Meat-foot slicing machine

A slicer and slicing technology, which is applied in meat cutting/trimming, processed meat, food science, etc. It can solve the problems of large movable range of knives, easy flying of minced meat, and small working space, so as to reduce the setting space of knives , Expand the safe working space and reduce the effect of flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Implementation form 1

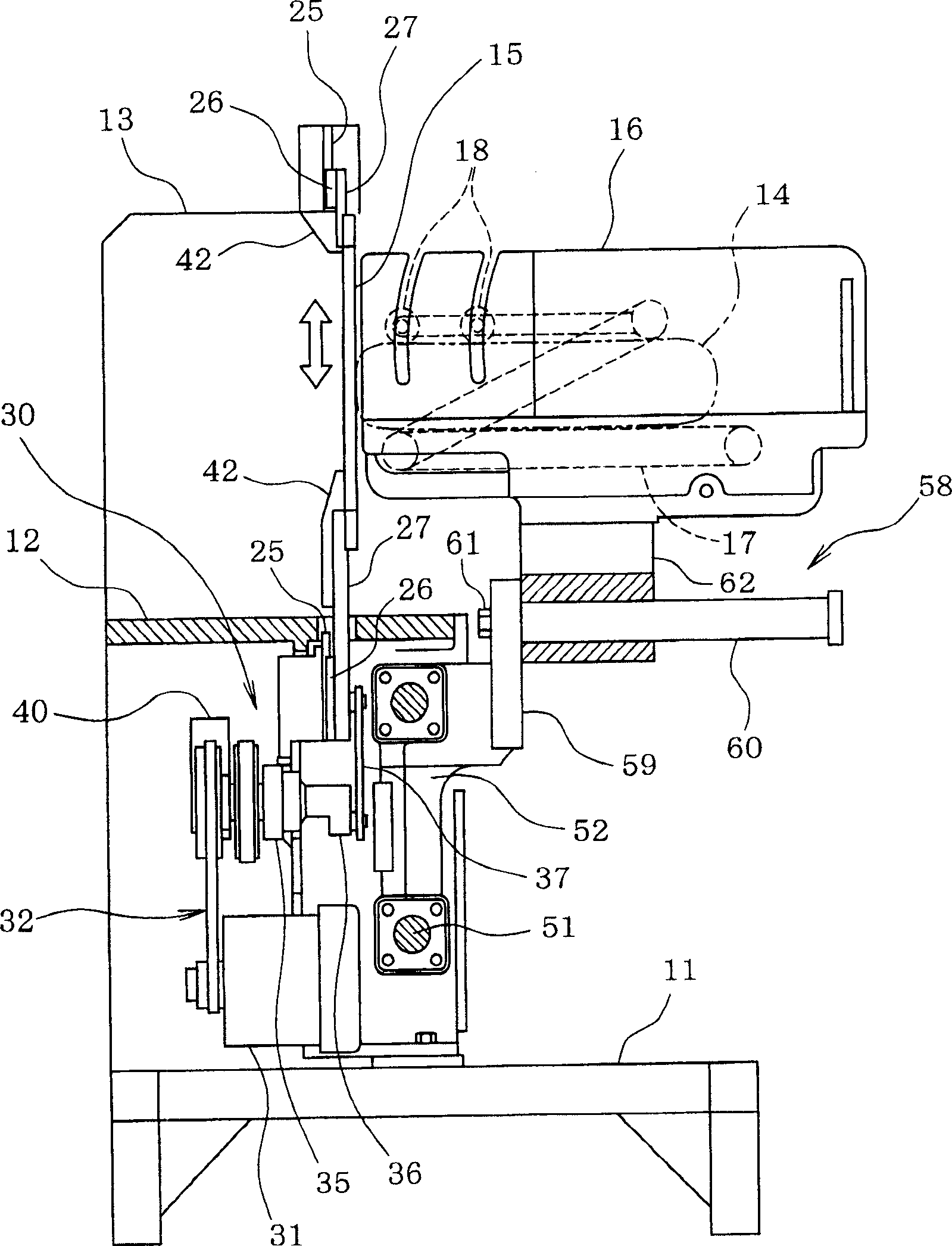

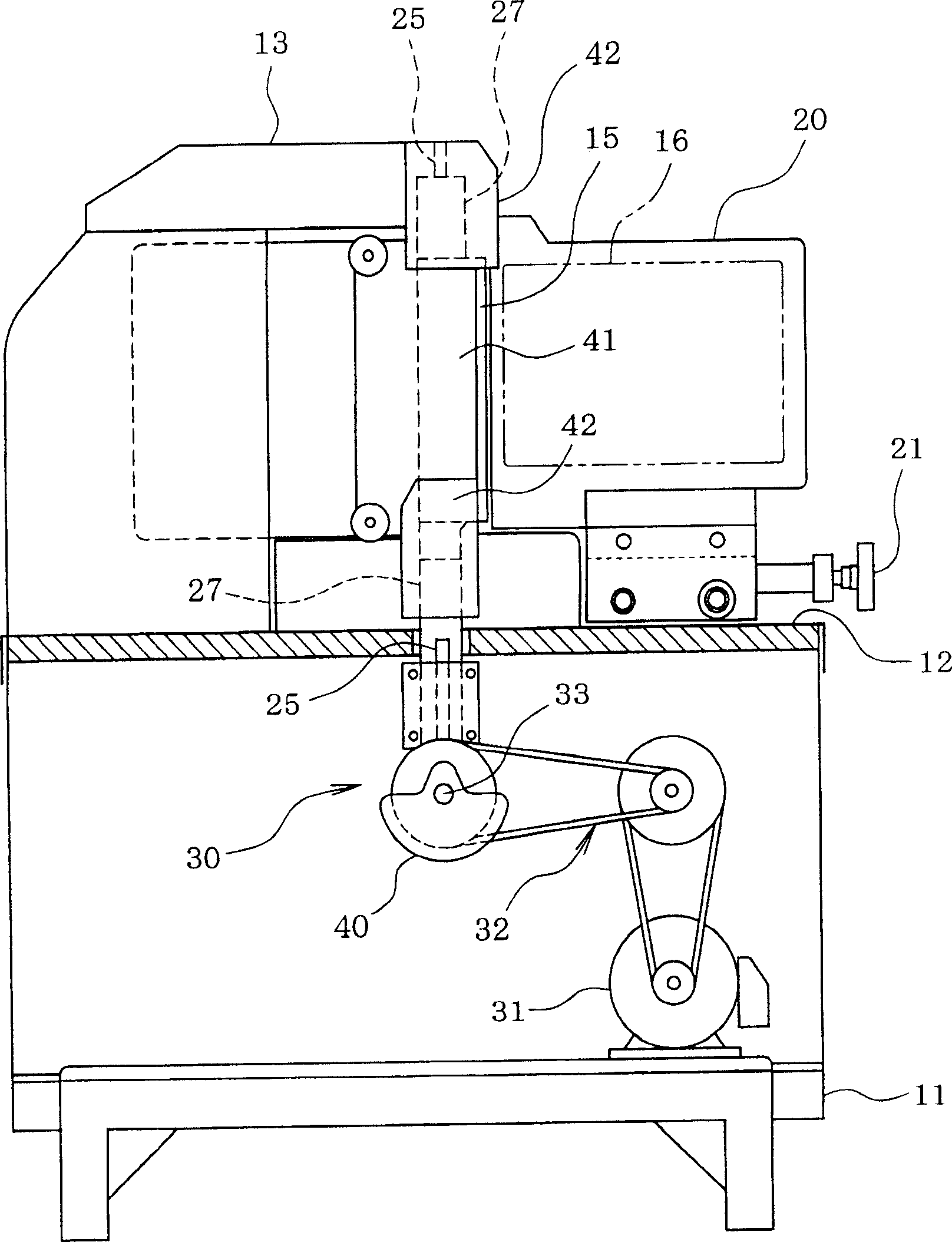

