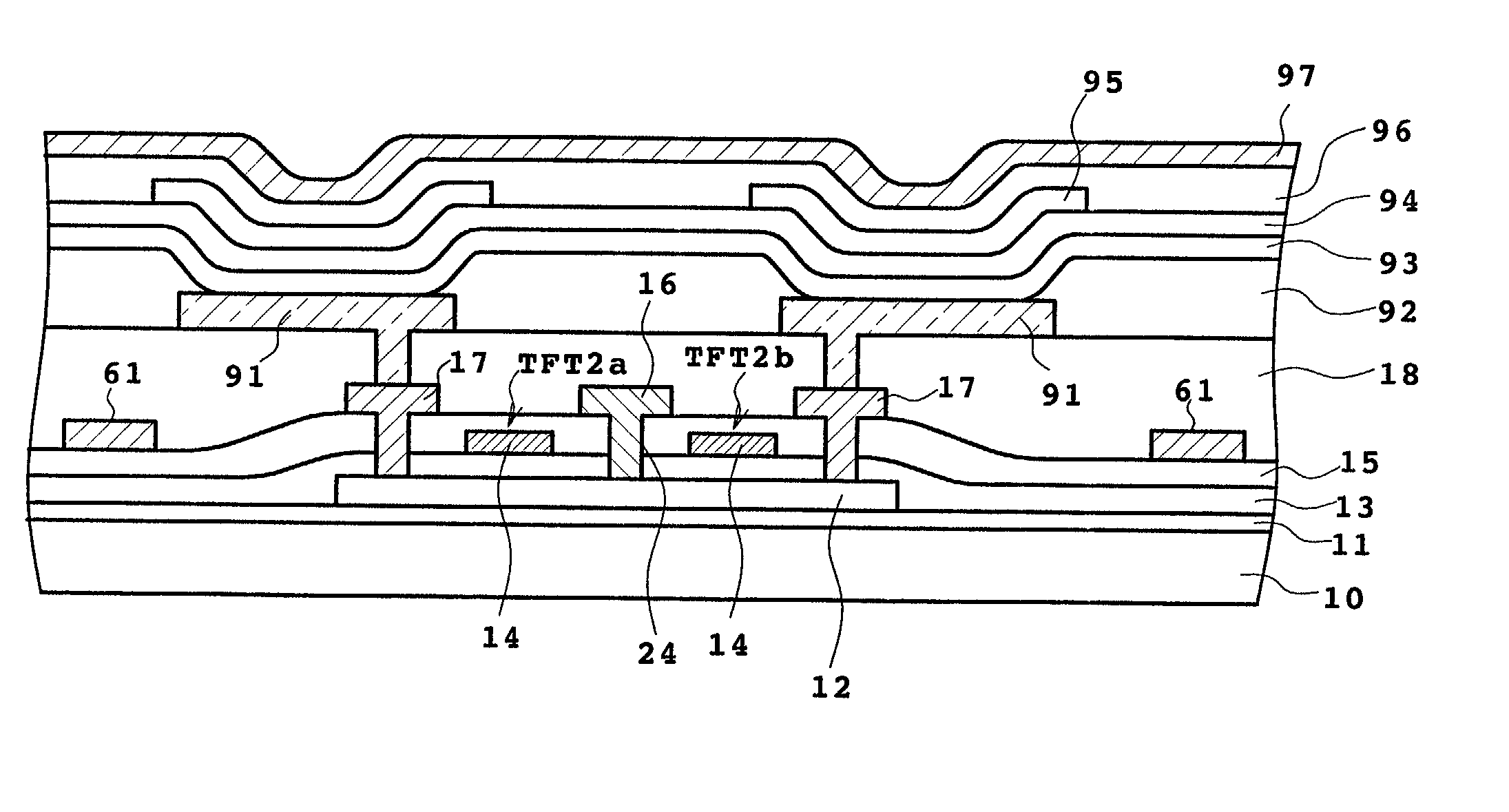

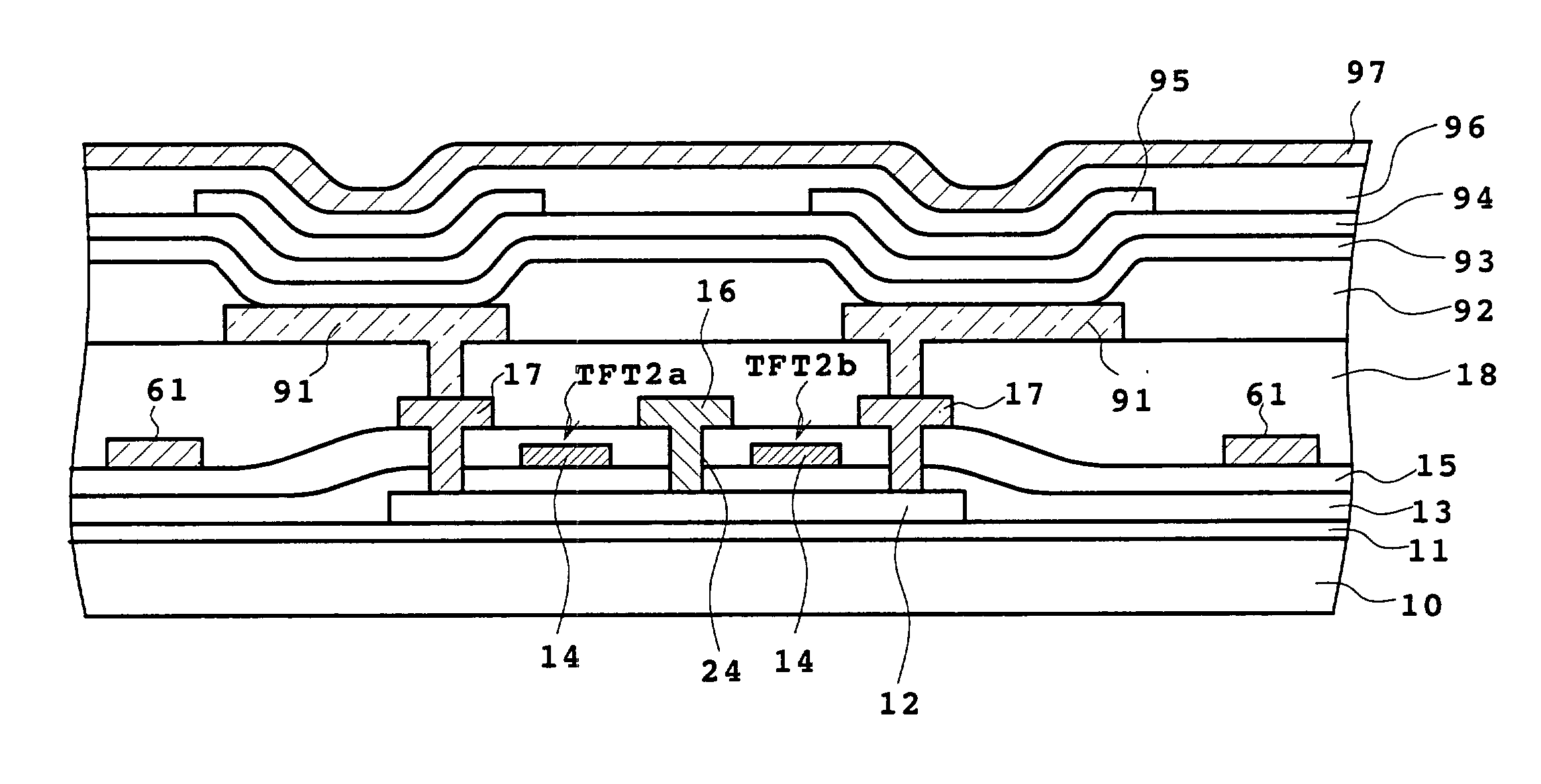

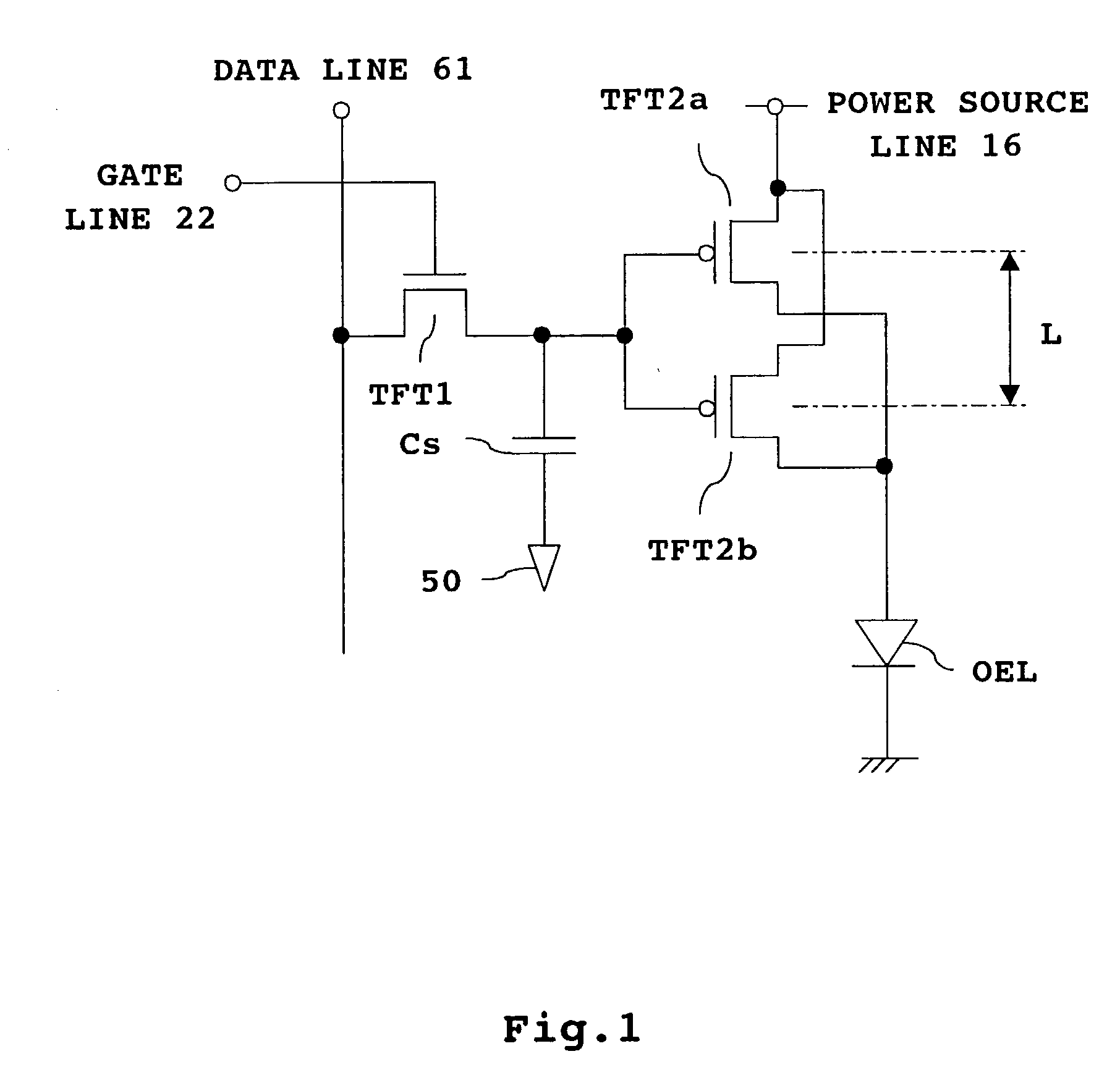

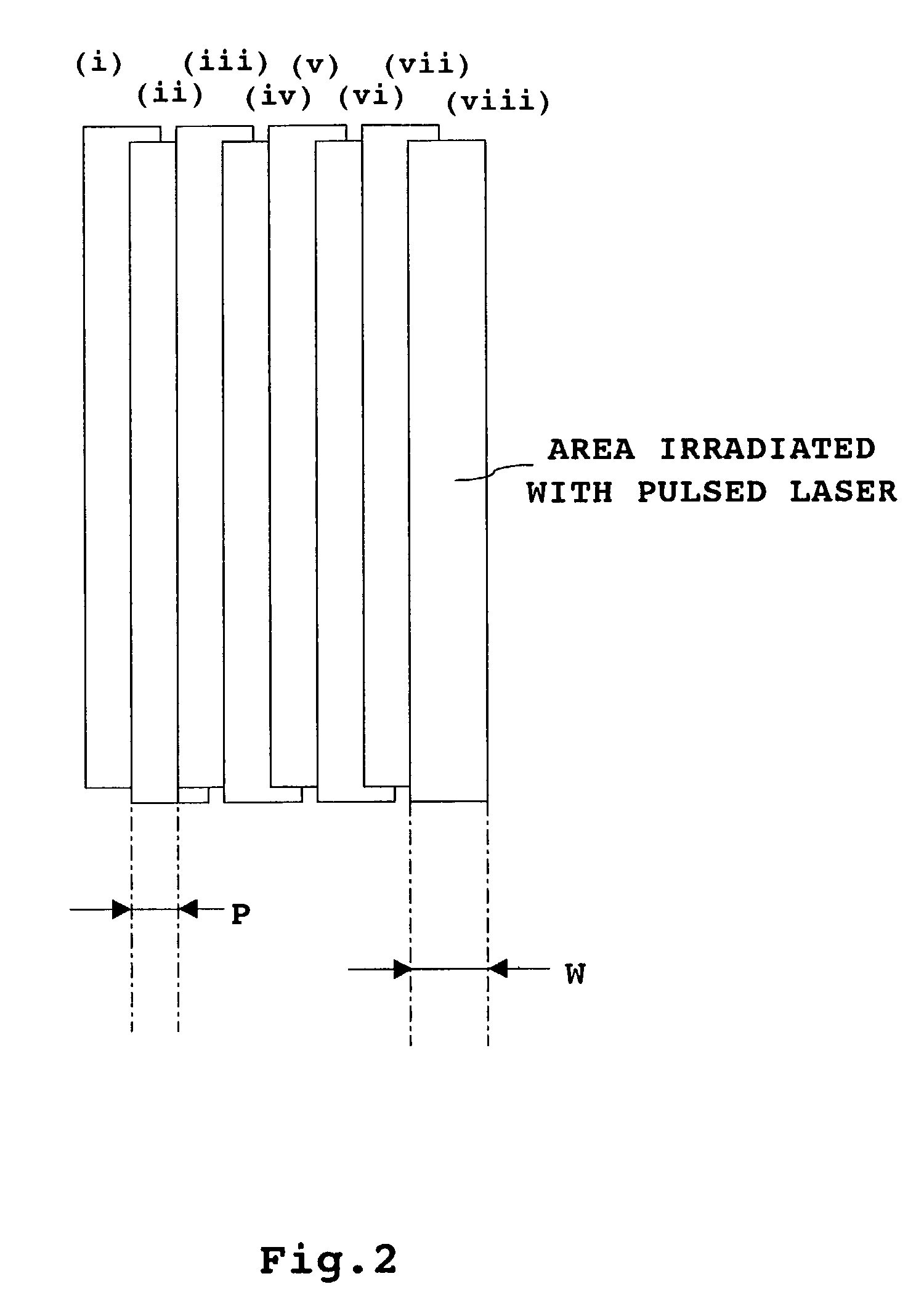

Semiconductor device having thin film transistor for supplying current to driven element

InactiveUS20020070381A1Avoid problemsReduce Brightness VariationsTransistorSolid-state devicesActive layerDriven element

Thin film transistors TFT2a and TFT2b for driving elements are formed in parallel between a power source line (16) and an organic EL element (60), and active layers (12) of the transistors TFT2a and TFT2b are spaced apart in a scanning direction of a laser used for annealing for polycrystallization. As a result, the annealing conditions for the transistors TFT2a and TFT2b will not be exactly the same, thereby reducing the chance of a same problem being caused in both transistors TFT2a and TFT2b.

