Vibration-damping support device

A support device and anti-vibration technology, which is applied in the direction of power devices, jet propulsion devices, internal combustion propulsion devices, etc., can solve the problems of larger manufacturing scale and higher manufacturing cost of anti-vibration support devices, and achieve reduced installation space and reduced Outer diameter size, effect of increasing degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Next, preferred embodiments for implementing the anti-vibration support device of the present invention will be described with reference to the drawings.

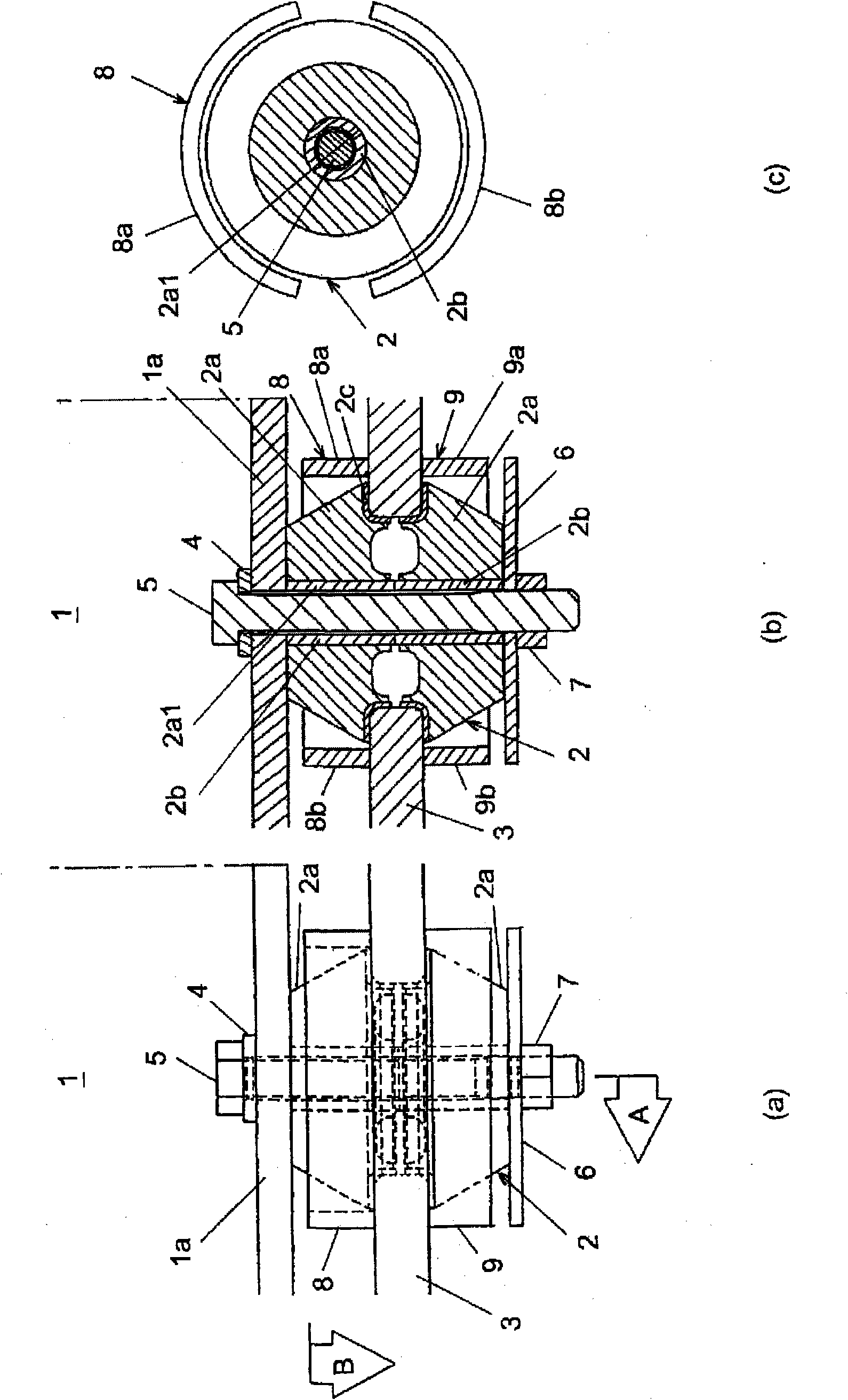

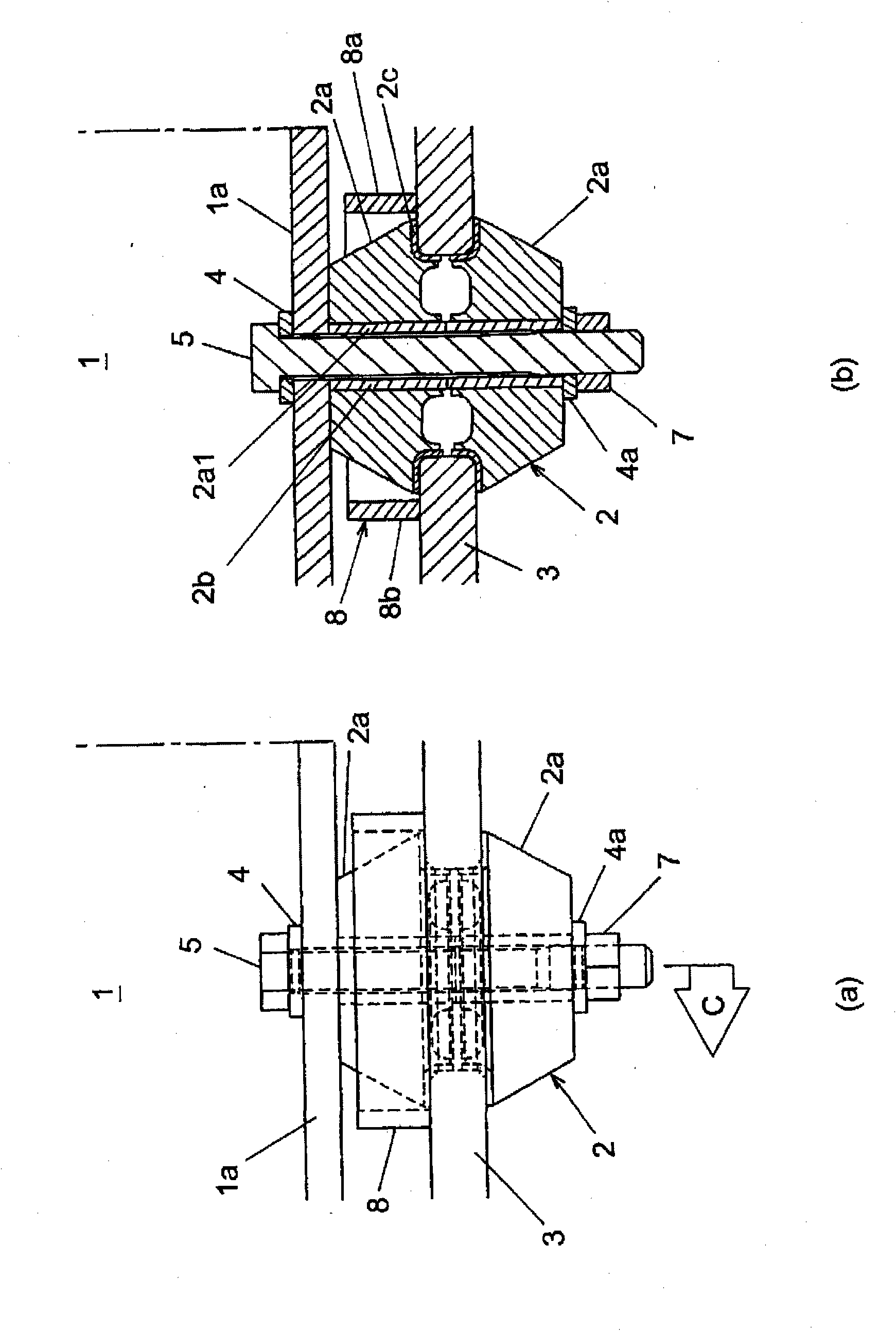

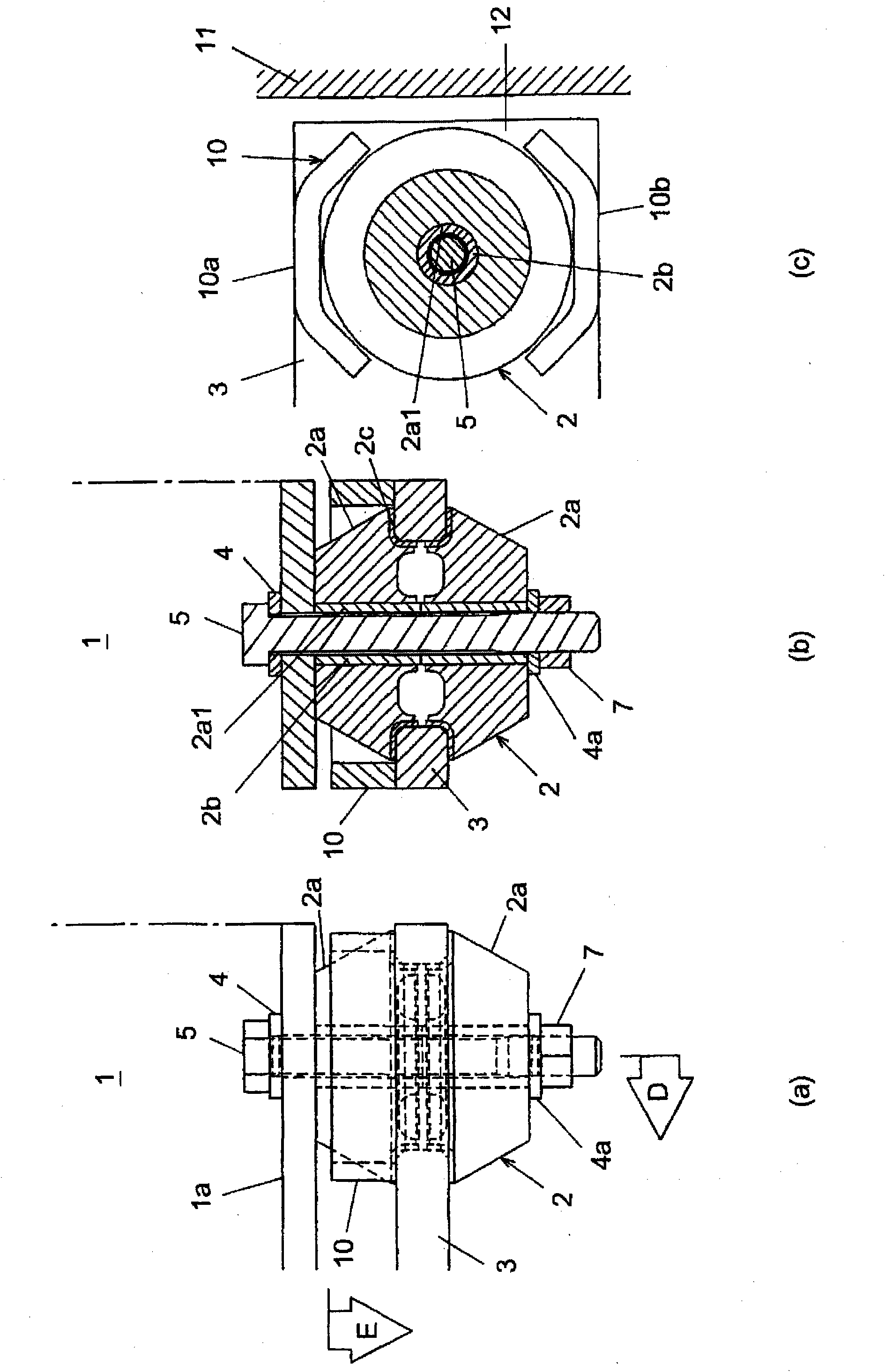

[0027] figure 1 It is a figure which shows the 1st embodiment of the anti-vibration support apparatus of this invention, (a) figure is a front view, (b) figure is A cross-sectional view of (a) figure, (c) figure is B cross-sectional view of (a) figure .

[0028] The anti-vibration support device of the first embodiment is a device used when the engine 1 is mounted on a vehicle body (rotation) frame in a construction machine such as a hydraulic excavator, such as figure 1 As shown in (a) and (b), the anti-vibration support device includes: a mounting part 1a to be installed on an anti-vibration object such as an engine 1, and a rubber body that absorbs the vibration of the engine 1 in the vertical direction and the horizontal direction. The support of the elastic member that constitutes etc., for example rubber su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com