Full-automatic copper strip machine and operation method thereof

A fully automatic, copper strip technology, applied in the direction of electrical components, circuits, connections, etc., can solve problems such as low precision, complicated use, troublesome use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Embodiment 1: the concrete structure of full-automatic copper strip machine of the present invention is as follows:

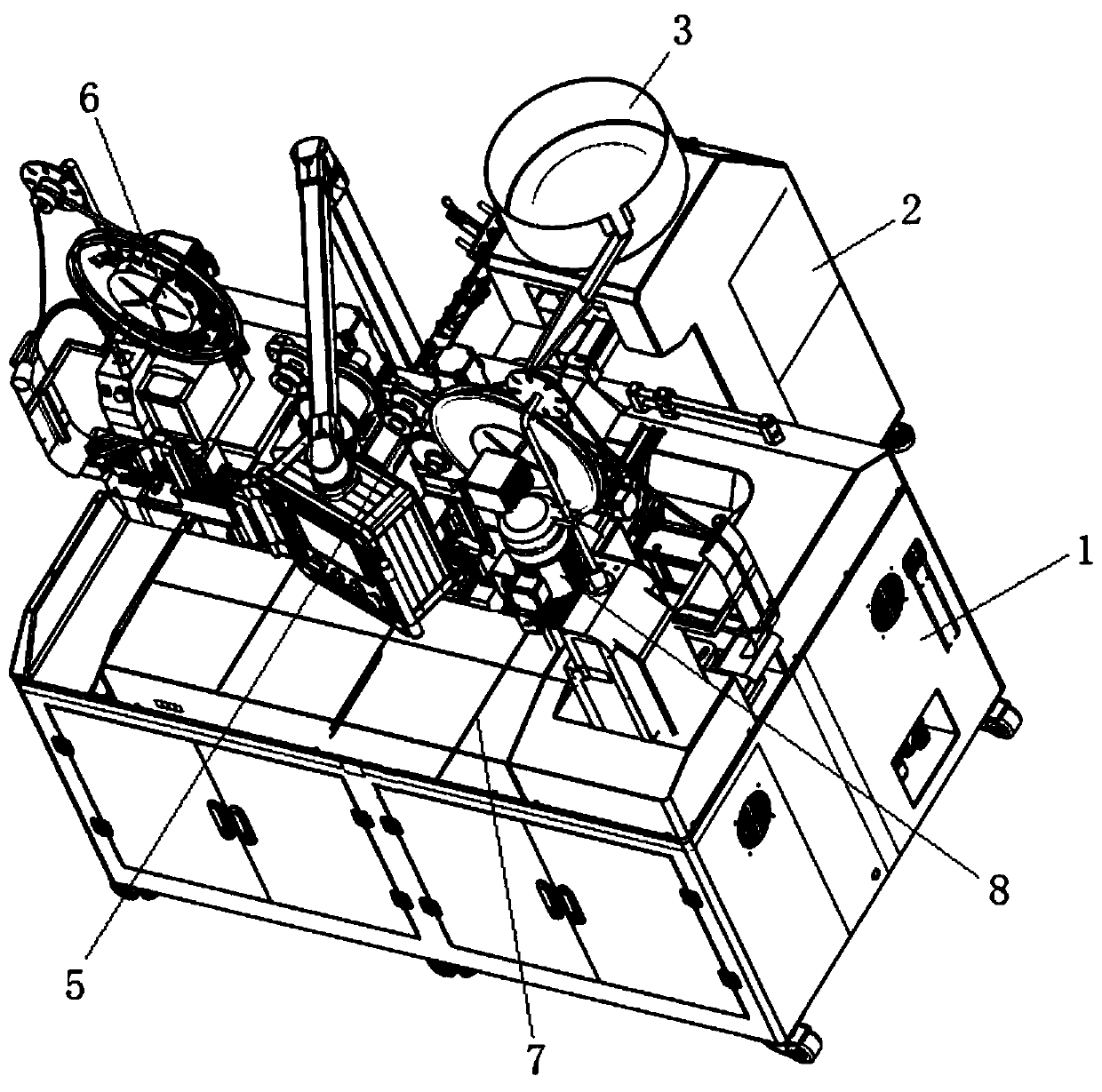

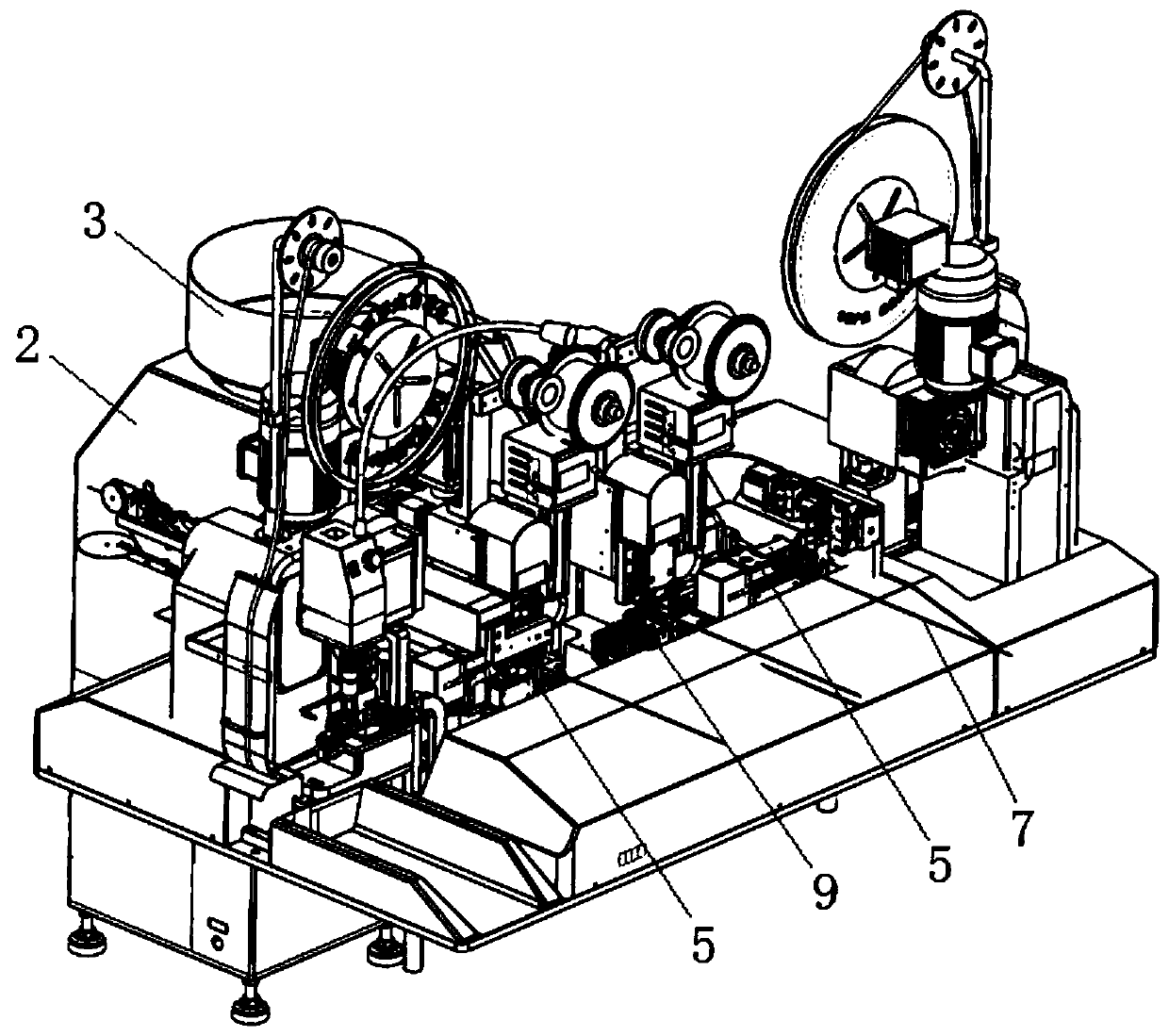

[0074] Please refer to the attached Figure 1-24 , a kind of fully automatic copper strip machine of the present invention, this fully automatic copper strip machine comprises frame 1, also comprises:

[0075] A vibrating device 2 arranged on one side of the frame 1, the vibrating device 2 is provided with a vibrating mechanism and a vibrating plate 3, the vibrating plate 3 is provided with a material guiding structure and a material discharging structure, and the vibrating mechanism vibrates Drive the vibrating plate 3 to vibrate, and through the guide structure and the material discharge structure, the direction of the material is corrected, and at the same time, it is vibrated and transported to the discharge port;