Owner:SANYO ELECTRIC CO LTD

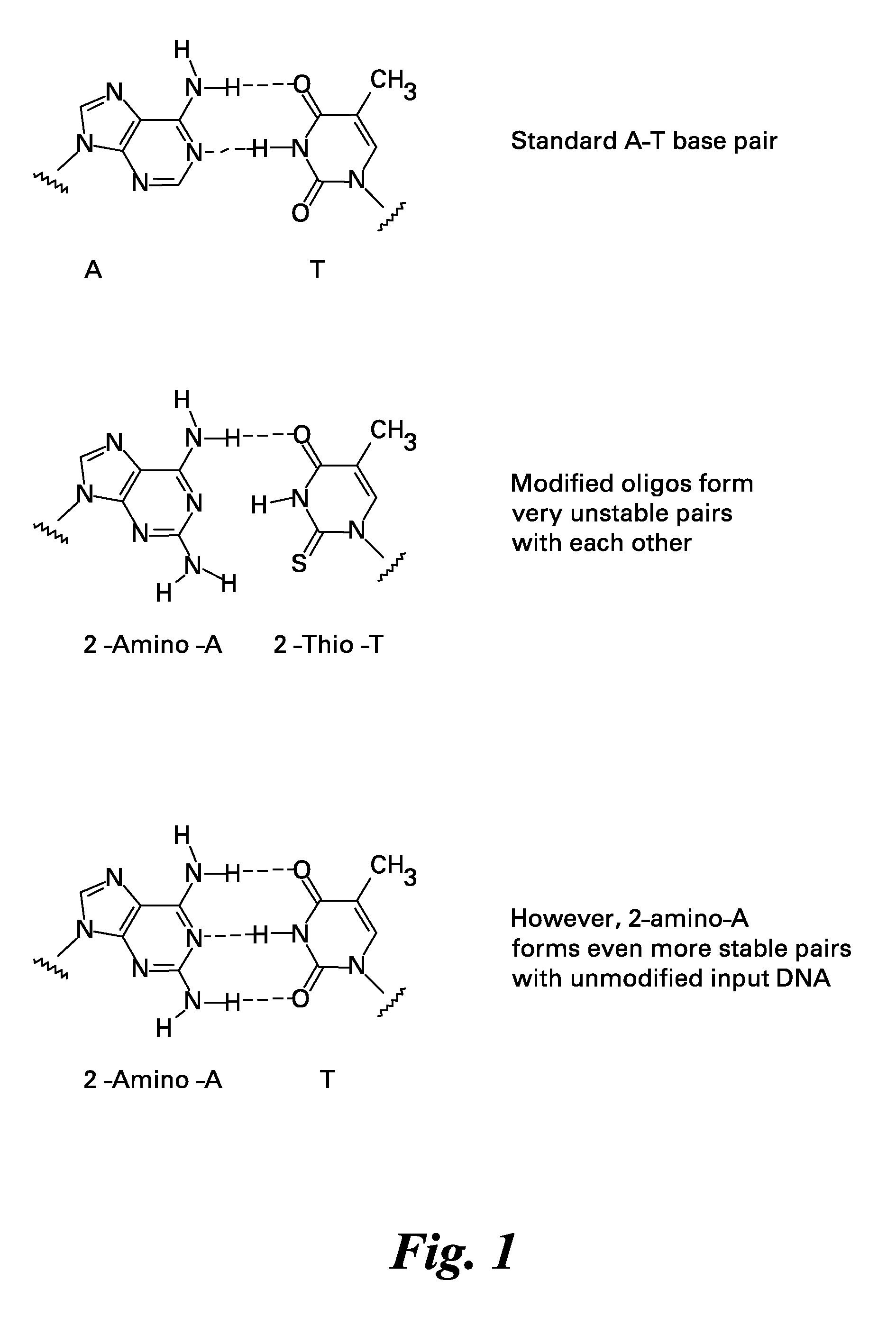

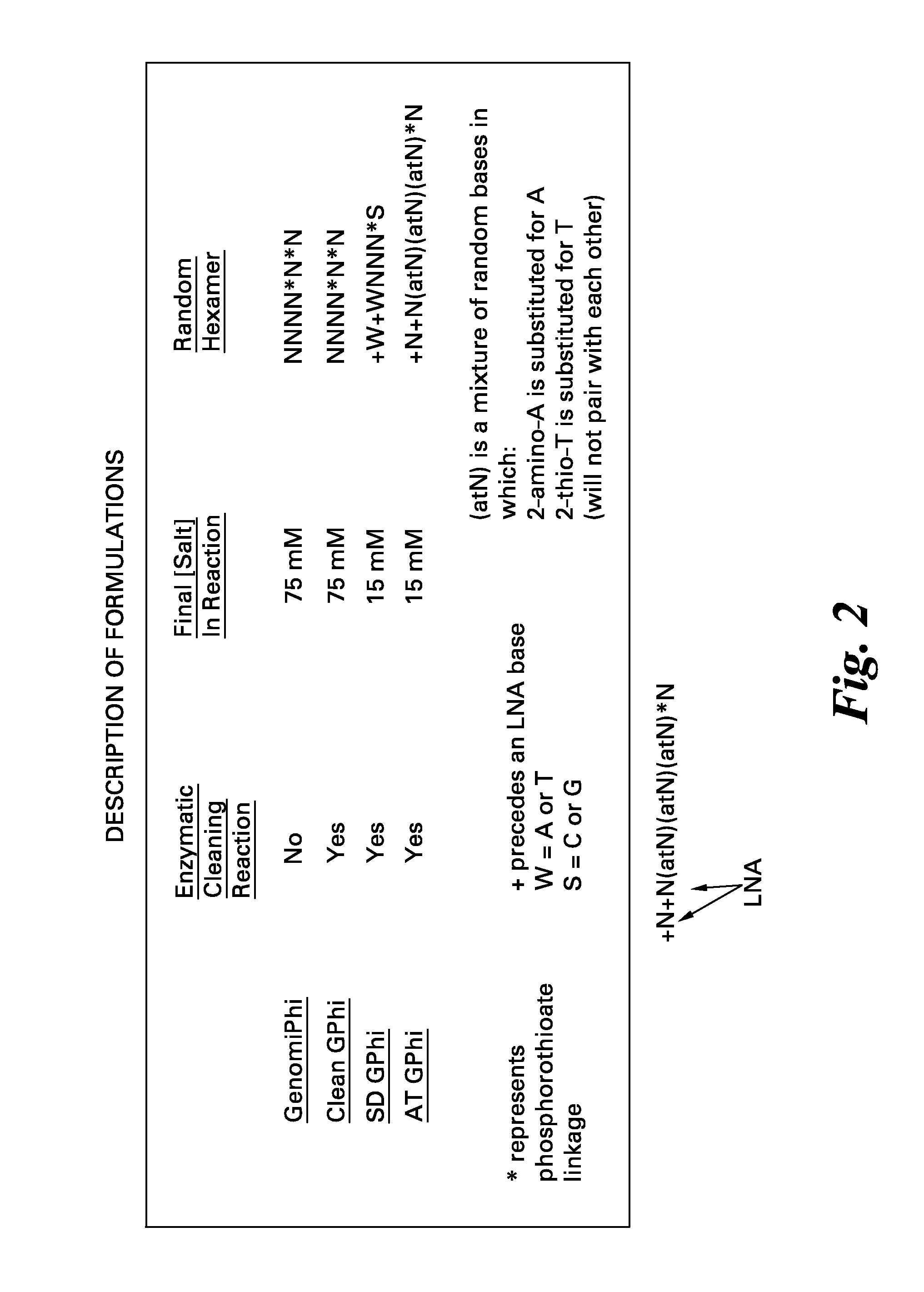

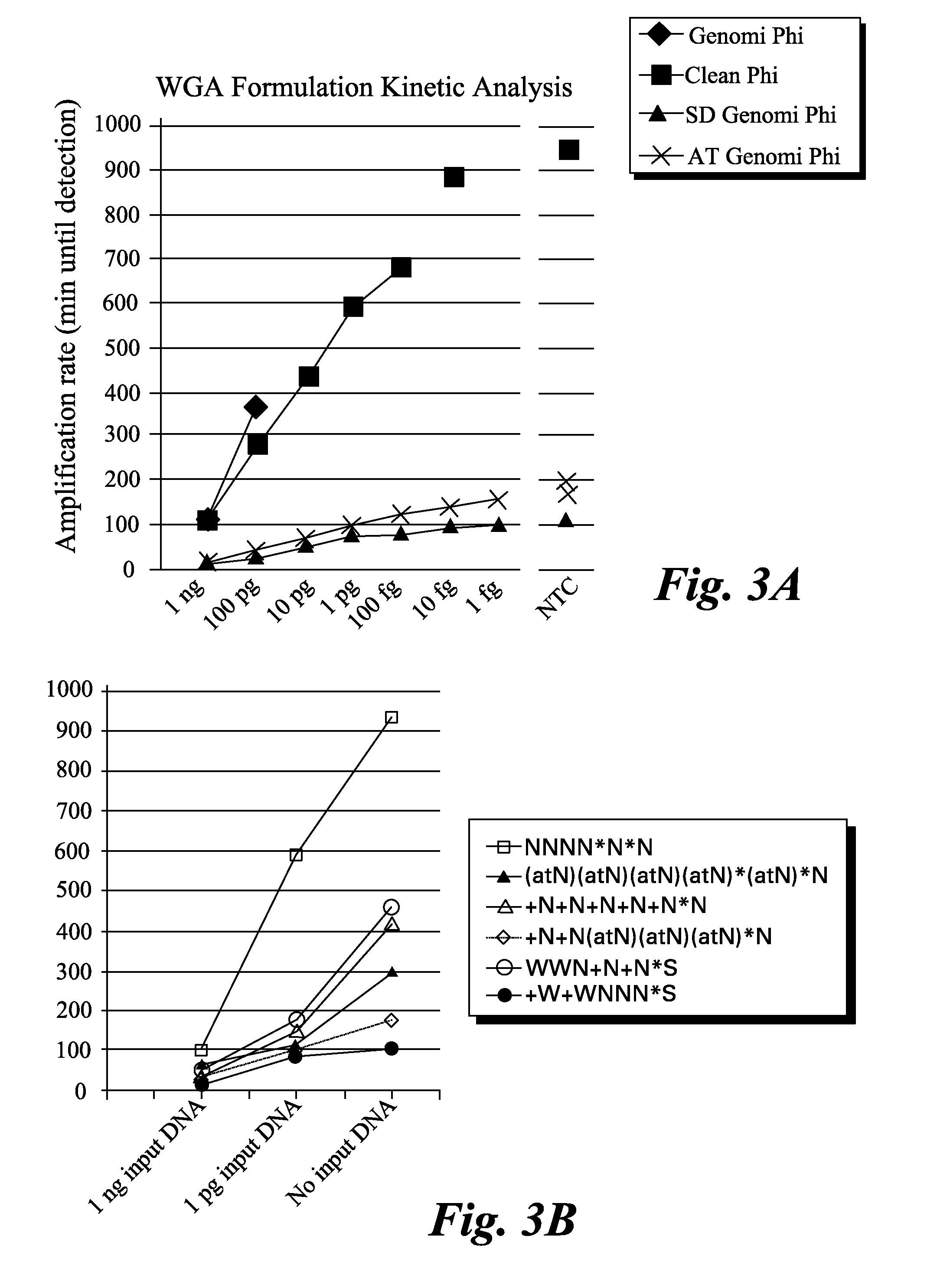

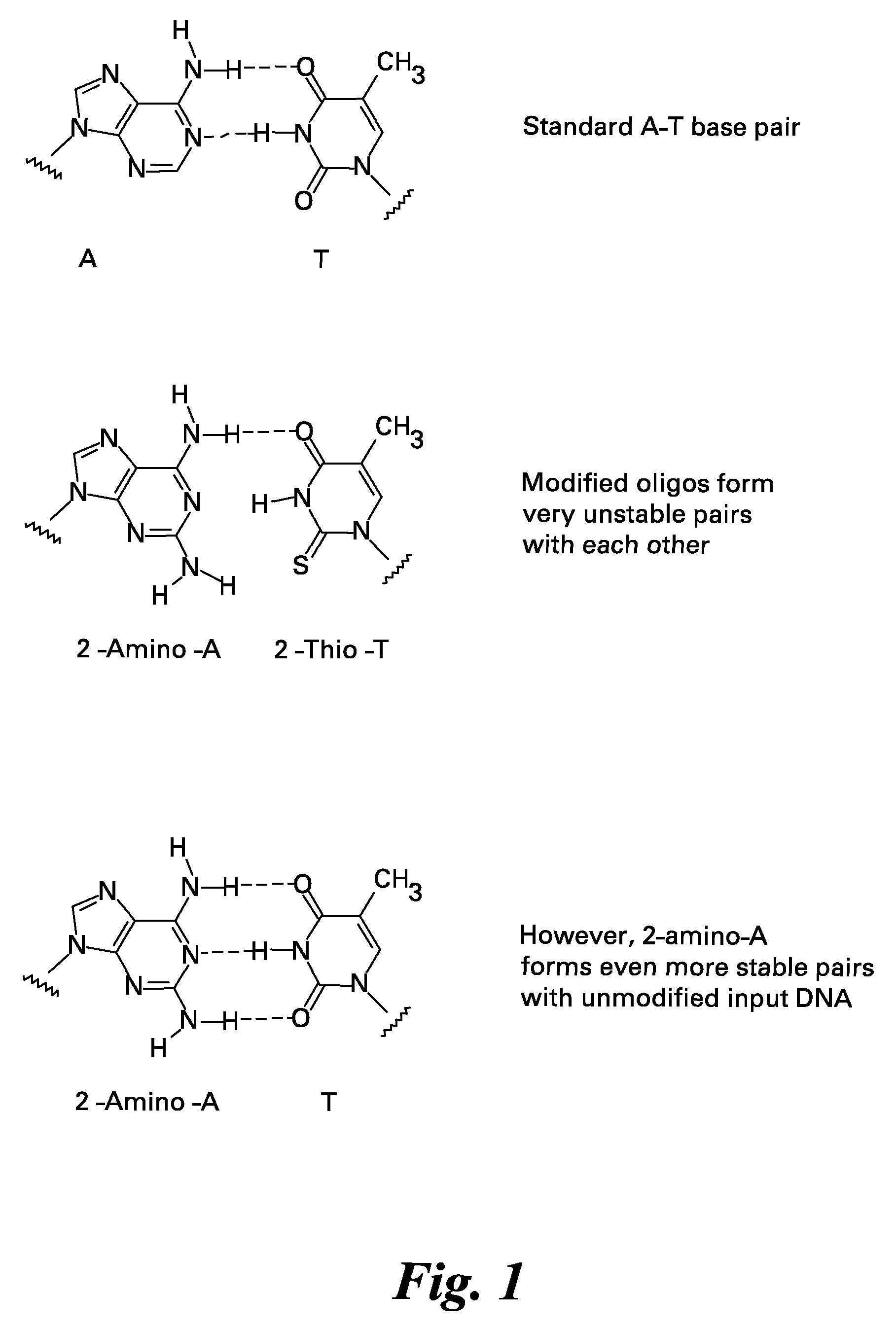

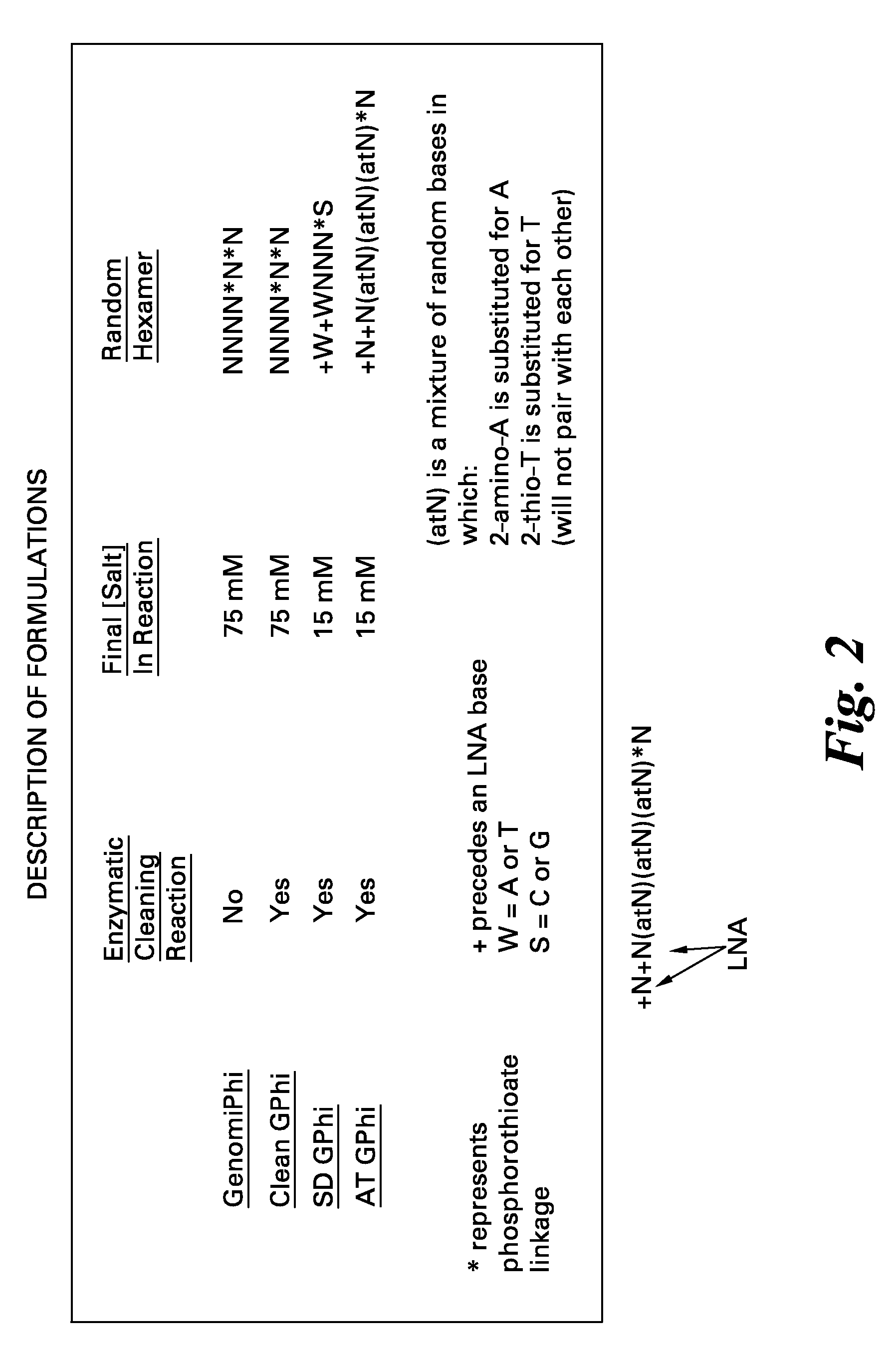

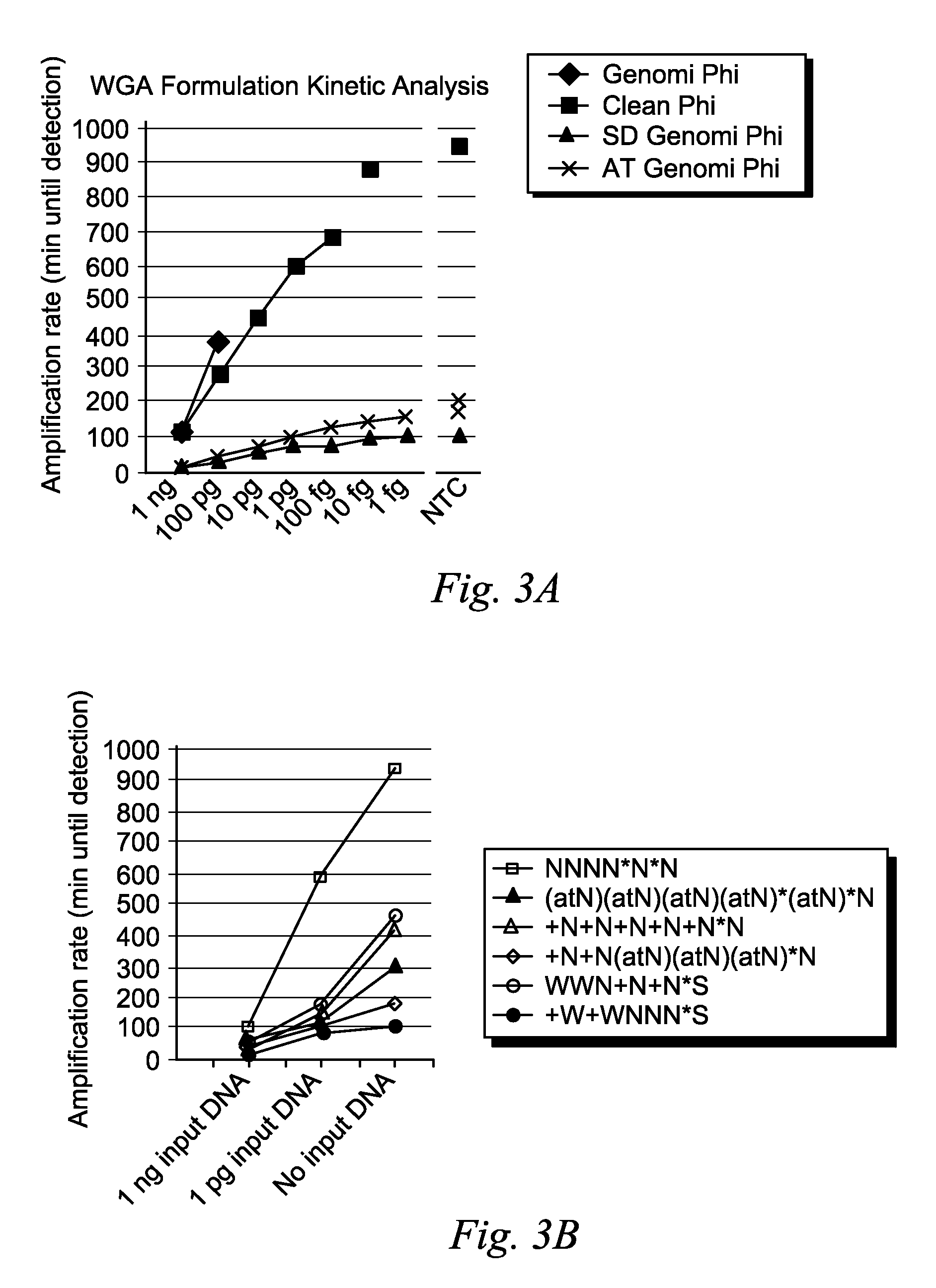

Methods and kits for reducing non-specific nucleic acid amplification

ActiveUS20130210078A1Efficient amplificationMinimize and prevent productionMicrobiological testing/measurementTransferasesPrimer dimerComputational biology

Methods and kits for efficient amplification of nucleic acids are provided. The disclosure generally relates to methods and kits for nucleic acid amplification of target nucleic acids of interest. The methods described herein promote the synthesis of the target nucleic acid (i.e., template nucleic acid) by reducing the production of undesirable primer-dimer structures and chimeric nucleic acid products during the amplification process by using novel modified primers.

Owner:GLOBAL LIFE SCI SOLUTIONS OPERATIONS UK LTD

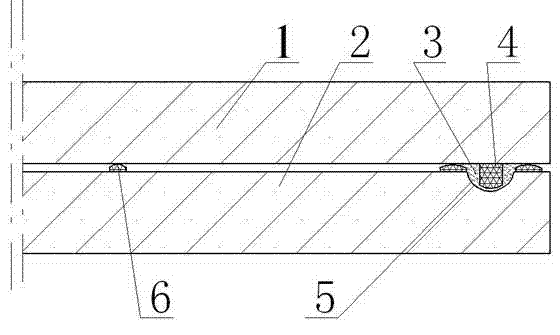

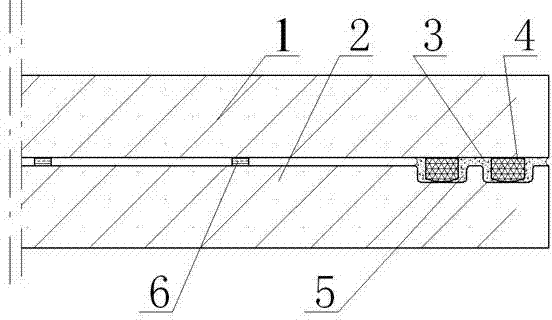

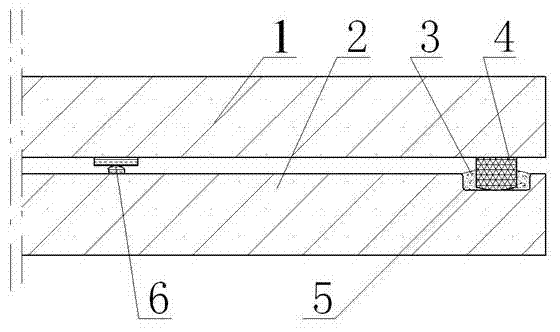

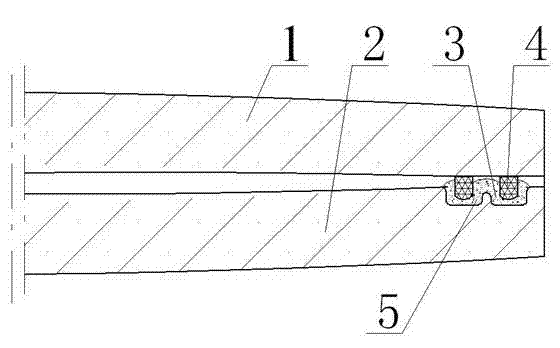

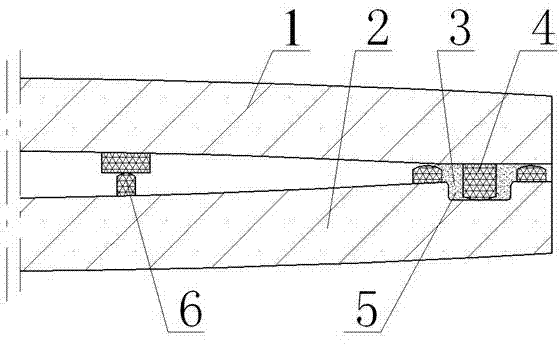

Glass solder-microwave welded and strip frame-groove-edge-sealed planar vacuum glass and manufacturing method thereof

InactiveCN102951828AGuaranteed tightnessExtend your lifeGlass reforming apparatusGlass productionMicrowave ovenMetallurgy

The invention relates to vacuum glass. The vacuum glass comprises upper glass and lower glass and is characterized in that an edge sealing strip frame is arranged at the welded periphery of the upper glass, an edge sealing strip frame and an edge sealing groove are arranged at the welded periphery of the lower glass, and the upper glass and the lower glass are welded together by utilizing glass solder in a microwave oven; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the edge sealing strip frames and the edge sealing groove can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology; and the method can be used for manufacturing both the ordinary vacuum glass and tempered vacuum glass.

