Patents

Literature

41results about How to "Realize automatic riveting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

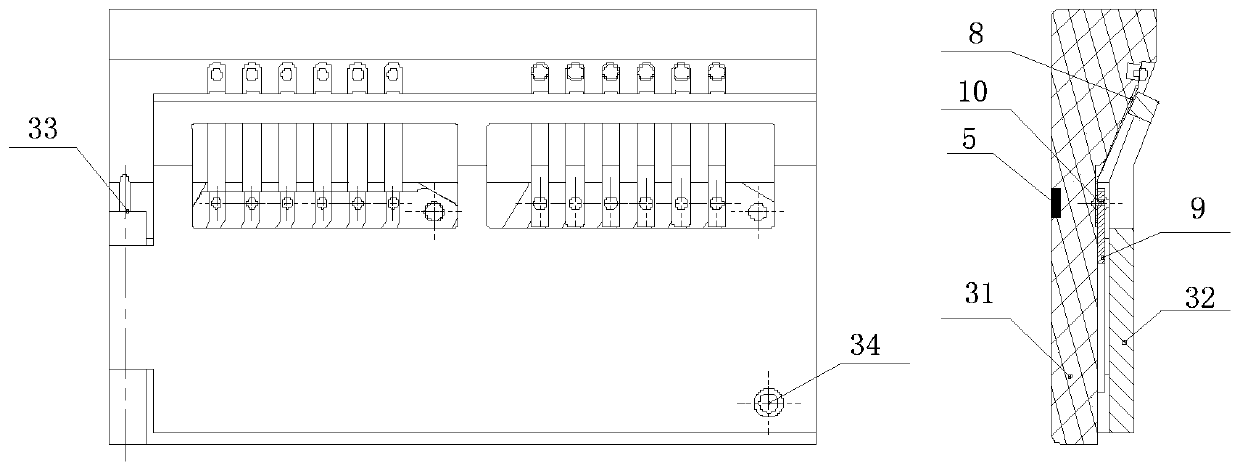

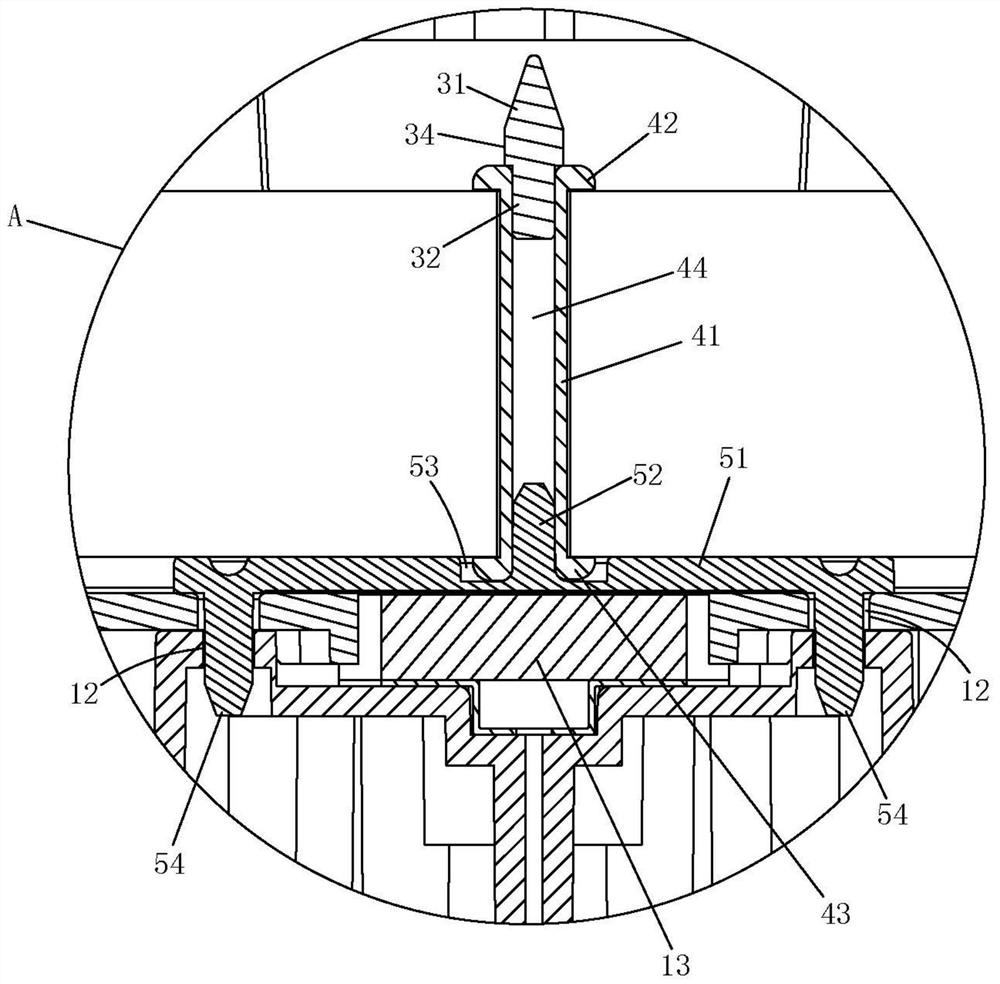

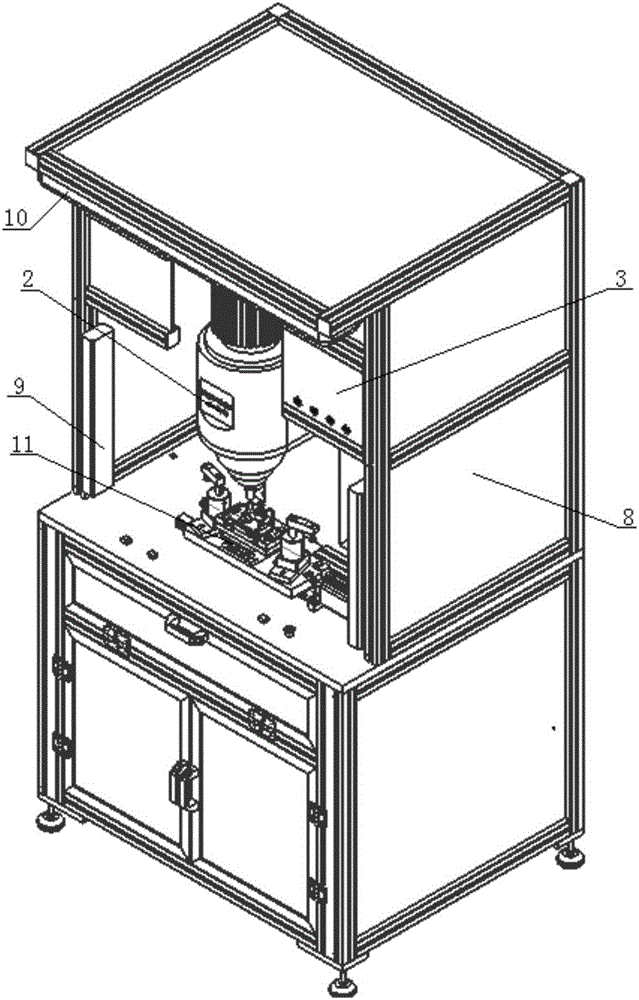

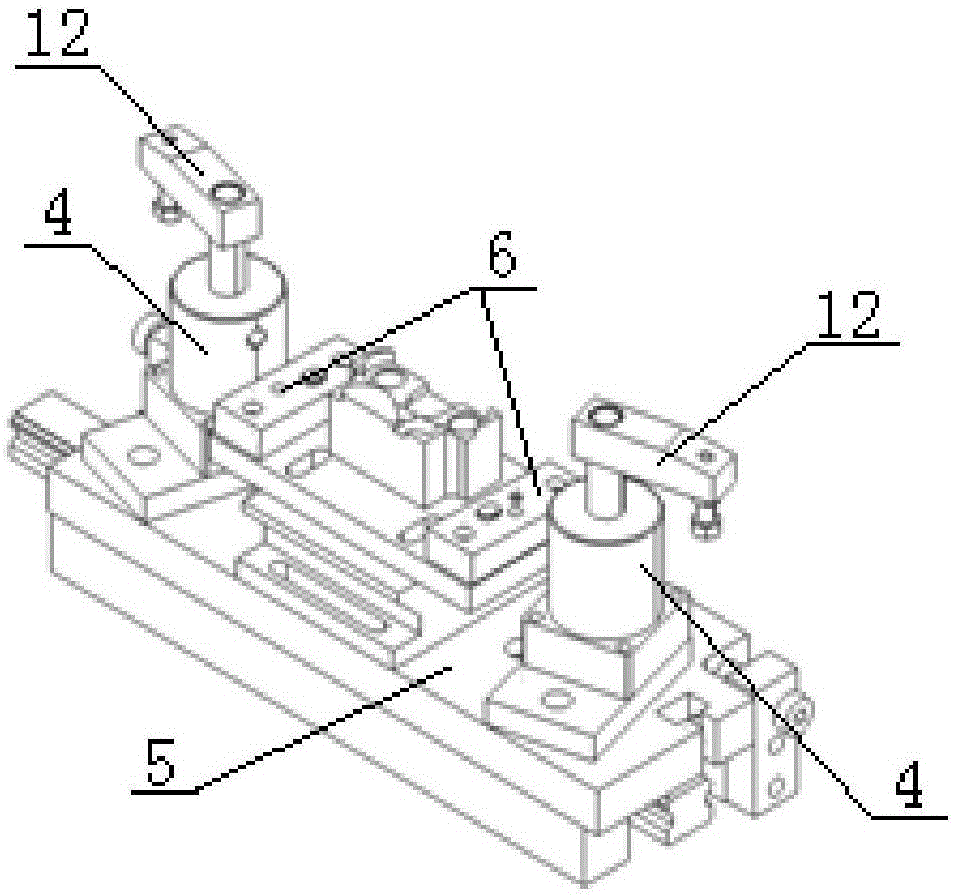

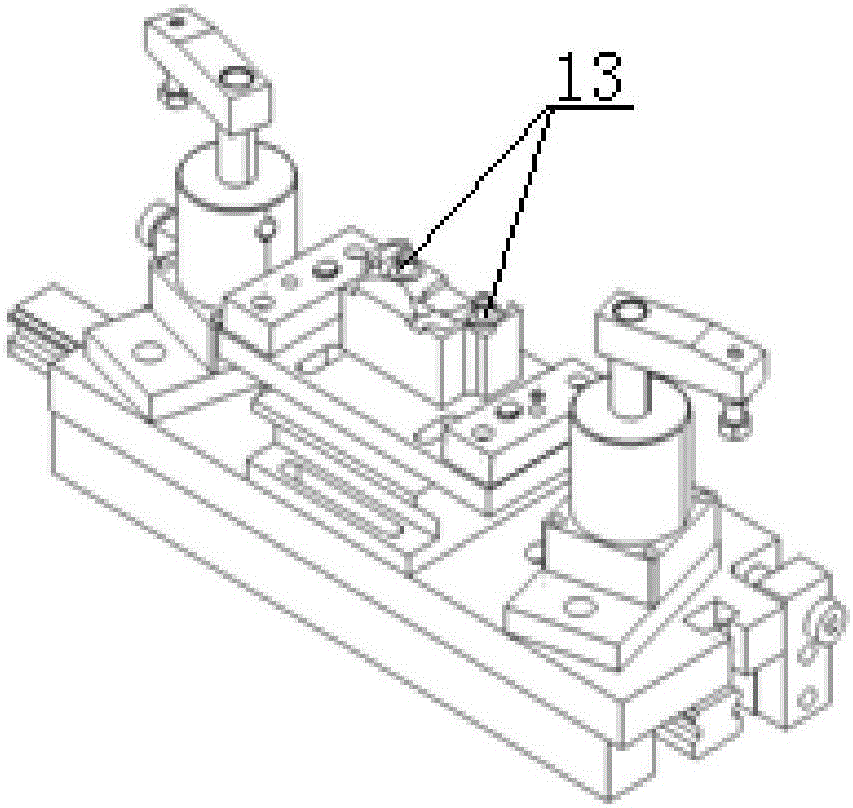

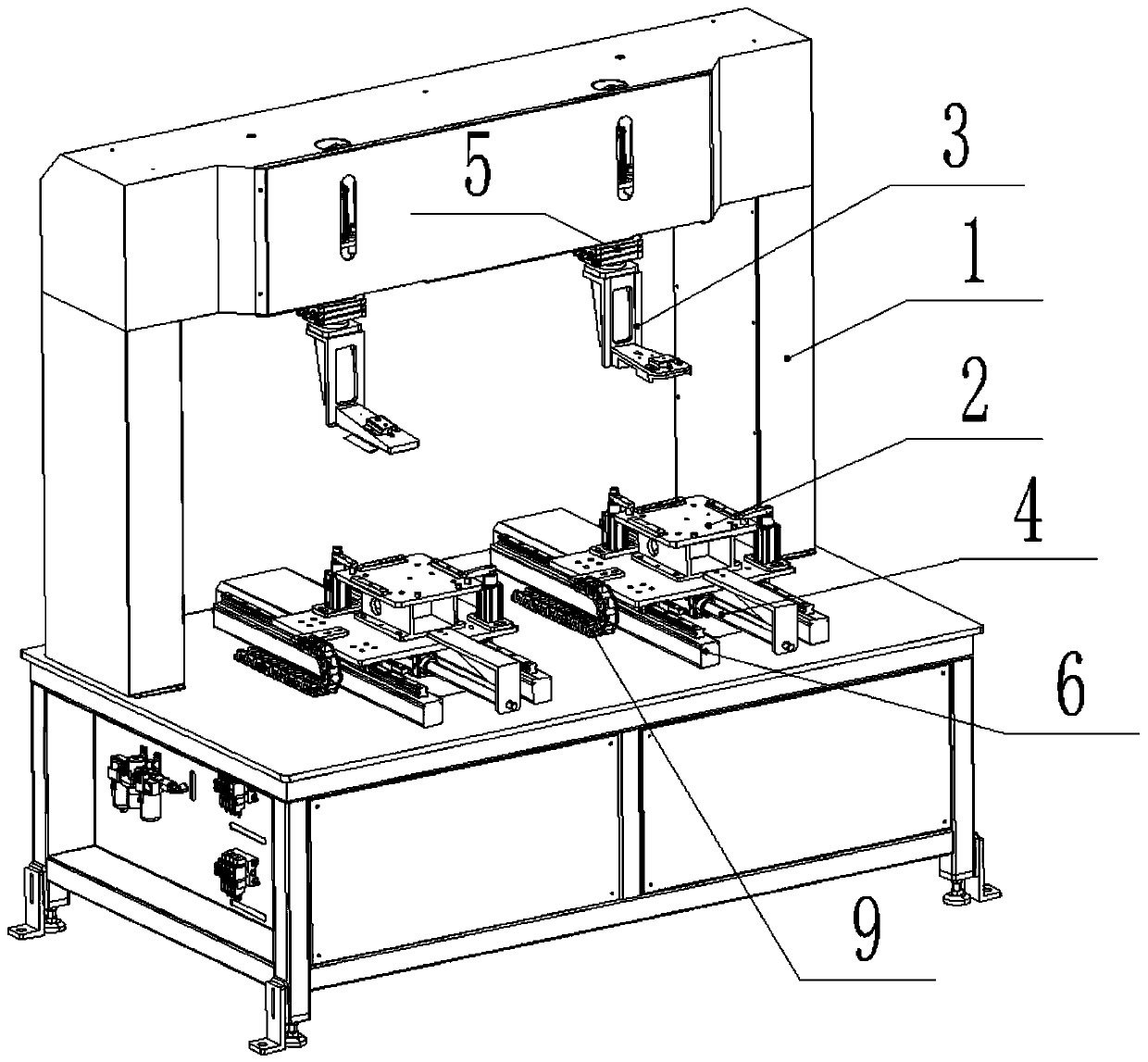

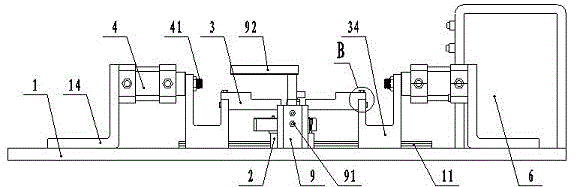

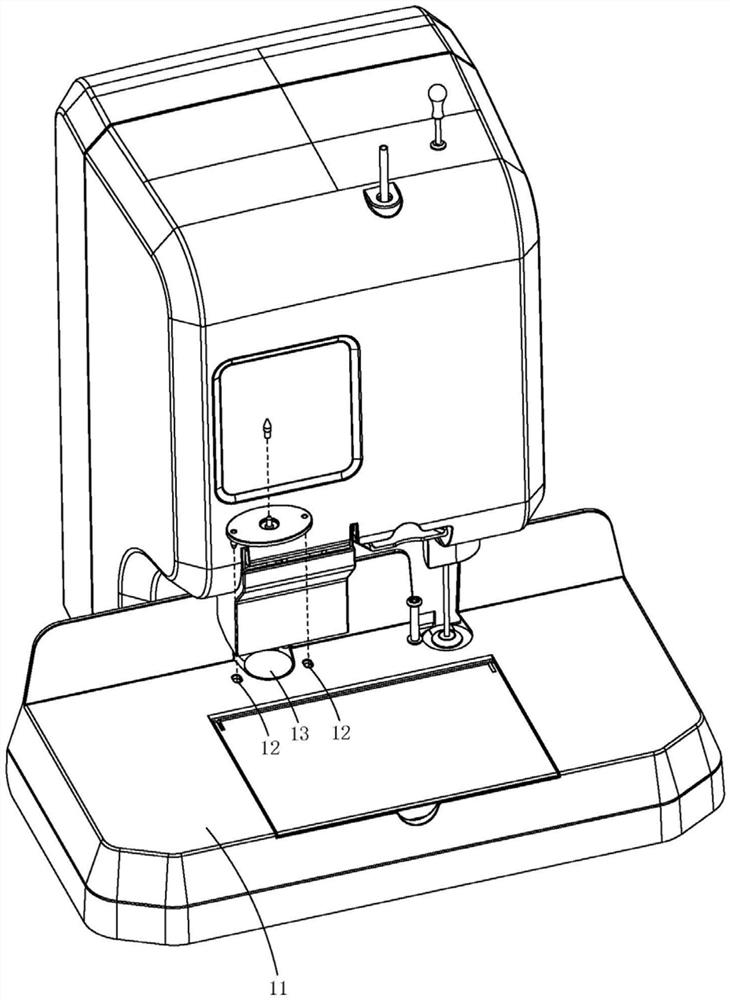

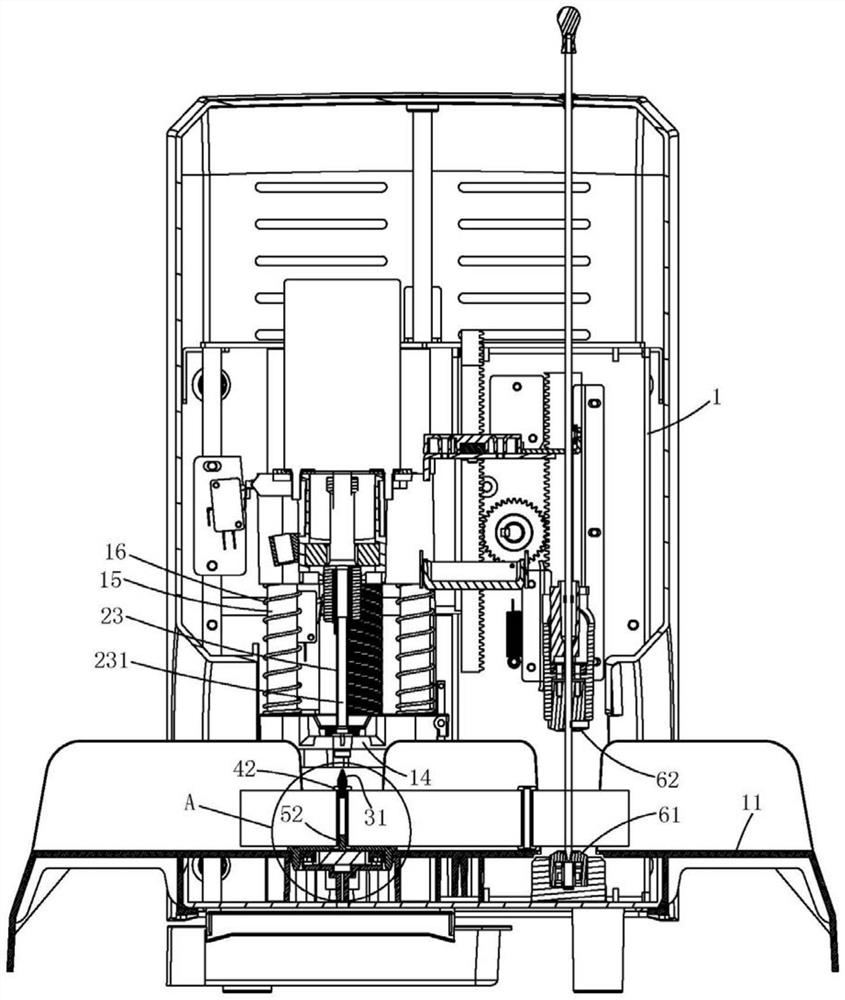

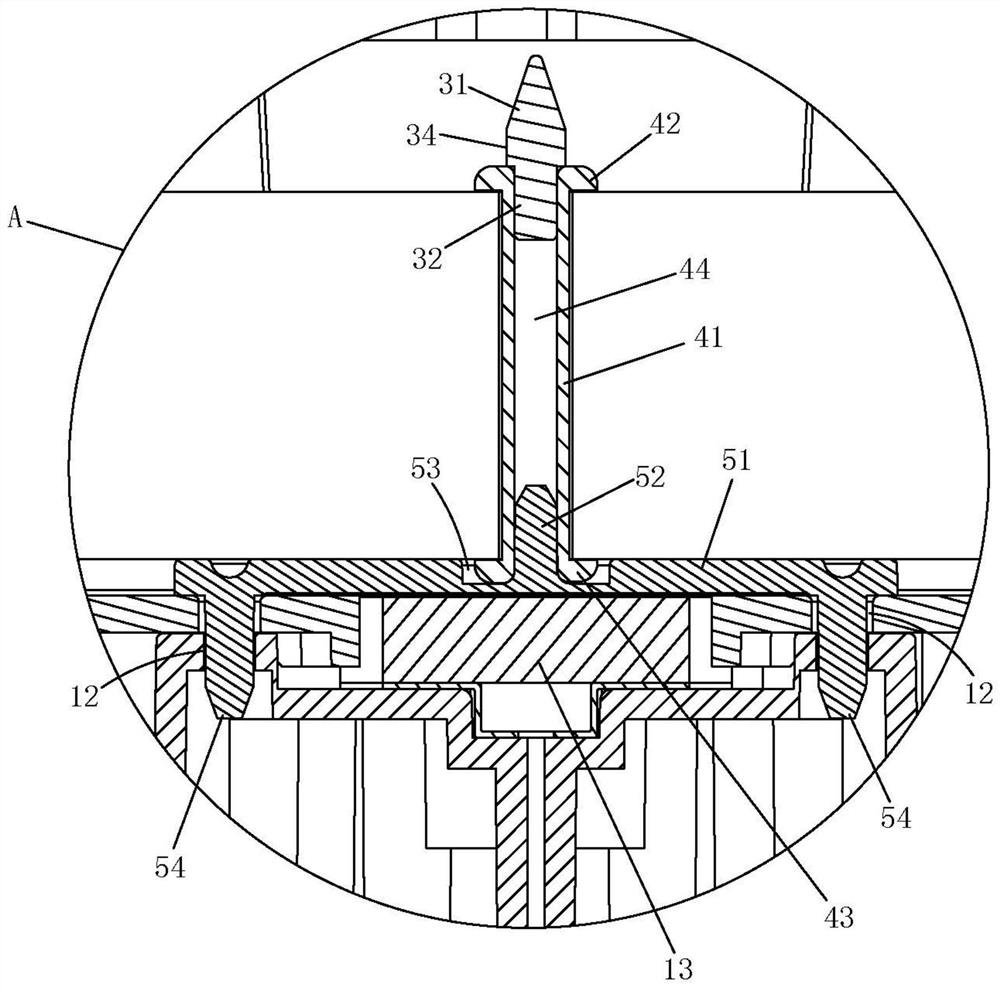

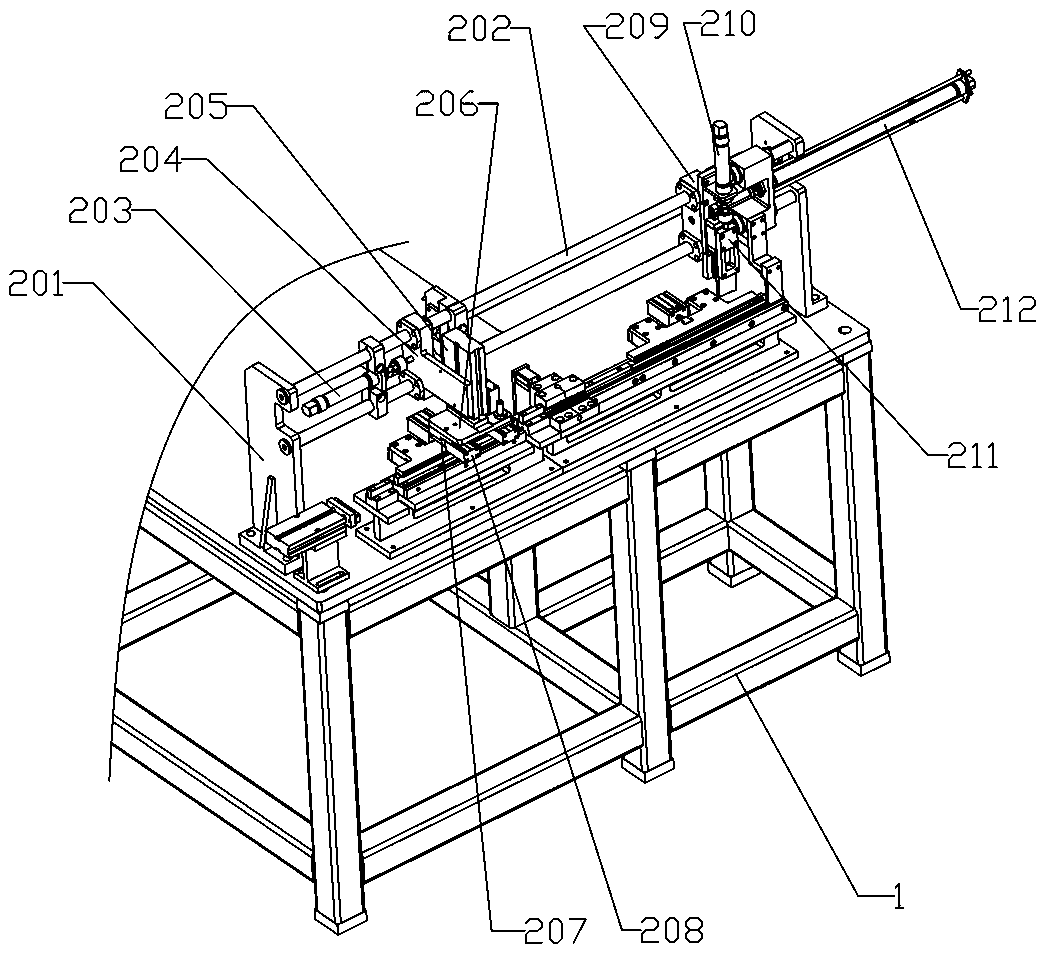

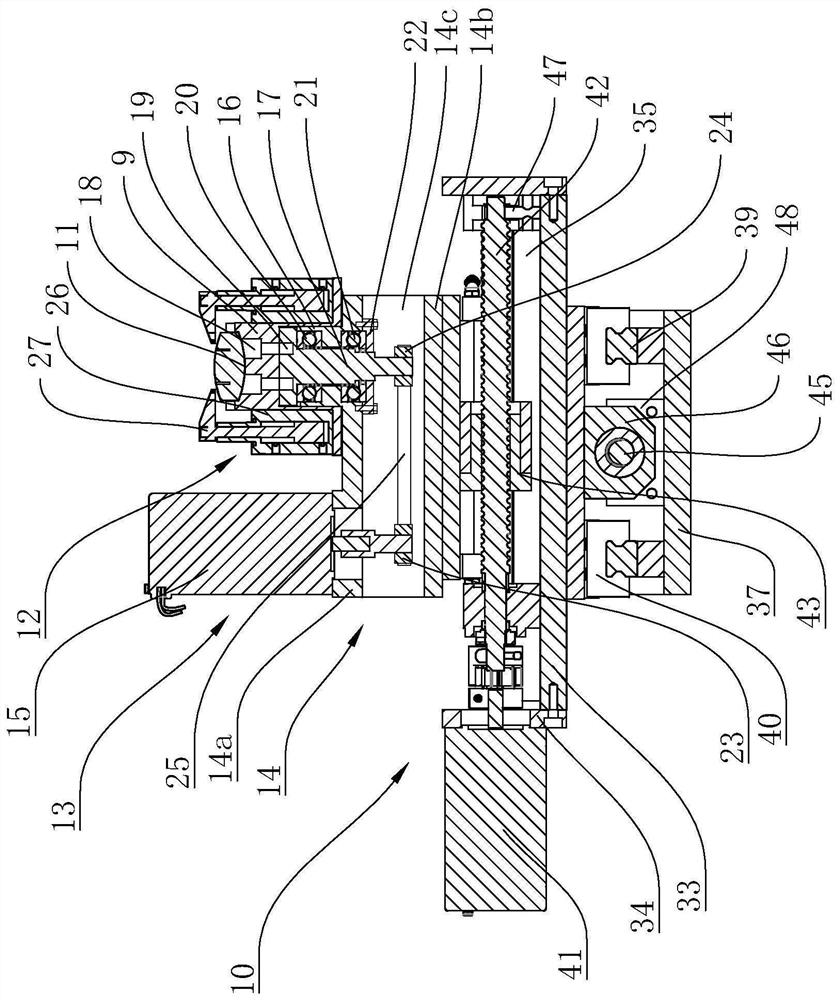

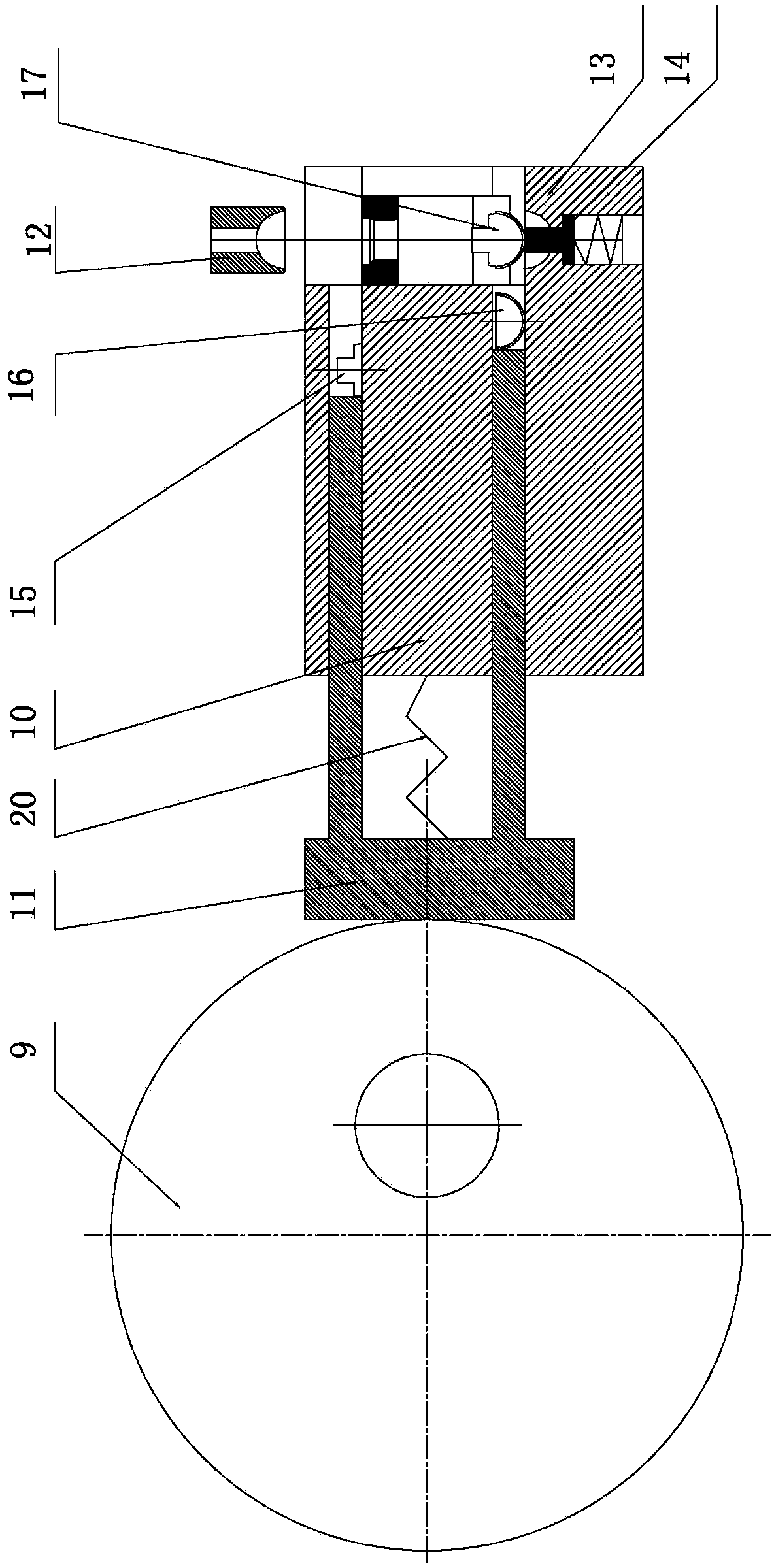

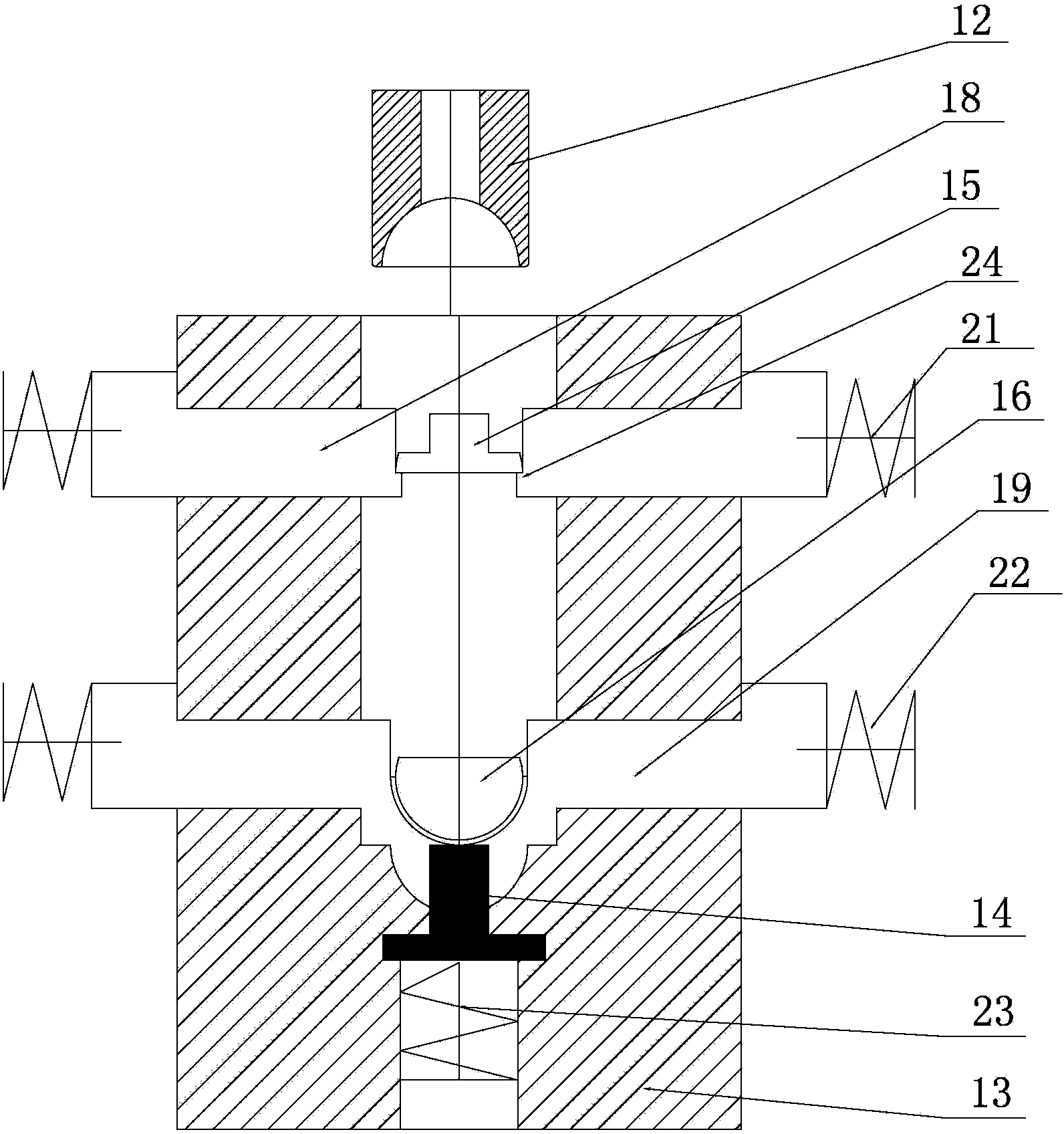

Multipoint rivet-free automatic riveting machine

InactiveCN102240746ARealize riveting automationNo manual operationMetal-working feeding devicesPositioning devicesPulp and paper industryAutomation

