Method of producing TA10 alloy rolls through twenty-roller cold rolling unit

A 20-high, cold rolling mill technology, applied in metal rolling, roll speed control, metal rolling, etc., to achieve the effects of convenient operation, lower production cost, increase output and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The method for producing TA10 alloy coils by adopting a 20-roller cold rolling mill according to the present invention comprises the following steps:

[0015] (1) Annealing the TA10 alloy coil with a thickness of 3.0mm and a width of 1250mm produced by a hot rolling mill, the annealing temperature is 740°C, and the annealing time is 240min;

[0016] (2) Shot blast the TA10 alloy coil after the annealing is completed, and then carry out pickling after the shot blasting is completed, and the proportion of the pickling solution is 5% HF, 25% HNO 3 and 70% H 2 O;

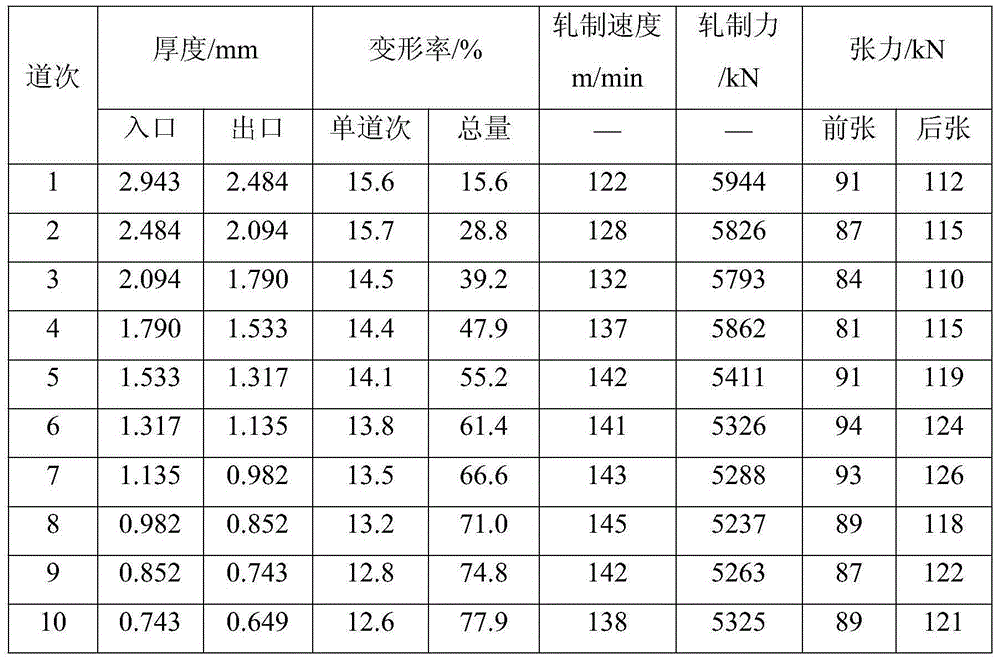

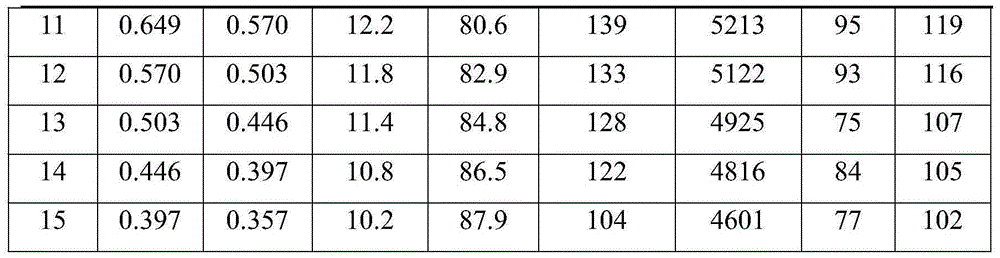

[0017] (3) After the pickling is completed, the coil is threaded, and the coil is placed on the coiling mechanism of the 20-roll cold rolling mill for threading, and the TA10 alloy coil is rolled in 8 to 15 passes with the 20-roll cold rolling mill; The rolling process is shown in Table 1, and TA10 alloy coils with a thickness of 0.4-1.0 mm can be obtained;

[0018] (4) Degrease the TA10 alloy coil rolled to t...

Embodiment 2

[0023] The method for producing TA10 alloy coils by adopting a 20-roller cold rolling mill according to the present invention comprises the following steps:

[0024] (1) Annealing the TA10 alloy coil with a thickness of 3.0mm and a width of 1400mm produced by a hot rolling mill, the annealing temperature is 780°C, and the annealing time is 300min;

[0025] (2) Shot blast the TA10 alloy coil after the annealing is completed, and then carry out pickling after the shot blasting is completed, and the proportion of the pickling solution is 8% HF, 20% HNO 3 and 72%H 2 O;

[0026] (3) After the pickling is completed, the coil is threaded, and the coil is placed on the coiling mechanism of the 20-roll cold rolling mill for threading, and the TA10 alloy coil is rolled in 8 to 15 passes with the 20-roll cold rolling mill; During the rolling process of the cold rolling mill, the reduction rate of each pass, that is, the deformation rate, is controlled at 10% to 16%, the rolling force i...

Embodiment 3

[0029] The method for producing a TA10 alloy coil by a twenty-high cold rolling mill comprises the following steps:

[0030] (1) Annealing the TA10 alloy coil with a thickness of 3.0mm and a width of 800mm produced by a hot rolling mill, the annealing temperature is 650°C, and the annealing time is 480min;

[0031] (2) Shot blast the TA10 alloy coil after the annealing is completed, pickling after the shot blasting is completed, the pickling liquid ratio is 10% HF, 15% HNO 3 and 75%H 2 O;

[0032] (3) After the pickling is completed, the coil is threaded, and the coil is placed on the coiling mechanism of the 20-roll cold rolling mill for threading, and the TA10 alloy coil is rolled in 8 to 15 passes with the 20-roll cold rolling mill; During the rolling process of the cold rolling mill, the reduction rate of each pass, that is, the deformation rate, is controlled at 10% to 16%, the rolling force is controlled at 4500 to 6000kN, and the rolling speed is controlled at 100 to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com