Owner:戴长虹

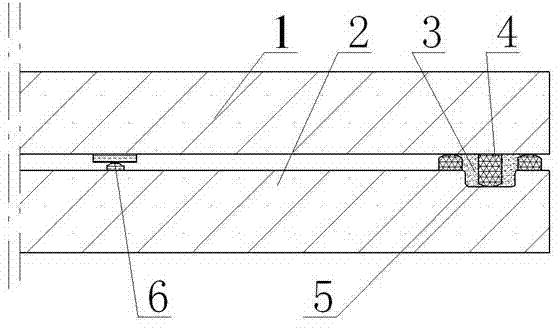

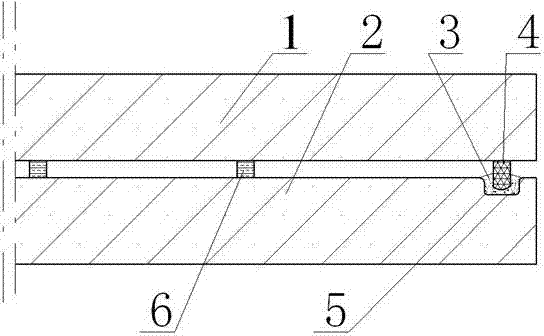

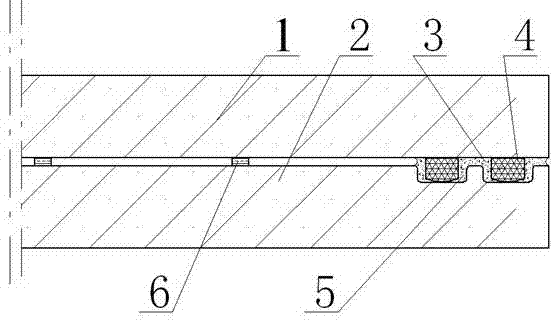

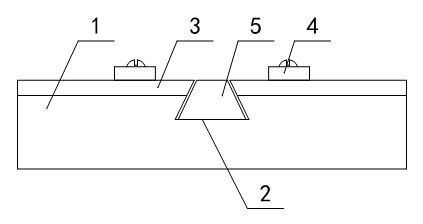

Planar vacuum glass welded by metal solders in microwave manner and subjected to edge sealing by groove, and manufacturing method of glass

InactiveCN102951809AGuaranteed tightnessExtend your lifeGlass reforming apparatusGlass productionMicrowave ovenMetal

The invention discloses vacuum glass. The vacuum glass consists of upper glass and lower glass and is characterized in that the welding periphery of the upper glass is provided with an edge sealing strip frame, and the welding periphery of the lower glass is provided with an edge sealing groove; and the upper and lower glass are welded together by metal or alloy solders in a microwave oven, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the edge sealing strip frame and the edge sealing groove. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without extraction openings in mass by virtue of a one-step method, and can be used for manufacturing not only common vacuum glass but also tempered vacuum glass.

Owner:戴长虹

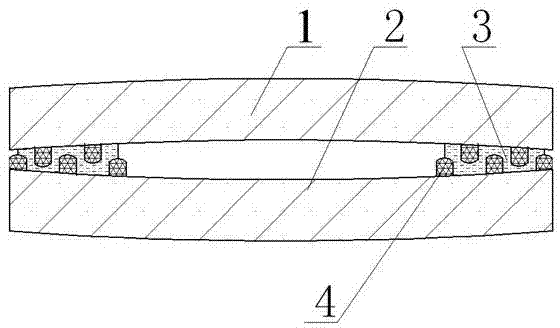

Convex vacuum glass welded by glass solders in microwave manner and subjected to edge sealing by strip frames, and manufacturing method of glass

InactiveCN102951806AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMicrowave ovenMetallurgy

The invention discloses vacuum glass. The vacuum glass is characterized in that upper glass and lower glass are convex; the peripheries of the upper and lower glass are provided with edge sealing strip frames; and the upper and lower glass are welded together by low-temperature glass solders in a microwave oven, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the upper and lower edge sealing strip frames. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without extraction openings in mass by virtue of a one-step method, and can be used for manufacturing common vacuum glass and tempered vacuum glass.

