Concrete conveying pipe and manufacturing method thereof, and concrete pump truck

A technology for concrete delivery pipes and manufacturing methods, which is applied to pipes, rigid pipes, flange connections, etc., and can solve the problems of high cost and low service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in a variety of different ways defined and covered by the claims.

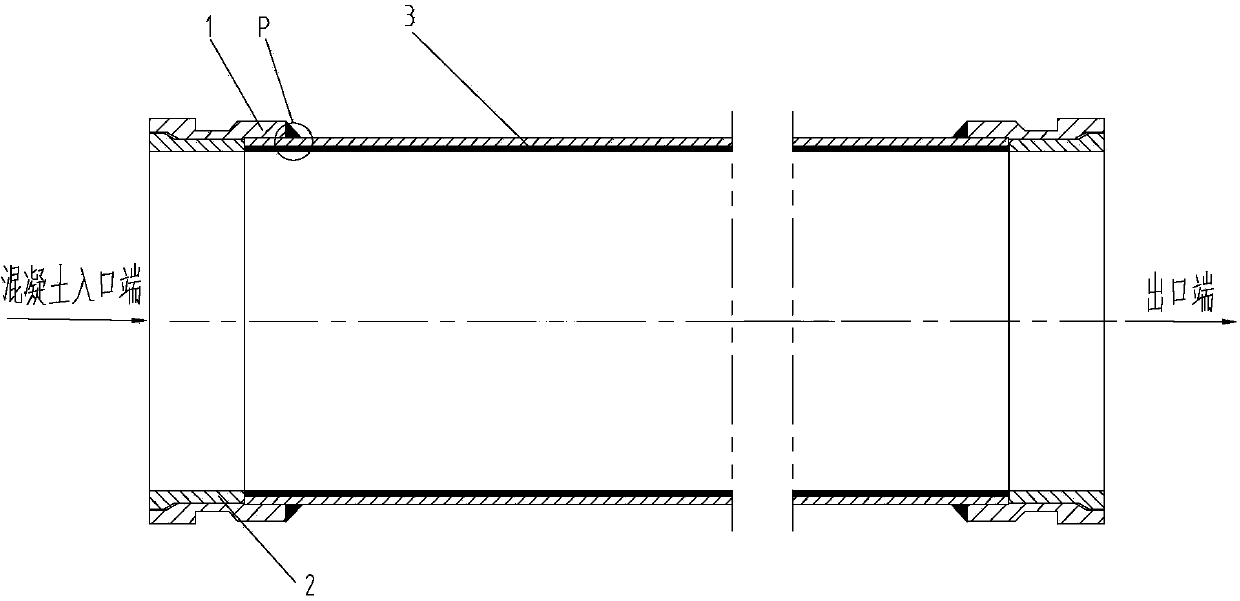

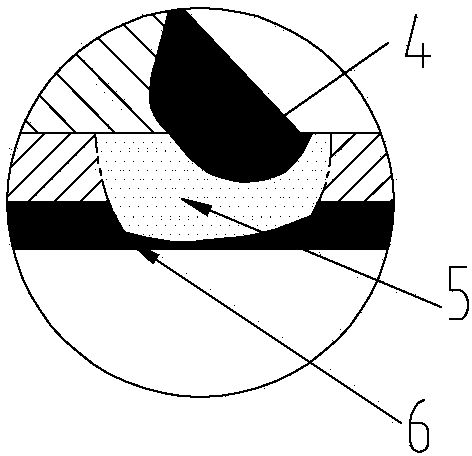

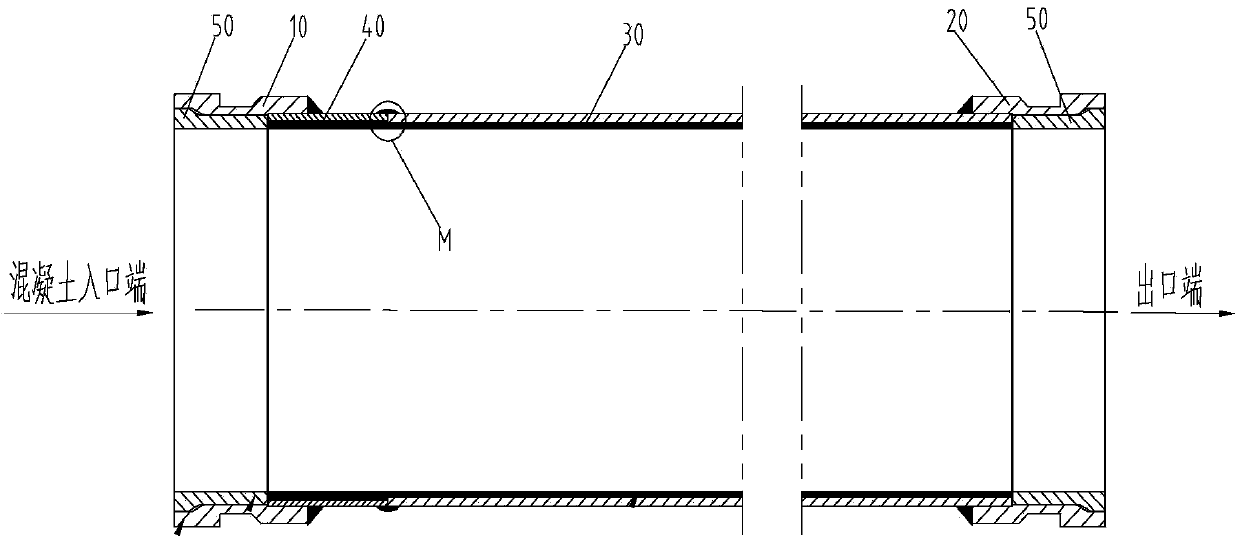

[0028] See image 3 with Figure 4 As shown, according to an embodiment of the present invention, a method for manufacturing a concrete delivery pipe is provided. The method sequentially includes a blanking step, a single and double-layer pipe welding step, a quenching step, and a flange welding step. First carry out the blanking step. In the blanking step, the single-layer pipe 30 and the double-layer pipe 40 are cut into predetermined lengths according to actual working conditions. In order to enable the concrete delivery pipeline of this embodiment to meet the harsh working conditions, this The single-layer pipe 30 in the embodiment is a hardenable pipe, such as alloy steel pipe; similarly, the inner pipe layer of the double-layer pipe 40 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com