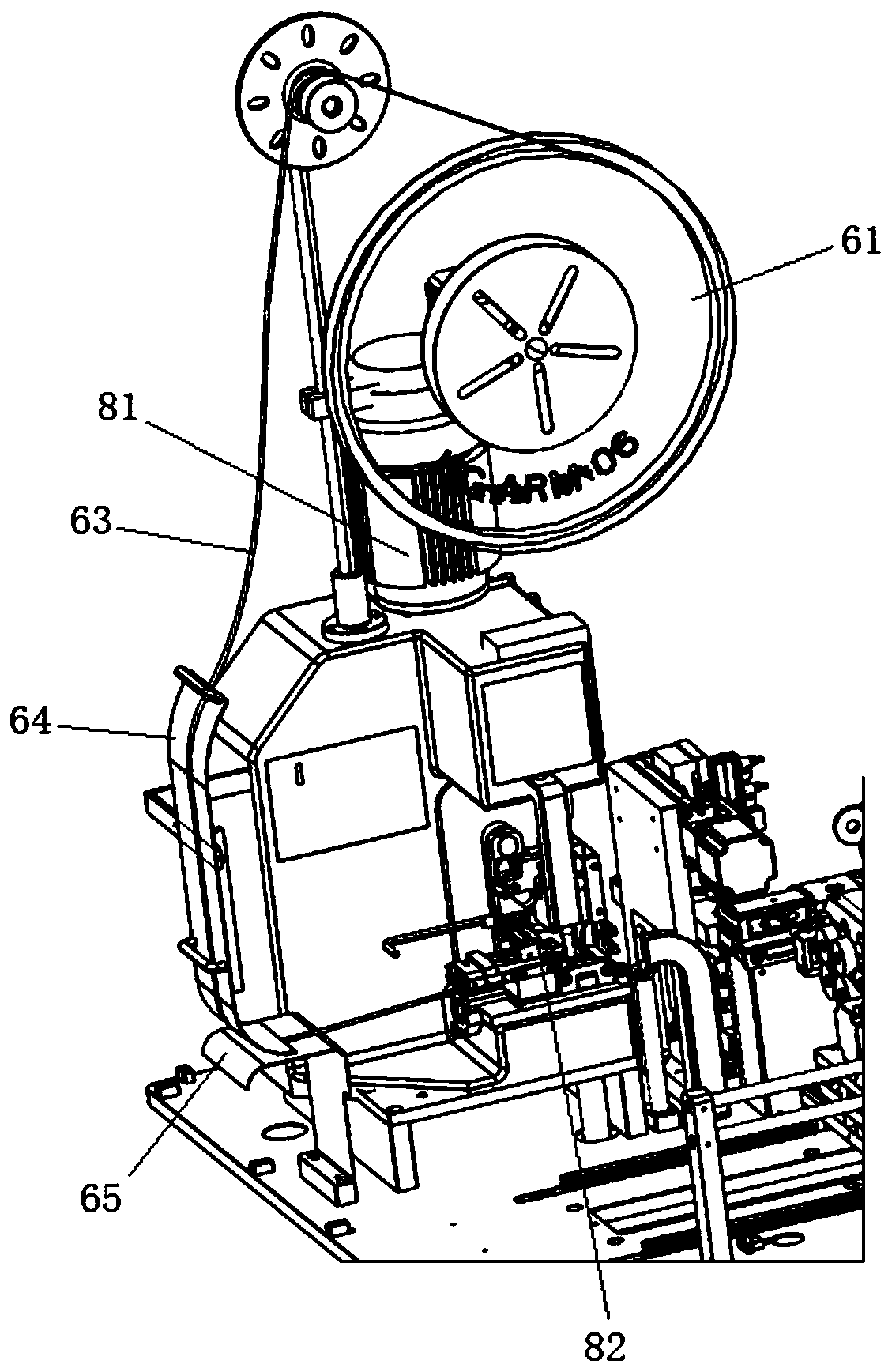

[0076] Copper strip feeding device 6, said copper strip feeding device 6 is provided with two groups, respectively on both sides of the...

Embodiment 2

[0105] Embodiment 2: an operation method of a fully automatic copper strip machine.

[0106] Step 1. Set the cable feeding device on the right side as the 1# wire feeding machine, cut and strip the wire after feeding, and expose the copper core wire inside one end of the cable;

[0107] Step 2, the transfer mechanism moves the processed cables in step 1 to the terminal forming device;

[0108] Step 3, the copper strip is formed into a terminal by the terminal forming device and the terminal is riveted on the copper core wire at one end of the cable;

[0109] Step 4, the transfer mechanism moves the cables after the riveted terminals to the cable connection device 9;

[0110] Step 5, optical fiber inspection is required after riveting the terminal to determine whether it is firm;

[0111] Step 5: During the operation from step 1 to step 4, the components are fed into the cable connection device 9 through the component feeding mechanism. The device rivets components and coppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com