Owner:戴长虹

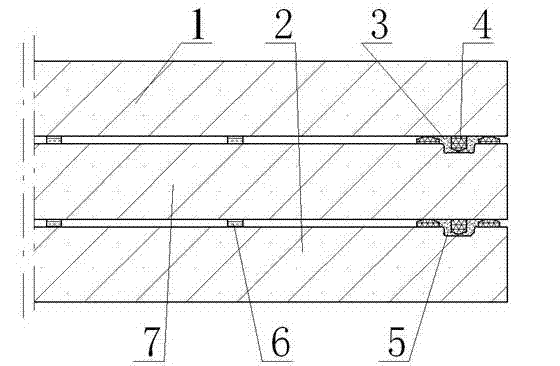

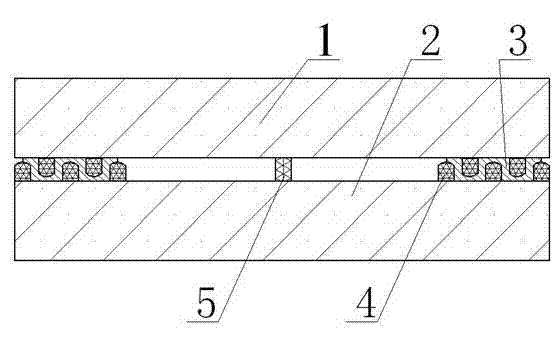

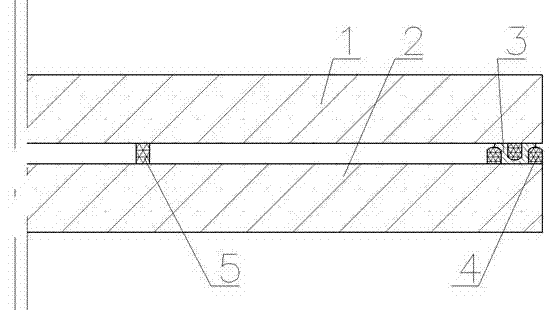

Planar vacuum glass welded by glass solders in microwave manner and subjected to edge sealing by strip frames, and manufacturing method of glass

InactiveCN102951817AEasy edge bandingExtend your lifeGlass reforming apparatusGlass productionMicrowave ovenMetallurgy

The invention discloses vacuum glass. The vacuum glass is characterized in that the peripheries of the upper and lower glass are provided with edge sealing strip frames; and the upper and lower glass are welded together by low-temperature glass solders in a microwave oven, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the upper and lower edge sealing strip frames. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without special extraction openings in mass by virtue of a one-step method, and can be used for manufacturing common vacuum glass and tempered vacuum glass.

Owner:戴长虹

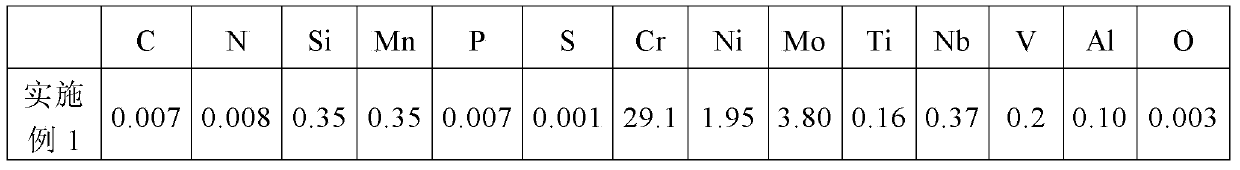

Sulfuric acid resistant ferritic stainless steel and manufacturing method thereof

InactiveCN105506502AHigh sulfuric acid corrosion resistanceImprove low temperature impact toughnessAlloyAustenite

The invention relates to a sulfuric acid resistant ferritic stainless steel and a manufacturing method thereof. The sulfuric acid resistant ferritic stainless steel comprises the following chemical components by weight: 0.002-0.015% of C, 0.002-0.015% of N, 0.2-1.0% of Si, 0.2-0.5% of Mn, less than or equal to 0.030% of P, less than or equal to 0.003% of S, 28-30% of Cr, 1.5-3% of Ni, 2.0-4.0% of Mo, 0.1-0.3% of V, 0.10-0.30% of Ti, 0.2-0.5% of Nb, 0.05-0.1% of Al, with the sum of Cr+3.3*Mo being greater than or equal to 38%, and Ti+Nb being greater than or equal to 16(C+N), less than or equal to 0.005% of O, and the balance Fe and inevitable impurities. The ferritic stainless steel provided by the invention can tolerate the corrosion of various concentration sulfuric acids at a temperature of less than 60 DEG C and at a concentration of less than or equal to 98wt%, also has good impact toughness and welding performance. With a pitting resistance equivalent PREN of greater than or equal to 38, the ferritic stainless steel has corrosion resistance far superior to conventional ferritic stainless steel, and is equivalent to superaustenitic stainless steel and nickel based alloys.

Owner:BAOSTEEL STAINLESS STEEL

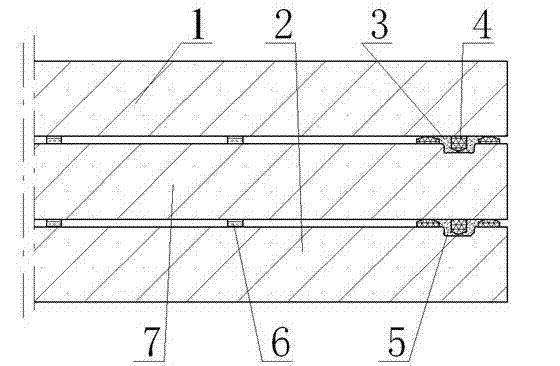

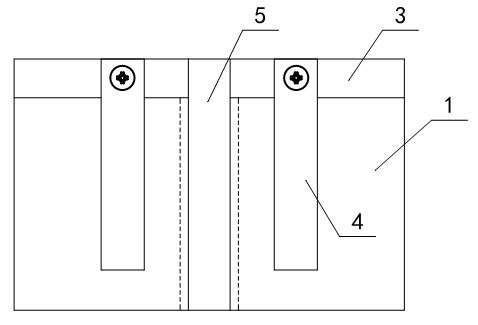

Planar vacuum glass welded by metal solders in microwave manner and subjected to edge sealing by strip frames and groove, and manufacturing method of glass

InactiveCN102951815AGuaranteed tightnessExtend your lifeGlass reforming apparatusGlass productionMicrowave ovenAlloy

The invention discloses vacuum glass consisting of upper glass and lower glass. The vacuum glass is characterized in that the periphery of the welding surface of the upper glass is provided with an edge sealing strip frame, and the periphery of the welding surface of the lower glass is provided with en edge sealing strip frame and an edge sealing groove; and the upper and lower glass are welded together by metal or alloy solders in a microwave oven, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the upper and lower edge sealing strip frames. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without extraction openings in mass by virtue of a one-step method, and can be used for manufacturing not only common vacuum glass but also tempered vacuum glass.

Owner:戴长虹

Glass solder-microwave welded and groove-edge-sealed planar vacuum glass and manufacturing method thereof

InactiveCN102951824AGuaranteed tightnessExtend your lifeGlass reforming apparatusGlass productionMicrowave ovenMetallurgy

The invention relates to vacuum glass. The vacuum glass comprises upper glass and lower glass and is characterized in that an edge sealing strip frame is arranged at the welded periphery of the upper glass, an edge sealing groove is arranged at the welded periphery of the lower glass, and the upper glass and the lower glass are welded together by utilizing glass solder in a microwave oven; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the edge sealing strip frame and the edge sealing groove can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology; and the method can be used for manufacturing both the ordinary vacuum glass and tempered vacuum glass.

Owner:戴长虹

Fracture welding and crack repairing method of band saw blade and matched welding tool set

InactiveCN102672302APrevent annealingConsistent thicknessWelding/cutting auxillary devicesAuxillary welding devicesSlagEngineering

According to a fracture welding method of a band saw blade disclosed by the invention, a burn fusion welding way is mainly utilized, a fused liquid obtained after the fracture of the band saw blade is fused is utilized to weld by bonding, and other metal welding rods and fluxes are not needed in the welding process. The fused liquid obtained after the band saw blade is fused is utilized to bond two sections of the band saw blade, a welding seam of the band saw blade is smooth, welding beading and welding slag are not produced, a welding part is not reground, and the annealing problem of the band saw blade in the regrinding process is avoided. Additionally, the thickness of the welding part conforms to the thickness of the band saw blade, the tensile strength of the welding part is high, the toughness of the welding part conforms to the toughness of the band saw blade, and the crack repairing problem of the band saw blade is effectively solved by using the burn fusion welding way.

Owner:HENAN UNIV OF SCI & TECH

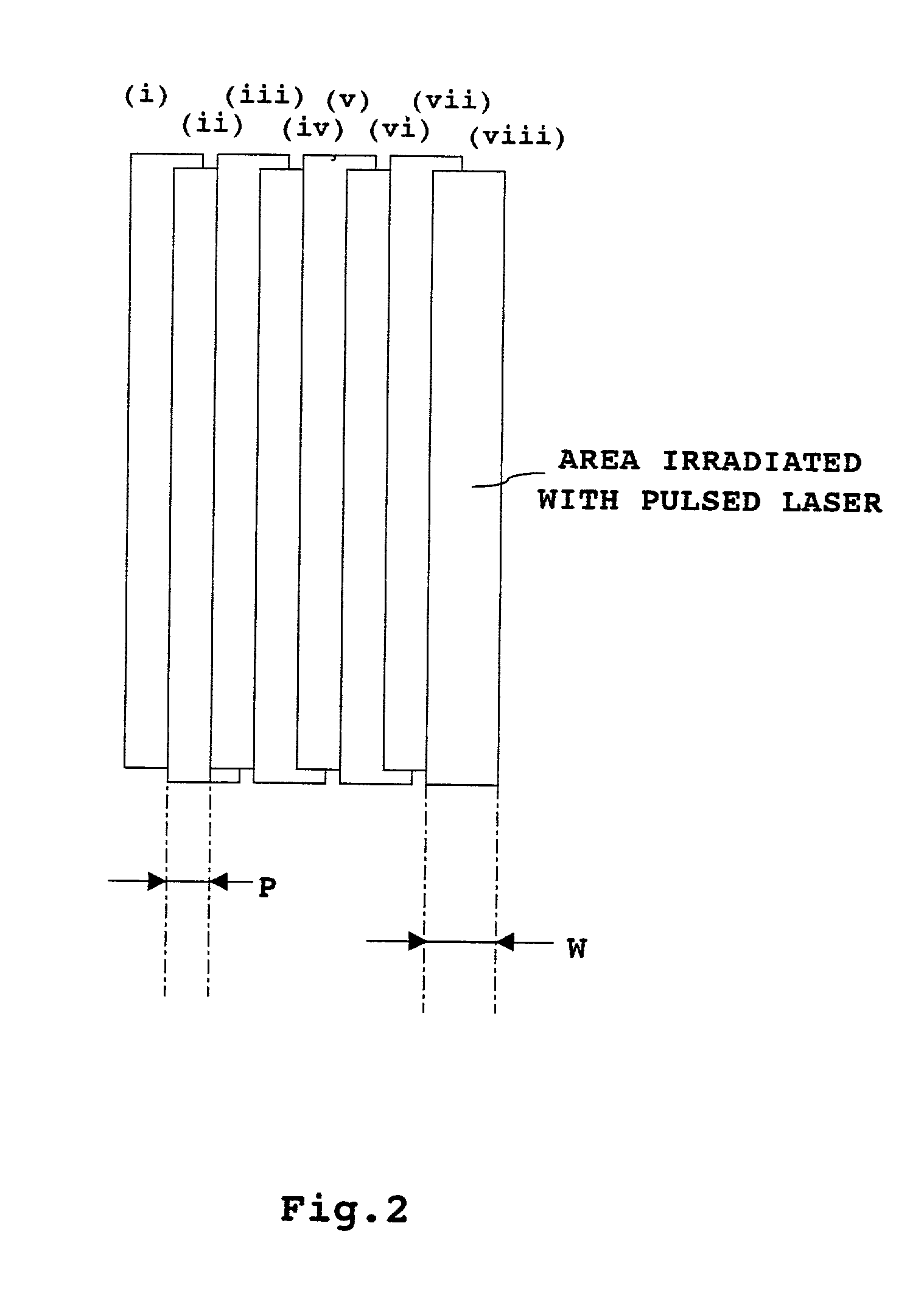

Semiconductor device having thin film transistor for supplying current to driven element

InactiveUS20030001157A1Avoid differencesPrevent annealingTransistorElectroluminescent light sourcesActive layerDriven element

Thin film transistors TFT2a and TFT2b for driving elements are formed in parallel between a power source line and an organic EL element, and active layers of the transistors TFT2a and TFT2b are spaced apart in a scanning direction of a laser used for annealing for polycrystallization. As a result, the annealing conditions for the transistors TFT2a and TFT2b will not be exactly the same, thereby reducing the chance of a same problem being caused in both transistors TFT2a and TFT2b.

Owner:SANYO ELECTRIC CO LTD

Mechanical parts having increased wear-resistance

InactiveUS8012274B2Extended service lifeHigh hardnessSolid state diffusion coatingThin material handlingWear resistantWear resistance

Owner:SKAFF OF AMERICA

Convex vacuum glass welded by glass solders in microwave manner and subjected to edge sealing by groove, and manufacturing method of glass

InactiveCN102951805AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMicrowave ovenConvex side

The invention discloses vacuum glass. The vacuum glass is characterized in that upper glass and lower glass are convex; the welding periphery of the upper glass is provided with an edge sealing strip frame, and the welding periphery of the lower glass is provided with an edge sealing groove; and the upper and lower glass are welded together by glass solders in a microwave oven, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the edge sealing strip frame and the edge sealing groove. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without extraction openings in mass by virtue of a one-step method, and not only can be used for manufacturing common vacuum glass, but also is particularly suitable for manufacturing of tempered vacuum glass; and the vacuum glass manufactured by the method is high in wind pressure resistance and good in heat insulation and sound insulation.

Owner:戴长虹

Metal solder-microwave welded and strip frame-groove-edge-sealed convex vacuum glass and manufacturing method thereof

InactiveCN102951830AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMicrowave ovenConvex side

The invention relates to vacuum glass. The vacuum glass is characterized in that each of upper glass and lower glass is convex glass, an edge sealing strip frame is arranged at the welded periphery of the upper glass, an edge sealing strip frame and an edge sealing groove are arranged at the welded periphery of the lower glass, and the upper glass and the lower glass are welded together by utilizing metal or alloy solder in a microwave oven; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the edge sealing strip frames and the edge sealing groove can ensure a good sealing effect. The method has the advantages of simple manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology, and the manufactured vacuum glass is strong in resistance to wind pressure and good in heat insulation and sound insulation; and the method can be used for manufacturing the ordinary vacuum glass and is particularly suitable for manufacturing tempered vacuum glass.