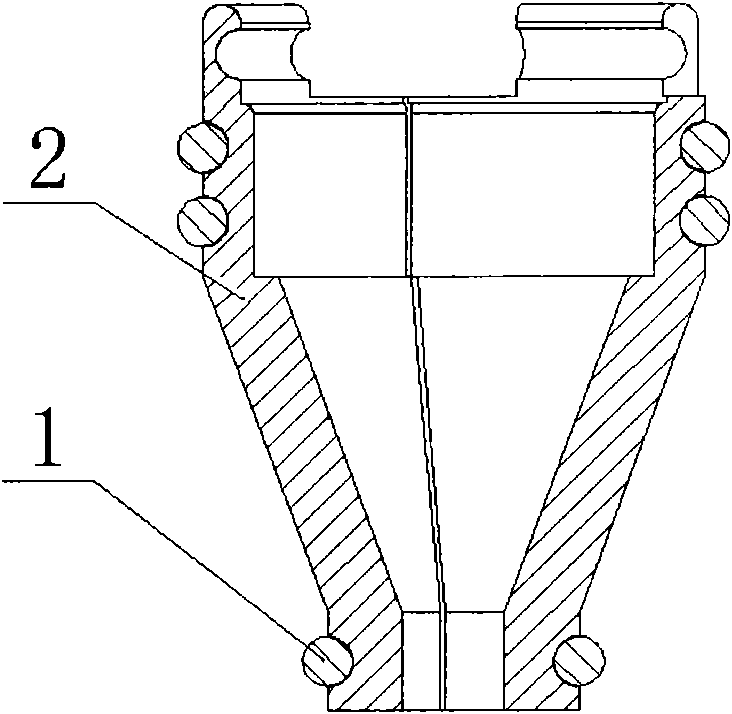

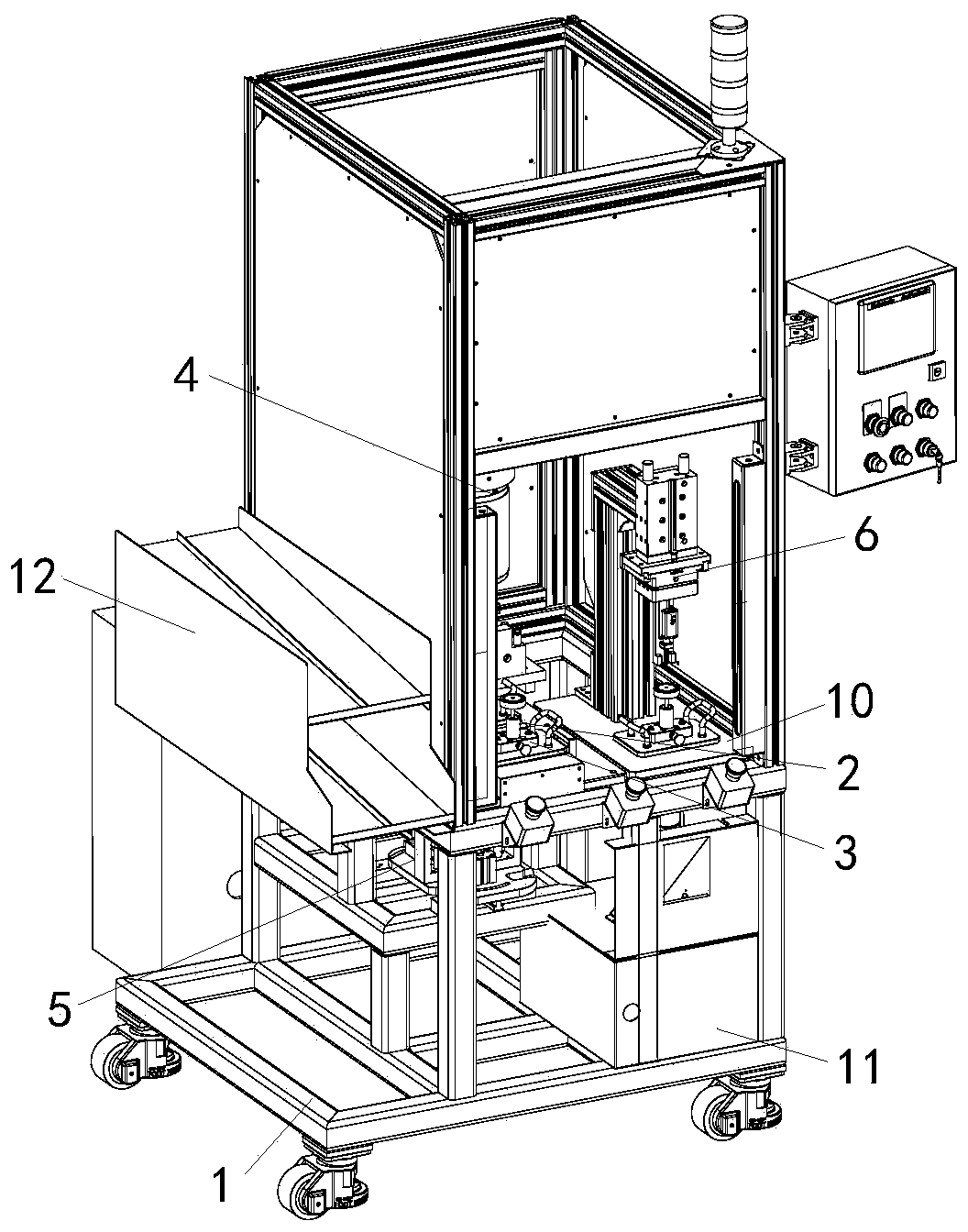

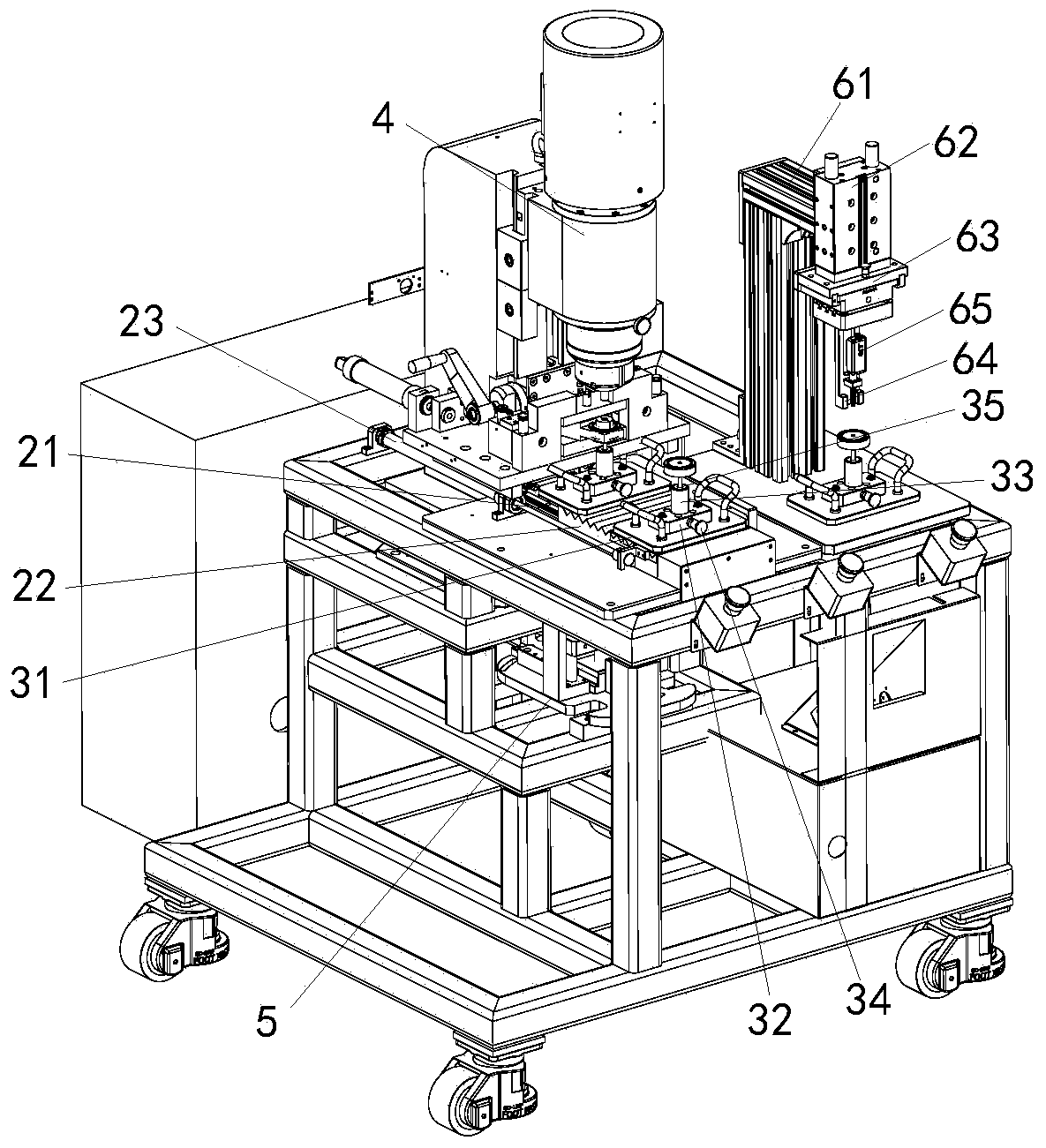

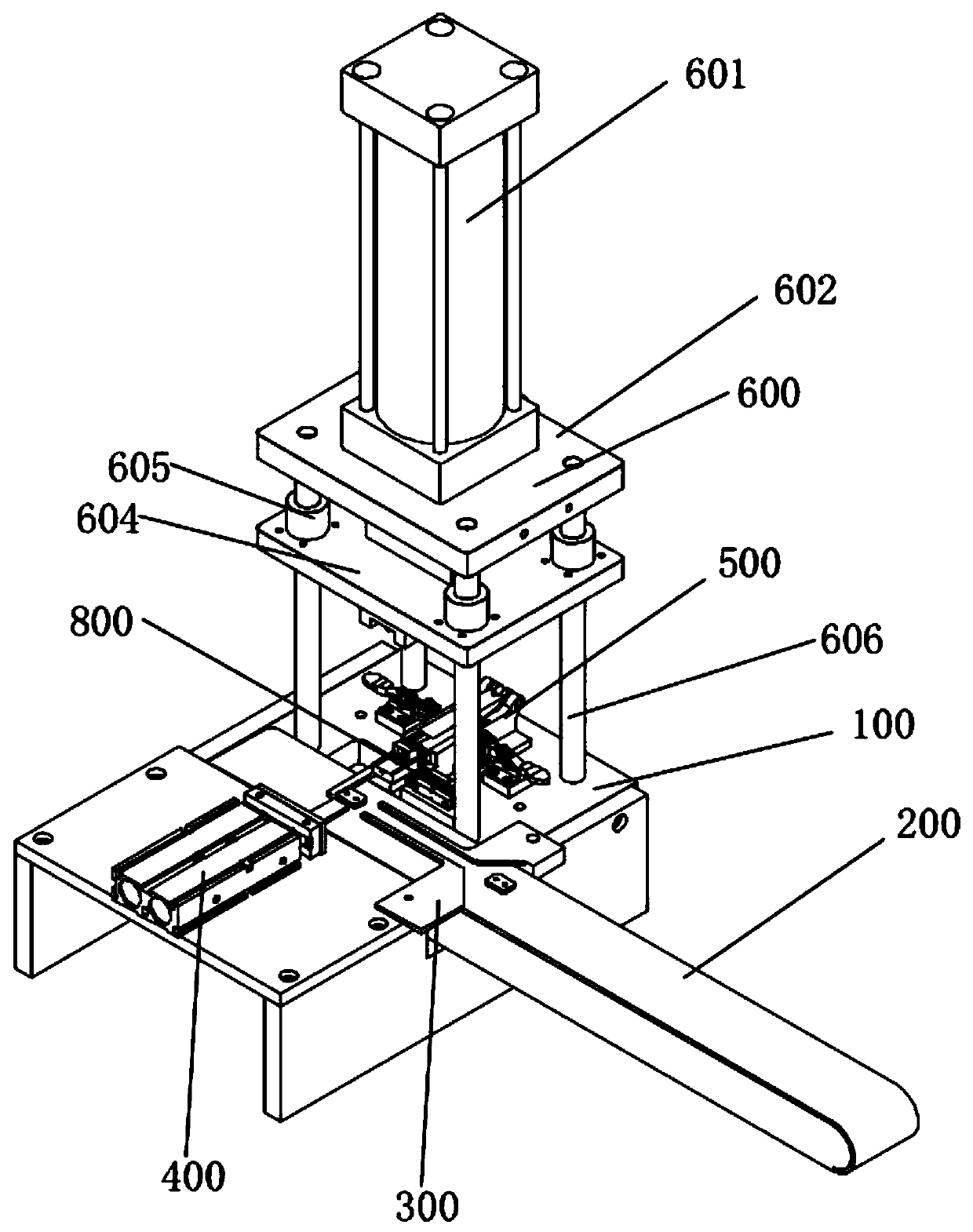

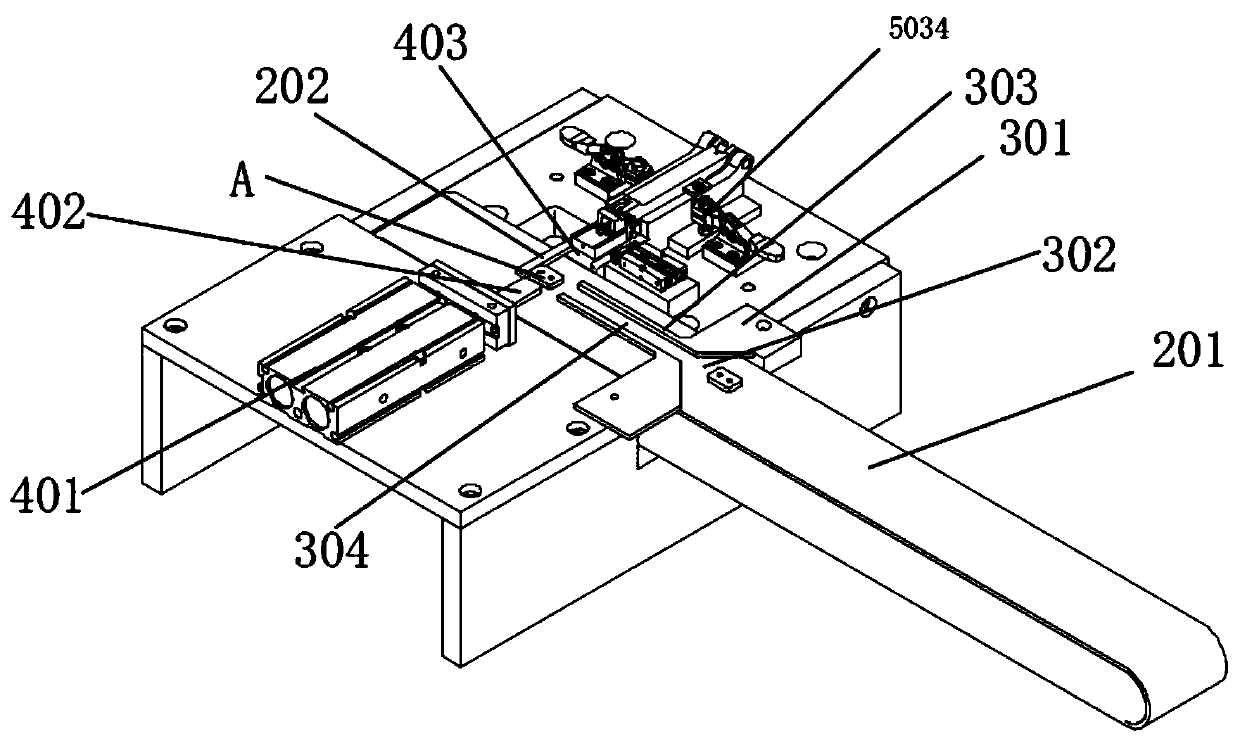

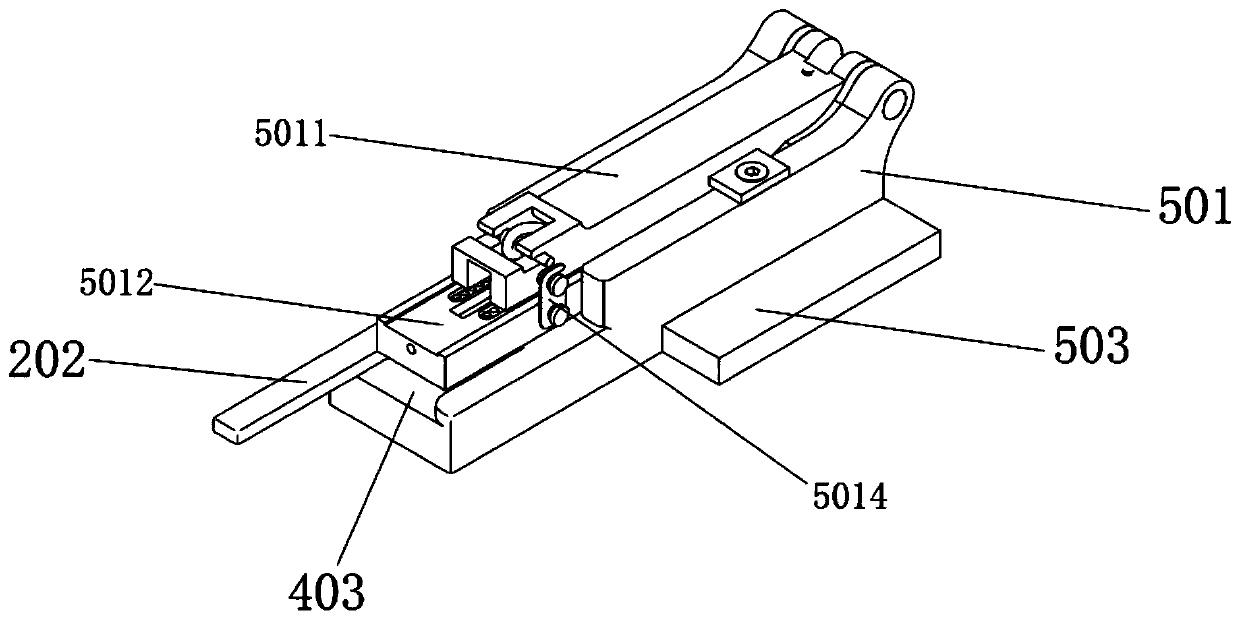

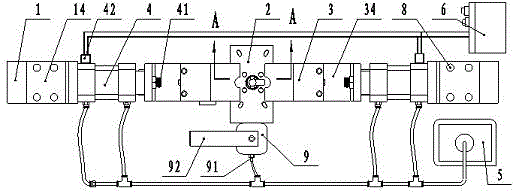

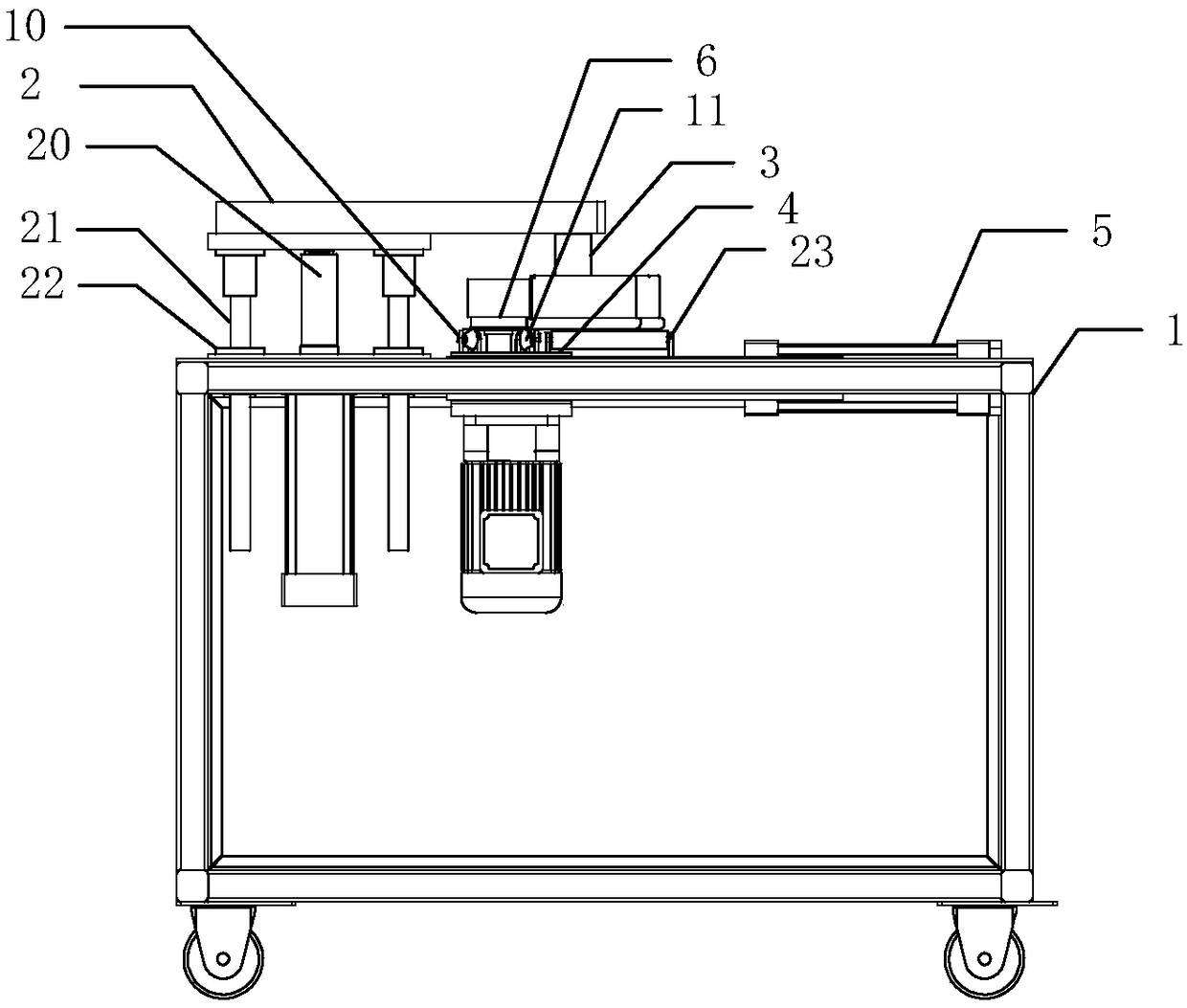

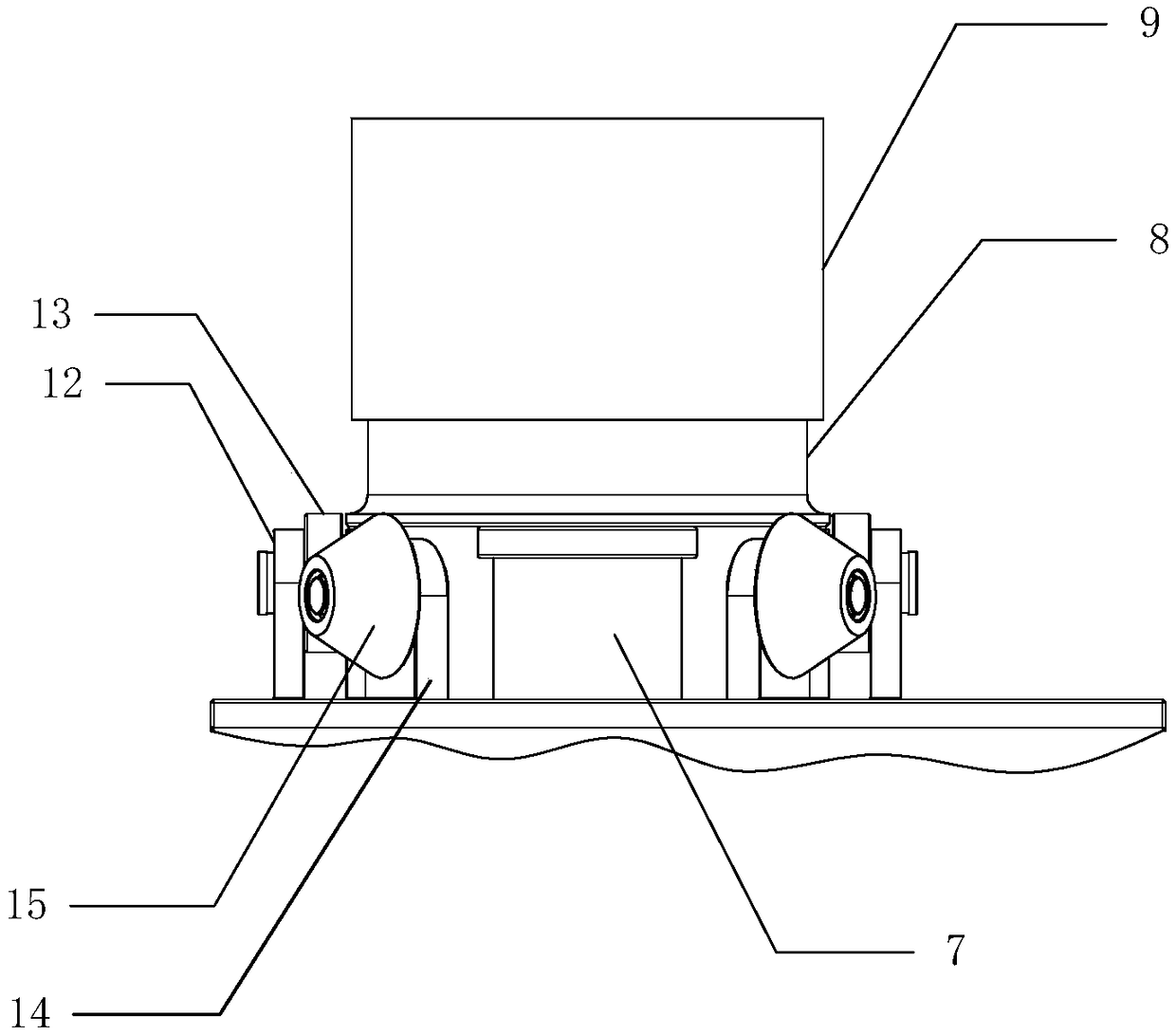

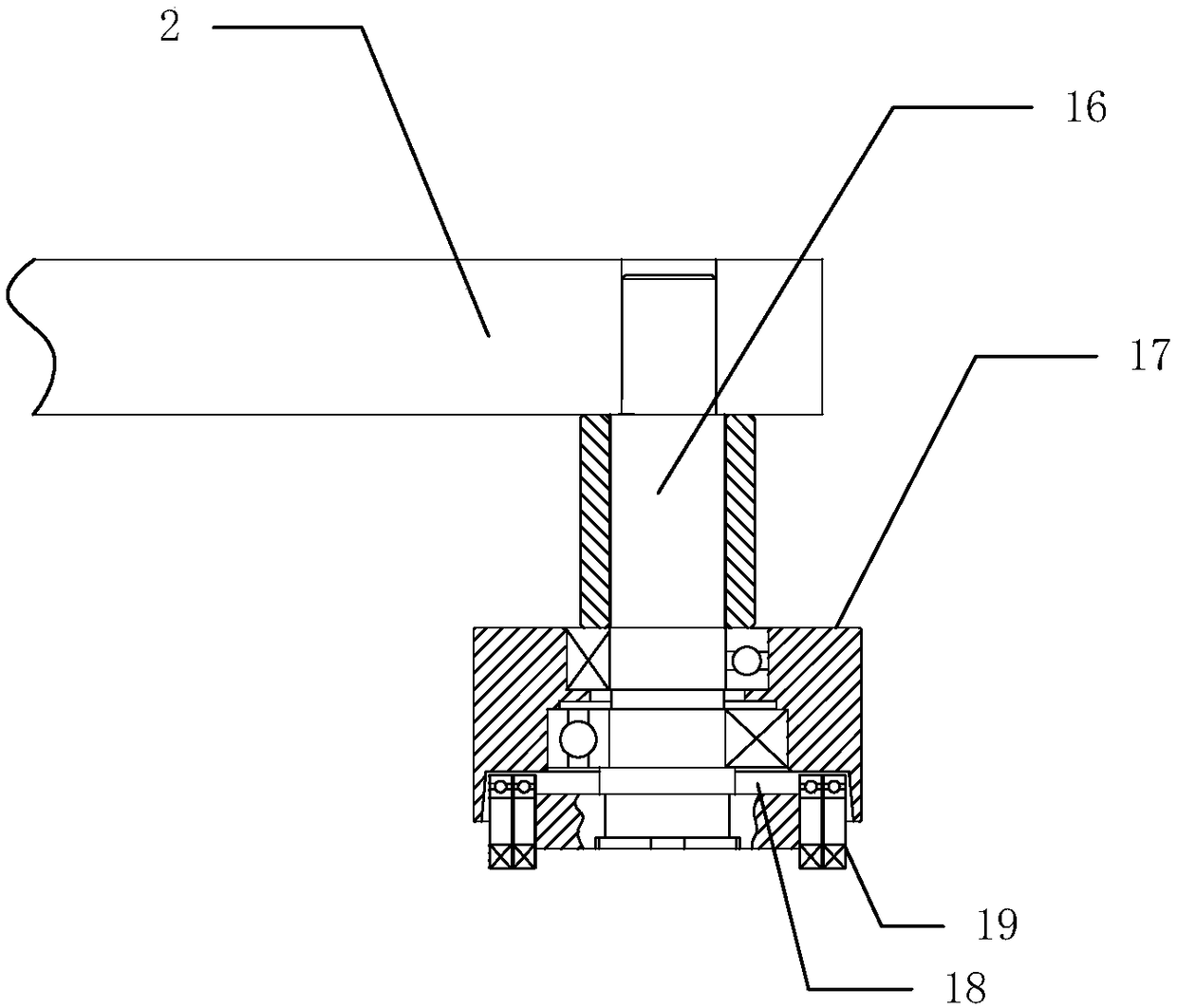

The invention provides a multipoint rivet-free automatic riveting machine, comprising an automatic riveting device, a machine frame and a positioning operating platform, wherein the automatic riveting device comprises a push device, a riveting convex-concave mould base, a demoulding device and a riveting convex-concave mould; the riveting convex-concave mould base is fixedly arranged on the push device; the riveting convex-concave mould is fixed on the riveting convex-concave mould base through the demoulding device; the automatic riveting device is arranged on the machine frame; the positioning operating platform comprises an operating platform, a servo positioning device, a pneumatic rotating positioning device and a pneumatic positioning device; the servo positioning device and the pneumatic positioning device are sequentially arranged at one side of the operating platform connected with the machine frame; and the pneumatic rotating positioning device is arranged at the side of theoperating platform and is next to the pneumatic positioning device. By adopting the multipoint rivet-free automatic riveting machine provided by the invention, multipoint riveting automation on a framework sectional bar is realized, and production efficiency is improved; riveting pressure consistency is realized, and product riveting quality is stabilized; and automatic riveting of framework sectional bars with different specifications is realized by adopting one riveting machine.

