High-strength high-toughness metal prefabricated material and preparation method thereof

A high-strength, toughness, metal technology, applied in the direction of metal material coating process, coating, etc., to achieve the effect of increasing strength, reducing weight and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: Selected area laser alloying manufactures high-strength toughness metal prefabricated material plate

[0045] Different thick plate components are used in automobile manufacturing to ensure the strength of the car body and reduce the weight of the car body. For example, using laser tailor welding technology to obtain DC01 front longitudinal beam plates with thicknesses of 1.8mm, 3.0, and 1.8mm, and thicknesses of 2.0mm , 3.0mm DC01 stringer plate. This kind of differential thickness plate, also known as unequal thickness plate, can reduce the weight of the car. Among them, the thicker part is the load-bearing part, which is mainly used to bear the load in the movement of the car; Small area, easy to deform, beneficial to improve the deep drawing performance of automotive workpieces. In addition to reducing the weight of the car, the poor thickness plate has another advantage in that it is convenient for the mechanical design of the body structure. In the ...

Embodiment 2

[0054] Embodiment 2: Laser alloying method for manufacturing automobile thin plate high-strength toughness metal prefabricated material plate

[0055] Passenger car exterior panels are not only exterior decorations, but also closed shell-shaped force-bearing parts, including front skirts, roof covers, front and rear doors, left and right side panels and fenders, front and rear panels Upper cover etc. These coverings can likewise be strengthened or lightened by the method according to the invention.

[0056] In this example, the HC220Y steel plate with a thickness of 0.7mm is used as the raw material, and the fiber laser is used as the heat source, and the laser power density is 1.5×10 5 W / cm 2 ~3.5×10 5 W / cm 2 , the diameter of the spot is 0.3mm, and the preset alloy powder is sprayed. The thickness of the preset alloy powder layer is 0.01-0.15mm, and the fast scanning line (width 0.3mm) of 1500-2300mm / s is obtained through the scanning galvanometer, which realizes the mil...

Embodiment 3

[0065] Embodiment 3: Selected area laser alloying manufactures high-strength toughness metal prefabricated material carbon steel plate

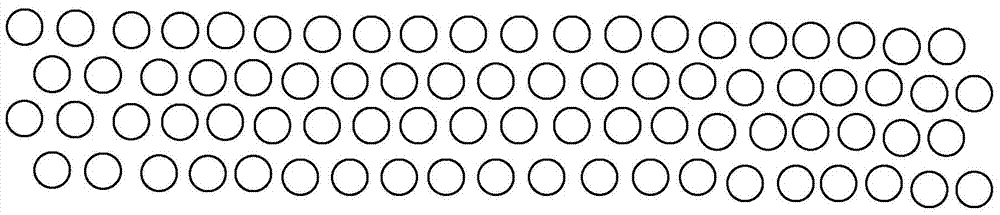

[0066] The FECR02 alloy powder is preset on the surface of the steel plate, and the thickness of the preset alloy powder layer is 0.1-1.0 mm. The chemical composition of the FECR02 powder is shown in Table 5. According to different plate components and laser process parameters, high-strength and tough metal prefabricated materials with different strengthening and toughening phase shapes, sizes and distribution densities can be obtained based on the selective laser alloying technology. The corresponding parameters are shown in Table 6. It can be seen that by selecting different matrix materials, spot diameters, power densities, distribution modes and densities of enhanced phases, fiber lasers and figure 1 As shown in the dot matrix pattern, the obtained high-strength and toughness metal prefabricated materials have large differences in streng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com