Centrifugal casting equipment

A technology of centrifugal casting and mold, which is applied in the field of centrifugal casting devices, can solve the problems of increasing installation space of centrifugal casting devices, expansion of equipment installation space, and increase of equipment costs, so as to achieve high-efficiency centrifugal casting operations, effective use of space, and reduction of equipment costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

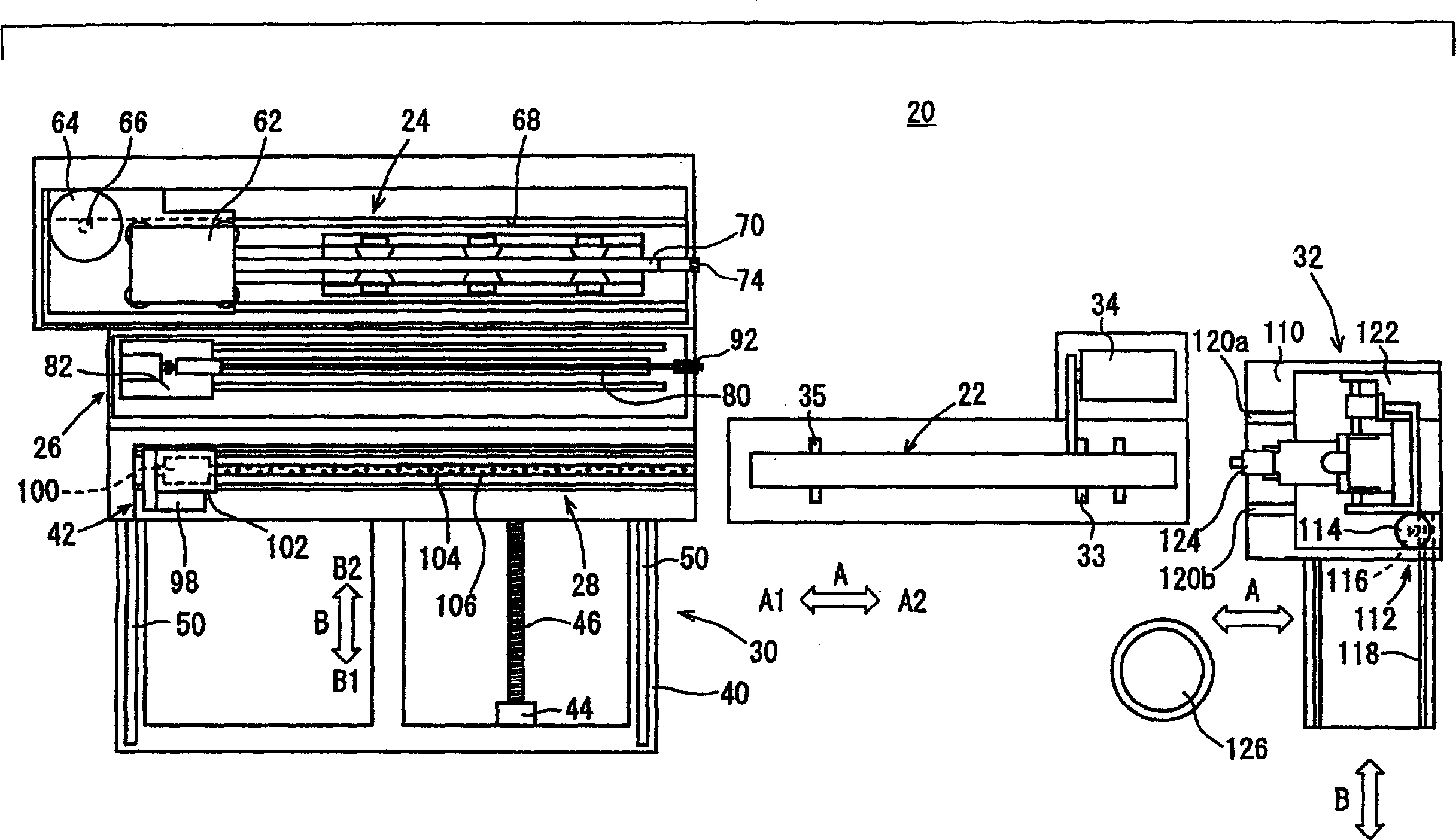

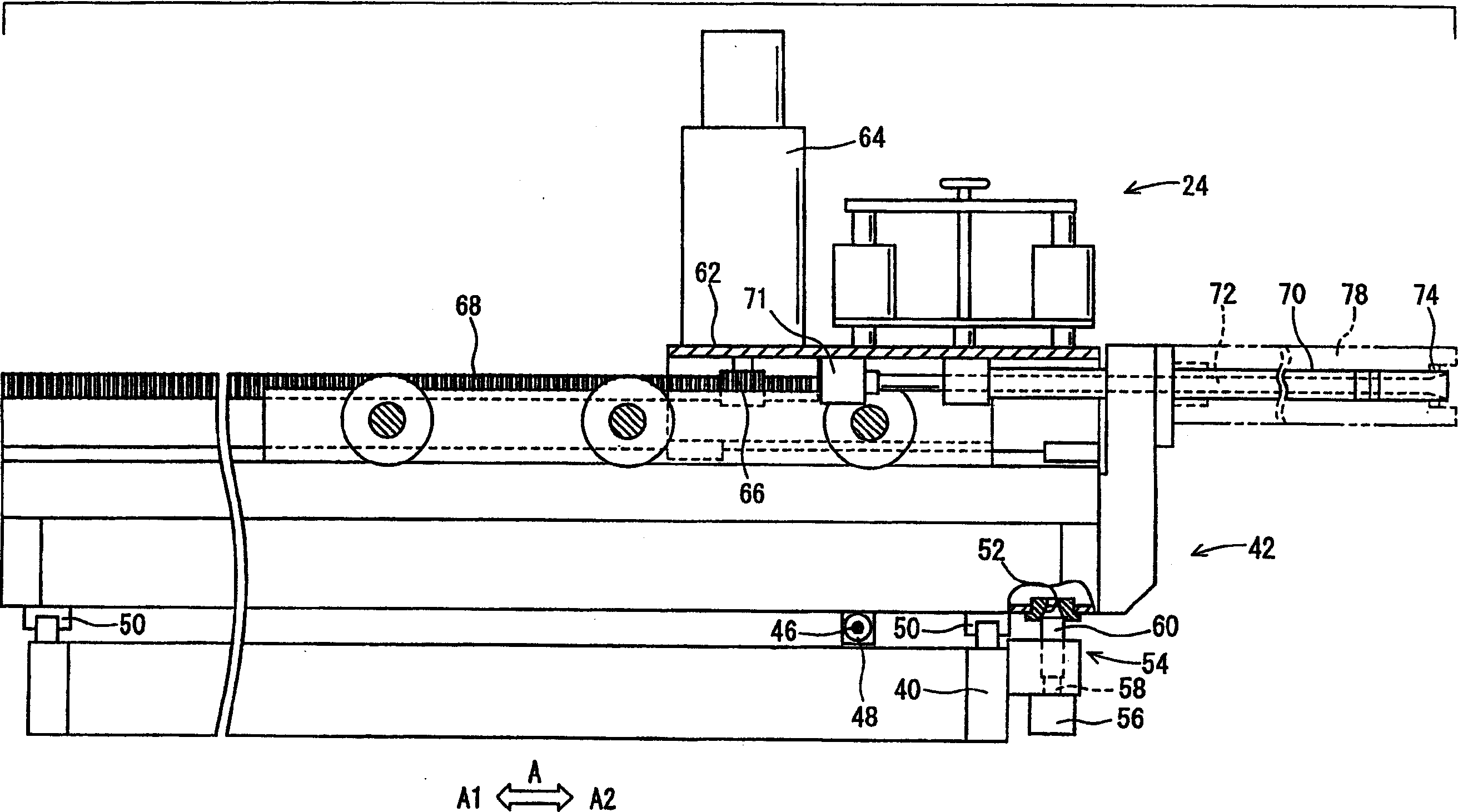

[0043] figure 1 It is a schematic plan view of the centrifugal casting device 20 according to the first embodiment of the present invention.

[0044]The centrifugal casting device 20 includes: a cylindrical centrifugal casting mold 22; a workpiece pulling mechanism 24 arranged side by side (direction of arrow A1) in the axial direction (direction of arrow A) of the above-mentioned centrifugal casting mold 22; Mechanism 26 and coating material application mechanism 28; Make the above-mentioned workpiece pulling mechanism 24, the above-mentioned cleaning mechanism 26 and the above-mentioned coating material application mechanism 28 along the direction of arrow B intersecting with the above-mentioned axial direction (direction of arrow A) A unit drive mechanism 30 for overall movement; and a pouring mechanism 32 disposed on the other side in the axial direction of the centrifugal casting mold 22 (direction of arrow A2).