Owner:TIANJIN RENYIHE AUTOMATION TECH

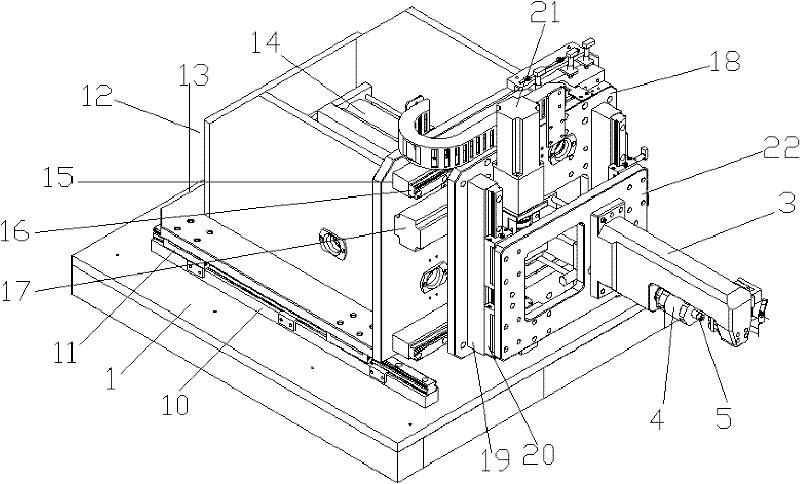

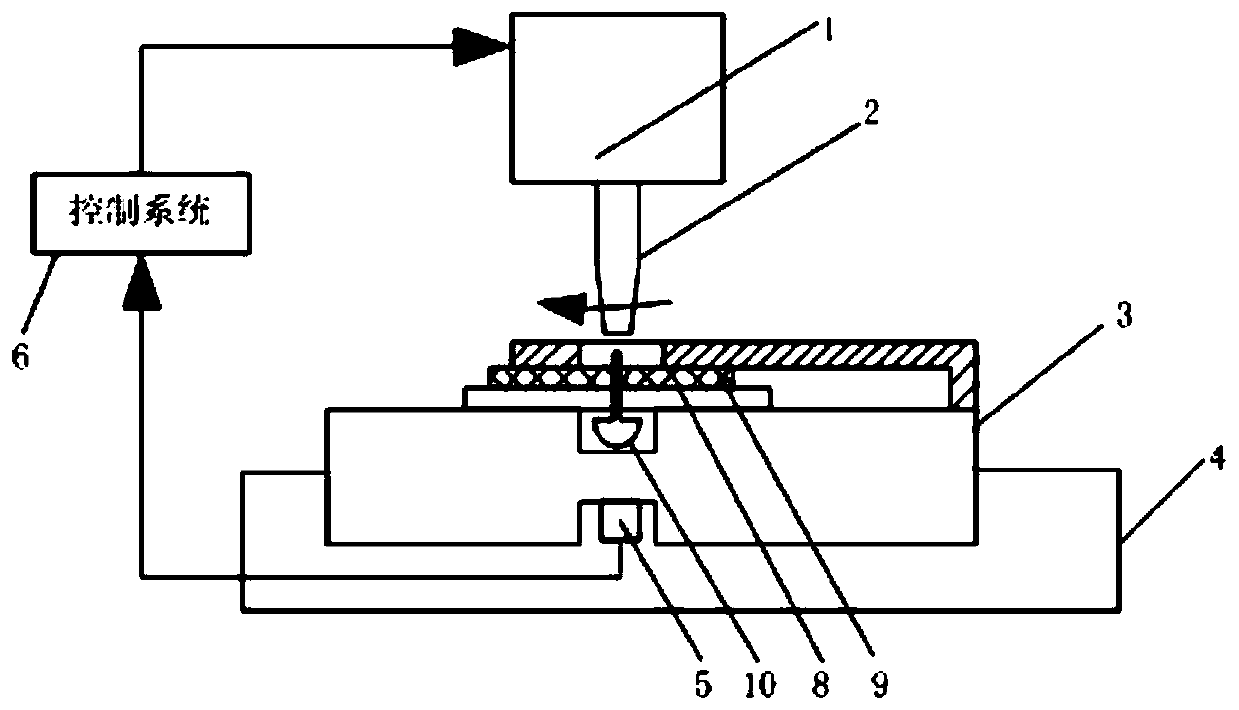

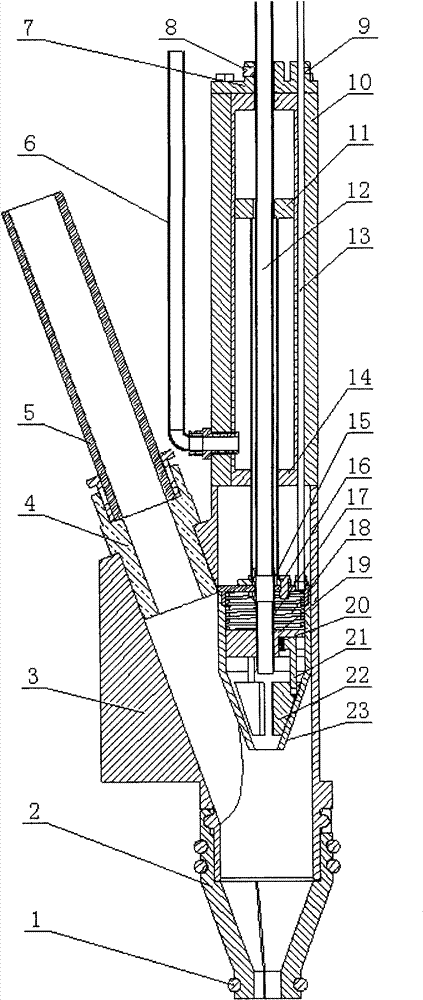

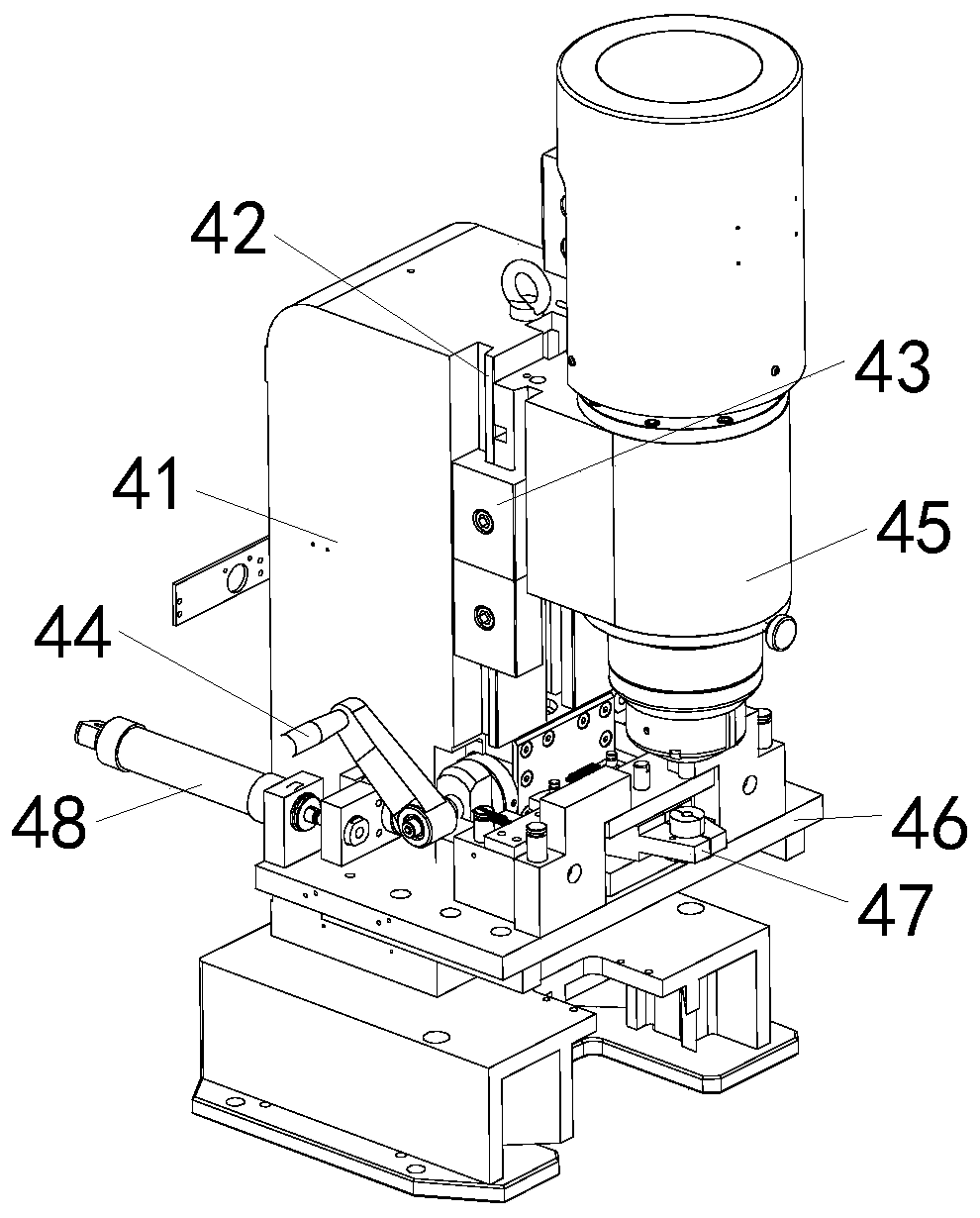

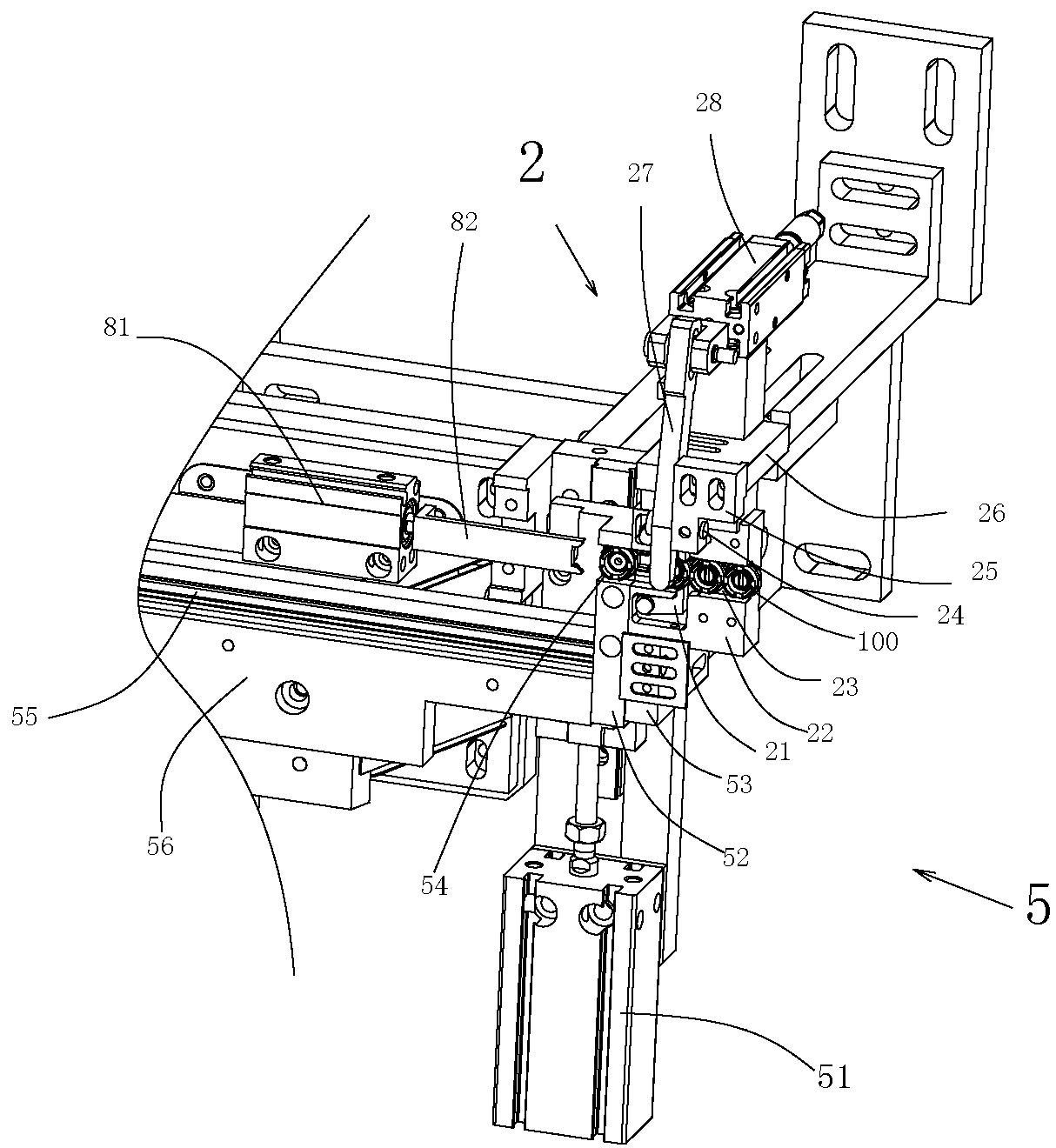

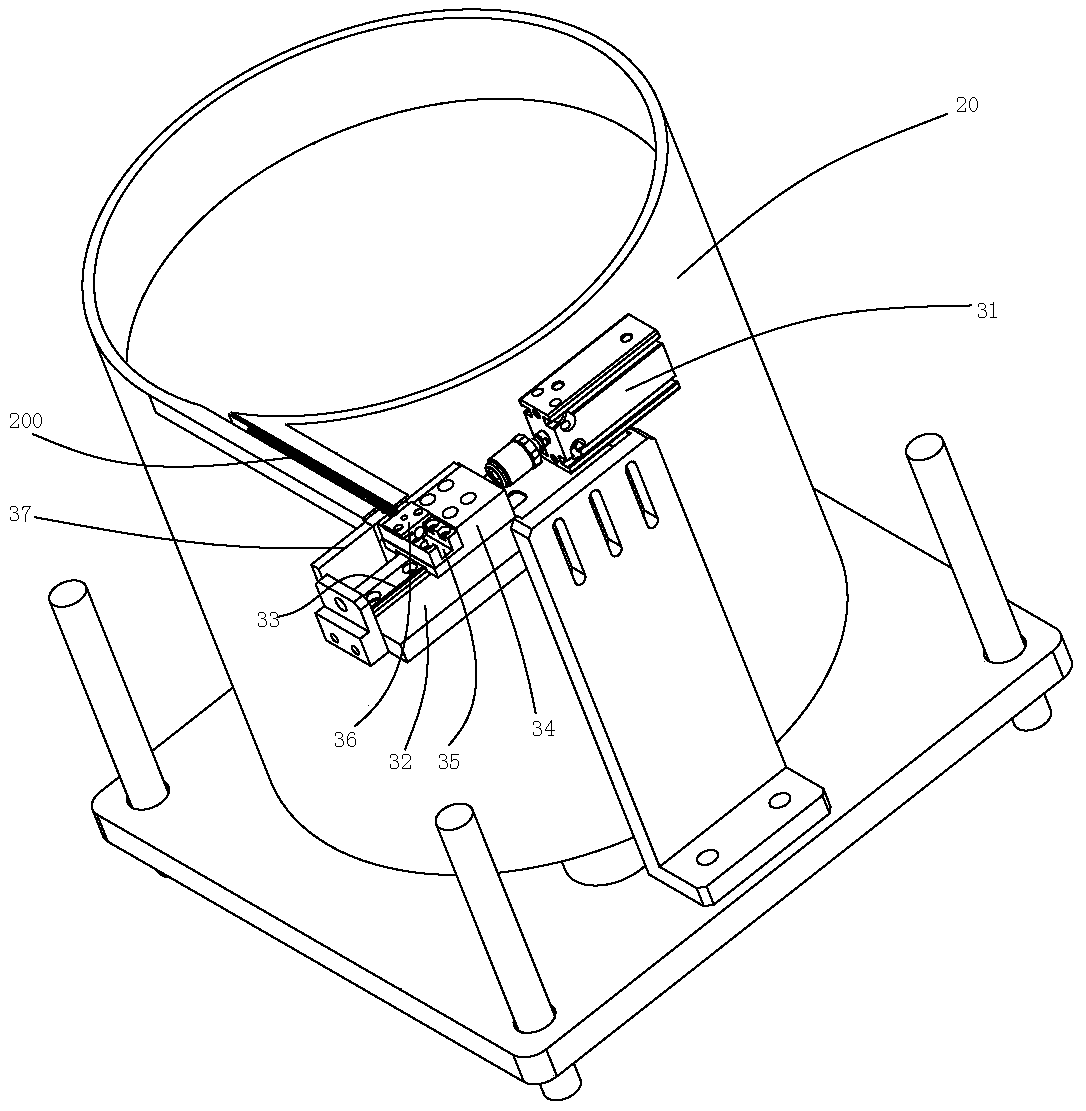

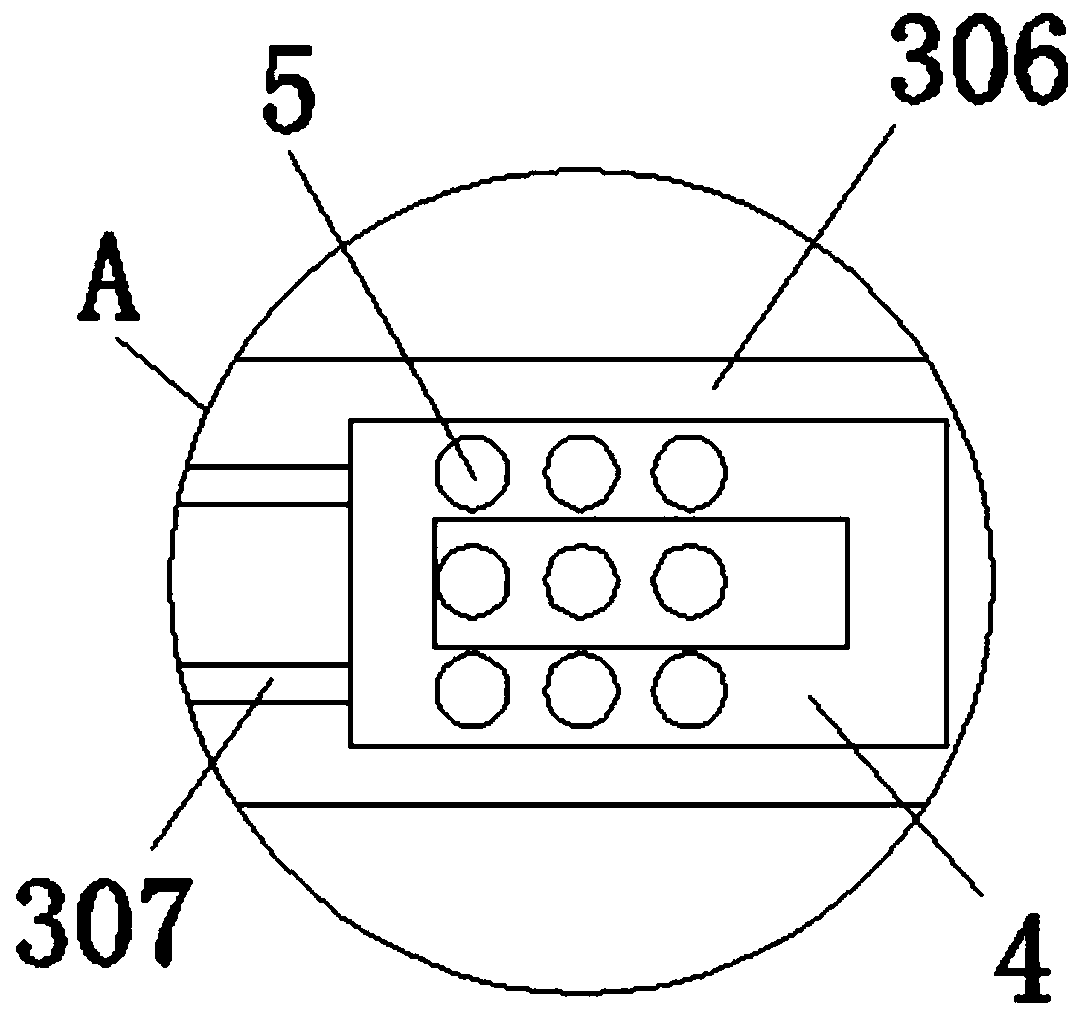

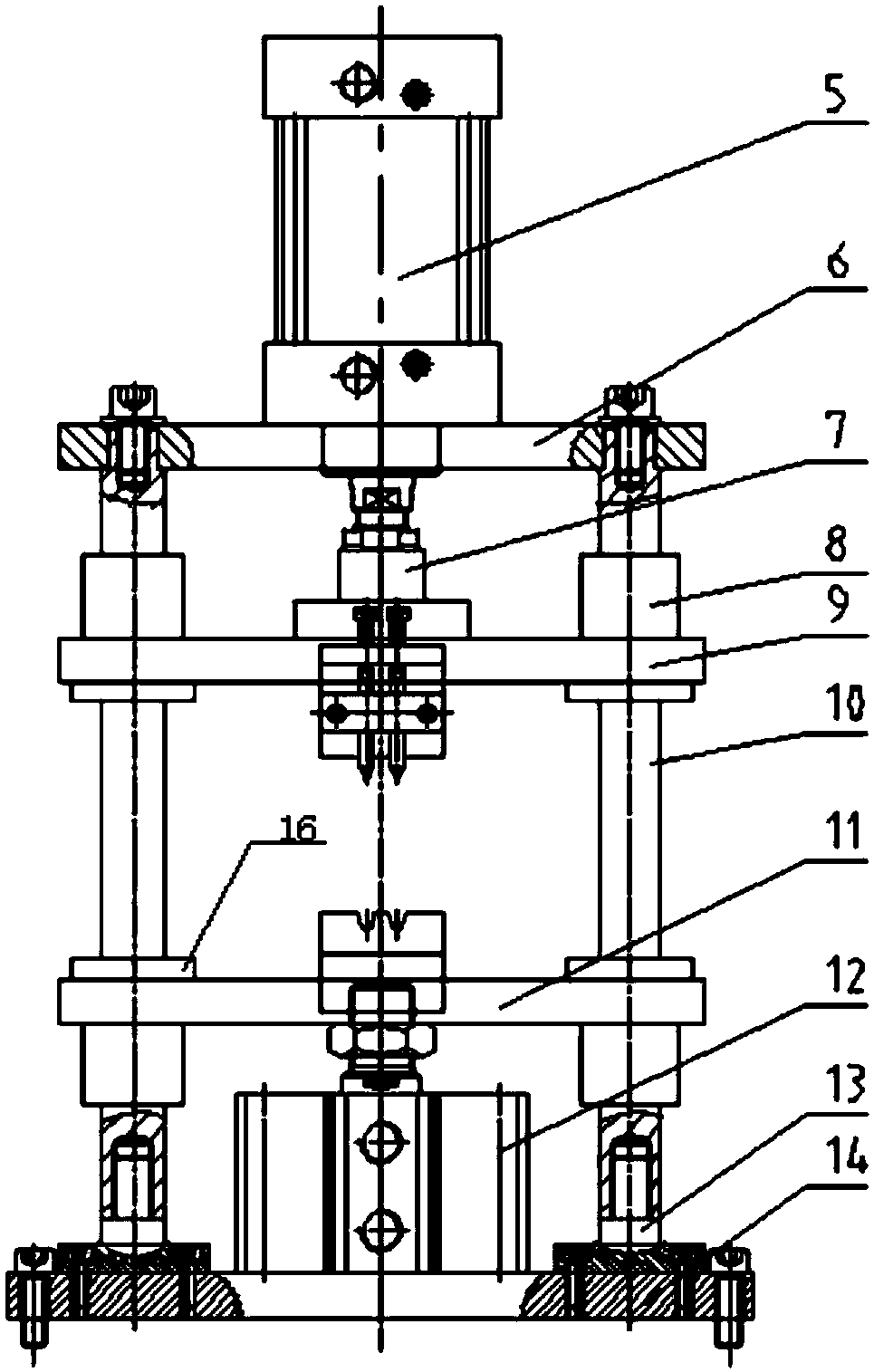

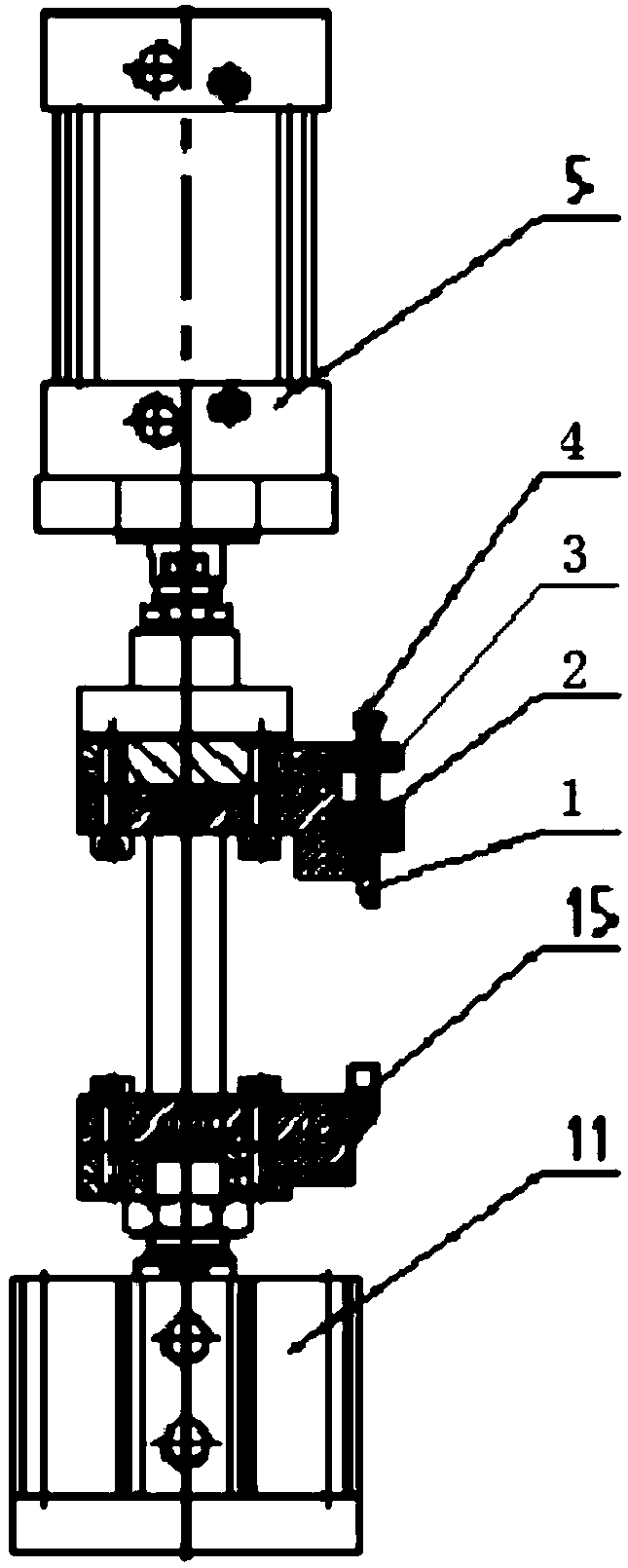

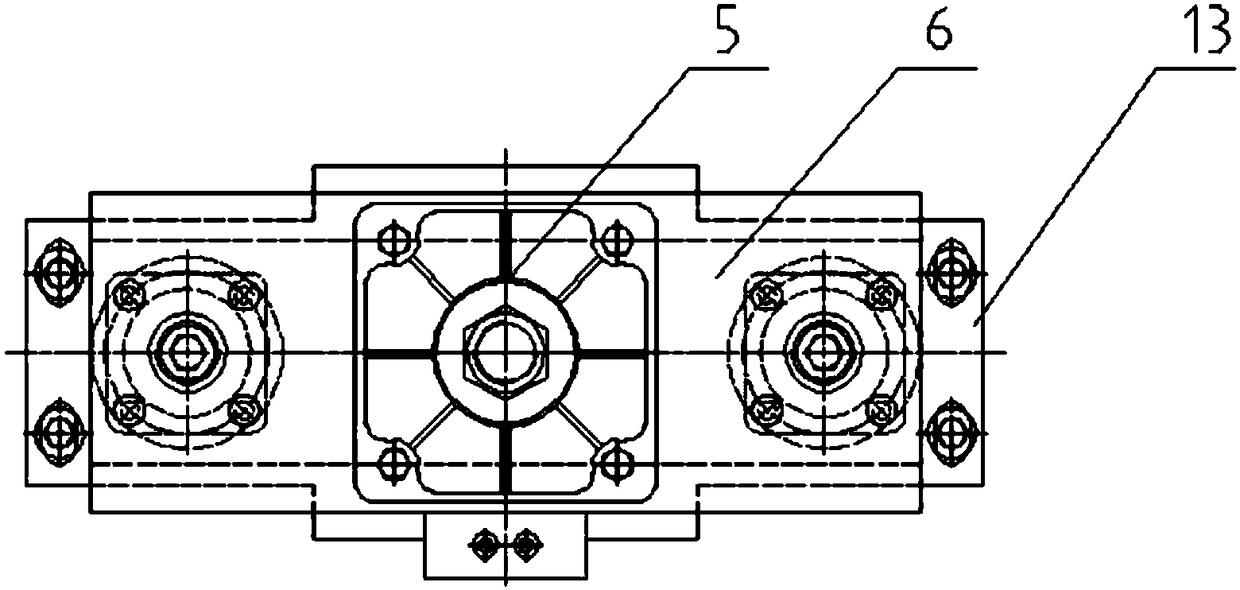

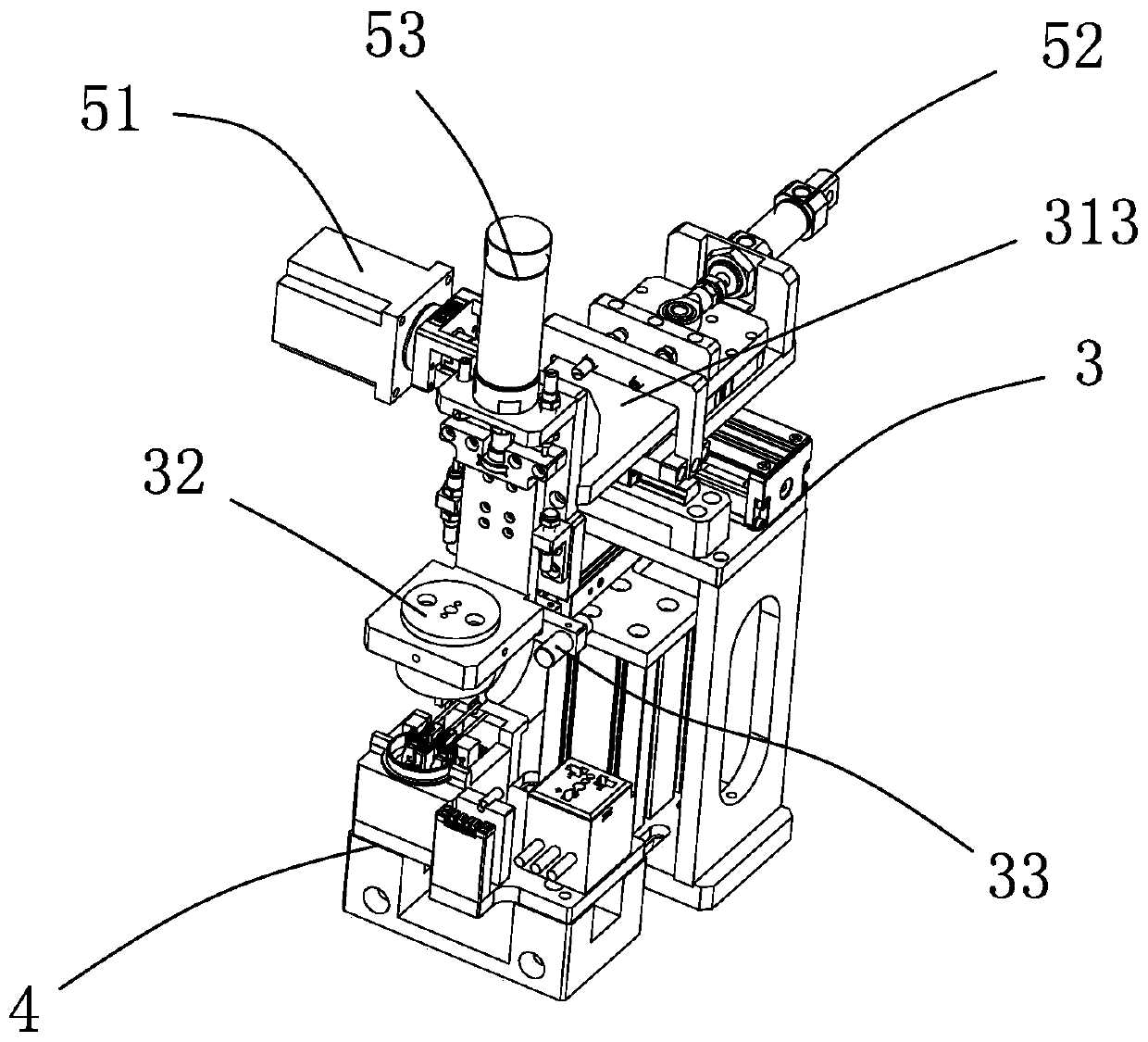

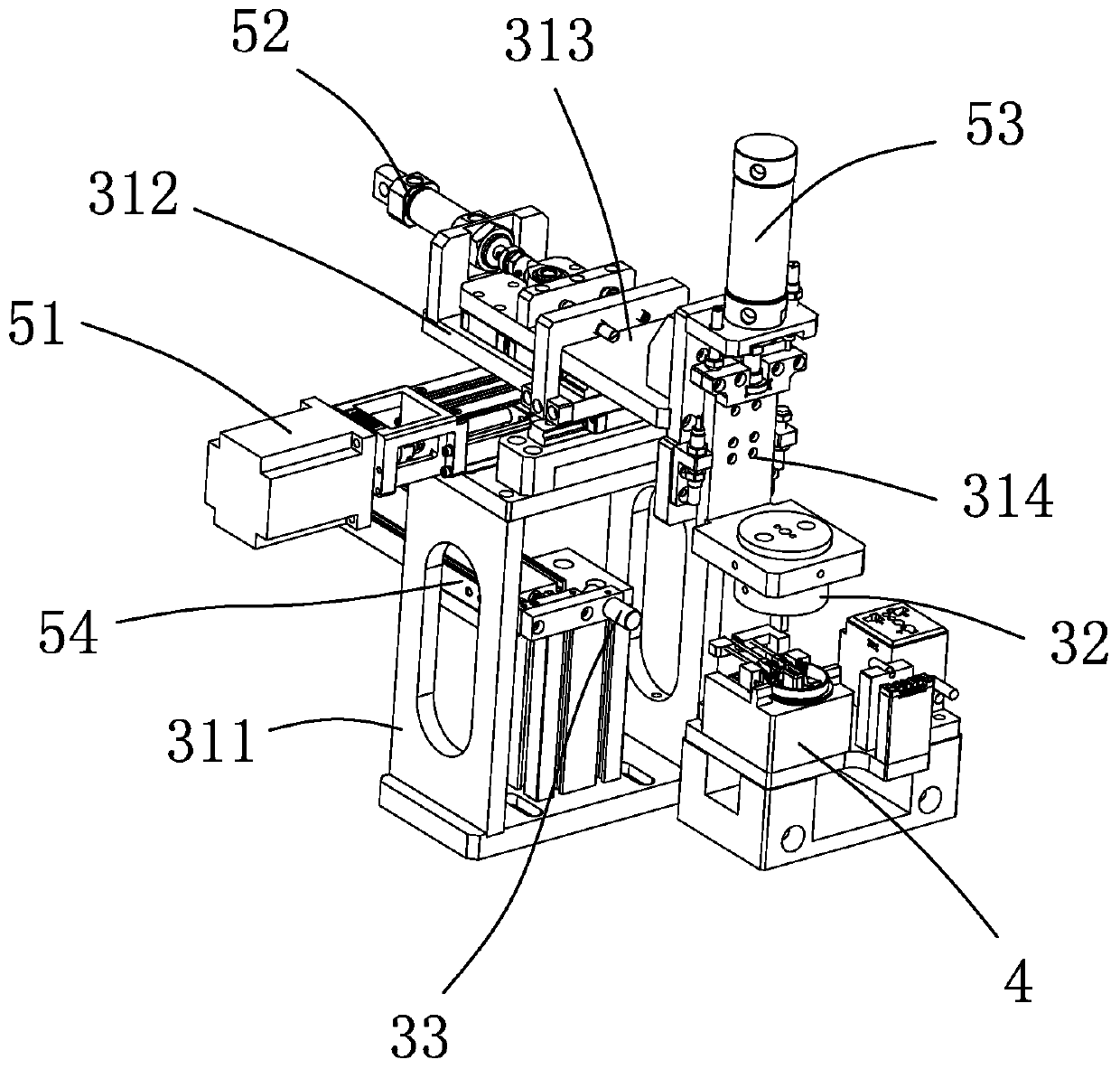

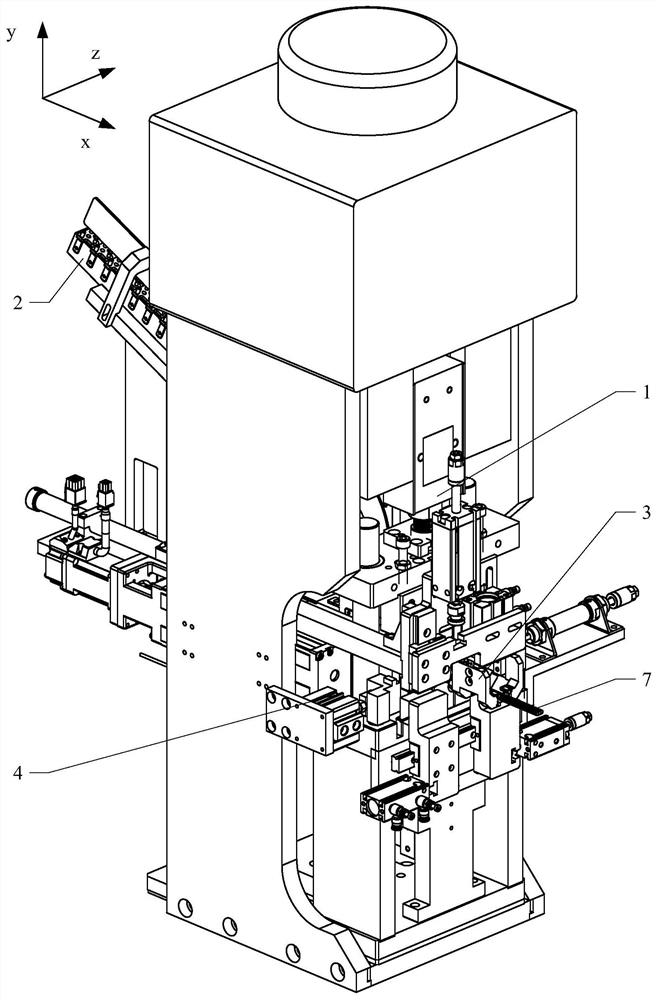

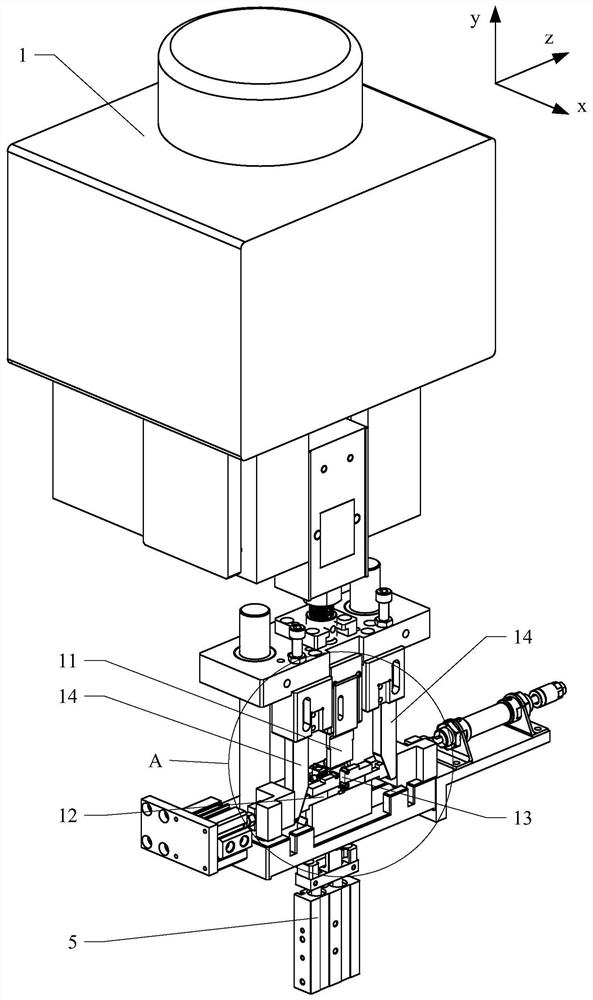

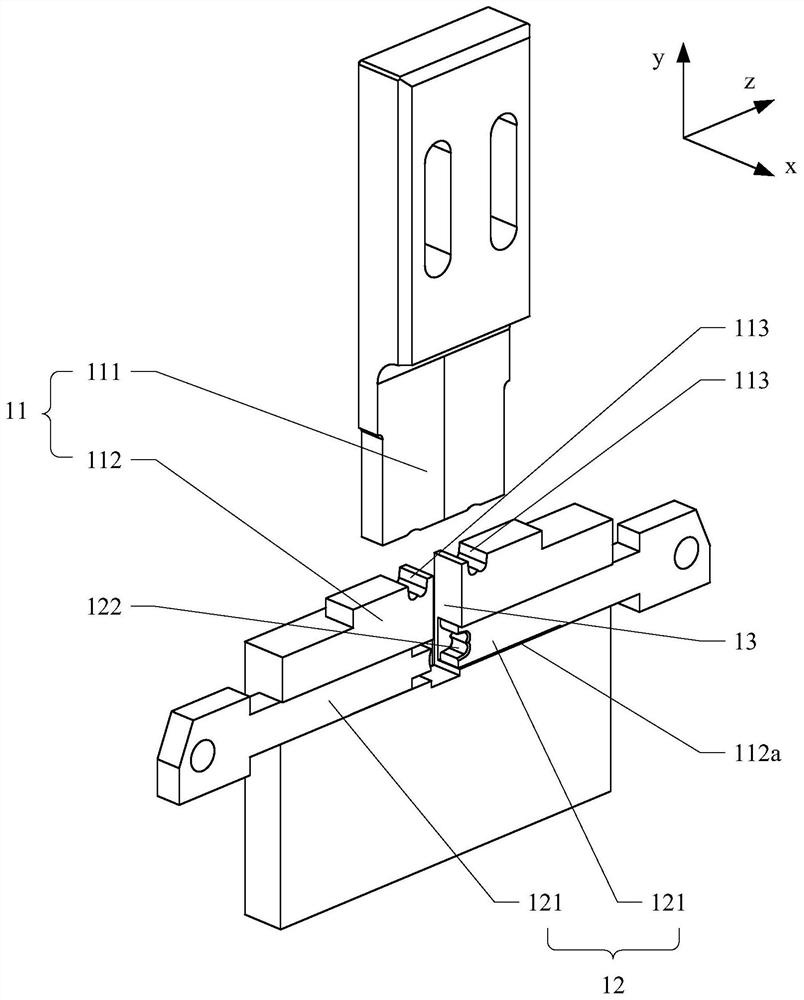

Automatic riveting device suitable for satellite disc type conductive slip ring ultra-thin reed

ActiveCN110504609AAutomatic riveting realizationImprove molding efficiencyBrushes manufactureControl systemEngineering

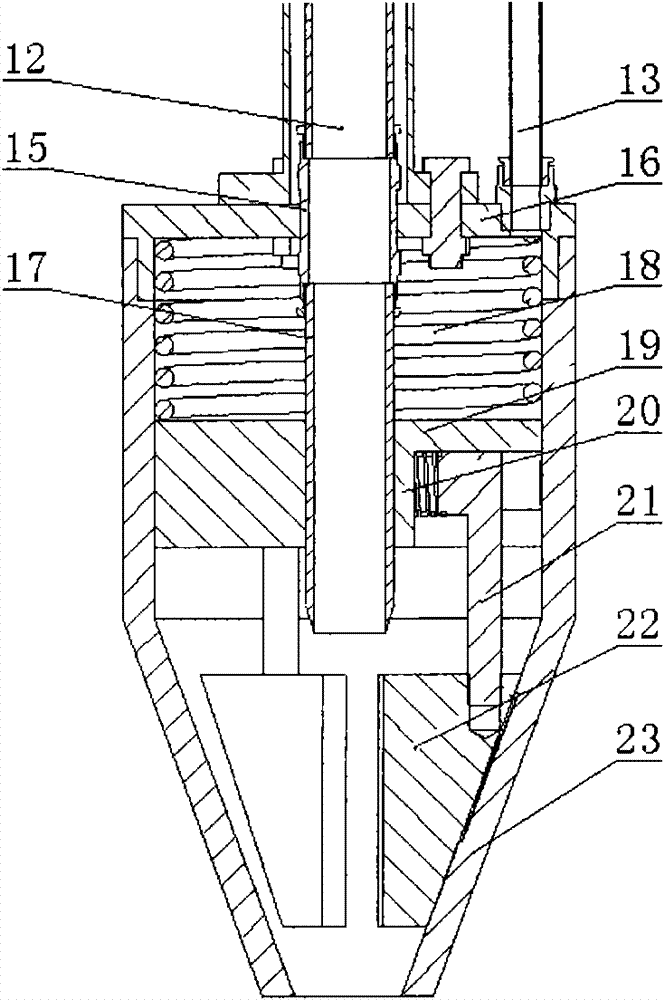

The invention relates to an automatic riveting device suitable for a satellite disc type conductive slip ring ultra-thin reed. The device comprises a riveting machine, a riveting head, a riveting fixed clamping tool, a precise driving platform, a sensor, a control system and the like. A rivet, the reed and a printed brush plate are accurately positioned through the riveting fixed clamping tool; the riveting machine is controlled by the control system, the riveting head is tightly absorbed by means of magnetic force, and the riveting head is pressed to a certain position through high-speed rotation; the sensor is used for feeding back riveting force to the control system in real time to finally achieve riveting of a fixed force value; after one point is riveted, the control system is used for controlling the precise driving platform to accurately move to a next riveting point, and the operation is repeated, so as to realize automatic riveting of the reed. According to the automatic riveting device in the invention, positioning and fastening of the reed are realized, through force feedback control, the pressing quality consistency of the riveting points is guaranteed to be good, andthe reliability is guaranteed to be high; and through the precise driving platform, automatic riveting of a group of reeds is realized, and the product quality precision and efficiency are improved.