Owner:戴长虹

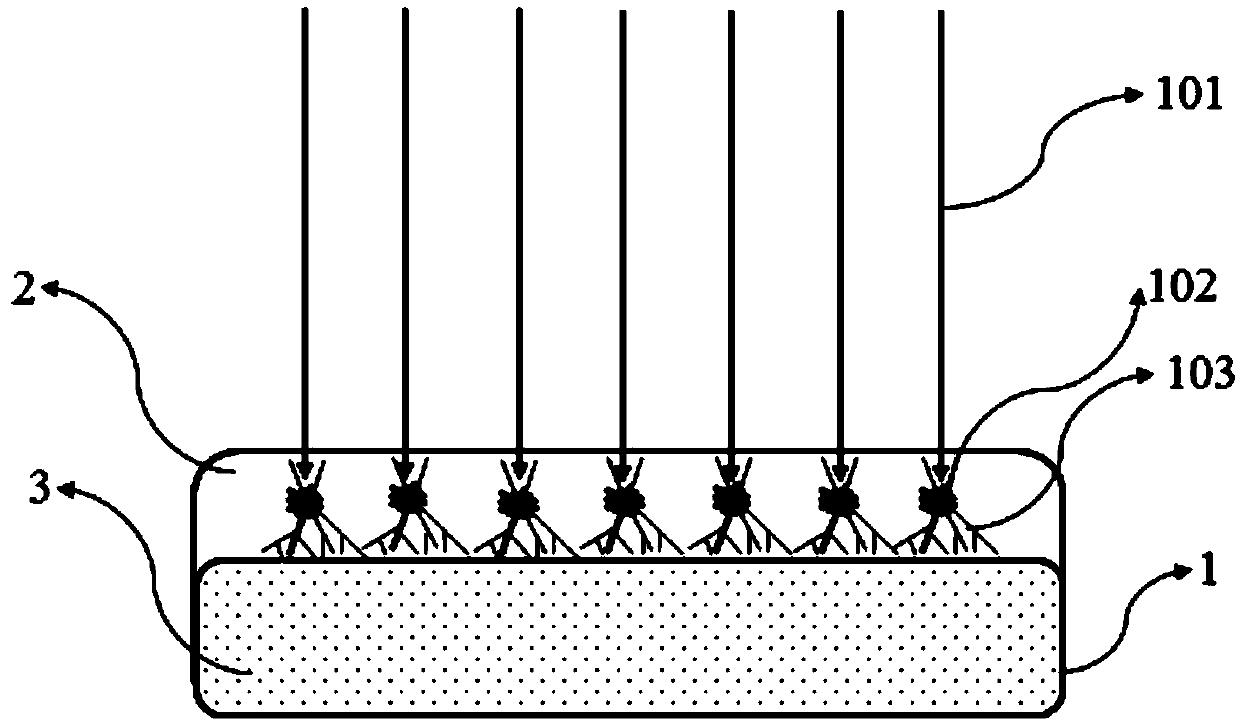

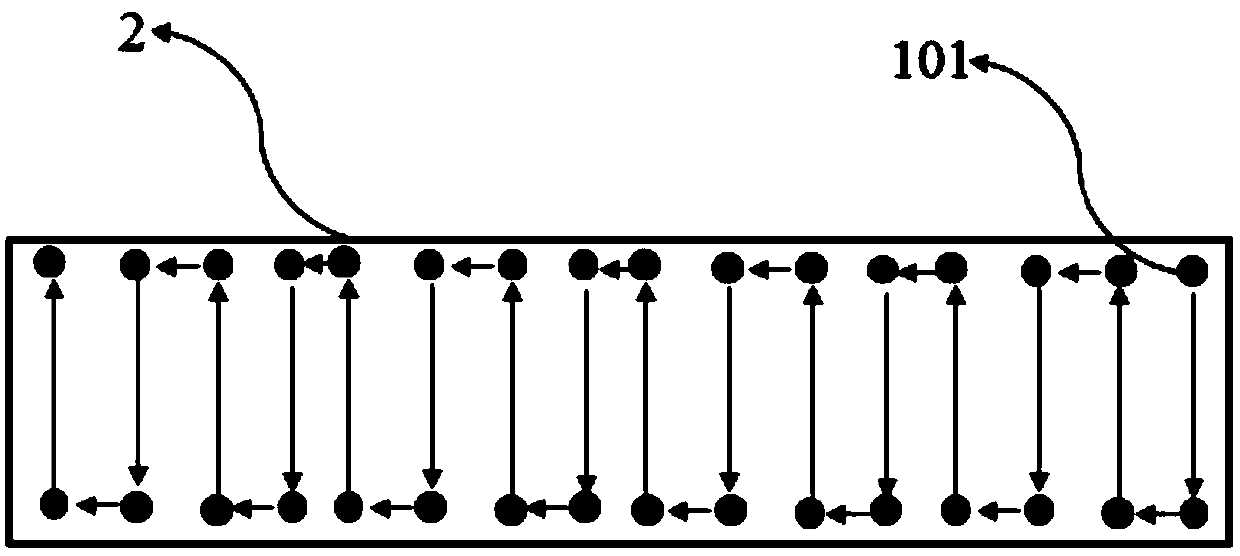

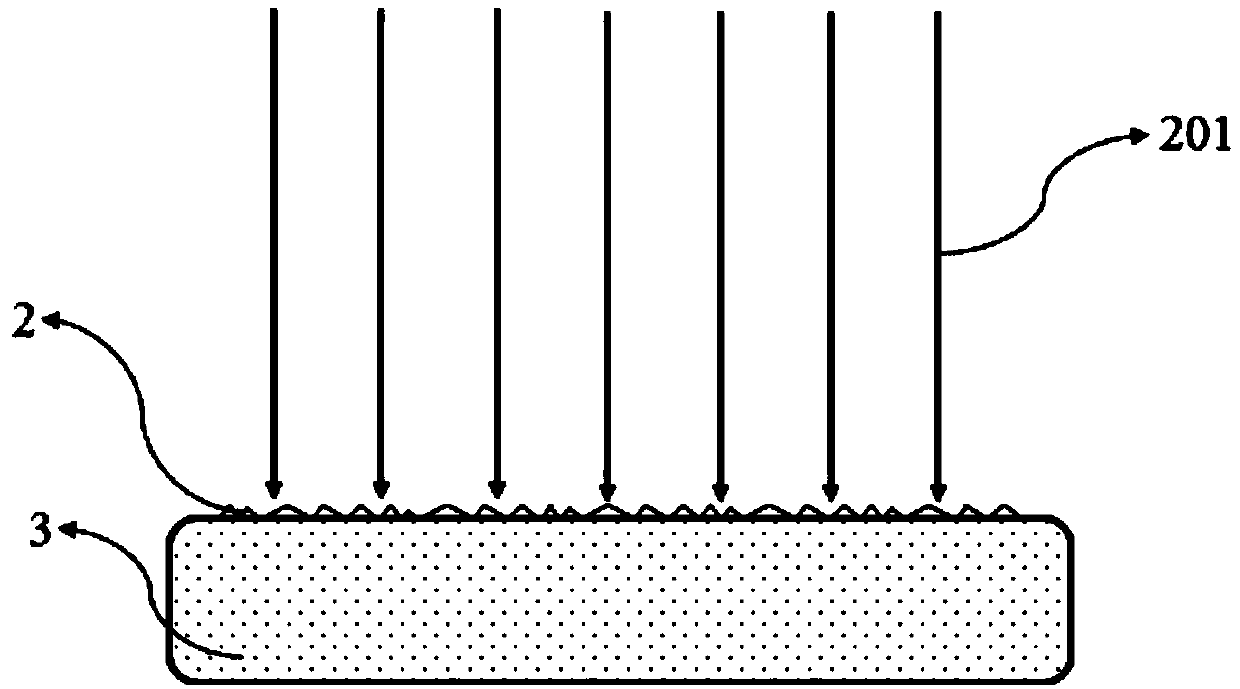

Laser paint removing method for polyimide coating enameled wire

The invention discloses a laser paint removing method for a polyimide coating enameled wire. The laser paint removing method is characterized by comprising the following steps: a, surface pretreatment: adjusting a focusing of a first laser beam on a paint layer of the enameled wire until the diameter of a light spot is minimum, and scanning the path in a non-cross manner until the whole paint layer is rough, invisible and smooth; b, heating to remove paint, adjusting a second laser beam to focus on a paint layer of the enameled wire until the diameter of a light spot covers the paint layer inthe width direction, and scanning the whole paint layer for multiple times in the length direction of the enameled wire until the paint layer falls off; and c, performing surface treatment again to remove residual paint, adjusting a third laser beam to focus on a paint layer of the enameled wire until the diameter of a light spot is minimum in an inert gas environment, and performing multi-time path cross scanning until the natural color of the copper substrate of the whole enameled wire is completely exposed. The required laser power is reduced compared with that of a single laser wavelengthand a single processing step, and the laser power requirement for reducing the wavelength is advantageous for reducing the production cost and reducing the energy consumption.

Owner:WUHAN LINGYUN PHOTOELECTRONICS SYST

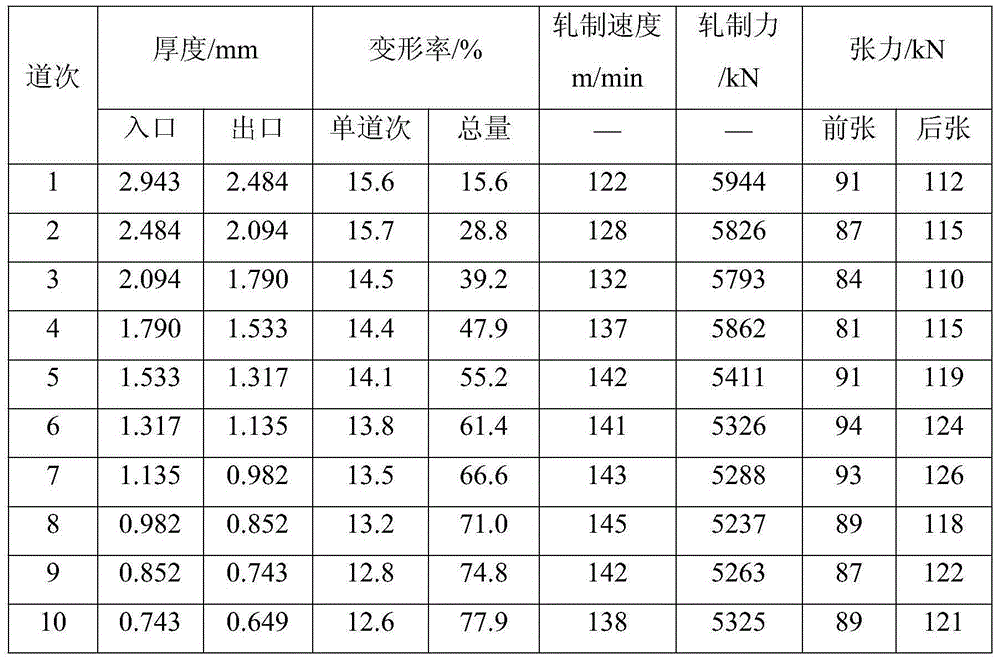

Method of producing TA10 alloy rolls through twenty-roller cold rolling unit

InactiveCN105149348AQuality assuranceQuality improvementRoll force/gap control deviceWork cleaning devicesAlloyContinuous rolling

The invention discloses a method of producing TA10 alloy rolls through a twenty-roller cold rolling unit. The TA10 alloy rolls, being 3.0 mm thick, produced by a hot continuous rolling mill are annealed at 650-780 DEG C for 240-480 minutes; shot blasting is carried out on the TA10 alloy rolls after annealing is completed, and acid pickling is carried out after shot blasting is completed; after acid pickling is completed, the twenty-roller cold rolling unit is used for rolling the TA10 alloy rolls for 8-15 times, and then the TA10 alloy rolls can be rolled to the target thickness, namely 0.4-1.0 mm; the TA10 alloy rolls rolled to the target thickness are degreased, wherein the degreasing temperature ranges from 65 DEG C to 80 DEG C. According to the invention, the target thickness, the pattern block and the required surface quality can be obtained through one single rolling process, the processes of degreasing, annealing, shot blasting, acid pickling and the like in the cold rolling process are avoided, the output and the yield of the cold TA10 alloy rolls can be greatly increased on the premise of guaranteeing the quality of the cold TA10 alloy rolls, and the production cost of the cold TA10 alloy rolls can be lowered.

Owner:YUNNAN TITANIUM IND

Metal solder-microwave welded and groove-edge-sealed convex vacuum glass and manufacturing method thereof

InactiveCN102951827AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMicrowave ovenAlloy

The invention relates to vacuum glass. The vacuum glass is characterized in that each of upper glass and lower glass is convex glass, an edge sealing strip frame is arranged at the welded periphery of the upper glass, an edge sealing groove is arranged at the welded periphery of the lower glass, and the upper glass and the lower glass are welded together by utilizing metal or alloy solder in a microwave oven; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the edge sealing strip frame and the edge sealing groove can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology, and the manufactured vacuum glass is strong in resistance to wind pressure and good in heat insulation and sound insulation; and the method can be used for manufacturing the ordinary vacuum glass and is particularly suitable for manufacturing tempered vacuum glass.