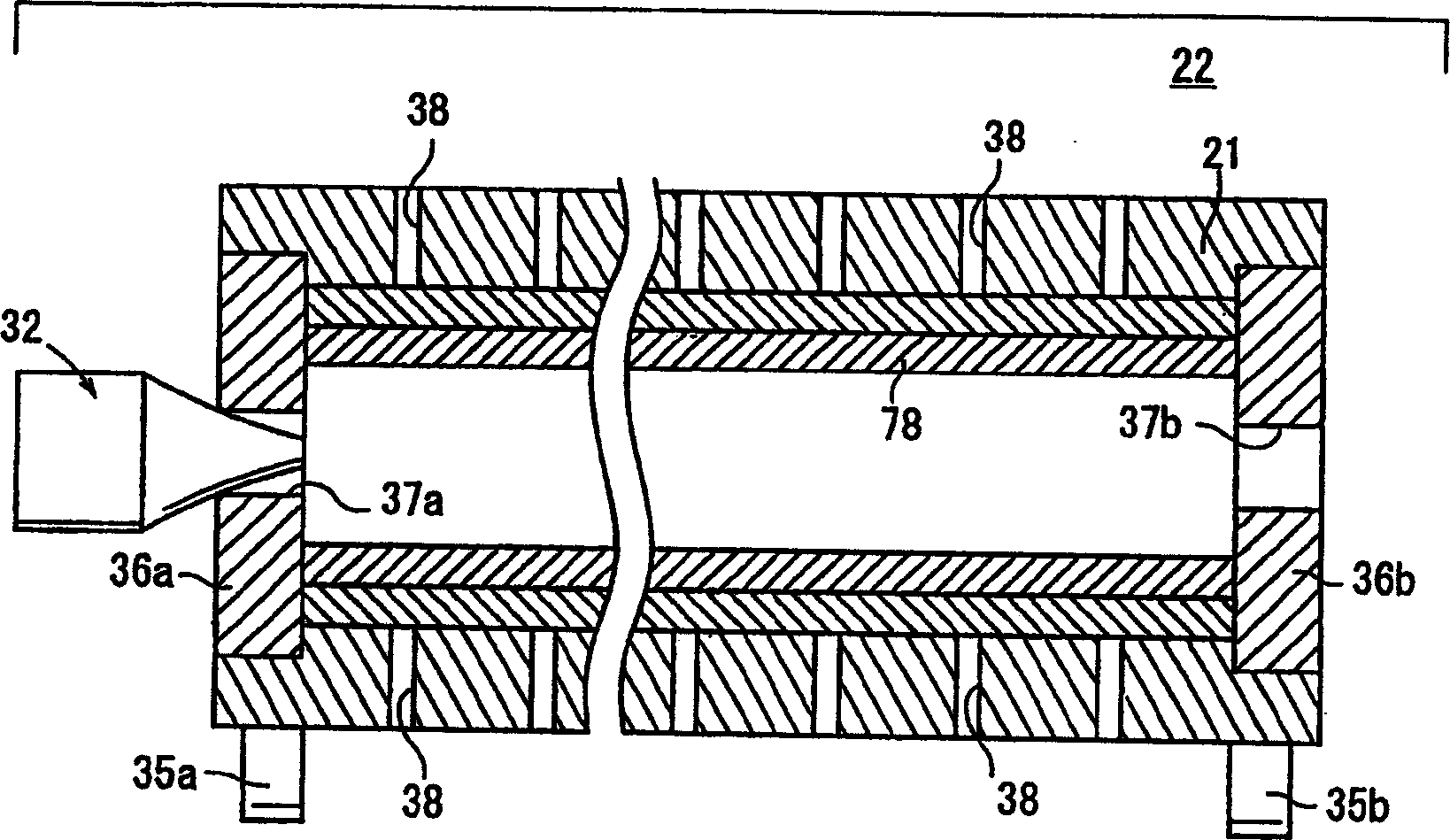

[0045] The centrifugal casting mold 22 has a long hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com