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

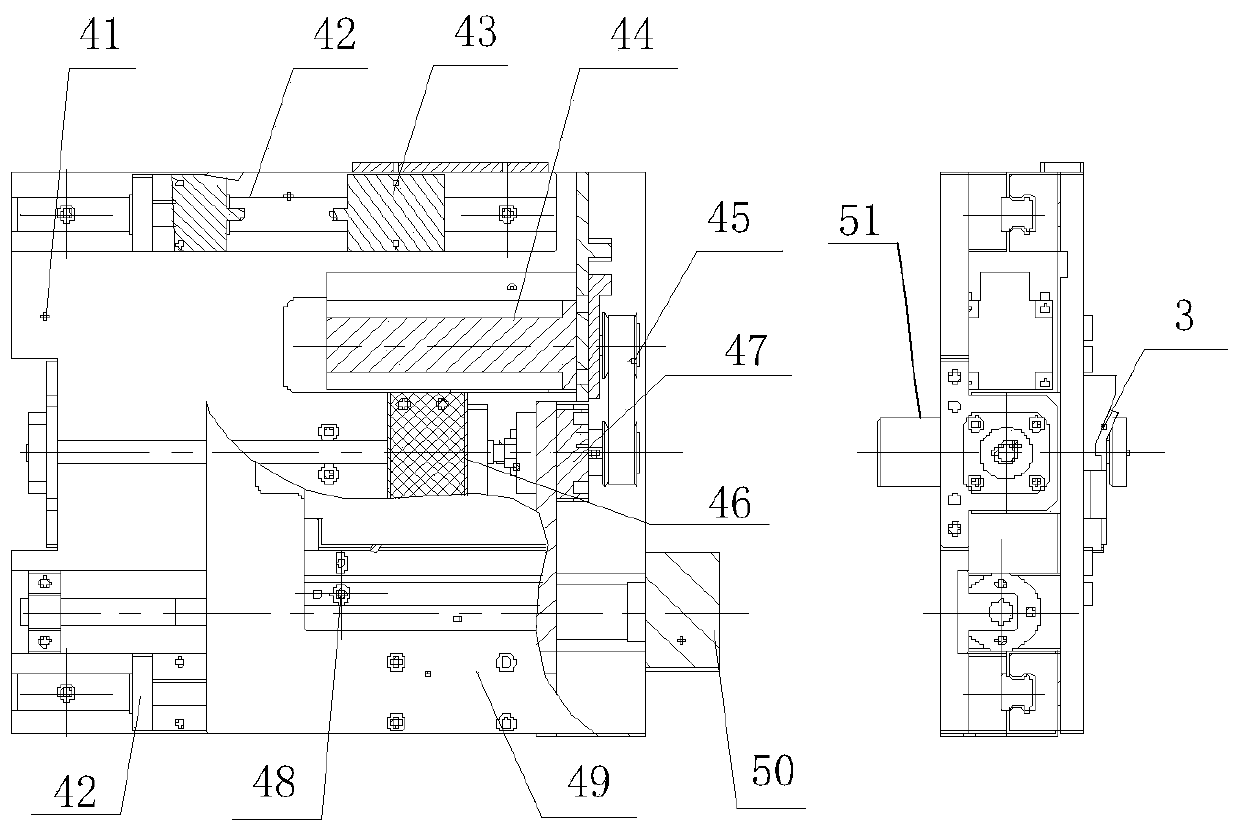

Riveting tube file binding machine capable of achieving automatic cutting-riveting rivet taking

InactiveCN112476574AEasy accurate and fast automatic resectionRealize automatic rivetingMetal working apparatusEngineeringRivet

The invention discloses a riveting tube file binding machine capable of achieving automatic cutting-riveting rivet taking. The riveting tube file binding machine comprises a tube cutting accessory which is selected to be used during rivet taking, and the tube cutting accessory comprises a rivet taking positioning needle. The rivet taking positioning needle comprises an upper guiding part used forbeing vertically aligned with a drilling tool and a lower inserting part used for being inserted into a riveting tube from an upper riveting tube head of a riveting tube already riveted to a bound file in a hot pressing manner and enabling the riveting tube to be vertically aligned with the drilling tool, and the upper end of the lower inserting part is connected to the bottom of the upper guidingpart. Through positioning of the rivet taking positioning needle and a positioning base, the riveting tube needing to be dismounted and the drilling tool are kept concentric and coaxial, after the upper riveting tube head is cut off, the upper riveting tube head adhering to the drilling tool is popped out of the drilling tool through a paper pressing plate in the upward moving and resetting process of the drilling tool, full-automatic rivet taking is achieved, the upper riveting head of the rivet tube can be easily, accurately, quickly and automatically cut off, the structure is simple, costis low, and use is convenient.

