Apparatus for forming tires utilizing rotary base

A technology of tire building machine and rotating base, which is applied in the field of tire building machines, and can solve the problems of high cost of mechanical devices, difficulty in producing various types of tires, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

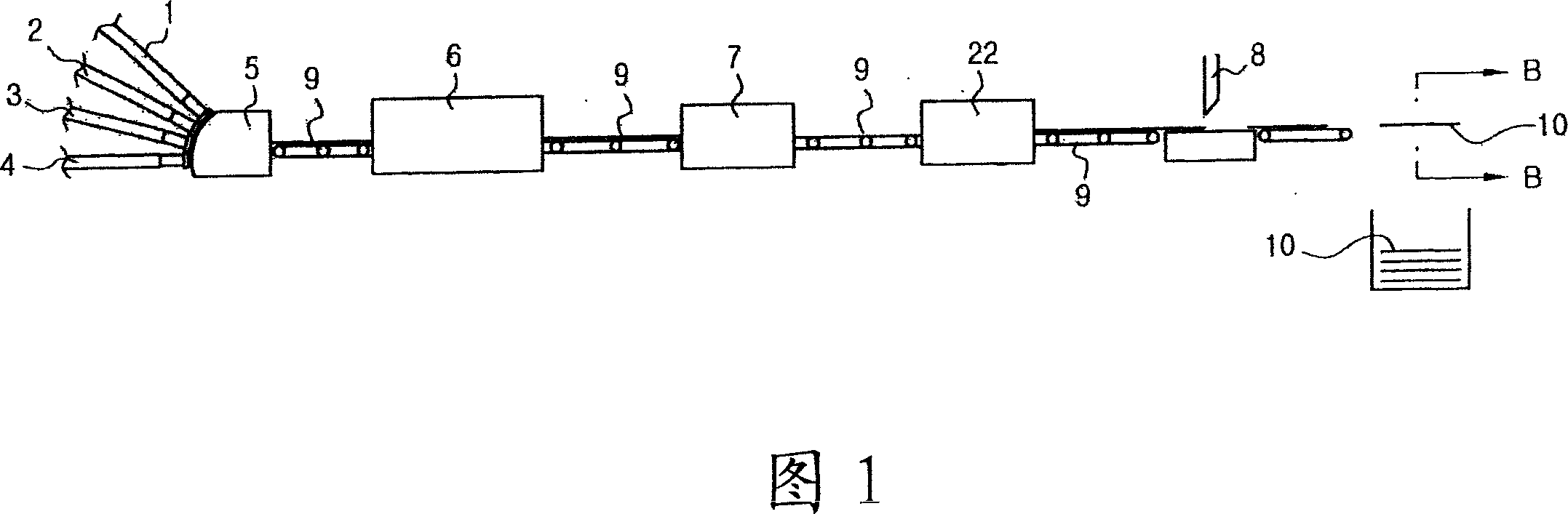

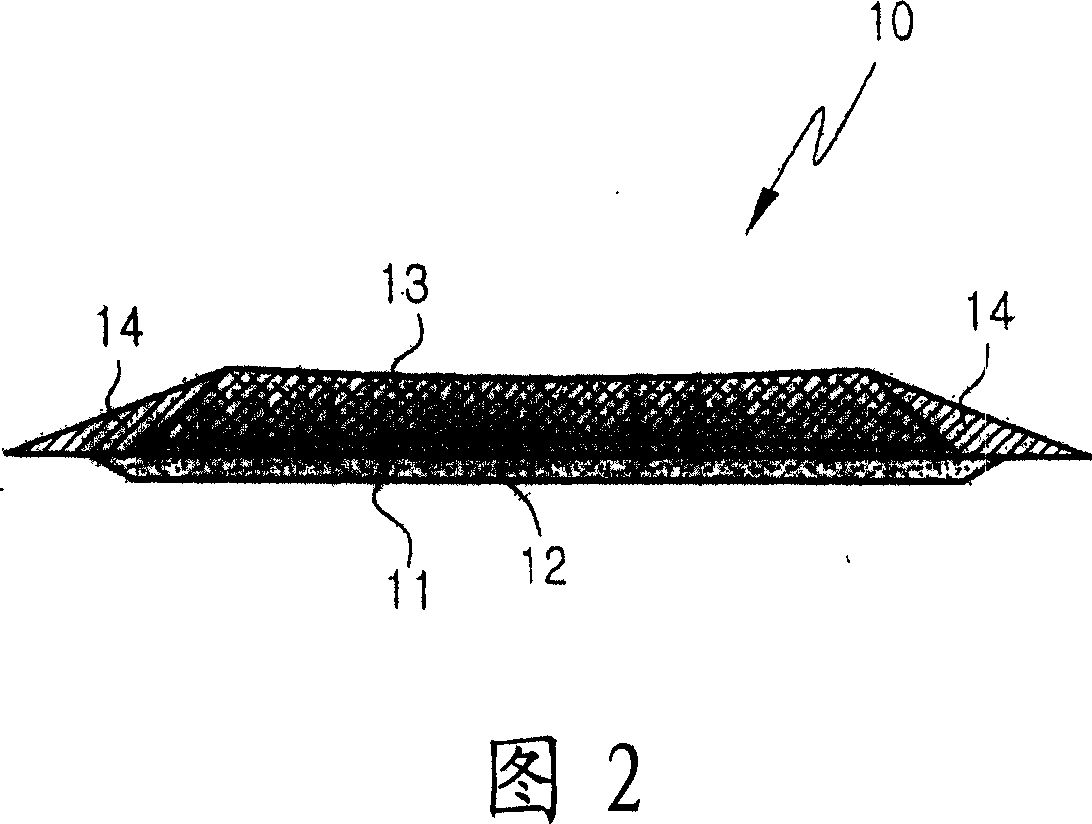

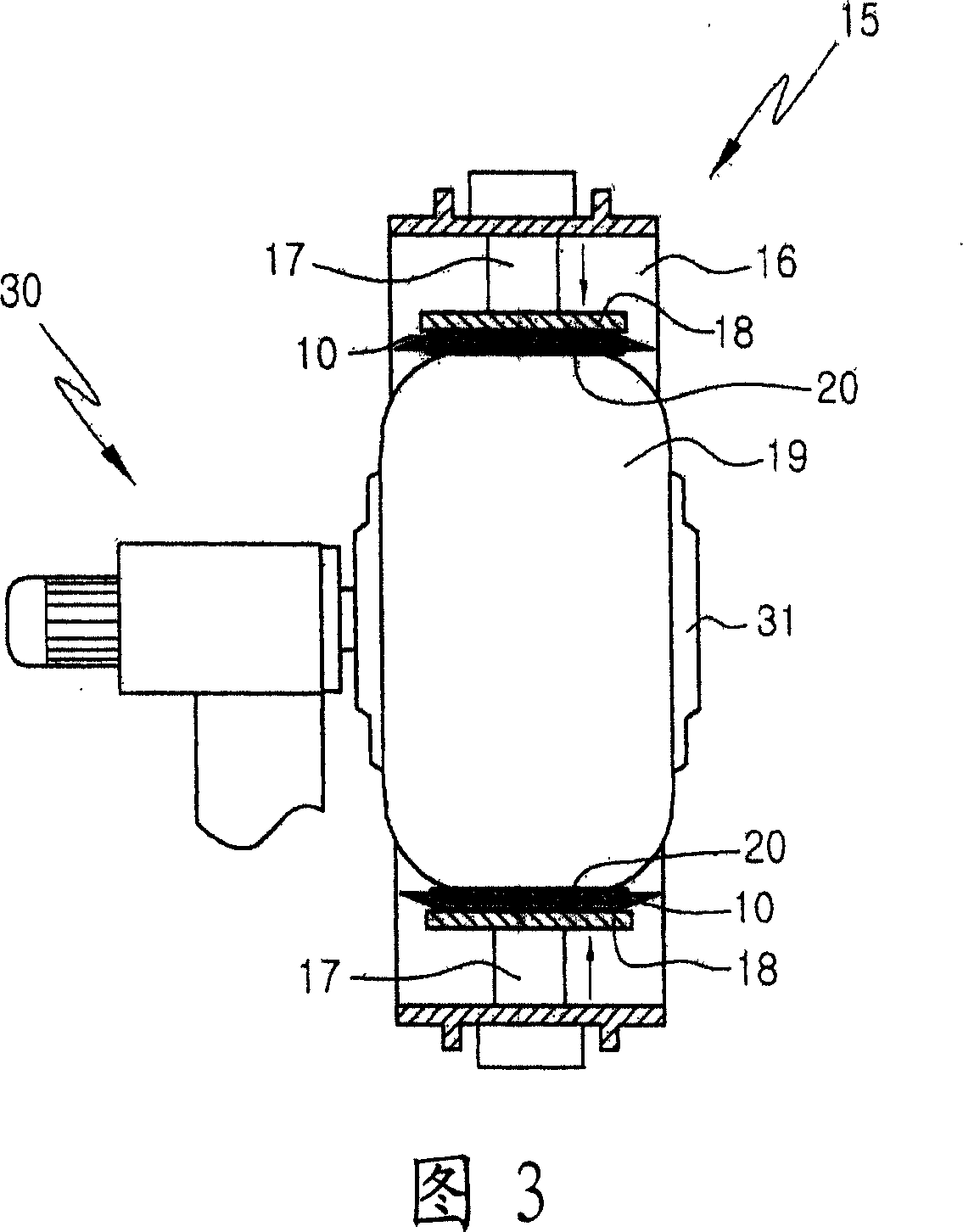

[0025] As an embodiment of the present invention, in order to manufacture tires of the most common shape, six molding machines 30 are arranged radially on the rotating base 32, and one conveying pressure ring 33 and four extruding rings are arranged outside the rotating base 32. Machine 1, 2, 3, 4.

[0026] FIG. 5 is a plan view showing the structure of the present invention, and FIG. 6 is a front view showing the structure of the present invention.

[0027] As shown in Fig. 5 and Fig. 6, 6 forming machines 30 are arranged radially on the top of the circular rotating base 32, and a conveying pressure ring 33 and 4 extruders 1, 2, 1 and 2 are arranged around the rotating base 32 3, 4, and correspond to the molding machines 30 formed on the upper part of the rotating base 32 respectively.

[0028] The spare tire 19 is installed on the molding machine 30 at the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com