Owner:戴长虹

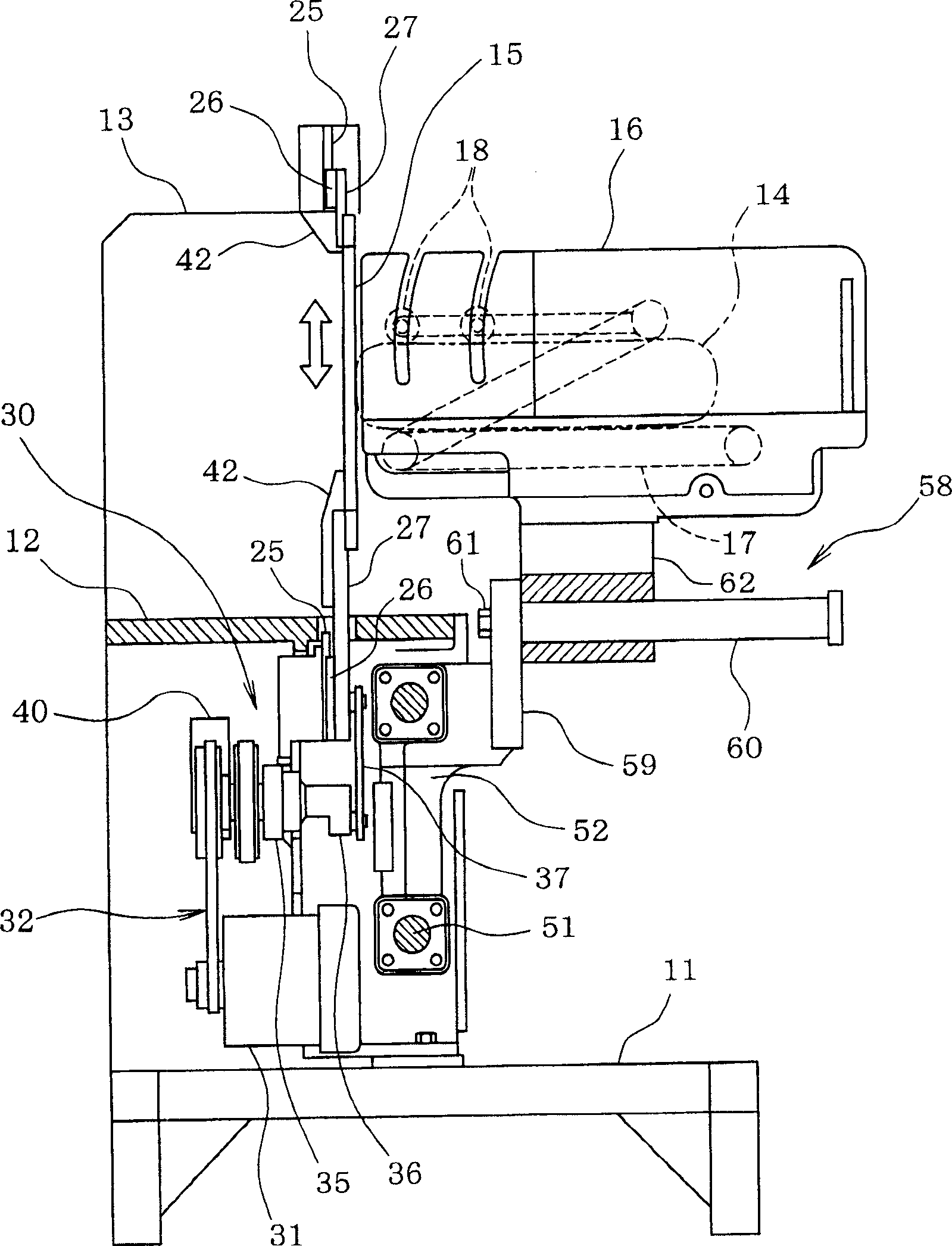

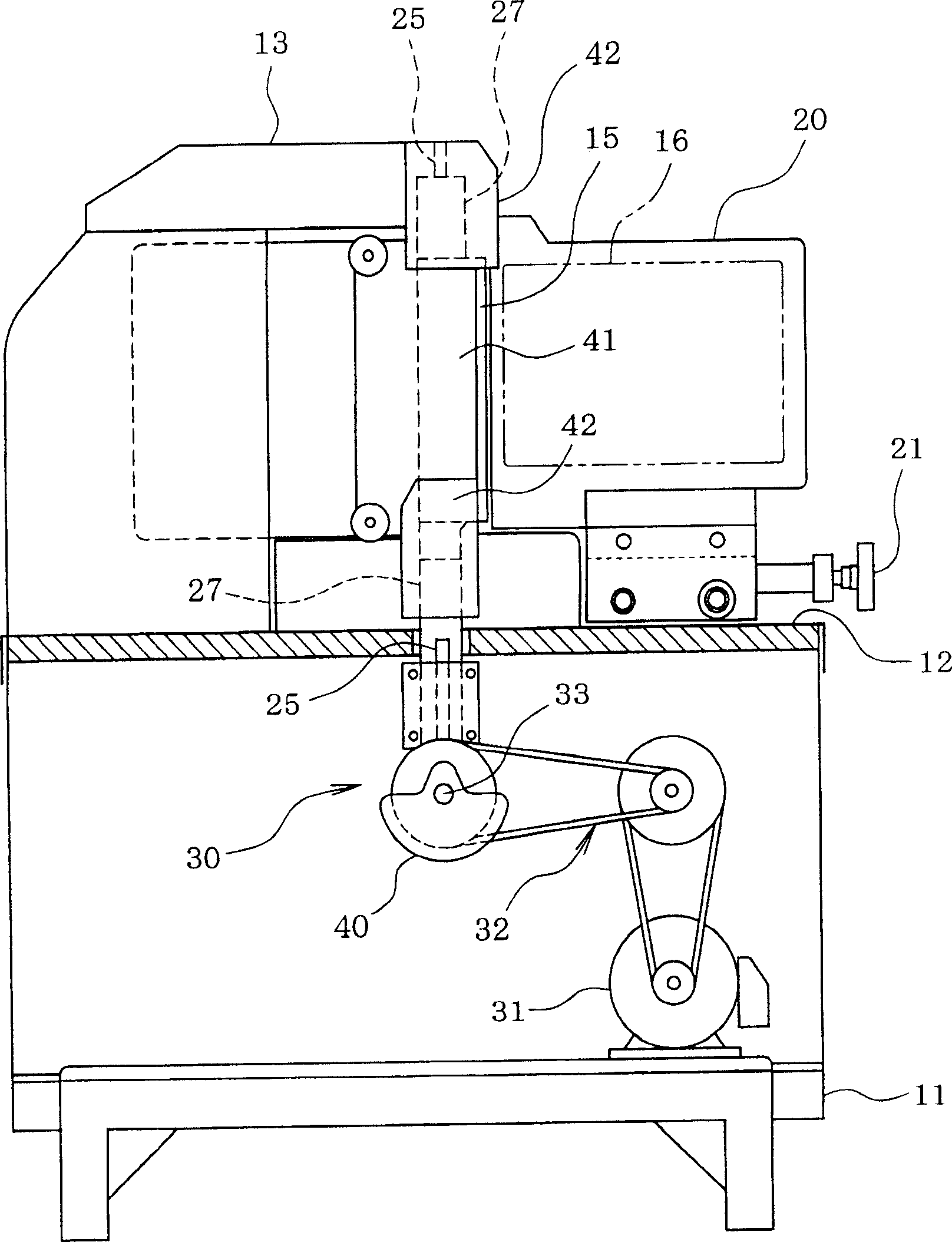

Meat-foot slicing machine

InactiveCN1507990AReduce the movable areaSave setup spaceMetal working apparatusMeat shaping/cuttingReciprocating motionEngineering

A flat cutter for slicing a meat mass is reciprocatably arranged in the vertical direction, and a tip part of the meat mass sent out of a meat box is sliced in the prescribed thickness by the flat cutter by repeating operation for reciprocating the meat box in the substantially parallel direction to the flat cutter and operation for respectively sending out the meat mass in the meat box by a prescribed quantity to the flat cutter side while reciprocating the flat cutter at a high speed, and a slice meat piece is discharged to the flat cutter side. Since the flat cutter is reciprocated in the vertical direction, a cutter movable area can be narrowed so that a safe work space can be widened. Moreover, a meat chip scattering range can be narrowed at slicing work; meat chip cleaning work can be easily performed; and work for grasping and dishing up the slice meat piece on a tray by a worker can be easily performed.

Owner:全 仙礼

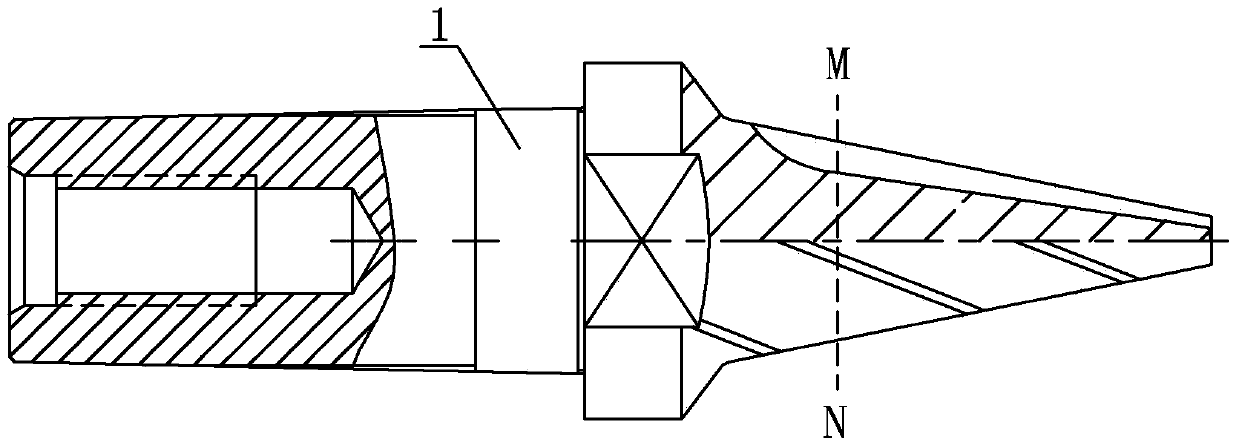

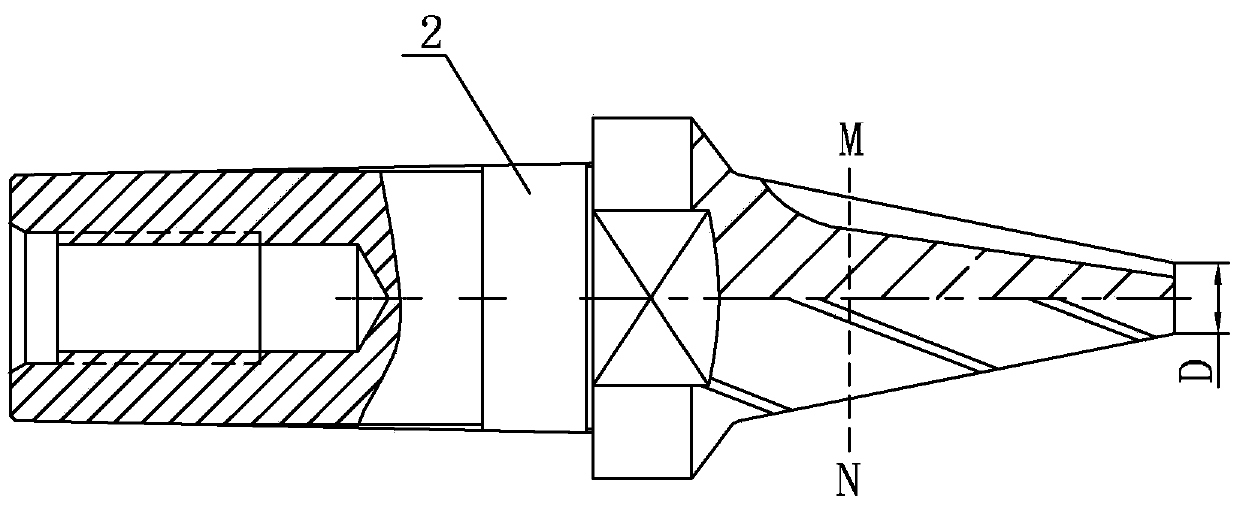

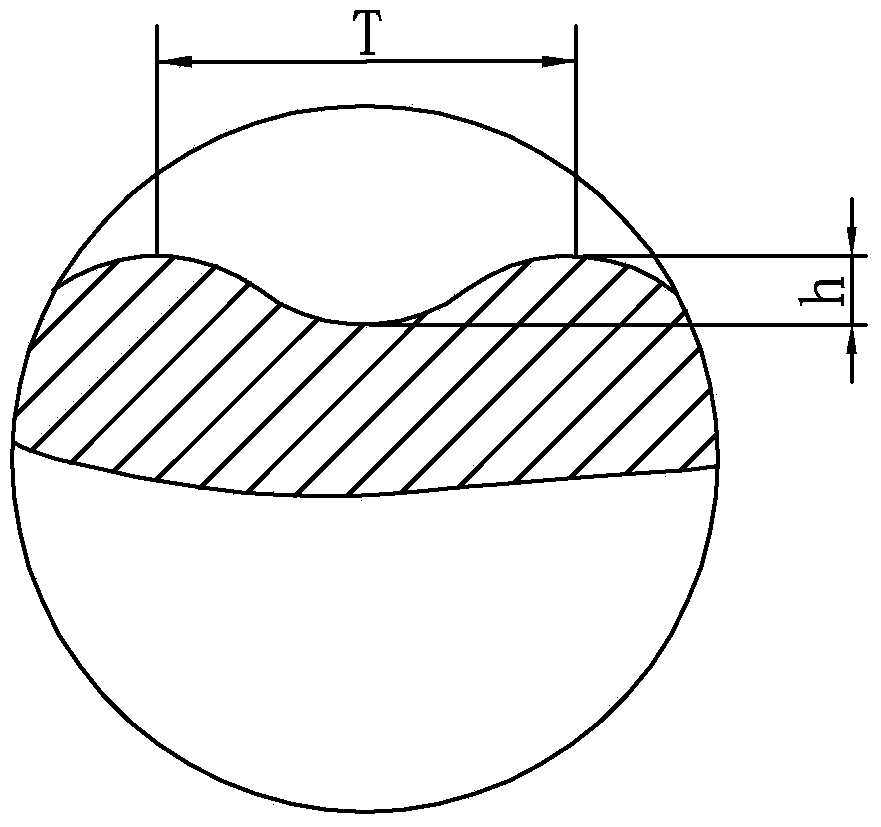

Recycling method of scrapped groove taper milling cutter

The invention relates to a recycling method of a groove milling cutter, in particular to a recycling method of a scrapped groove taper milling cutter, and aims to solve the problem that existing groove taper milling cutters are scrapped and cannot be used any more due to small-end cracked teeth and breakage both caused by small diameter of small ends after the groove taper milling cutters are used. The recycling method includes the following steps: 1, determining processing margin; 2, improving the small end of the groove taper milling cutter; 3, improving a profile shaped line of a thread portion of the groove taper milling cutter; 4, improving end teeth of the groove taper milling cutter. The recycling method is applicable to improving the scrapped groove taper milling cutter.

Owner:HARBIN TURBINE +1

Convex low-altitude glass welded by metal solders in microwave manner and subjected to edge sealing by groove, and manufacturing method of glass

InactiveCN102951808AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMicrowave ovenAlloy

The invention discloses low-altitude glass. The low-altitude glass is characterized in that upper glass and lower glass are convex; the welding periphery of the upper glass is provided with an edge sealing strip frame, and the welding periphery of the lower glass is provided with an edge sealing groove; and the upper and lower glass are welded together by metal or alloy solders in a microwave oven, so that the low-altitude glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the edge sealing strip frame and the edge sealing groove. A manufacturing method of the low-altitude glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing low-altitude glass in mass by virtue of a one-step method, and not only can be used for manufacturing common low-altitude glass, but also is particularly suitable for manufacturing of tempered low-altitude glass; and the low-altitude glass manufactured by the method is high in wind pressure resistance and good in heat insulation and sound insulation.

Owner:戴长虹

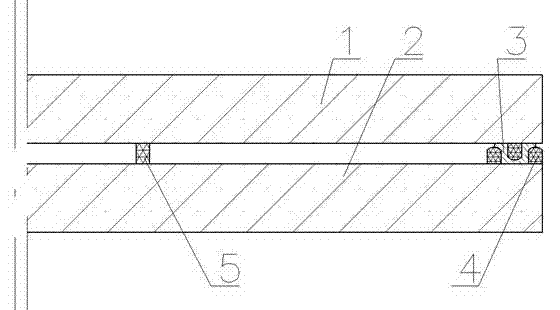

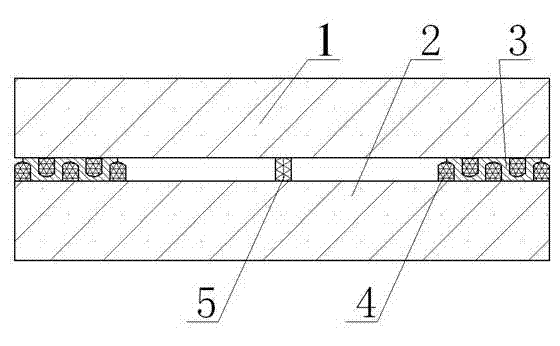

Planar vacuum glass welded by metal solders in microwave manner and subjected to edge sealing by strip frames, and manufacturing method of glass

InactiveCN102951811AExtend your lifeGuaranteed tightnessGlass reforming apparatusGlass productionMicrowave ovenAlloy

The invention discloses vacuum glass. The vacuum glass is characterized in that the peripheries of upper and lower glass are provided with edge sealing strip frames; and the upper and lower glass are welded together by metal or alloy solders in a microwave oven, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the upper and lower edge sealing strip frames. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without extraction openings in mass by virtue of a one-step method, and can be used for manufacturing not only common vacuum glass but also tempered vacuum glass.