Owner:东莞市骏能电子科技有限公司

Self-starting radial riveting work station and riveting method

The invention discloses a self-starting radial riveting work station and a riveting method. The self-starting radial riveting work station comprises a worktable, a riveting clamp, a riveting machine and a control system, wherein the riveting clamp and the riveting machine are arranged on the worktable; the riveting machine is arranged above the riveting clamp; the worktable is provided with a safety raster; the riveting clamp comprises pressing air cylinders and a sliding clamp, the pressing air cylinders are arranged on two sides of the sliding clamp, the sliding clamp is provided with a proximity sensor, and piston rods of the pressing air cylinders are provided with pressing heads; and the control system is connected with the safety raster, the pressing air cylinders, the proximity sensor and the riveting machine. The control system controls the riveting machine to realize automatic riveting, safety of workers is guaranteed, and the safety of the riveting process is improved.

Owner:湖北航宇精工科技有限公司

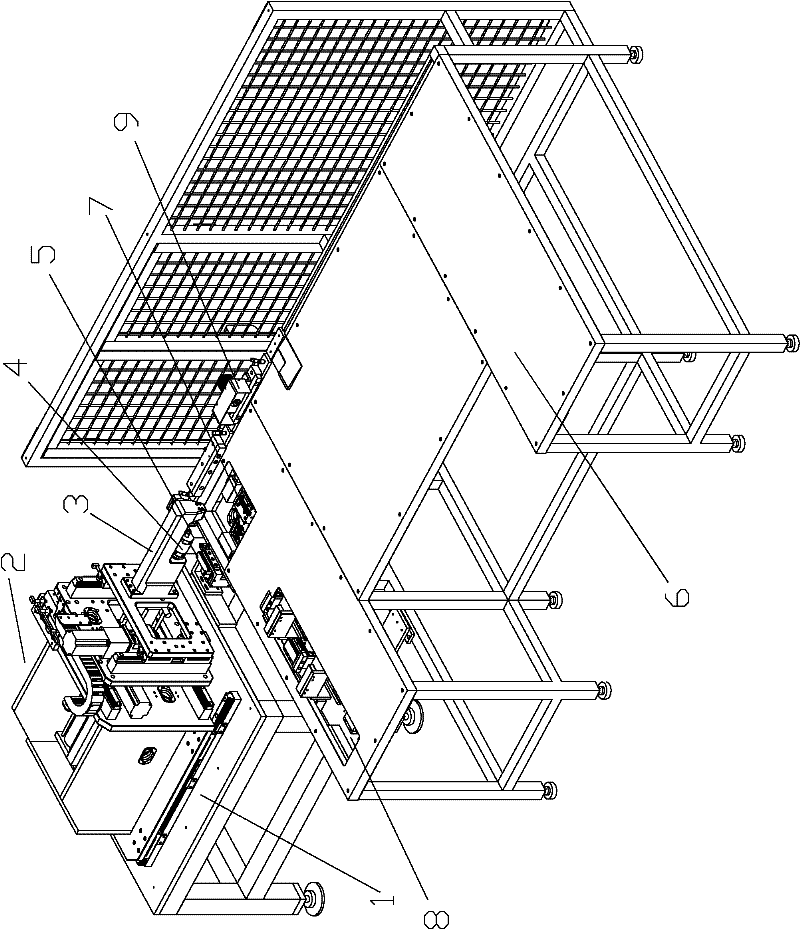

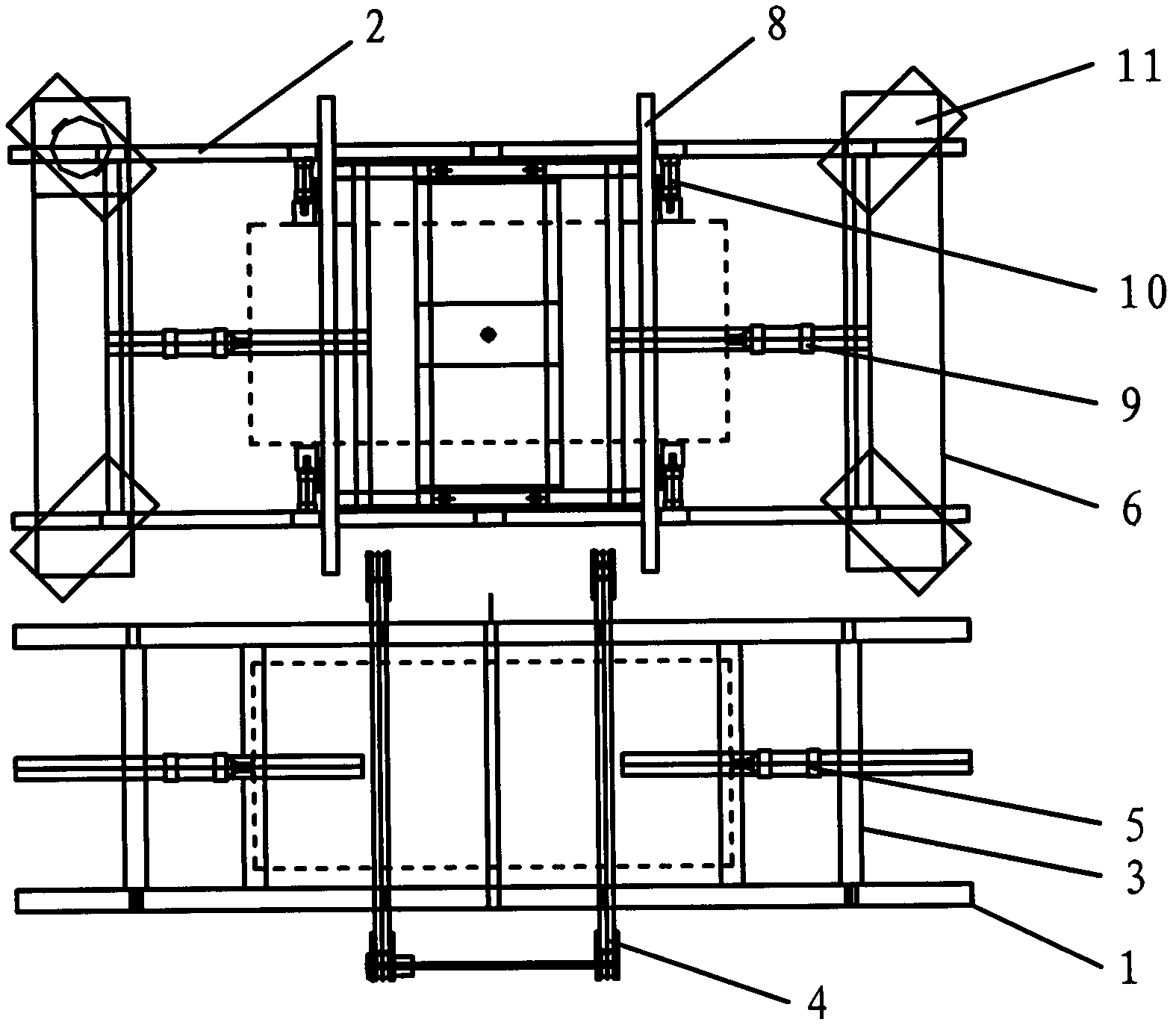

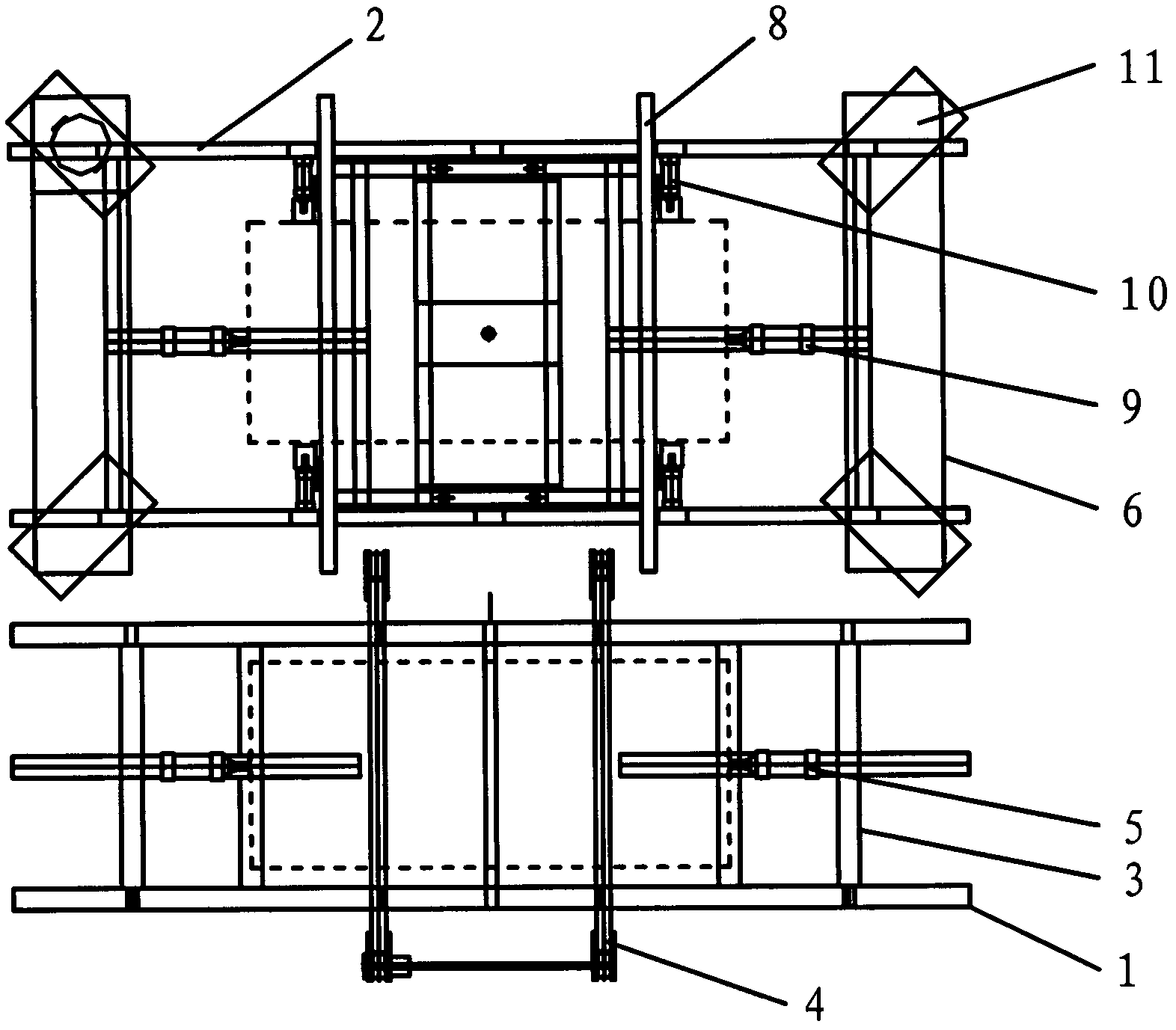

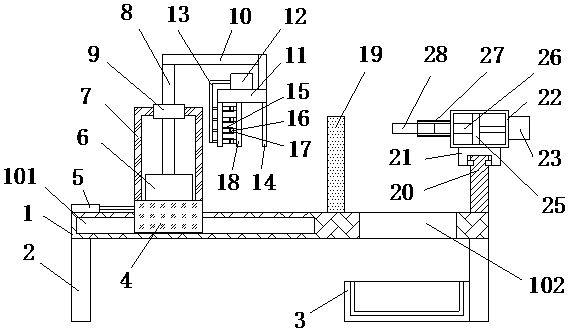

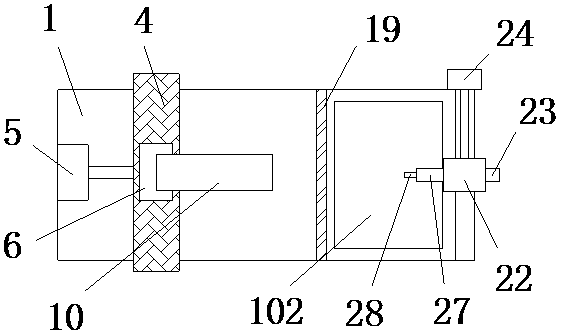

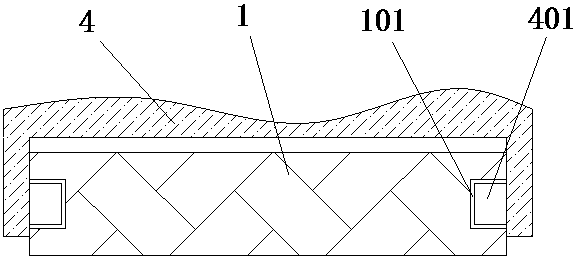

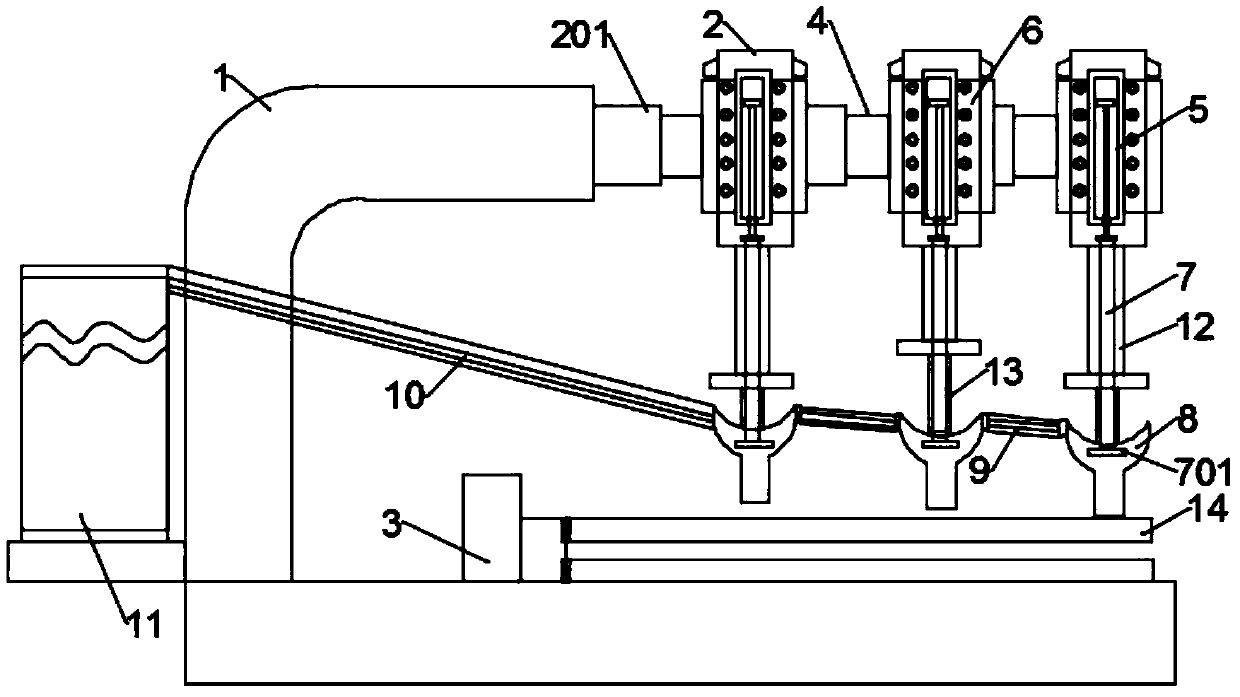

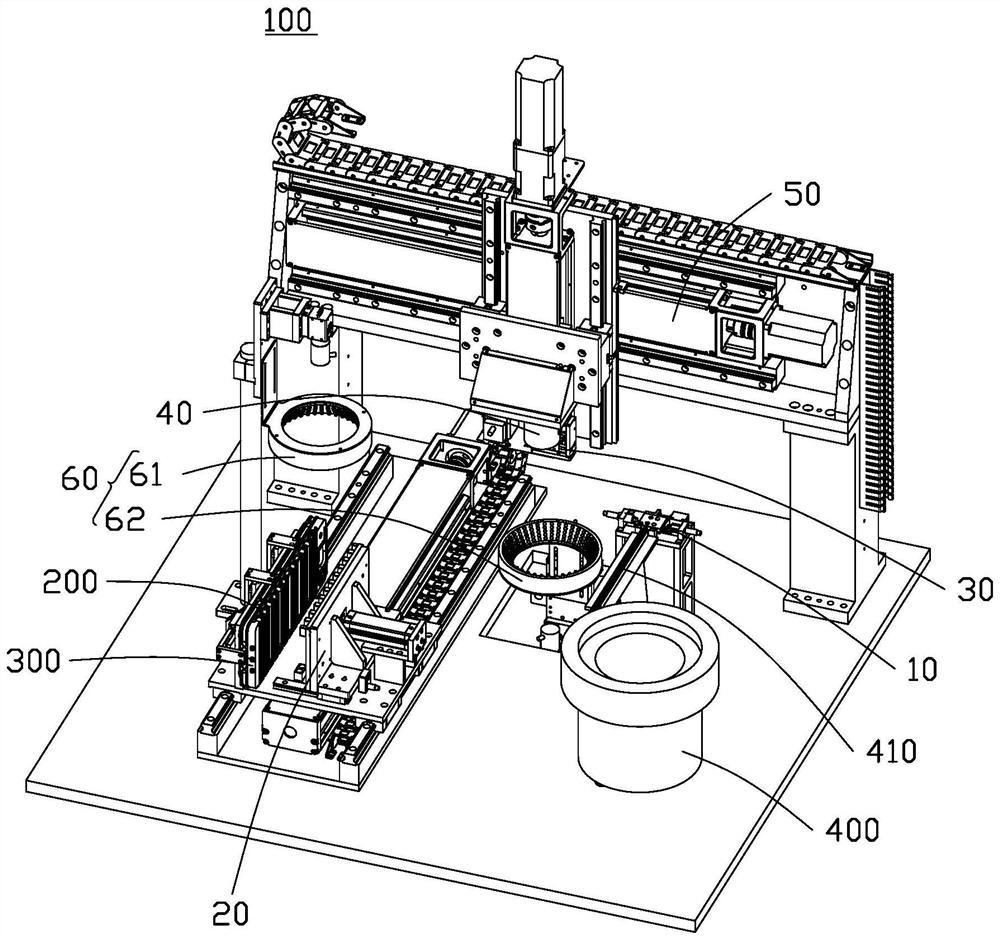

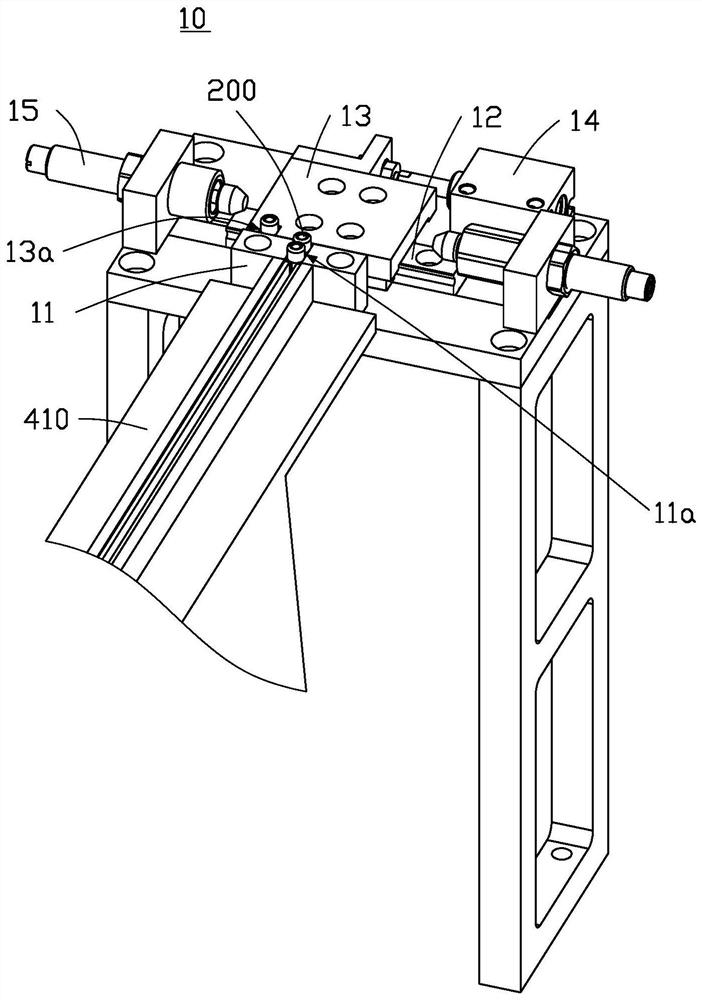

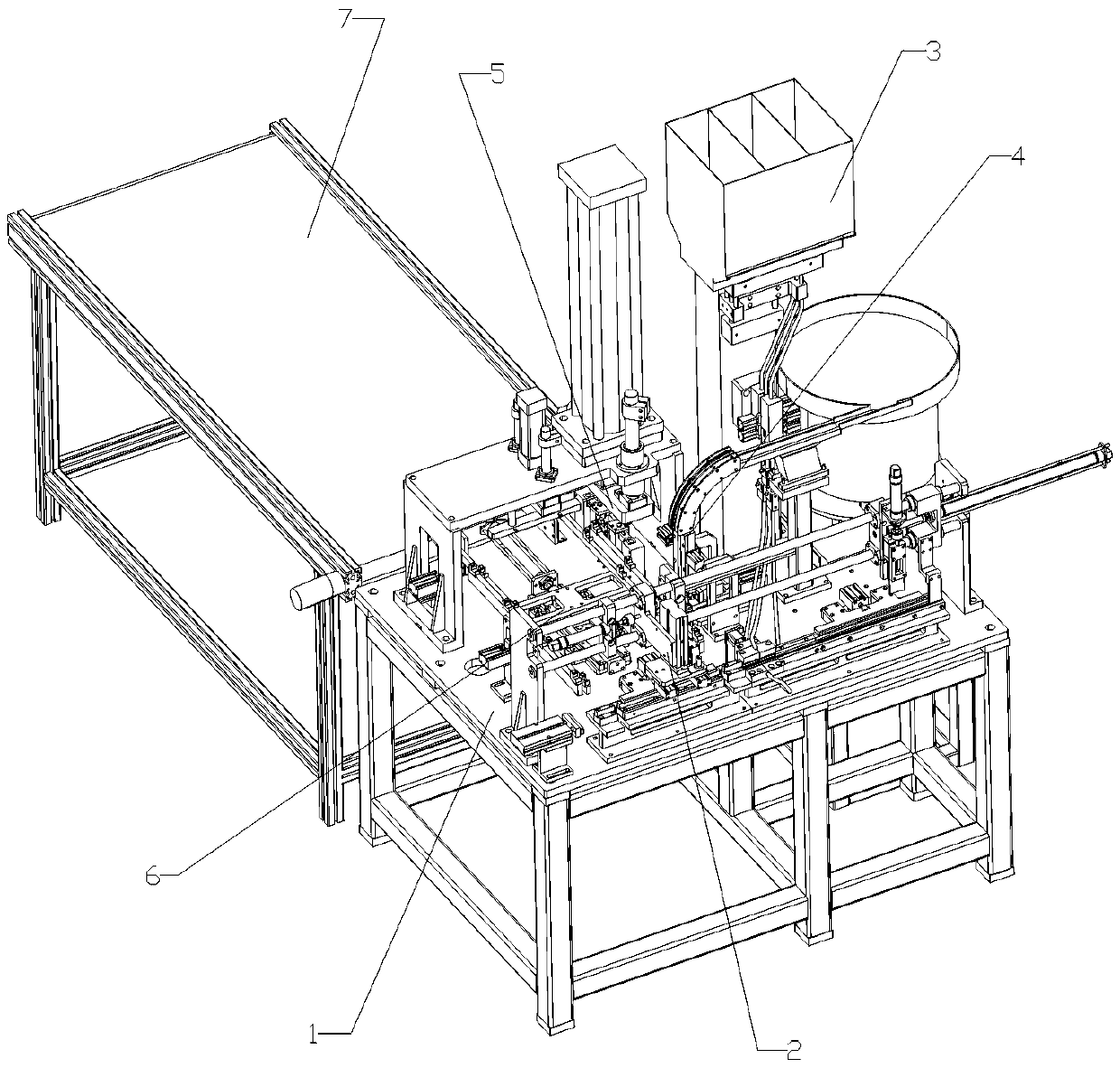

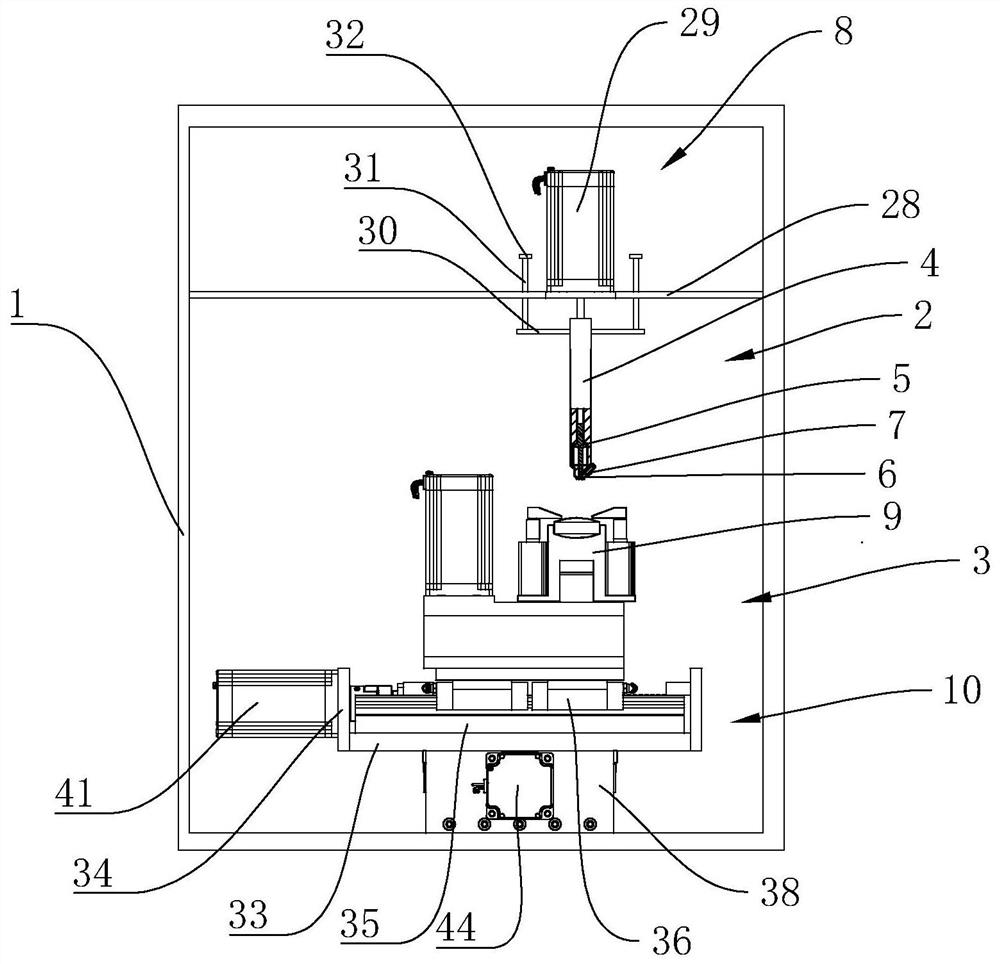

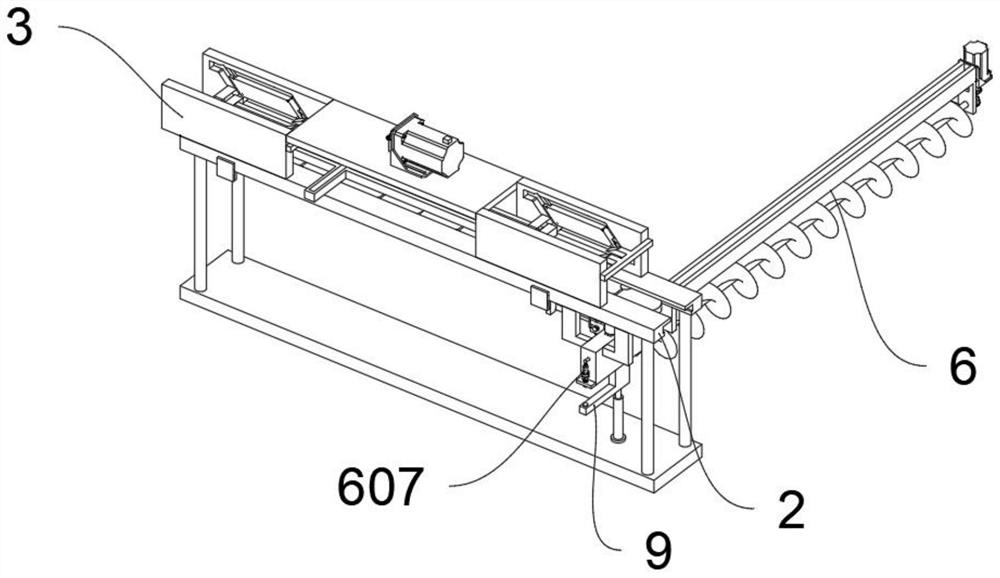

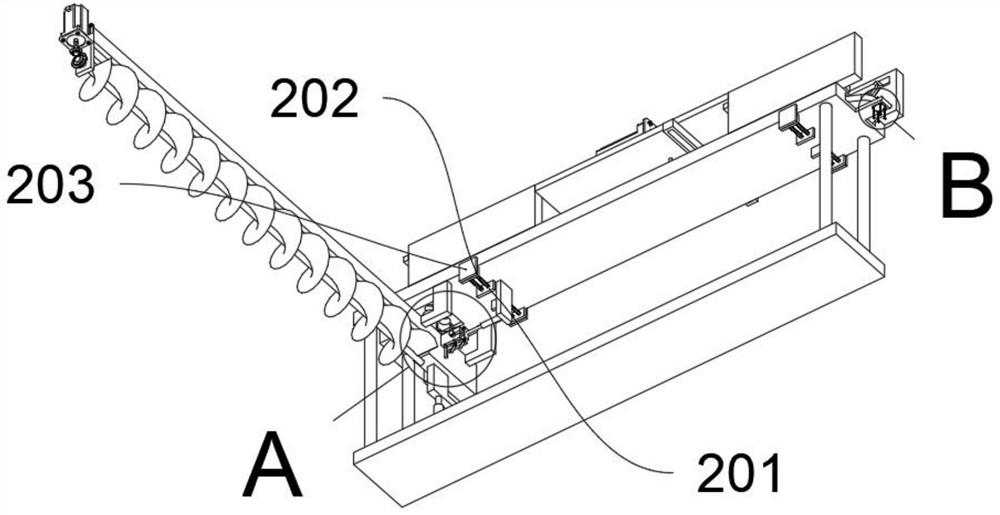

Automatic assembly machine of solar panel frame

InactiveCN102615214ARealize automatic combinationRealize automatic rivetingMetal-working apparatusPower beltDiagonal

The invention discloses an automatic assembly machine of a solar panel frame, which comprises a preassembly table and an assembly table. The preassembly table comprises a machine frame, a power belt is arranged at the middle position of the top of the machine frame, and pre-positioning cylinders are arranged on the two sides of the power belt. The assembly table comprises a machine frame, a belt machine is arranged at the middle position of the top of the machine frame, a lifting cylinder is arranged at the bottom of the belt machine, a left location cylinder and a right location cylinder are arranged at the middle position of the belt machine, a turning plate cylinders for location in a front-and-back mode are arranged at two ends of the two sides of the belt machine, four riveting oil cylinders are arranged at four diagonal positions of the belt machine, adjustable cylinders are arranged at the bottoms of the riveting oil cylinders, and an inductive switch is arranged on the assembly table. The automatic assembly machine has the advantages of achieving automatic assembly and automatic riveting pressing of frames, and being good in product quality and high in production efficiency.

Owner:CHANGZHOU MEIRUN SOLAR

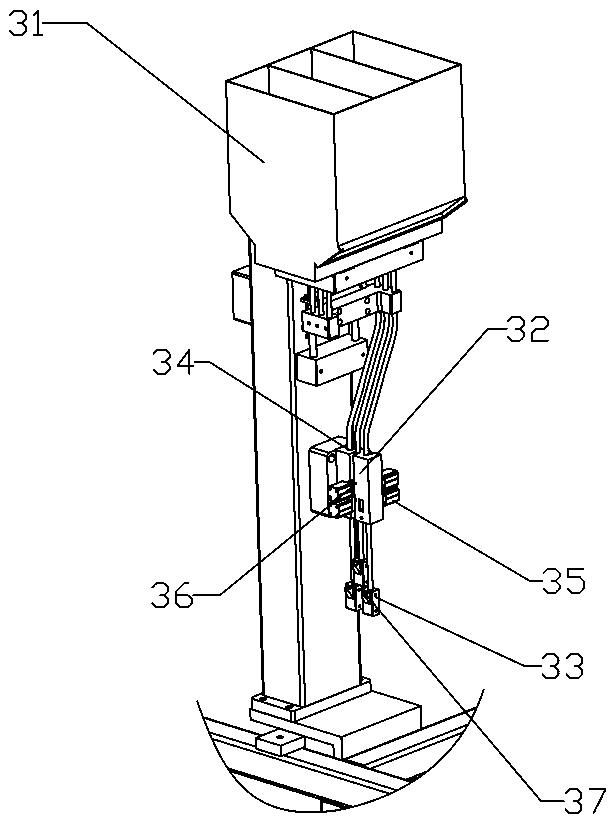

Automatic rivet pulling device