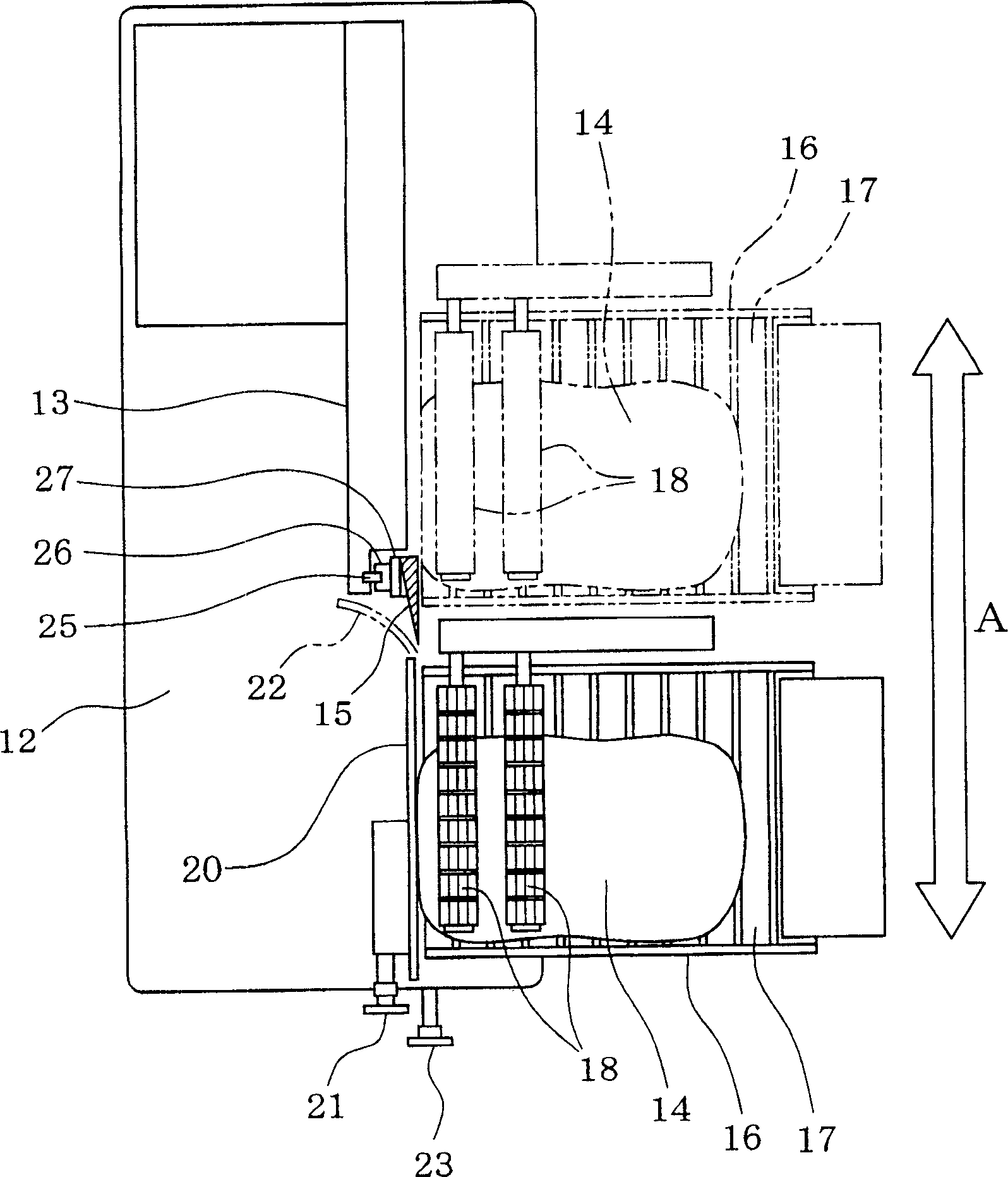

[0021] Below, according to Figure 1 to Figure 7 , Embodiment 1 of the present invention is demonstrated.

[0022] here, figure 1 is the front view of the longitudinal section of the meat slicer, figure 2 is a longitudinal sectional side view of the meat slicer, image 3 is the top view of the meat slicer, Figure 4 is a front view of the longitudinal section of the flat tool and its periphery, Figure 5 is a longitudinal section side view of the flat tool and its periphery, Figure 6 is a cross-sectional view of a flat tool, Figure 7 It is a longitudinal section front view of the meat box reciprocating drive mechanism and its peripheral parts.

[0023] First, use Figure 1 ~ Figure 3 The overall structure of the meat slices is briefly described. Such as figure 1 As shown, a workbench 12 is installed on the top of the main body seat 11 of the meat slicer, and on the cutter seat 13 above the workbench 12, a flat cutter 15 (cutter for s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com