Owner:戴长虹

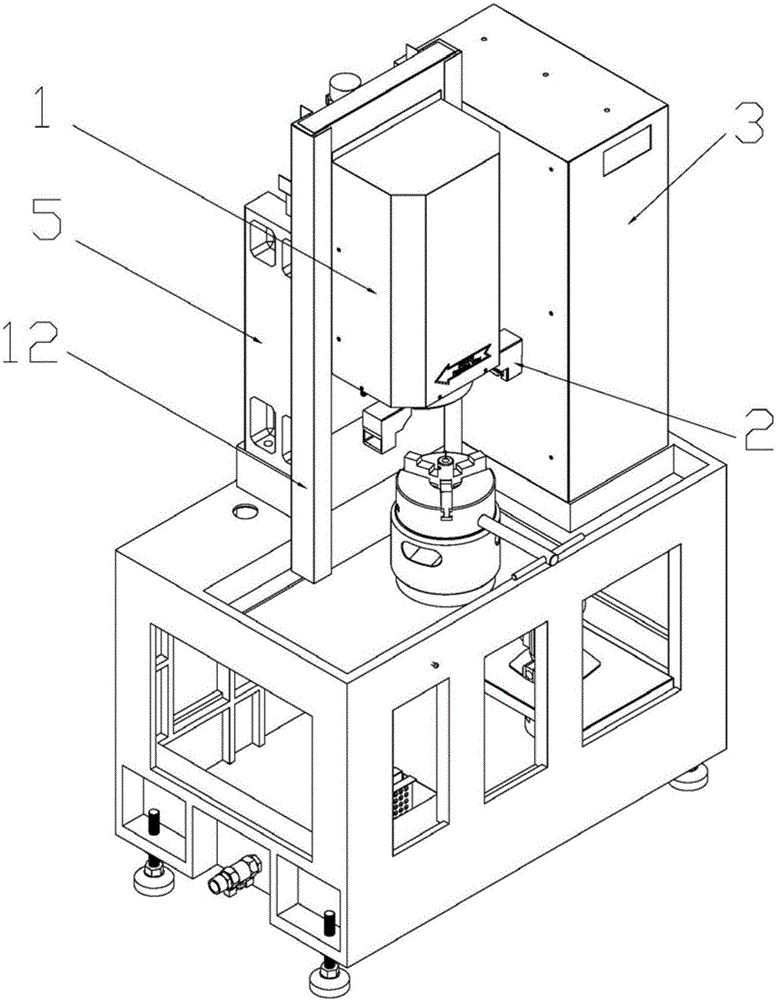

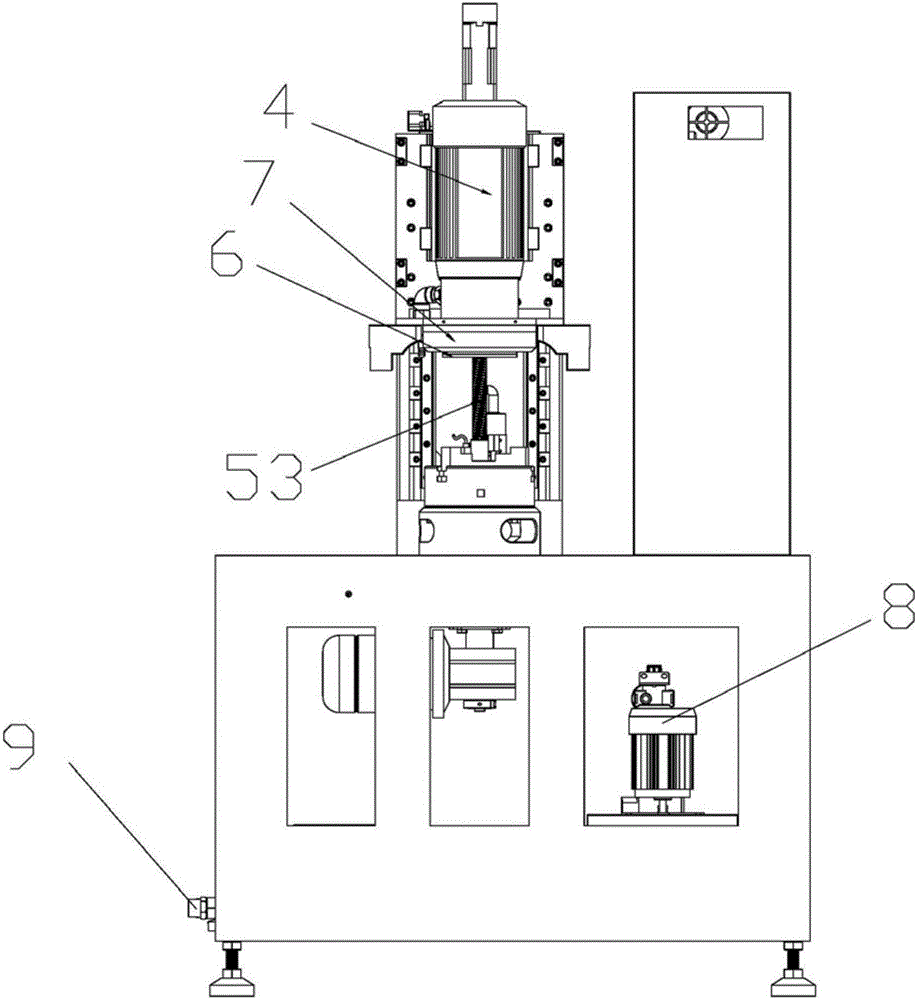

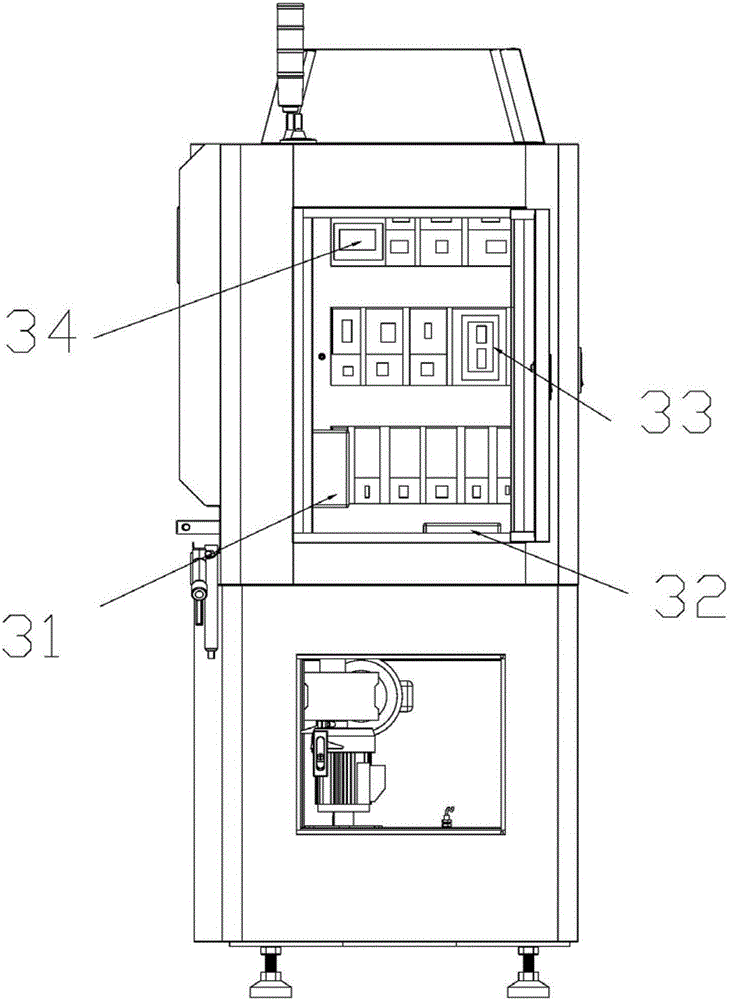

Automatic numerical control grinding machine for punch press die machining and using method thereof

ActiveCN105666288AExtended service lifeAvoid harmGrinding drivesGrinding feed controlNumerical controlAutomatic train control

The invention discloses an automatic numerical-control grinding machine for punch press die machining and a using method thereof and belongs to the field of grinding machines. The problem that an existing grinding machine is poor in cooling effect, severe in grinding environment, short in service life and low in machining precision is solved. The automatic numerical-control grinding machine comprises a spindle grinding wheel seat, a grinding head motor arranged on the spindle grinding wheel seat and a grinding wheel arranged on the grinding head motor and further comprises a cooling water pan, wherein the cooling water pan is in a shape of a hollow disc and is arranged between the grinding head motor and the grinding wheel and surrounds the spindle between the grinding head motor and the grinding wheel. Water spraying holes are formed in the inner wall of the cooling water pan. The automatic numerical-control grinding machine can effectively improve the cooling efficiency and improve a grinding environment, accordingly the service life of the machine is prolonged, the grinding precision is improved, and the automatic numerical-control grinding machine has higher safety performance and provides guarantee for safe production.