The invention provides an automatic rivet pulling device which comprises a rivet pulling cavity, a rivet drawing chuck, a power device and a core discharging pipe, wherein the rivet pulling cavity provides a space for the rivet drawing chuck, and rivets are fed in by virtue of an external rivet feeding pipe; driven by the power device, the rivet drawing chuck clamps, pushes and draws the rivets; and finally a drawn rivet mandrel is discharged from the core discharging pipe. By adopting the automatic rivet pulling device provided by the invention, automatic rivet pressing, rivet drawing and core discharging can be carried out under the control of a control system, automatic rivet drawing can be realized, and the automatic rivet pulling device can be integrated into an automatic assembling line. And a corresponding control system adopts a sensor to realize control, thus the control type is simple, convenient and reliable. An elastic clamping piece and a three-jaw structure are adopted, multiple rivets in different specifications can be accepted, and the generality is higher; and the whole structure size is compact, thus the automatic rivet pulling device provided by the invention can be applicable to multiple workplaces.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Riveting equipment

InactiveCN110038968ARealize automatic rivetingSave human effortMetal working apparatusBiochemical engineeringActuator

The invention provides riveting equipment. The riveting equipment comprises a machine frame, a workbench arranged on the machine frame, a feeding and discharging mechanism arranged on the workbench, apositioning mechanism arranged on the feeding and discharging mechanism, a riveting mechanism arranged above the feeding and discharging mechanism, a supporting mechanism arranged below the rivetingmechanism, a height testing mechanism arranged on one side of the feeding and discharging mechanism and a waste box arranged below the workbench. The feeding and discharging mechanism is used for feeding of a product, the positioning mechanism is used for positioning the product part, and comprises a rod piece, a piston and a gasket, specifically, the piston and the gasket are arranged on the rodpiece in a sleeving mode, after the product is jacked by the supporting mechanism, the gasket and the piston are riveted to the rod piece by the riveting mechanism, a product is obtained, then the product is moved to the height testing mechanism, so that the height of a riveting point is detected, if the product is tested to be qualified, next production is performed, if the product is tested to be not qualified, the product is placed into the waste box, the riveting equipment achieves automatic riveting of an actuator, and labor is saved.

Owner:SUZHOU UNIV OF SCI & TECH

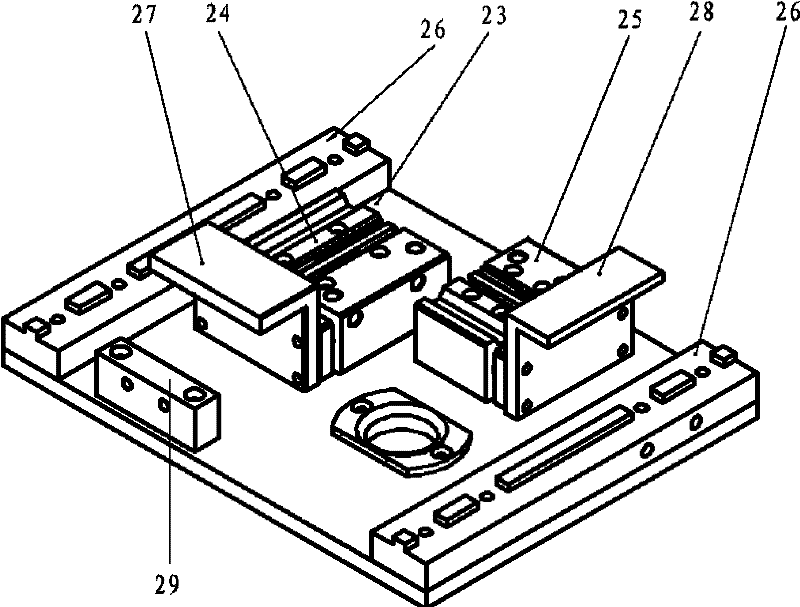

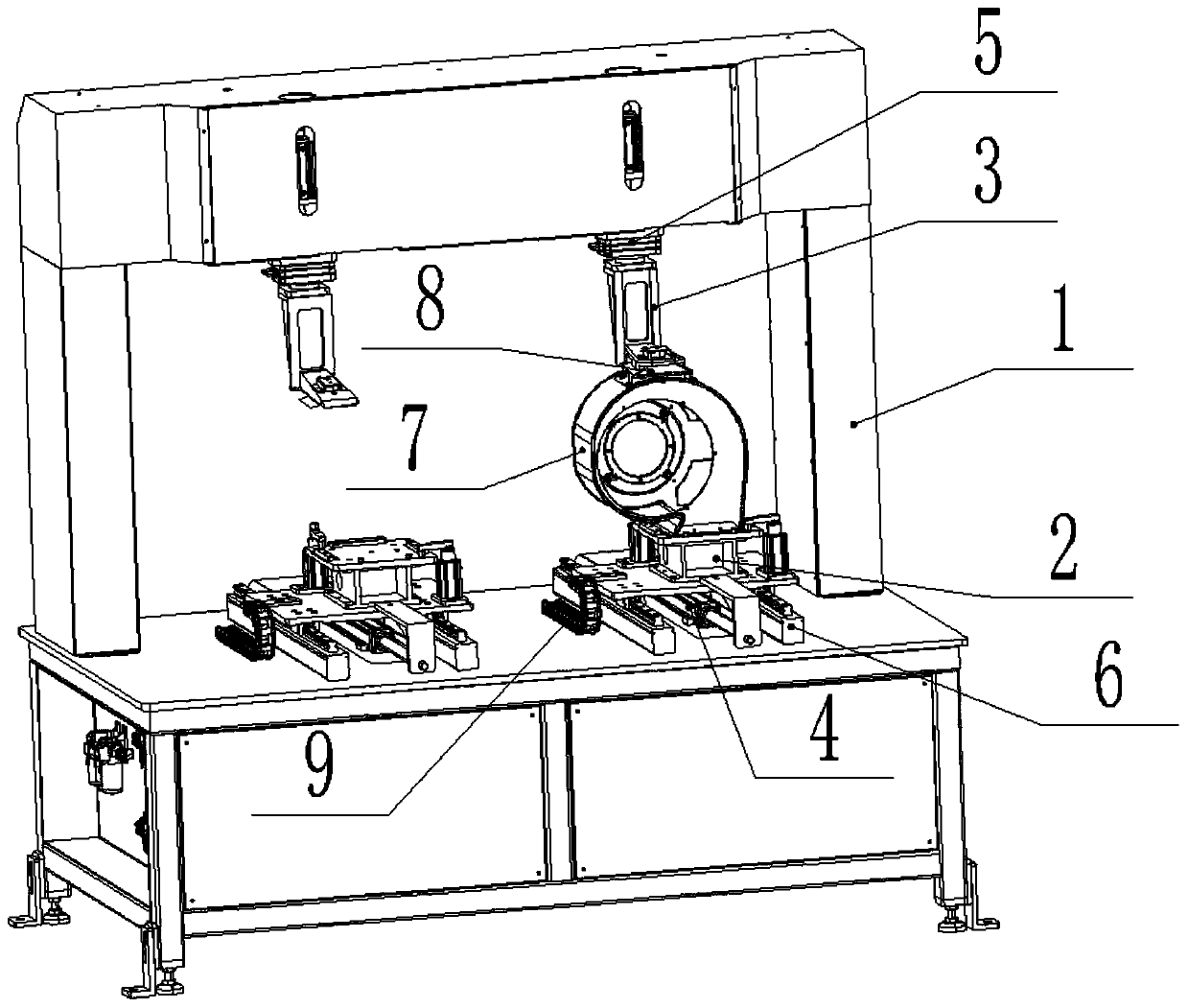

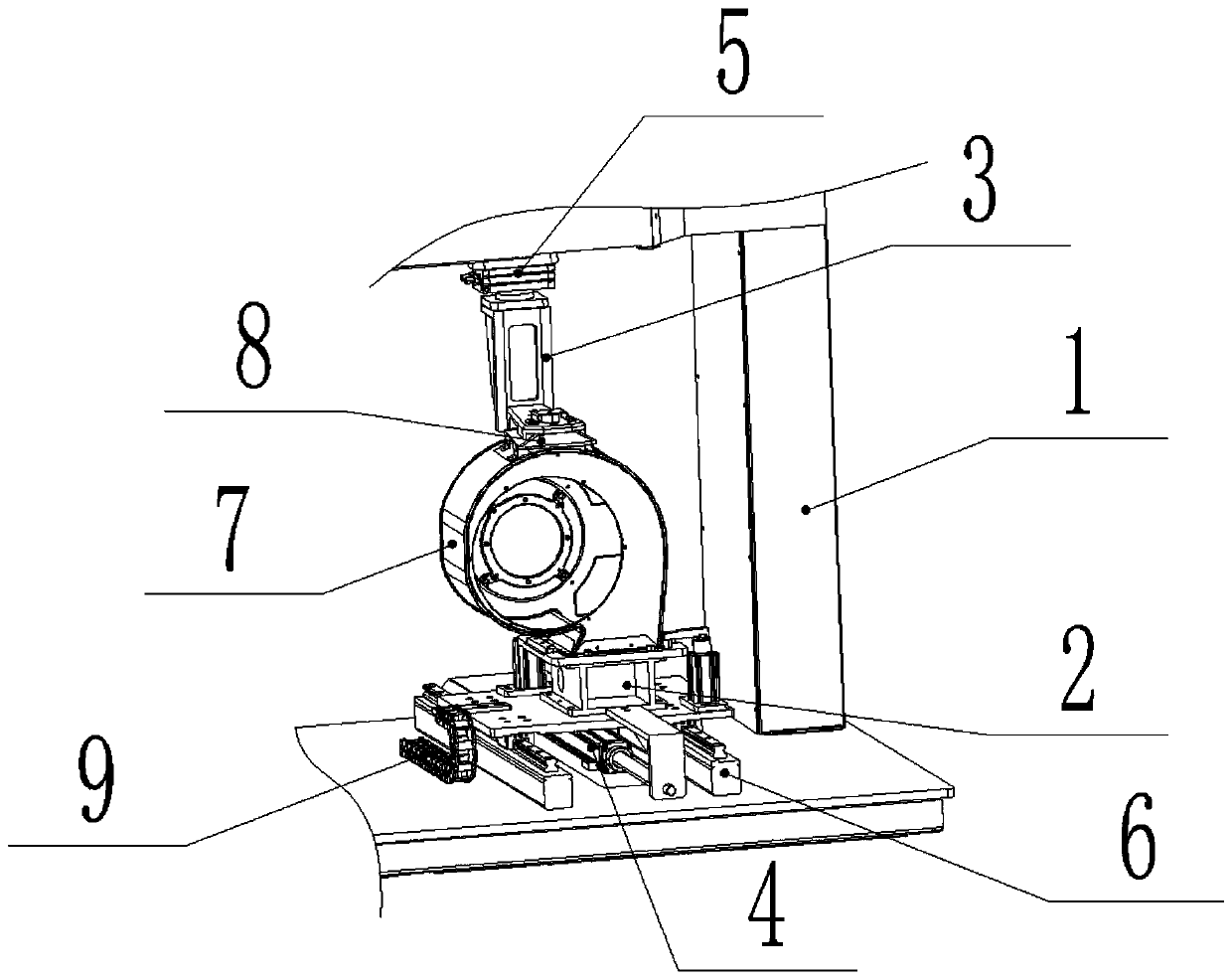

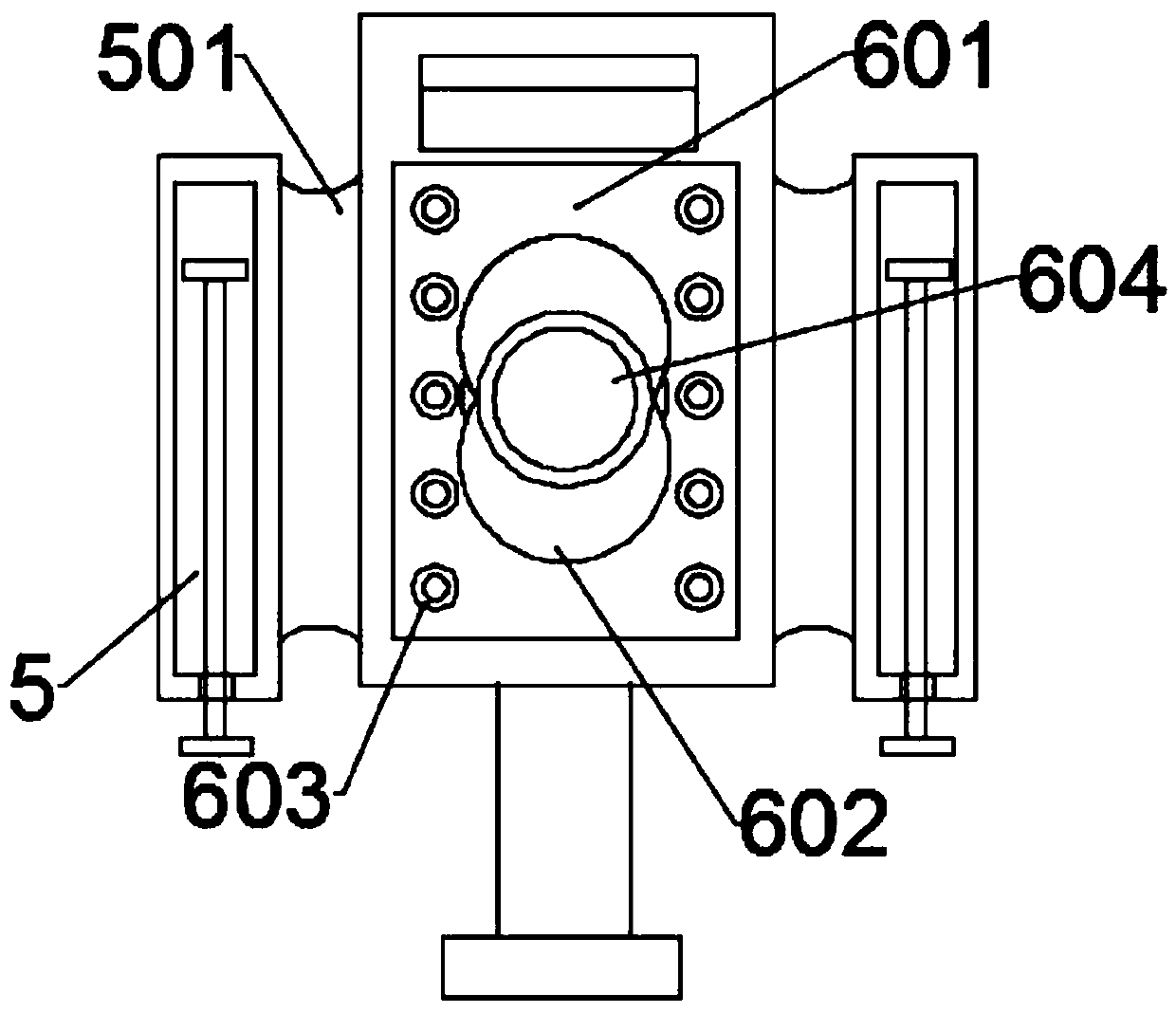

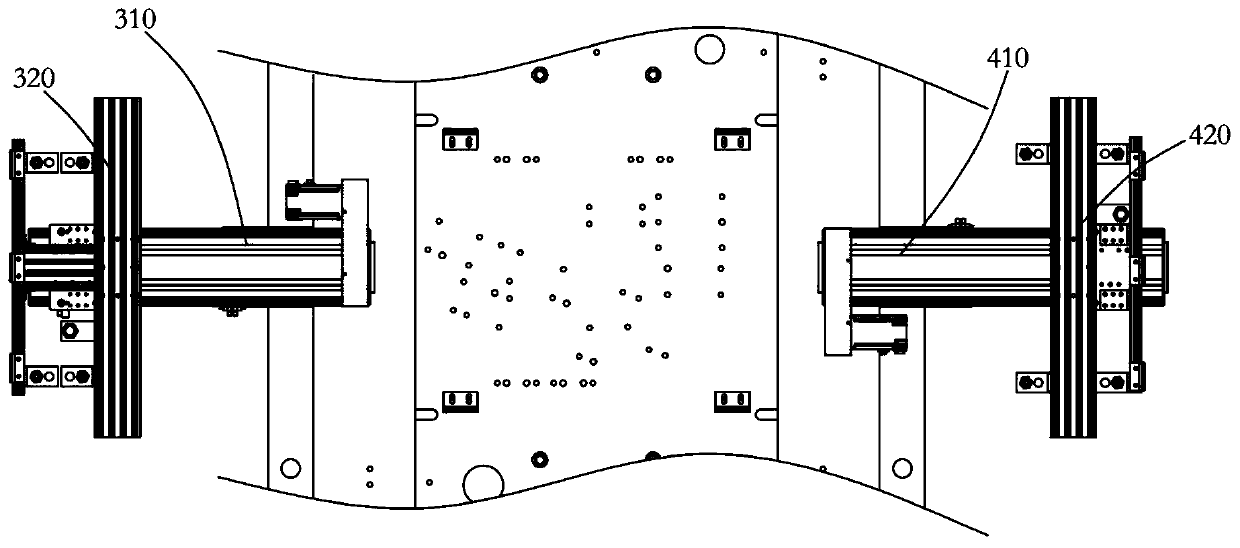

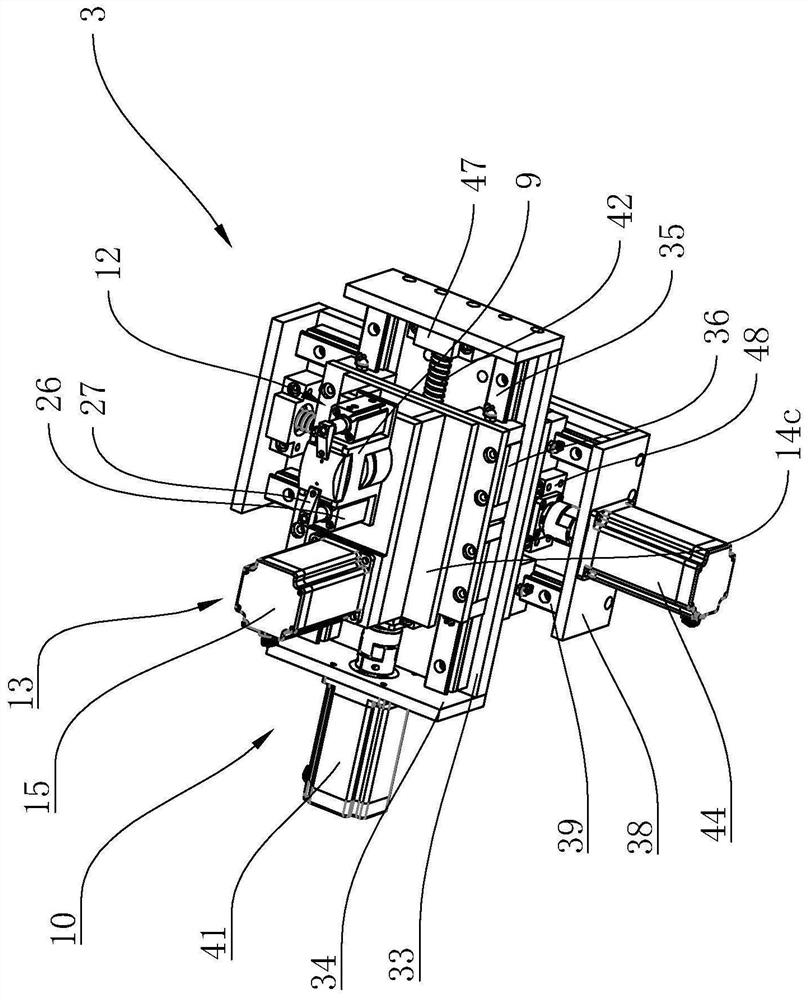

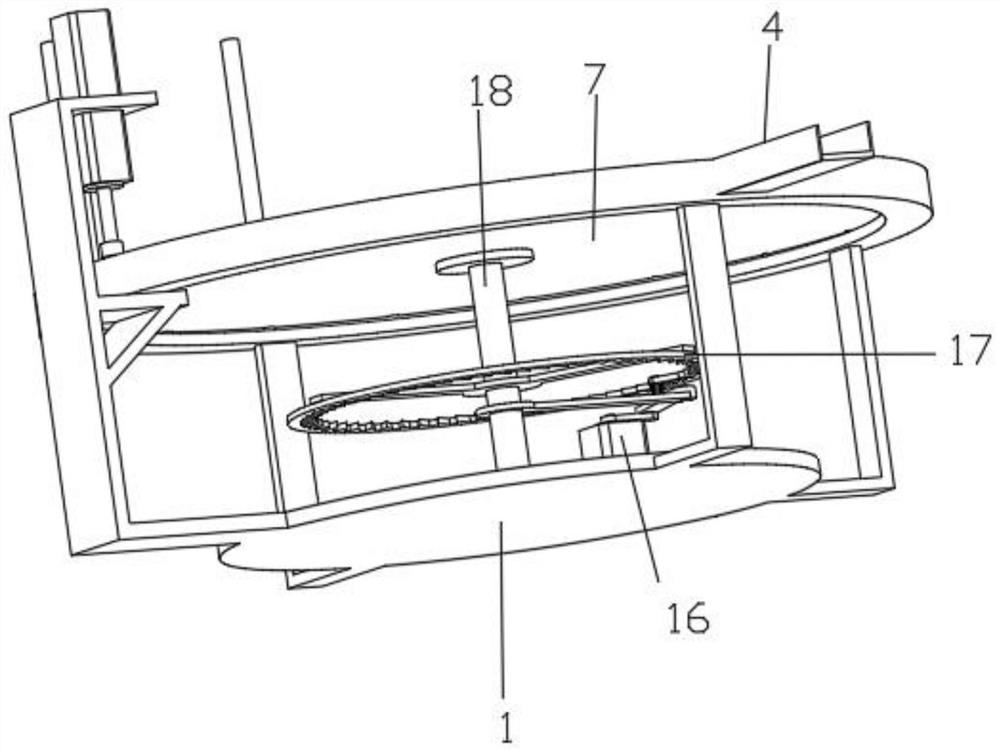

Positioning device for spiral case oil guide groove and riveting system

InactiveCN110587249ARealize automatic rivetingImprove riveting efficiencyMetal working apparatusEngineeringMachine

