Method for sealing vacuum glass and vacuum glass product

A vacuum glass and glass plate technology, applied in welding equipment, improvement of windows/doors, building components, etc., can solve problems such as damage to vacuum glass and danger in places where vacuum glass is used, and achieve stress avoidance, high air tightness, Guarantee the effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with accompanying drawing.

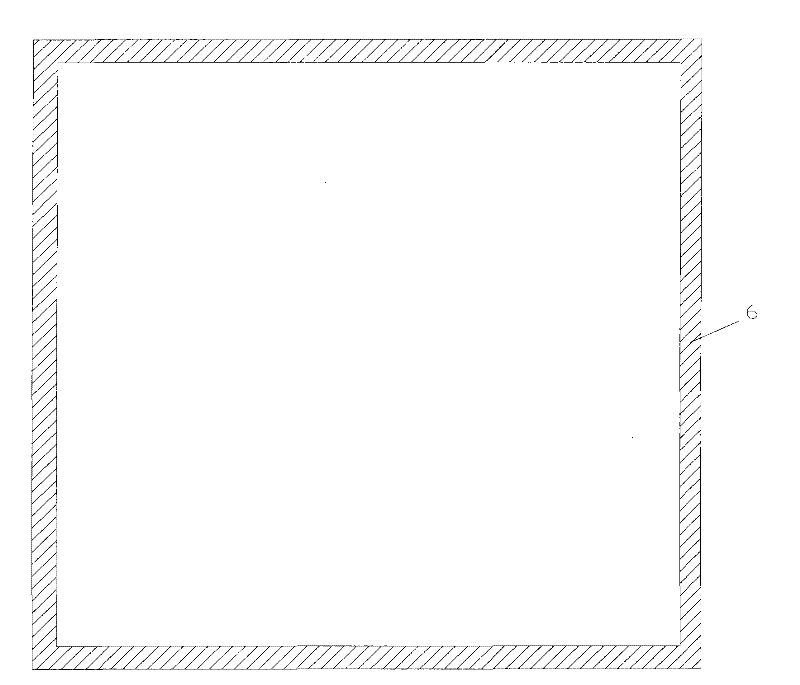

[0053] by Figure 4 The shown embodiment 1 is taken as an example. When making vacuum glass according to the sealing method of the present invention, first, a metal paste coating is prepared on the surface of the edge of the glass plate to be sealed; then, the glass plate is heated to sinter the metal paste coating into a metallized layer 6 that is bonded to the glass plate, and the sintered metallized layer 6 is as image 3 Shown in; Then, carry out toughening or semi-tempering or thermal strengthening treatment to glass plate according to known process; Then, the two glass plates 1,2 to be sealed are pressed Figure 4 The state shown is compounded, and the two metallized layers 6 corresponding to each other on the two glass plates 1 and 2 are set as Figure 5 The cross-section shown is a U-shaped metal sheet 7, so that the two sides 7a, 7b of the metal sheet 7 are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com