Fracture welding and crack repairing method of band saw blade and matched welding tool set

A technology of welding method and repair method, which is applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems such as welding spatter and welding slag at the welding part, solve the problem of repair, have high tensile strength, and avoid annealing problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

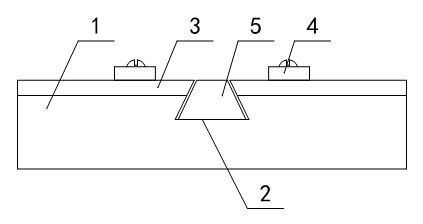

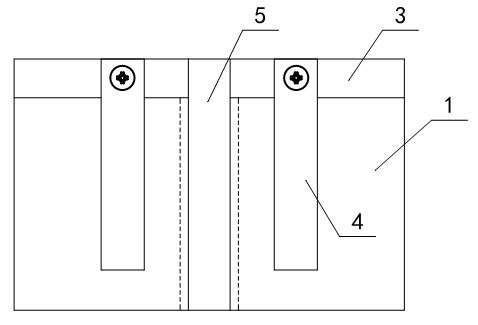

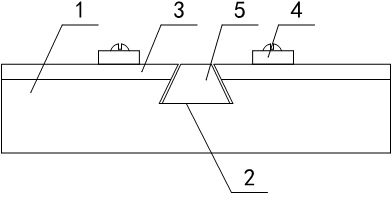

[0017] The fracture welding and crack repair of the band saw blade of the present invention are mainly carried out by the welding process, and the frocks used during the welding are as follows: figure 1 , figure 2 As shown, the tooling includes a backing plate 1 for padding the lower part of the band saw blade. The upper end surface of the backing plate 1 is a working surface, and a groove 2 is opened in the middle of the working surface of the backing plate 1. On the working surface A pressing device for fixing the fracture portion of the band saw blade is respectively provided near the edges of both sides of the groove 2. In this embodiment, the pressing device includes bosses 3 respectively protruding from the working surfaces on both sides of the groove. , the height of the two bosses 3 is equivalent to the thickness of the band saw blade to be repaired, the extension direction of the two bosses 3 is perpendicular to the groove 2, and the two bosses 3 are vertically insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com