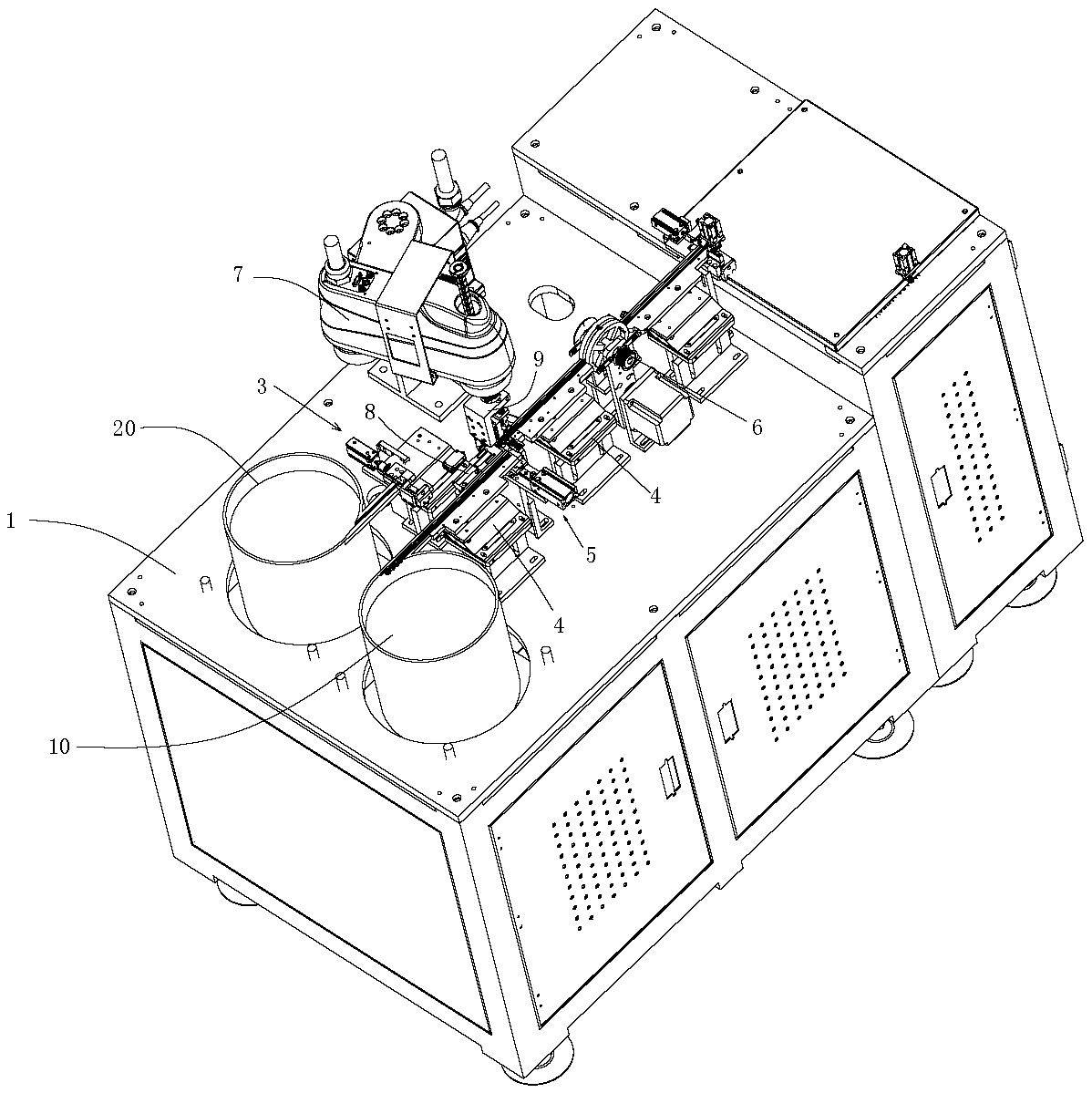

The invention discloses a positioning device for a spiral case oil guide groove. The positioning device for the spiral case oil guide groove comprises a machine body, a positioning and clamping mechanism, a first driving mechanism, a clamp mechanism, and a second driving mechanism; the positioning and clamping mechanism is used for positioning and clamping the spiral case; the first driving mechanism is arranged on the machine body and is connected with the positioning clamping mechanism, and is used for driving the positioning and clamping mechanism to move linearly; the clamp mechanism is used for positioning and clamping the oil guide groove; and the second driving mechanism is arranged on the machine body and connected with the clamp mechanism, and is used for driving the clamp mechanism to move linearly. The invention also provides a riveting system for the spiral case oil guide groove. The riveting system for the spiral case oil guide groove comprises the spiral case oil guide groove positioning device and a riveting material taking device. According to the positioning device for the spiral case oil guide groove and the riveting system, the automation degree is high, the labor intensity is low, the production efficiency is high, and the riveting quality is high.

Owner:湖南创研智能装备有限公司

Automatic riveting method and automatic riveting device

The invention discloses an automatic riveting method and an automatic riveting device. The automatic riveting device comprises a support and further comprises a conveying mechanism, a direction correcting mechanism, a workpiece clamping mechanism, a rivet clamping mechanism and a riveting mechanism which are arranged on the support. The conveying mechanism comprises a conveyer belt used for conveying workpieces and a material stopping block used for stopping the workpieces. The direction correcting mechanism comprises a funnel-shaped correction groove with a wide front part and a narrow back part, and the correction groove is composed of inclined blocks. The workpiece clamping mechanism comprises a first drive cylinder, a feeding block and a groove station. The first drive cylinder is connected with the feeding block and drives the feeding block. The feeding block pushes the workpiece blocked and stopped by the material stopping block into the groove station. The rivet clamping mechanism comprises a rivet box and rivets arranged in the rivet box. The riveting mechanism comprises a second drive cylinder and a pressing block, wherein the second drive air cylinder drives the pressingblock to press the rivets in the rivet box into the workpieces in the groove station. The automatic riveting device achieves full-automatic riveting of the workpieces, greatly lowers labor investment,is low in labor cost and greatly improves production efficiency.

Owner:深圳市正和首信精密科技有限公司

Assembly riveting machine

The invention relates to an assembly riveting machine. The assembly riveting machine comprises a first vibrating disk, a second vibrating disk, a lantern ring transfer device, a connecting core transfer device, a riveting device and a pushing device, wherein an outlet of the first vibrating disk is connected with a carrying device; an outlet of the second vibrating disk is connected with a guide block; the lantern ring transfer device comprises a carrying block provided with a mounting hole used for accommodating a lantern ring, the two sides of the mounting hole are open, and the carrying block is connected with a longitudinal linear module used for driving the carrying block to move to an assembly station; the connecting core transfer device comprises a clamp and a movable mechanical arm, the clamp is used for clamping a connecting core, and then the connecting core is transferred by the movable mechanical arm to the assembly station to be inserted into the lantern ring; the rivetingdevice comprises an accommodating groove, and a rivet pressing rod is arranged on one side of the accommodating groove; and the pushing device comprises a pushing block and a horizontal linear module. According to the assembly riveting machine, the connecting core can be assembled in the lantern ring through the lantern ring transfer device and the connecting core transfer device, and then the assembled component is conveyed through the pushing device to the riveting device to be riveted, so that automatic riveting is realized, manual work is not needed, and the labor cost is reduced.

Owner:东莞市展荣电子设备有限公司

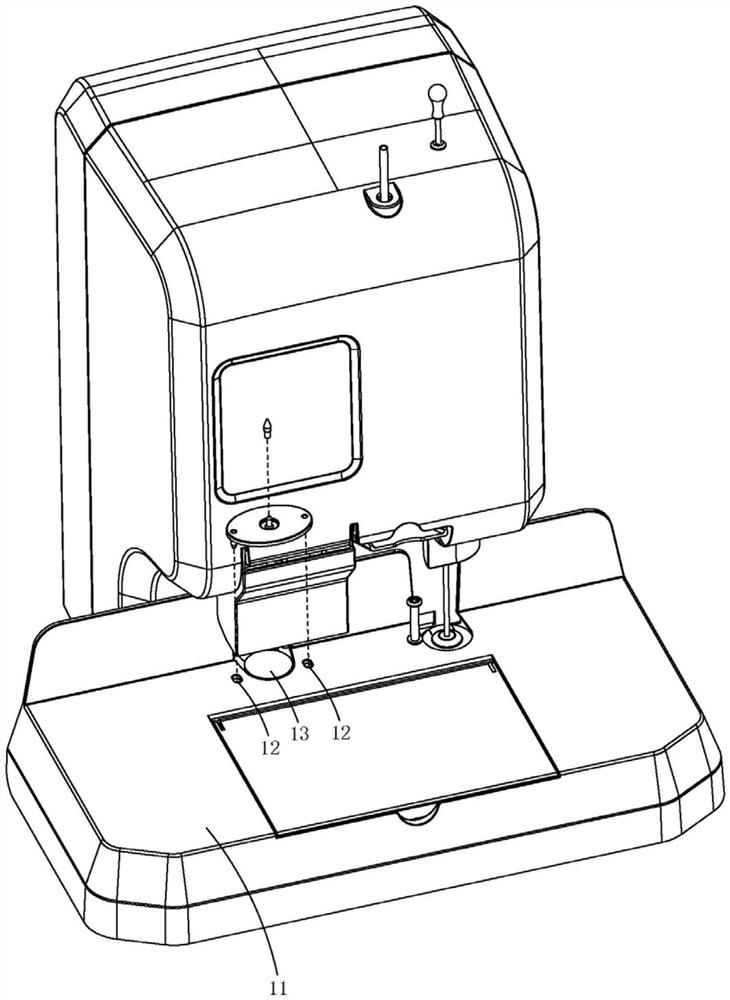

Automatic riveting machine used for packaging box production

The invention discloses an automatic riveting machine used for packaging box production. The automatic riveting machine comprises a rivet rack, three pressing oil cylinders and a carrier clamping frame, wherein the rivet rack is of a C-shaped structure; the two ends of the rivet rack are connected with the pressing oil cylinders and the carrier clamping frame; the three pressing oil cylinders areconnected through a telescopic post; two regulating air pressure cylinders are symmetrically mounted at the front side and the rear side of each pressing oil cylinder; the telescopic post is fixedly mounted on the side surfaces of the pressing oil cylinders through limiting plates; gas piston rods of the two regulating air pressure cylinders are connected with rivet guide tubes through regulatingrods; the rivet guide tubes are connected through a rivet transmitting plate; the rivet guide tubes are connected with a rivet vibrating feeding plate through rivet conveying plates; piston rods of the pressing oil cylinders are connected with guide holes of the rivet guide tubes through pushing cylinders; the front side end of the carrier clamping frame is equipped with two pairs of upper and lower clamping strip plates; and three rivets of a packaging box can be simultaneously pressed for being fixed.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

A quick riveting device for bus duct

The invention discloses a rapid riveting device for a bus groove. The rapid riveting device for the bus groove comprises a support plate, sliding grooves, a blanking hole, support legs, a material storage housing, a first sliding frame, a slider, a linear motor, an electro-hydraulic push rod, limit rods, an output rod, a guide ring, a connecting plate, a fixing seat, a micro air pump, a gas pipe,first clamp plates, connecting cylinders, pistons, moving rods, second clamp plates, a fixing plate, a positioning plate, a second sliding frame, a placement housing, an air cylinder, an electric pushrod, a push block, a push rod, a sleeve and a rivet. The rapid riveting device for the bus groove has a simple structure, and is novel in design, the fixing of a bus groove requiring riveting is facilitated, it is ensured that the fixed bus groove is stable and does not deviate in the process of moving and riveting, the riveting quality of the bus groove is improved, the riveting effect is guaranteed, the workers can operate conveniently, under the action of a movable riveting mechanism, the automatic riveting of the bus groove is realized, the labor intensity of the workers is reduced, and the riveting efficiency of the workers on the bus groove is improved.

Owner:ZHENJIANG GARDERMOEN INTELLIGENT POWER TECH CO LTD

Terminal riveting machine

PendingCN112688142ARealize automatic rivetingHigh degree of automationLine/current collector detailsEngineeringMechanical engineering

The invention discloses a terminal riveting machine which is used for riveting connecting pieces on a terminal and comprises a rack, a terminal feeding device, a connecting piece conveying device and a rivet pressing device. Wherein the connecting pieces are connected to a connecting piece belt and are sequentially arranged in the length direction of the connecting piece belt; the rack is provided with a terminal riveting station, a connecting piece riveting station and a connecting piece channel suitable for the connecting piece belt to penetrate through. The connecting piece conveying device is suitable for acting to drive the connecting piece belt in the connecting piece channel to move and enable connecting pieces on the connecting piece belt to be conveyed to the connecting piece riveting station one by one; the terminal feeding device bears the terminals and is suitable for acting to convey the terminals to the terminal riveting station one by one; the rivet pressing device is suitable for acting to press and rivet the connecting pieces in the connecting piece riveting station on the terminal in the terminal riveting station and cut off the connecting piece from the connecting piece belt. The riveting efficiency can be improved, the labor cost is reduced, and the automation degree is improved.

Owner:溧阳市华达电子电器厂

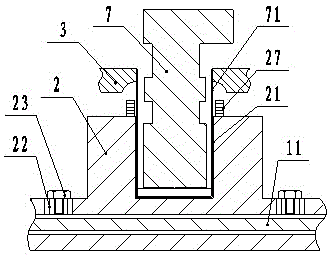

A riveting assembly of a sensor protective cover

ActiveCN102729027BImprove performanceRealize automatic rivetingMetal working apparatusSolenoid valveStructural engineering

The invention discloses a riveting assembly of a sensor protective cover, including a bottom plate (1), a fixing seat (2), two Huff molds (3), two cylinders (4), an air source (5) and a PLC Electric control cabinet (6), characterized in that the cylinder (4), the fixing seat (2) and the base plate (1) are fixedly connected, and the piston rod (41) of the cylinder (4) is connected to the Huff mold (3) fixedly connected, the Huff mold (3) is matched with the sensor skeleton (7), the fixed seat (2) is provided with a positioning hole (21) matched with the sensor shield (71), the air source ( 5) It is connected with the cylinder (4), and the PLC electric control cabinet (6) is connected with the solenoid valve (42) of the cylinder (4). Through the innovation of riveting tooling equipment and its structure, the present invention provides an automatic riveting assembly of a protective cover with high production efficiency, low cost and reliable performance for a riveting assembly of a sensor protective cover.

Owner:宁波拓普电器有限公司

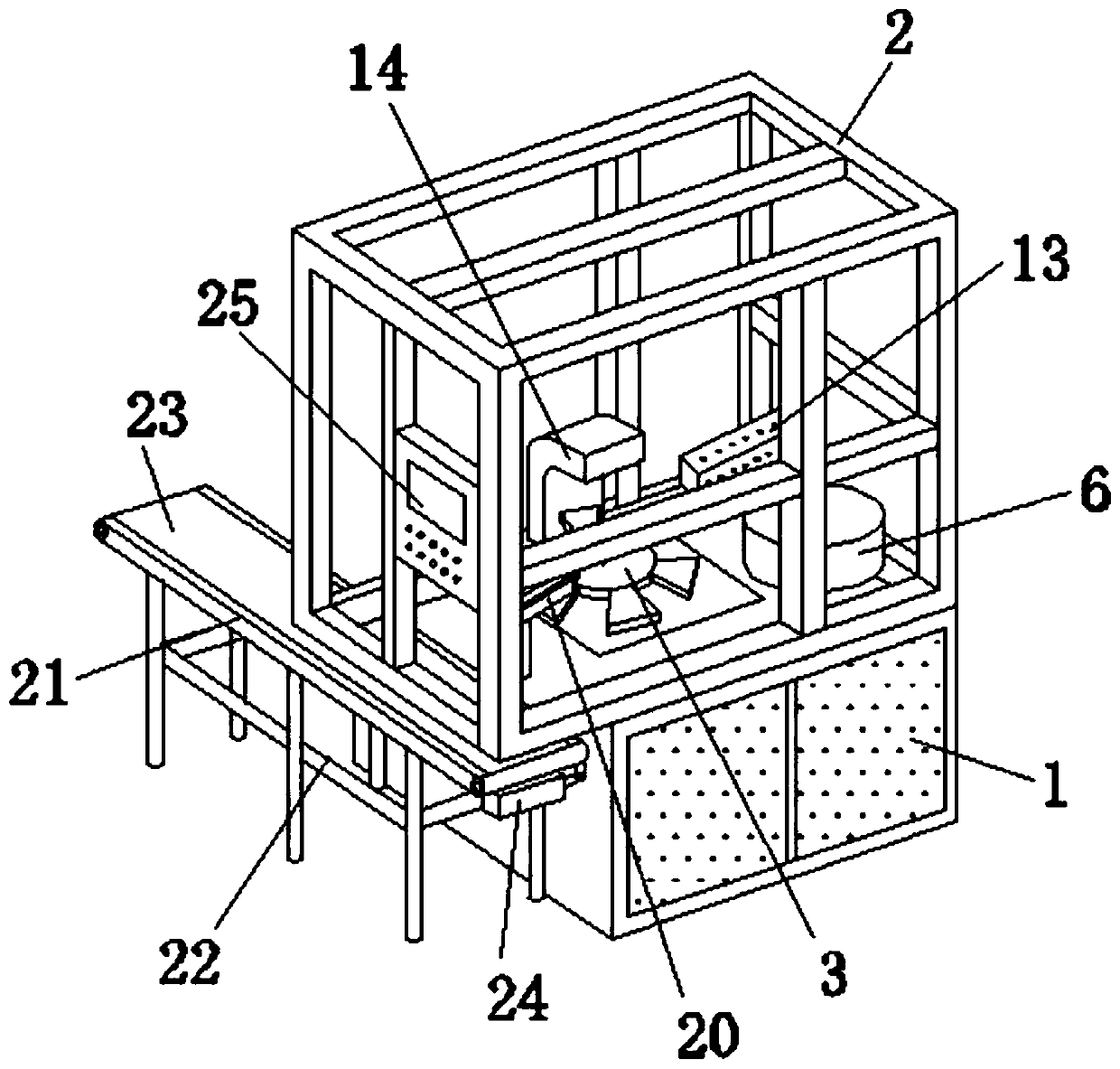

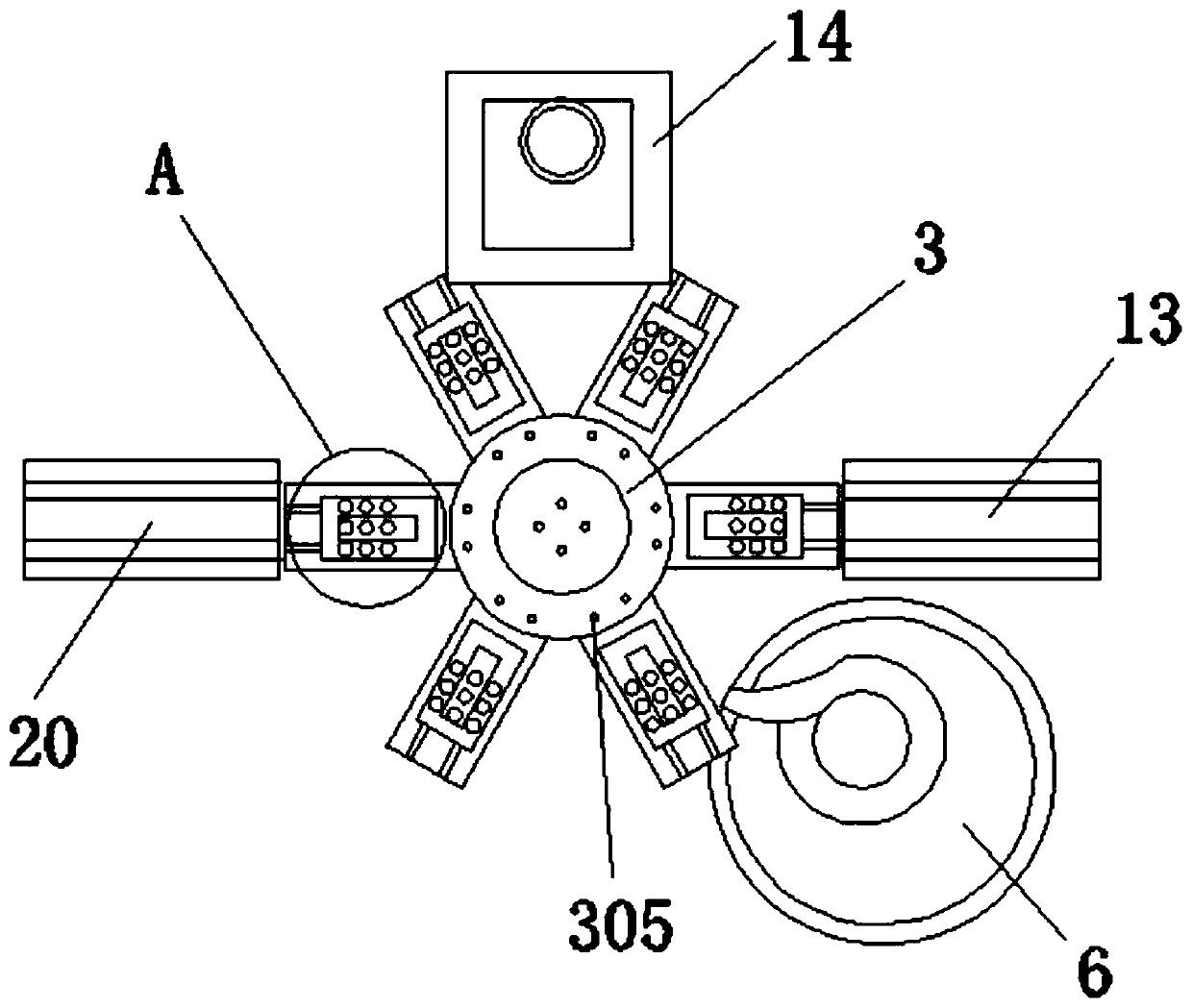

Intelligent control-based multifunctional small riveting production line

The invention provides an intelligent control-based multifunctional small riveting production line, and relates to the technical field of riveting production lines. The intelligent control-based multifunctional small riveting production line involves a lower frame, wherein an aluminum alloy outer cover is arranged at the top of the lower frame, an indexing device is arranged at the center of the lower frame, a material aligning mechanism is arranged at one side of the indexing device, a feeding mechanism, corresponding to the material aligning mechanism, is arranged at one side of the indexingdevice, and a hydraulic riveting mechanism is arranged at the side, opposite to the material aligning mechanism, of the feeding mechanism; and a discharging mechanism is arranged at the center of thelower frame and at the side opposite to the feeding mechanism, and a conveying device is arranged at the side, close to the discharging mechanism, of the lower frame. The complete automatic rivetingproduction line is formed through the combination of various mechanisms, so that a large amount of manpower is saved, the labor intensity of workers is reduced, the processing quality and the processing efficiency of products are improved, and meanwhile, the interchangeability and the intelligent control force of the production line are enhanced.

Owner:珠海华德力电气有限公司

A lamp leg guide wire riveting device and a riveting method thereof

PendingCN109256652ALarge riveting areaReduce frictional resistanceLine/current collector detailsEngineeringSlide plate

The invention provides a lamp leg guide wire riveting device comprising a bottom plate. A shaft seat is arranged at that top of the bottom plate, two guide columns are arranged at the top of the shaftseat. A top plate is arranged at the top of a guide column, A low end of that guide post is slidably connected with a second linear bear, A slide plate is arranged between the second linear bearings,a lifting cylinder arranged at the top of the bottom plate is connected to the bottom of the slide plate, a first linear bearing is arranged at the top of the support plate on the guide post, an upper sliding plate is arranged between the first linear bearings, and a lower pressure cylinder is arranged at the top of the top plate. A square rivet needle is adopted, the rivet point is of a long groove type, the riveting area is large, the riveting guide wire is firmly fixed in the lamp leg aft riveting, the guide column and the first linear bearing are matched with the second linear bearing, the friction resistance is small, the guide property is good, the lifting cylinder and the lower pressure cylinder are adopted, the structure is simple, and automatic riveting can be realized.

Owner:南京合力电光源设备制造厂

Automatic coupler welding device

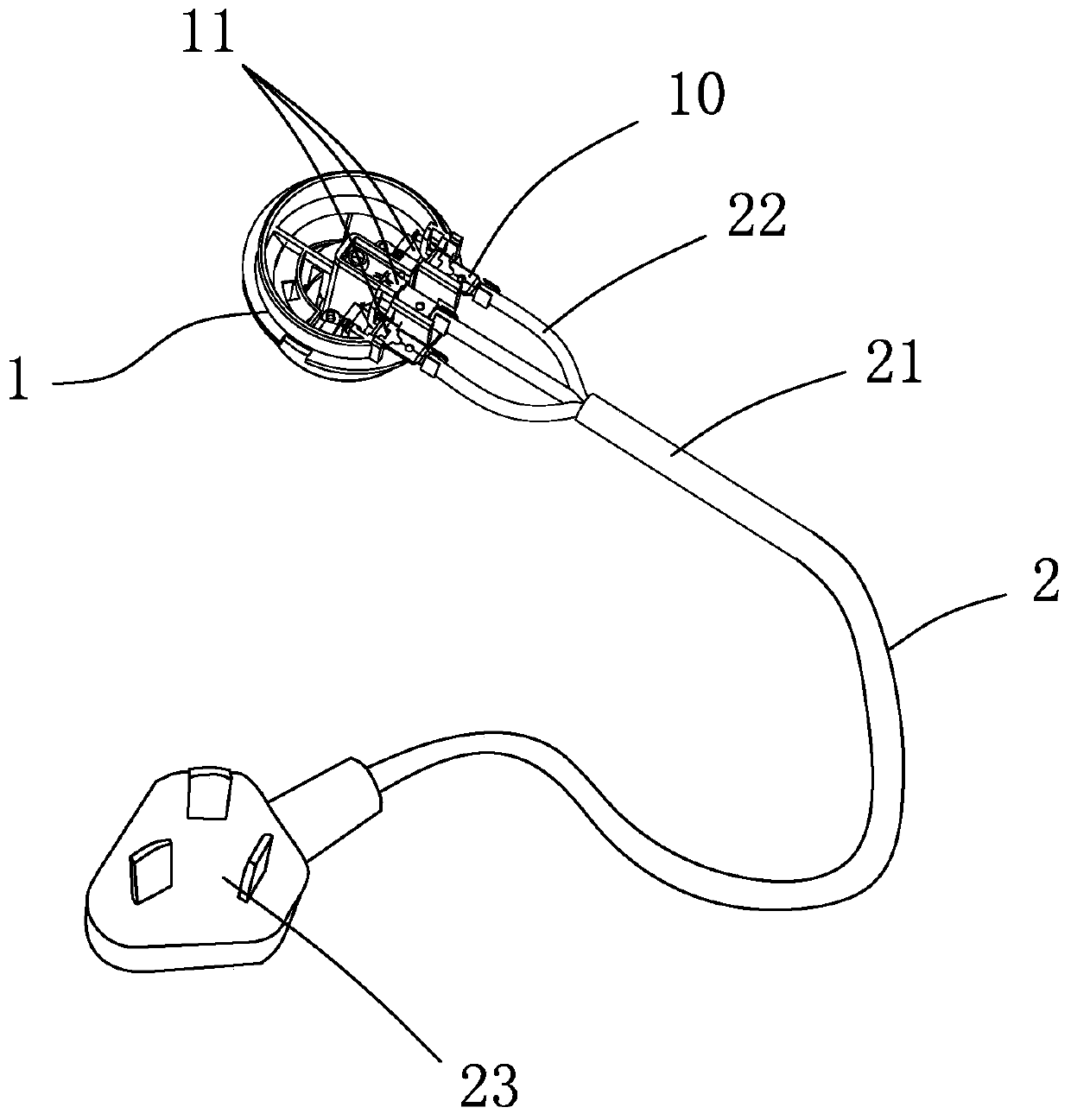

PendingCN110091026ARealize automatic rivetingIncrease productivitySoldering bitsSoldering ironCopper wireEngineering

The invention discloses an automatic coupler welding device which comprises a welding mechanism and a carrier. The carrier comprises a welding groove for supporting and positioning a riveting positionbetween a conductive sheet and one end of a power line, and a conductive block in matched contact with the conductive sheet. The welding mechanism comprises a machine frame, a welding head, a conductive contact and a driving assembly, wherein the welding head, the conductive contact and the driving assembly are arranged on the support. The welding head and the conductive contact are electricallyconnected with the positive pole and the negative pole of a welding circuit correspondingly, the welding head can be driven by the driving assembly to press the riveting position between the conductive sheet and one end of the power line in the welding groove, and the conductive contact can be driven by the driving assembly to press the conductive block. The automatic coupler welding device is simple in structure, can automatically weld the riveting position of a connecting terminal of the conductive sheet and the copper wire part of a branch line, and improves the production efficiency.

Owner:ZHEJIANG DAWEI ELECTRONICS +1

Automatic Terminal Riveting Device

ActiveCN111293570BRealize automatic rivetingImprove securityLine/current collector detailsWire rodKnife blades

The embodiment of the present invention discloses an automatic terminal riveting device including a riveting system, a terminal conveying system and a wire conveying system. The riveting system includes at least one riveting blade set and at least one of the two riveting blades in the riveting blade set One is a power blade, the riveting blade set has a riveting port for riveting terminals, the terminal conveying system transports the terminal to the riveting port, the wire conveying system conveys the wire, and the riveting blade set automatically crimps the wire and the terminal area for crimping. Therefore, the automatic terminal crimping device of the embodiment of the present invention can realize automatic crimping between the terminal and the wire, which improves the production efficiency and the safety in the production process.