Owner:安徽雷默模具制造有限公司

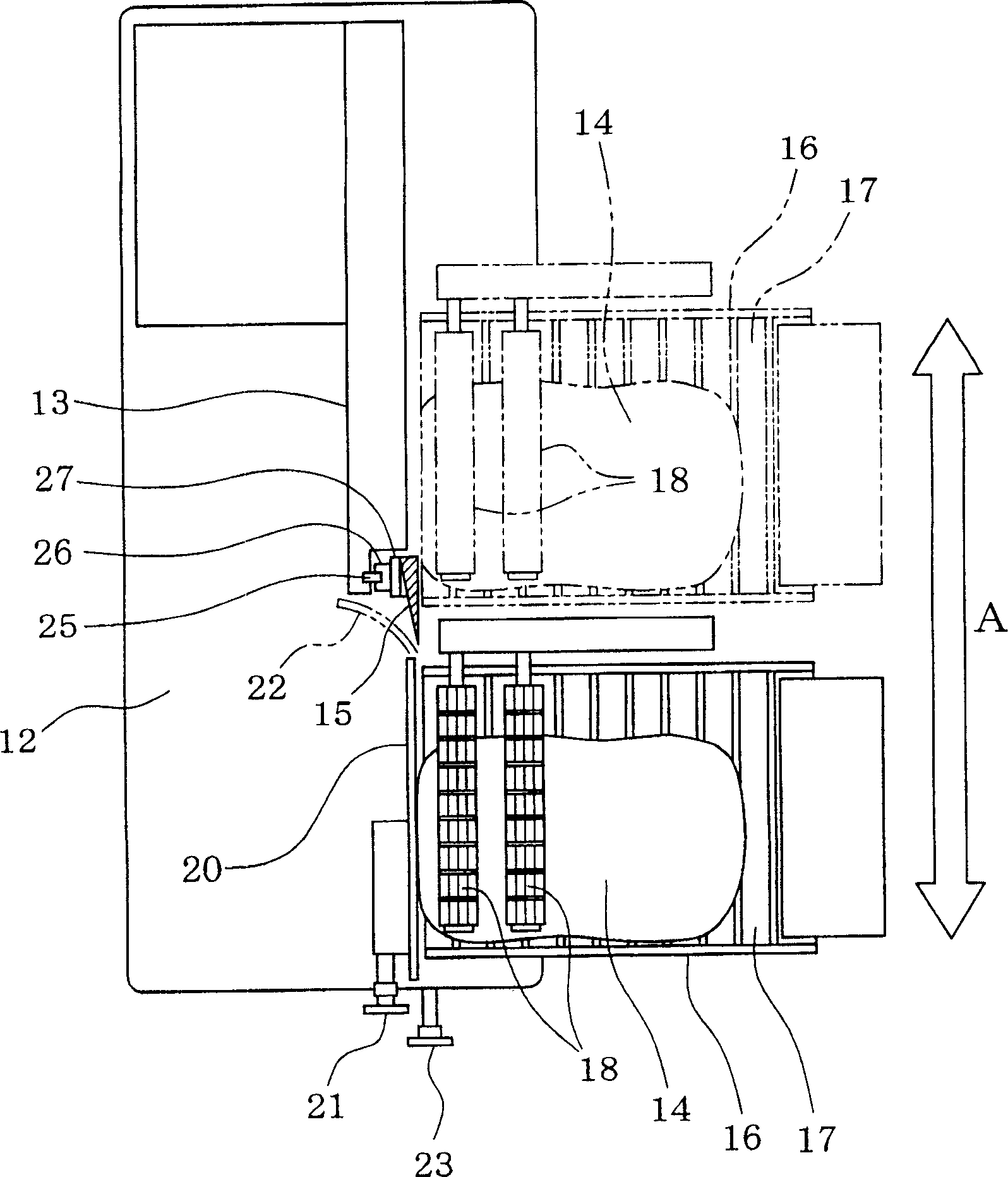

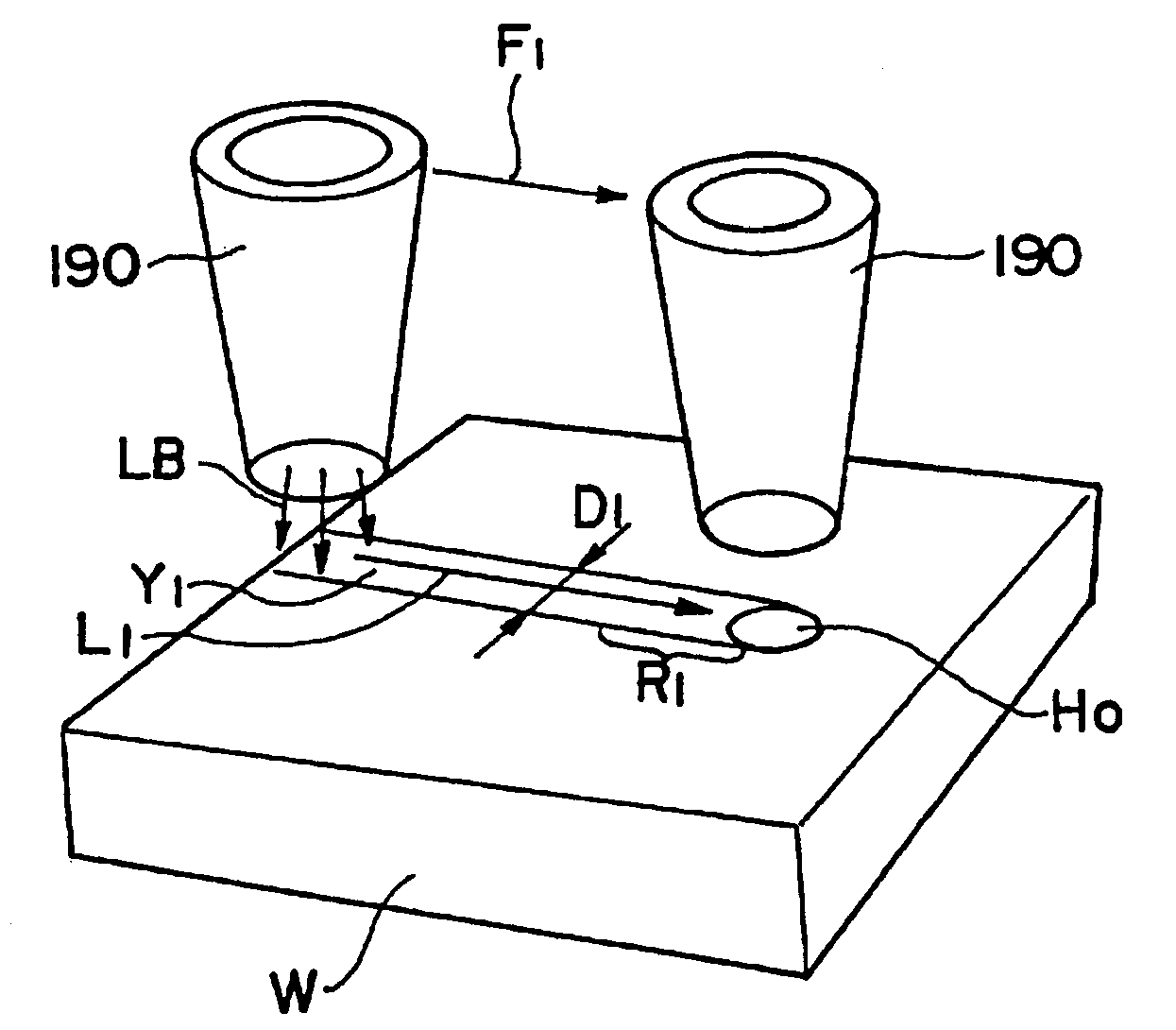

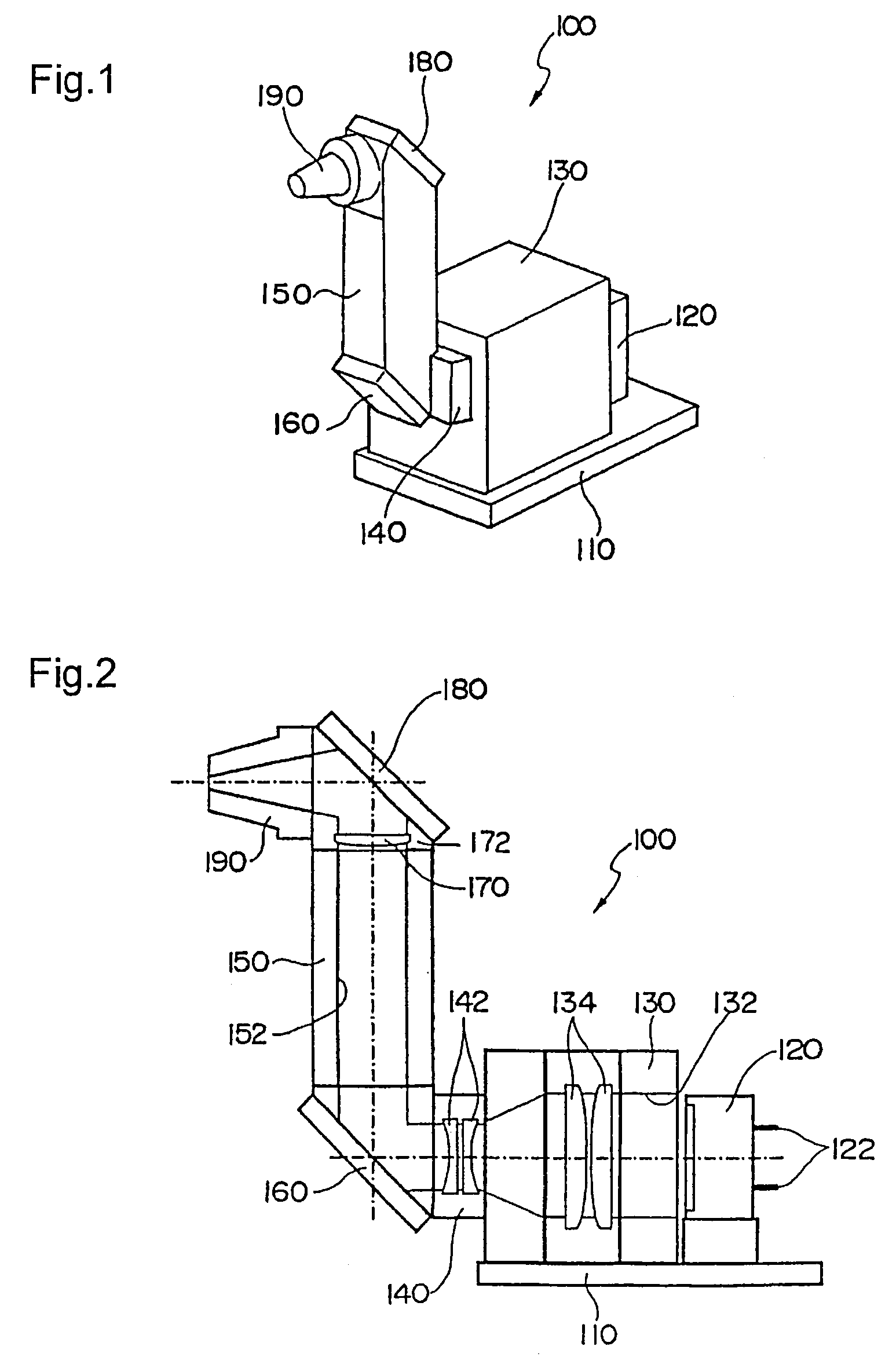

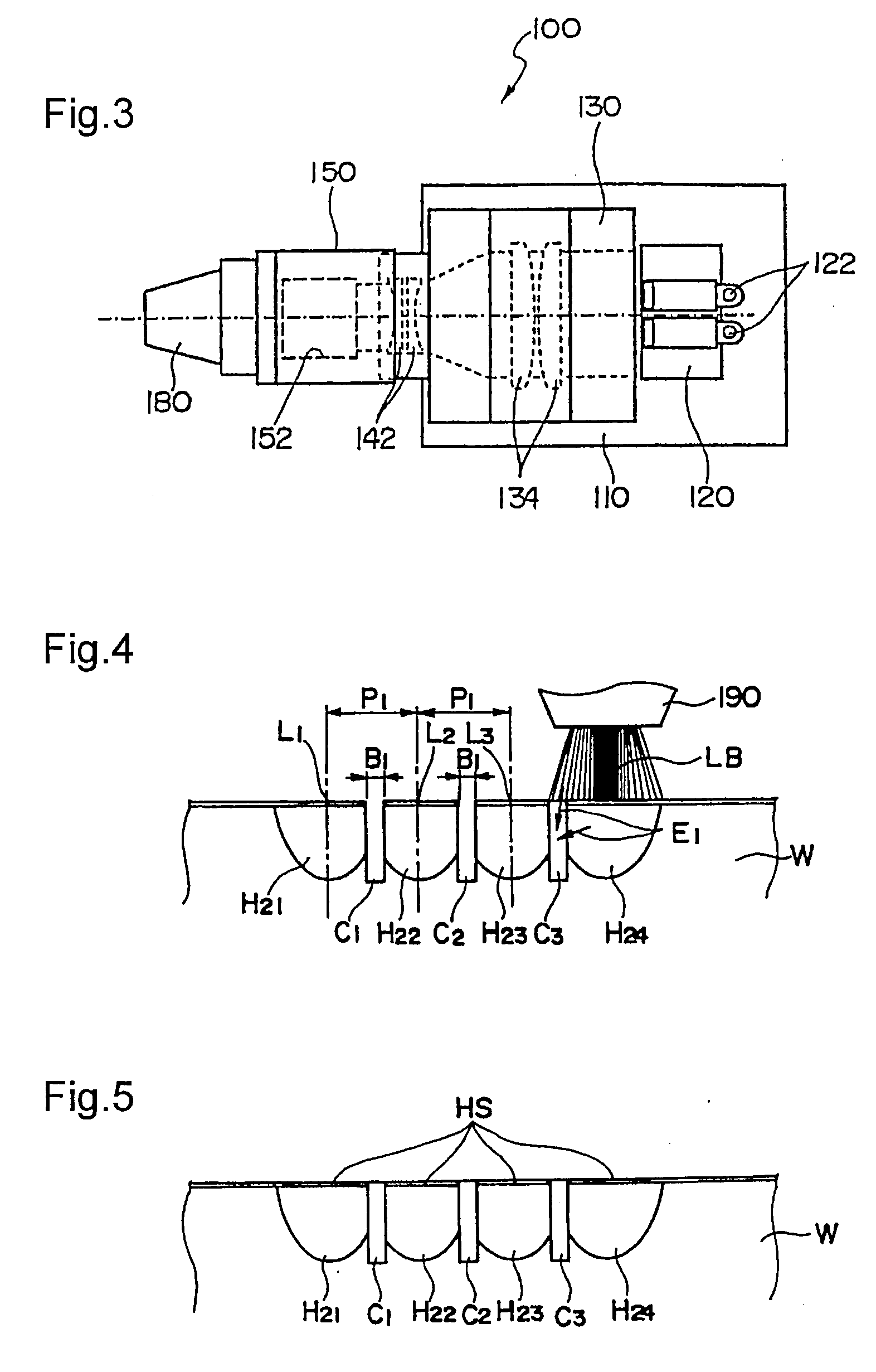

Laser hardening method

InactiveUS20070235431A1Large width dimensionPrevent annealingLaser beam welding apparatusThermal energyOptoelectronics

The invention provides a laser hardening method capable of preventing adjacent already-hardened layers from being annealed. In the laser hardening method of the present invention, conduits C1, C2 and C3 are processed in advance midway between pitches P1 along which a hardening nozzle 190 performs overlap hardening. After moving the nozzle 190 along a center line L3 to process a hardening layer H23, the nozzle 190 is moved in parallel for a single pitch P1 to perform hardening of a hardening layer H24. Thermal energy E1 of the laser beam LB is also irradiated toward the direction of the hardening layer H23, but it is blocked by the conduit C3 that prevents the laser beam from annealing the hardening layer H23.

Owner:YAMAZAKI MAZAK KK

Methods and kits for reducing non-specific nucleic acid amplification

ActiveUS9353393B2High bonding strengthMinimizes and eliminates problemMicrobiological testing/measurementTransferasesPrimer dimerComputational biology

Methods and kits for efficient amplification of nucleic acids are provided. The disclosure generally relates to methods and kits for nucleic acid amplification of target nucleic acids of interest. The methods described herein promote the synthesis of the target nucleic acid (i.e., template nucleic acid) by reducing the production of undesirable primer-dimer structures and chimeric nucleic acid products during the amplification process by using novel modified primers.

Owner:GLOBAL LIFE SCI SOLUTIONS OPERATIONS UK LTD

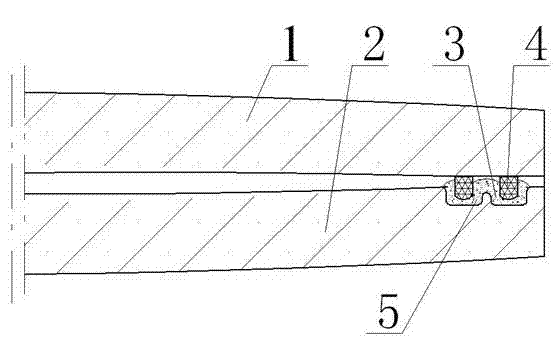

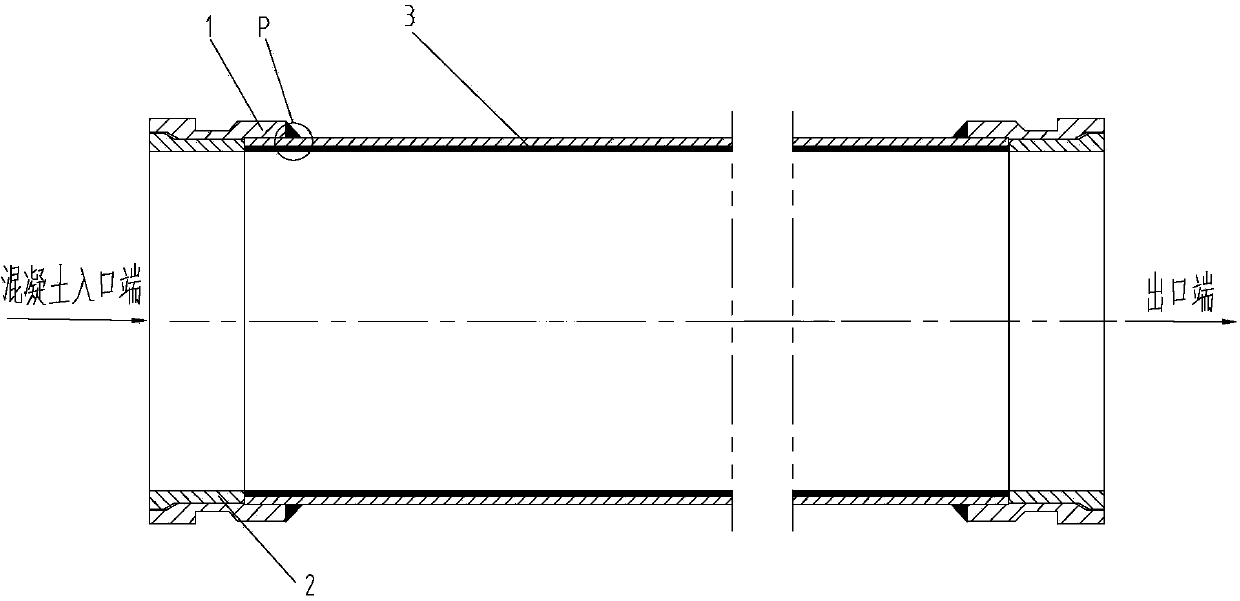

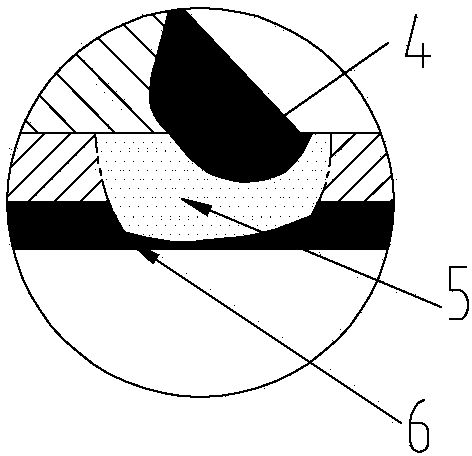

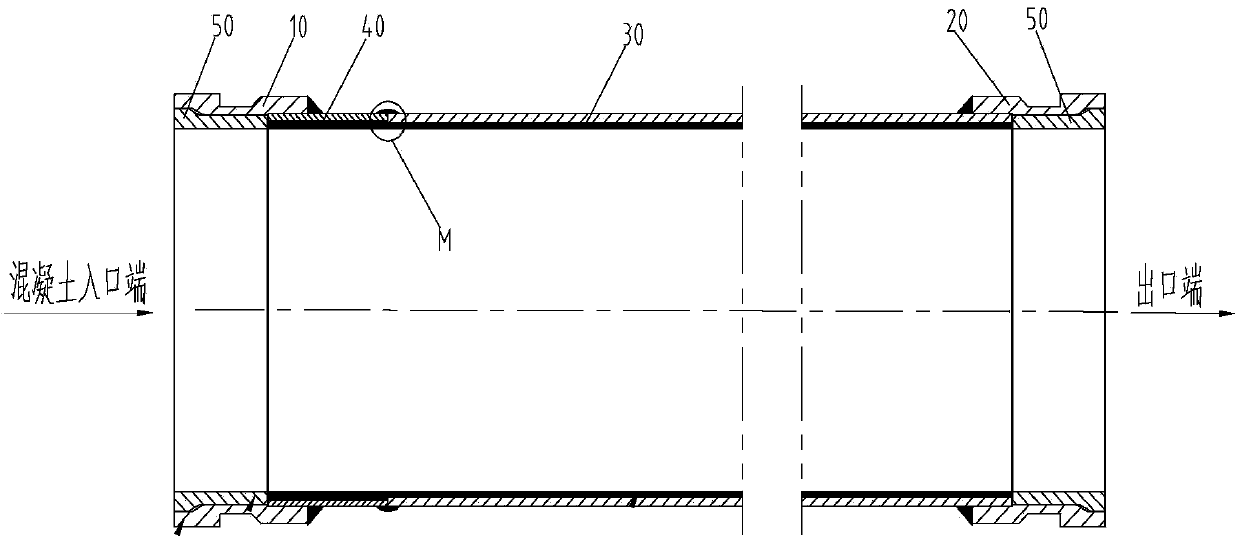

Concrete conveying pipe and manufacturing method thereof, and concrete pump truck

ActiveCN104209712ALittle influence of welding heatMeet working conditionsFlanged jointsFurnace typesPipe layerCarbon steel

The invention provides a concrete conveying pipe and a manufacturing method thereof, and a concrete pump truck. The manufacturing method of the concrete conveying pipe comprises the steps of blanking: cutting a single-layer pipe and a double-layer pipe which have preset lengths, wherein the single-layer pipe is a quenchable pipe; an inner pipe layer of the double-layer pipe is a quenchable layer, and an outer pipe layer of the double-layer pipe is a carbon steel layer; single-layer pipe and double-layer pipe welding: welding the single-layer pipe and the double-layer pipe through butting to form an integrated pipe, wherein at least one end of the integrated pipe is the double-layer pipe; quenching: quenching the inner wall of the integrated pipe. According to the manufacturing method of the concrete conveying pipe, the concrete conveying pipe which is long in service life and high in stability can be manufactured.

Owner:ZOOMLION HEAVY IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com