Owner:ASAP TECH (JIANGXI) CO LTD

An automatic riveting machine for packaging box production

The invention discloses an automatic riveting machine used for packaging box production. The automatic riveting machine comprises a rivet rack, three pressing oil cylinders and a carrier clamping frame, wherein the rivet rack is of a C-shaped structure; the two ends of the rivet rack are connected with the pressing oil cylinders and the carrier clamping frame; the three pressing oil cylinders areconnected through a telescopic post; two regulating air pressure cylinders are symmetrically mounted at the front side and the rear side of each pressing oil cylinder; the telescopic post is fixedly mounted on the side surfaces of the pressing oil cylinders through limiting plates; gas piston rods of the two regulating air pressure cylinders are connected with rivet guide tubes through regulatingrods; the rivet guide tubes are connected through a rivet transmitting plate; the rivet guide tubes are connected with a rivet vibrating feeding plate through rivet conveying plates; piston rods of the pressing oil cylinders are connected with guide holes of the rivet guide tubes through pushing cylinders; the front side end of the carrier clamping frame is equipped with two pairs of upper and lower clamping strip plates; and three rivets of a packaging box can be simultaneously pressed for being fixed.

Owner:ANHUI POLYTECHNIC UNIV

Rivet pipe file binding machine capable of automatically cutting and taking rivets

PendingCN113370296AEasy accurate and fast automatic resectionRealize automatic rivetingMetal working apparatusPaperboardIndustrial engineering

The invention discloses a rivet pipe file binding machine capable of automatically cutting and taking rivets. The rivet pipe file binding machine capable of automatically cutting and taking the rivets comprises a pipe cutting accessory selected for use during rivet taking, wherein the pipe cutting accessory comprises a rivet taking positioning needle; the rivet taking positioning needle comprises an upper guide part used for being vertically aligned with a drilling tool and a lower inserting part used for being inserted into a riveting pipe from the head of an upper riveting pipe of the riveting pipe which is hot-pressed and riveted to a binding file and enabling the riveting pipe to be vertically aligned with the drilling tool; and the upper end of the lower inserting part is connected to the bottom of the upper guide part. According to the rivet pipe file binding machine capable of automatically cutting and taking the rivets provided by the invention, the rivet taking positioning needle and a positioning seat are used for positioning, so that the rivet pipe needing to be removed and the drilling tool are kept concentric and coaxial; after the head of the upper riveting pipe is cut off, the head of the upper riveting pipe adhered to the drilling tool is popped out of the drilling tool through a paper pressing plate in the upward moving and resetting process of the drilling tool, so that full-automatic rivet taking is achieved, and the upper riveting head part of the riveting pipe can be easily, accurately, quickly and automatically cut off; and the structure is simple, the cost is low, and use is convenient.

Owner:东莞市骏能电子科技有限公司

Riveting device

PendingCN114472727ARealize automatic rivetingImprove efficiencyMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

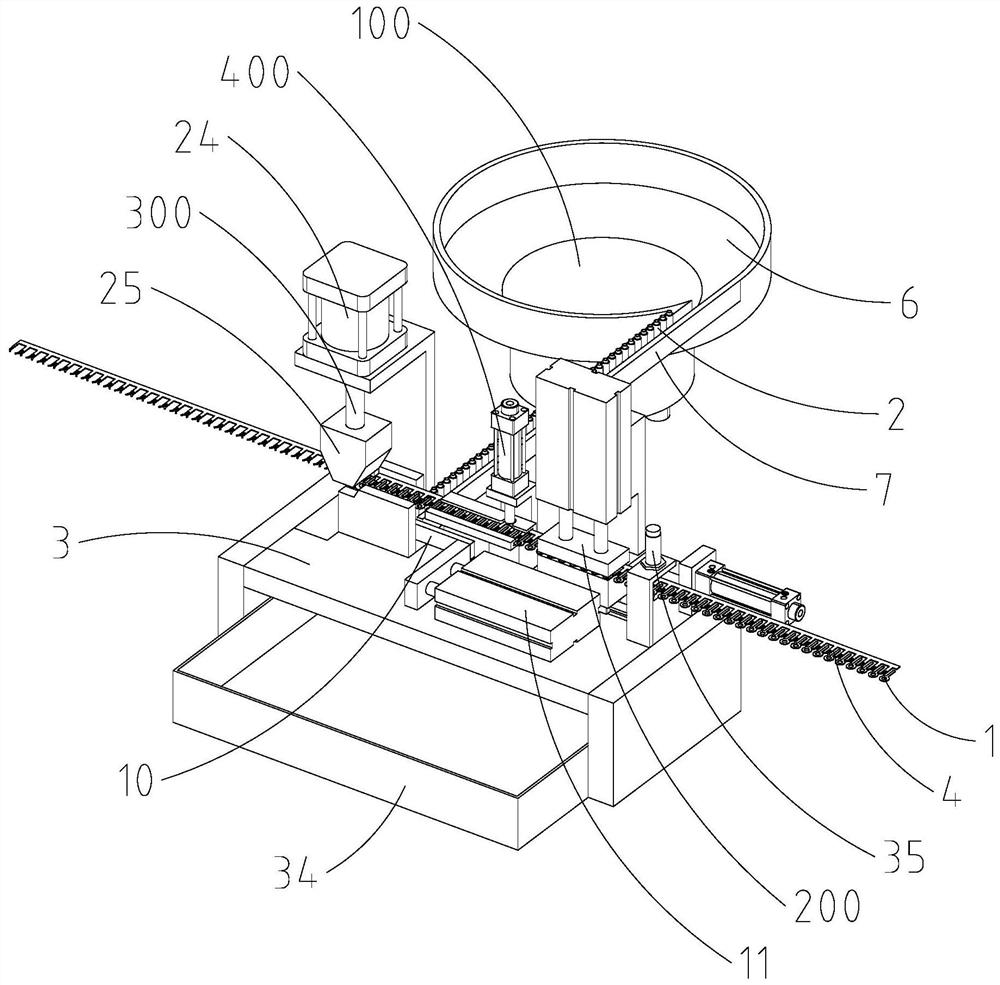

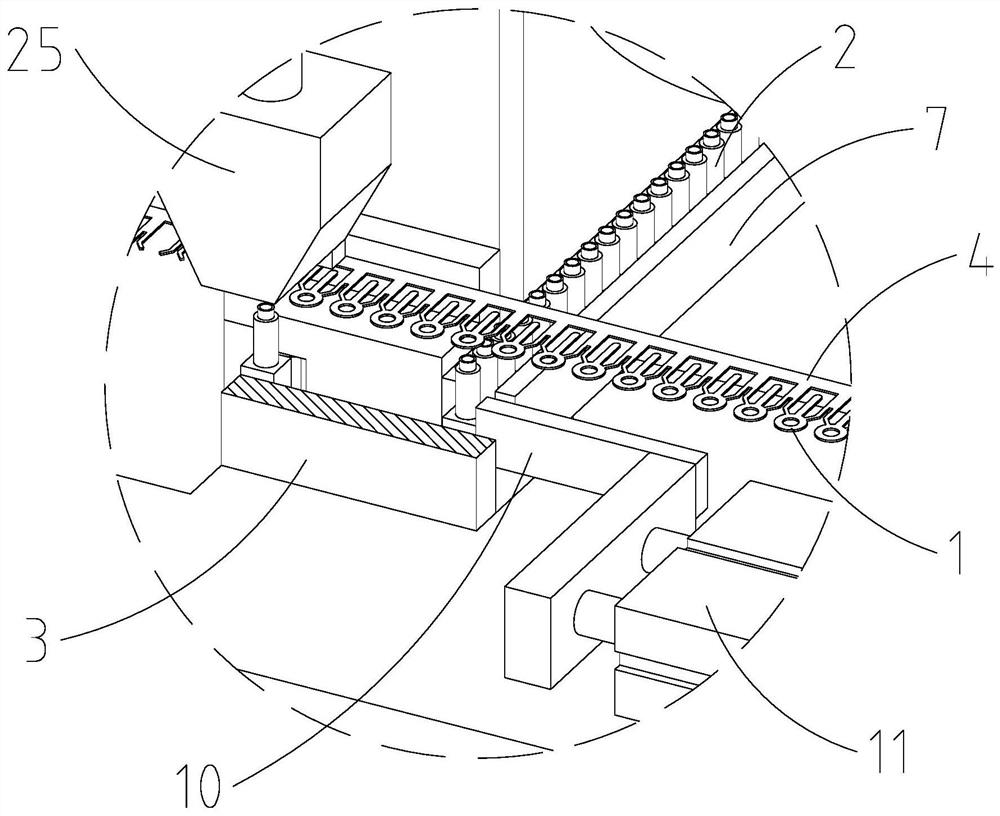

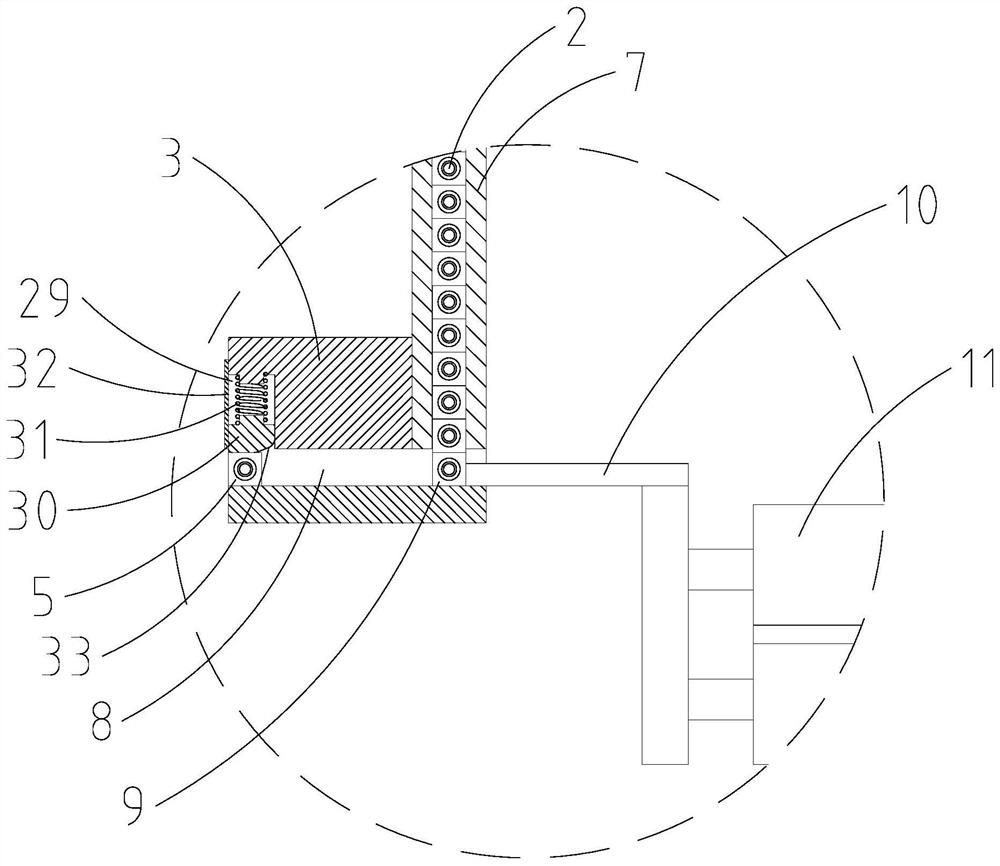

A riveting device comprises a vibrating disc used for feeding and further comprises a dislocation mechanism, a positioning mechanism, a grabbing mechanism, a rotating mechanism and a driving mechanism, the dislocation mechanism is connected with a discharging port of the vibrating disc and used for staggering the forefront material, the positioning mechanism is used for positioning a workpiece, the grabbing mechanism is used for grabbing the material, the rotating mechanism can rotate the material, and the driving mechanism is used for driving the rotating mechanism to rotate. And the driving mechanism is used for driving the grabbing mechanism to grab the materials and riveting the materials onto the workpieces. According to the riveting device, one material is separated through the dislocation mechanism, then the separated material is grabbed through the grabbing mechanism, after the angle of the material is adjusted through the rotating mechanism, the material is riveted to the workpiece through the driving mechanism, and the purposes of automatic riveting and efficiency improvement are achieved.

Owner:FUZHUN PRECISION TOOLING (JIASHAN) CO LTD

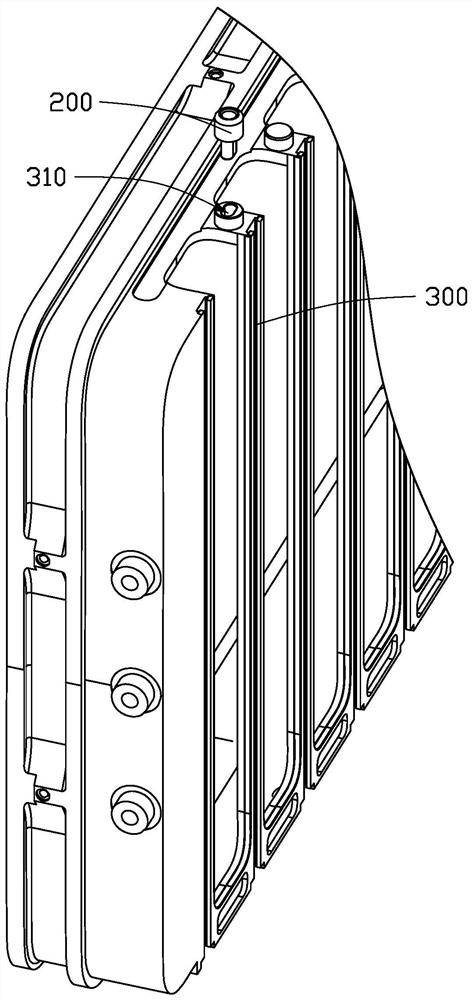

Positioning adjustment mechanism for air conditioner back plates

Owner:SUZHOU SIMITCH MASCH CO LTD

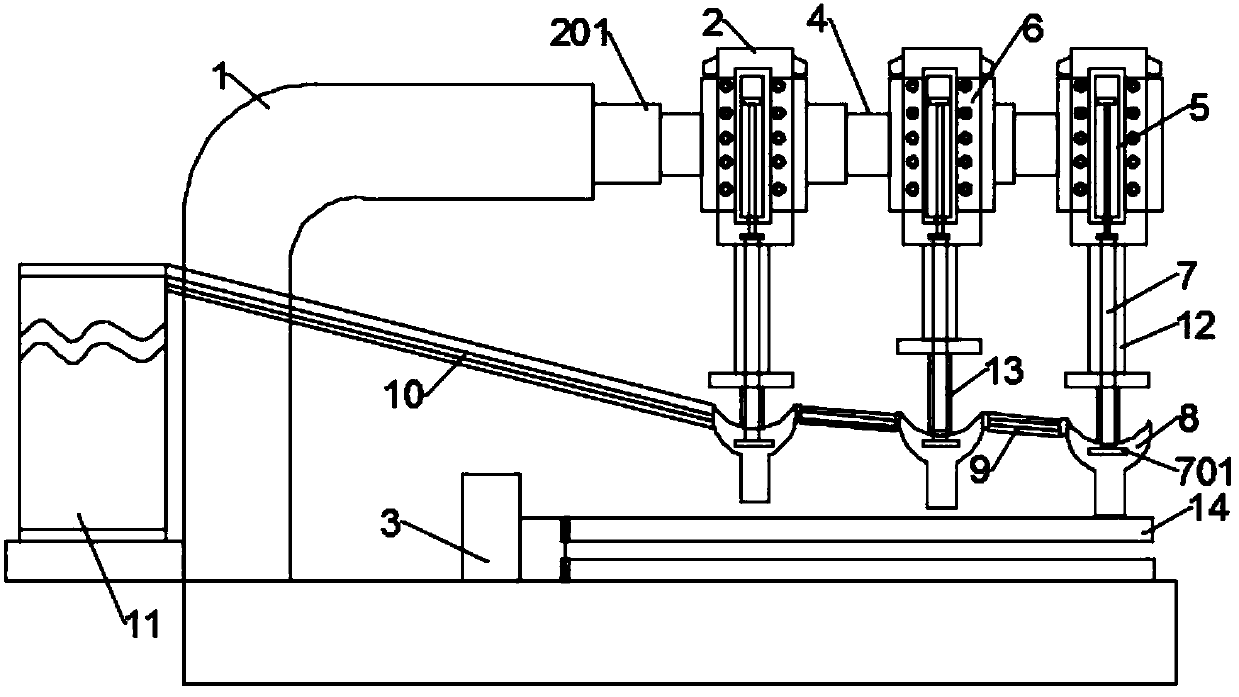

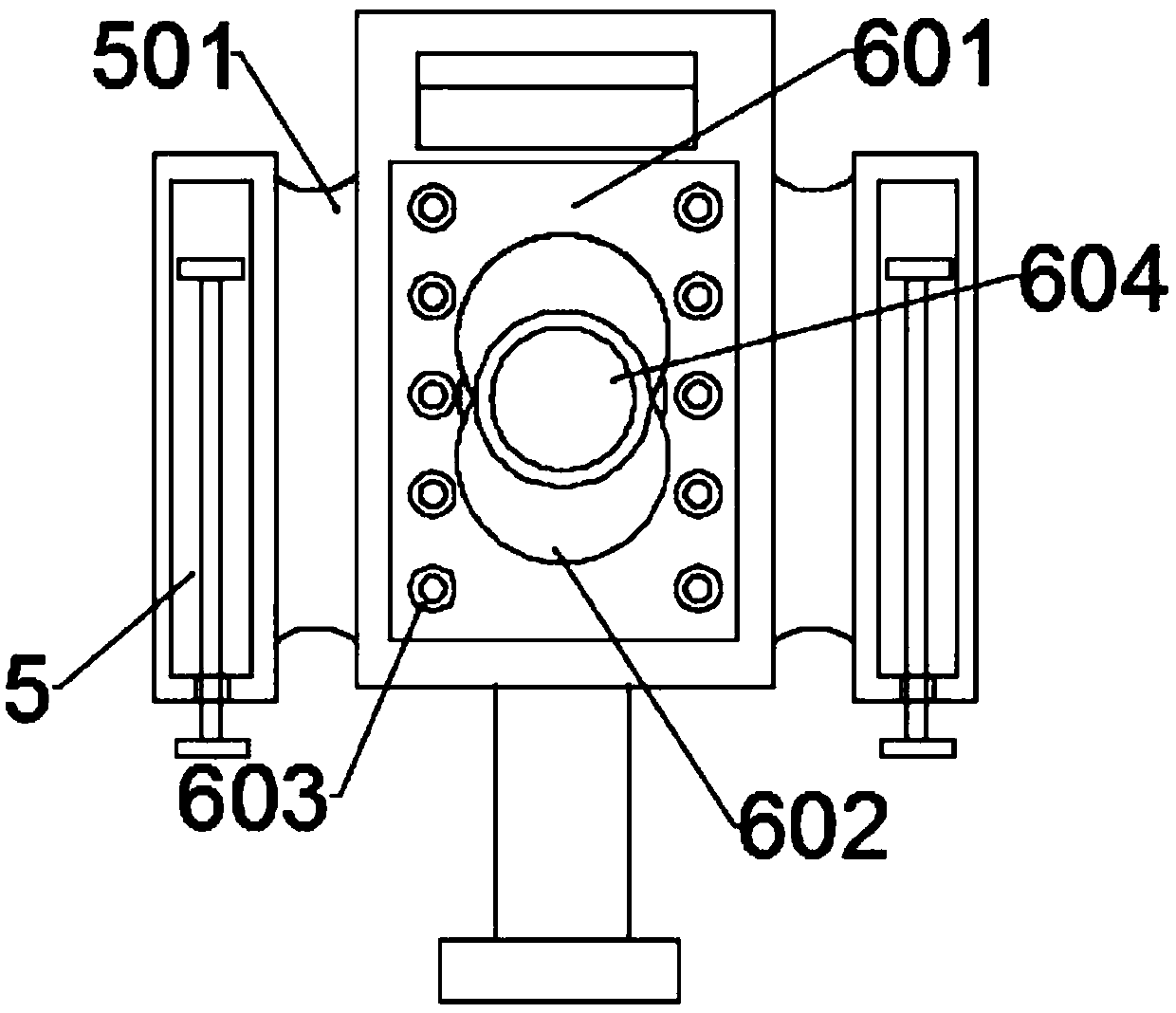

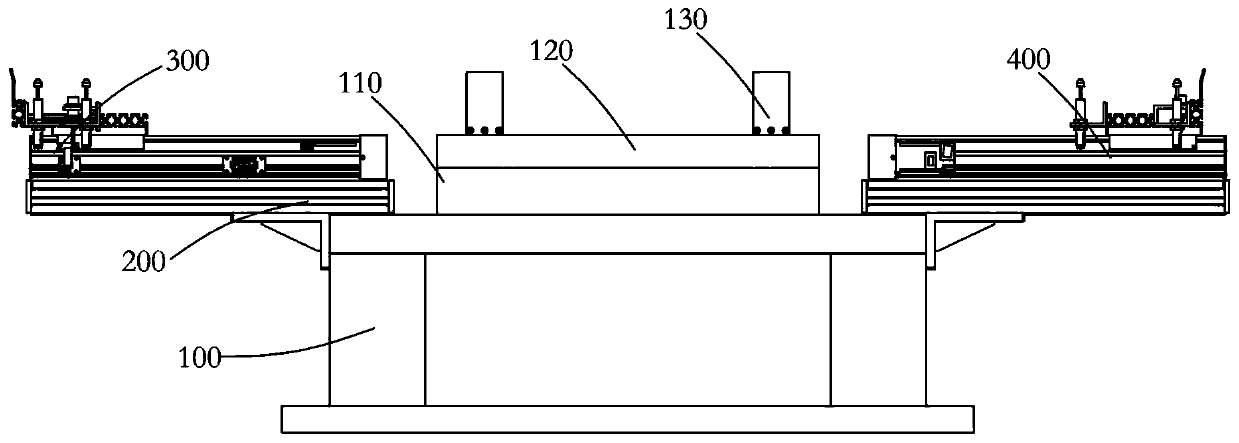

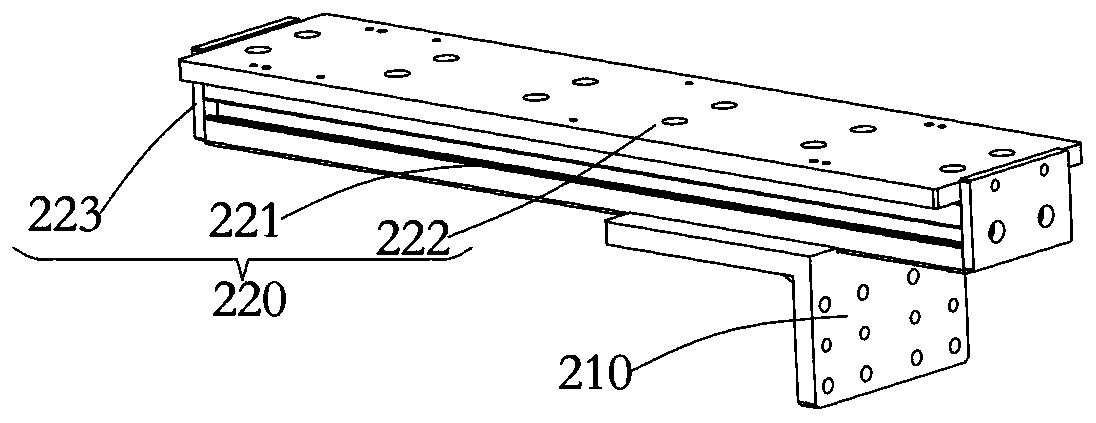

An automatic assembly machine for slide rails

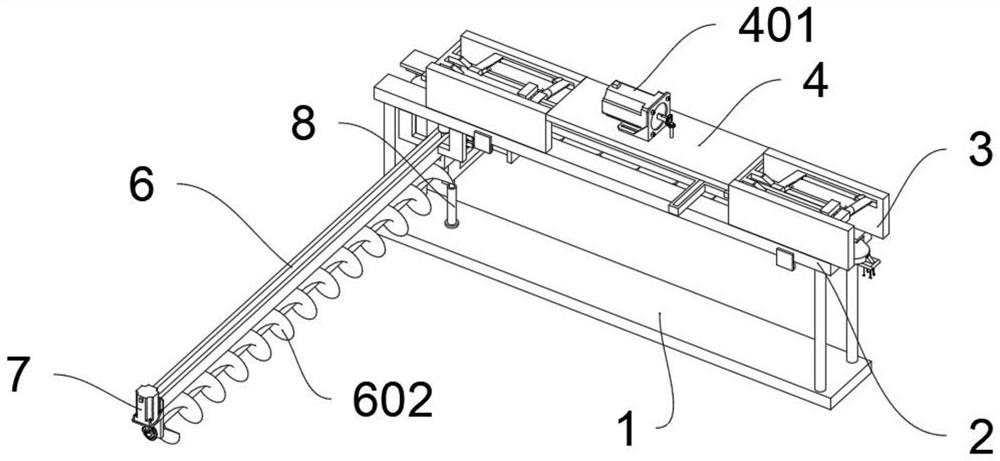

ActiveCN105643272BRealize automatic rivetingImprove stabilityAssembly machinesEngineeringAssembly automation

The invention discloses an automatic assembling machine for a slide rail. The machine comprises a frame, and is characterized in that a slide rail cup-joint ball loading mechanism, a ball separating and blowing mechanism, a stopper assembling mechanism and a stopper riveting mechanism are arranged on the frame in sequence; an outlet end of the ball separating and blowing mechanism is connected with the slide rail cup-joint ball loading mechanism; the stopper assembling mechanism is arranged at an outlet end of the slide rail cup-joint ball loading mechanism; and a feeding mechanism is arranged between the stopper assembling mechanism and the stopper riveting mechanism. The automatic assembling machine for the slide rail is high in stability and assembly automation degree.

Owner:GUANGDONG SACA PRECISION MFG CO LTD

Fully-automatic padlock trademark riveting device

The invention provides a fully-automatic padlock trademark riveting device and belongs to the technical field of riveting equipment. The fully-automatic padlock trademark riveting device comprises a riveting mechanism and a padlock positioning fastening mechanism which are arranged inside a rack, wherein the riveting mechanism comprises an air hammer and an air hammer lifting component connected with the air hammer, the air hammer is internally provided with a punching head with the cross section being in a shape like a Chinese character 'zhong', the bottom of the air hammer is further provided with a material inlet passage, and the side portion of the air hammer is further provided with a material inlet pipe communicating with the material inlet passage. According to the fully-automatic padlock trademark riveting device, the padlock positioning fastening mechanism can fix a padlock and a trademark nameplate and can drive the padlock to move in the horizontal direction to make a riveting hole in the padlock be aligned with the riveting mechanism rapidly and accurately, so that padlock trademark automatic riveting is realized, the padlock trademark riveting efficiency can be effectively improved, and the personnel workload can be greatly reduced.

Owner:烟台三环锁业集团浦江有限公司

Belt cover riveting machine

The invention discloses a belt cover riveting machine. The belt cover riveting machine includes a workbench, a horizontal pressing rod is connected to the workbench through a lifting mechanism in a transmission mode, and an upper pressing wheel assembly is disposed on the bottom side of one end of the horizontal pressing rod. A movable plate is disposed below the upper pressing wheel assembly, andthe movable plate is connected to the top side of the workbench by a sliding mechanism in a transmission mode. A moving pressing wheel assembly is arranged on the top side of the movable plate, and more than one elastic bracket is arranged on the side of the moving pressing wheel assembly. The belt cover riveting machine can improve the processing efficiency of riveting on belt covers, improves the stability of the processing quality, solves the noise problem generated during processing, and is suitable for modern enterprise processing and production.

Owner:FOSHAN CITY NANHAI POPULA FAN

Automatic assembly production device provided with detection device for automotive lock catches

InactiveCN112808868AEasy to mass produceEasy to transportMetal-working feeding devicesVehicle componentsManipulatorIndustrial engineering

The invention discloses an automatic assembly production device provided with a detection device for automotive lock catches, and relates to the technical field of automobile assembly. The problems that conveying of workpieces can be performed only through a multi-axis conveying type structure such as manipulators, a structure is complicated and the consumption cost is higher when the assembly device used at present is adopted can be solved. The automatic assembly production device provided with the detection device for the automotive lock catches comprises a base, wherein a feeding slideway is fixedly arranged on the top of the base through a support; the feeding slideway also comprises a connecting piece, a spring rod A and a positioning piece; two groups of bump structures are fixedly arranged on the two sides of the bottom of the feeding slideway; through arrangement of the positioning piece and a self-locking piece, an auxiliary fixing function can be provided for the workpieces, and a continuous auto-reciprocating mechanism is constituted by further utilizing a connecting shaft, a fixed connecting rod and a sliding shaft sleeve, so that continuous intermittent conveying of the workpieces can be performed, and convenience is provided for workers to put the workpieces; and therefore, the conveying structure is simple, the cost is reduced, environmental protection is achieved, and mass production of the lock catches is facilitated.

Owner:胡民杰

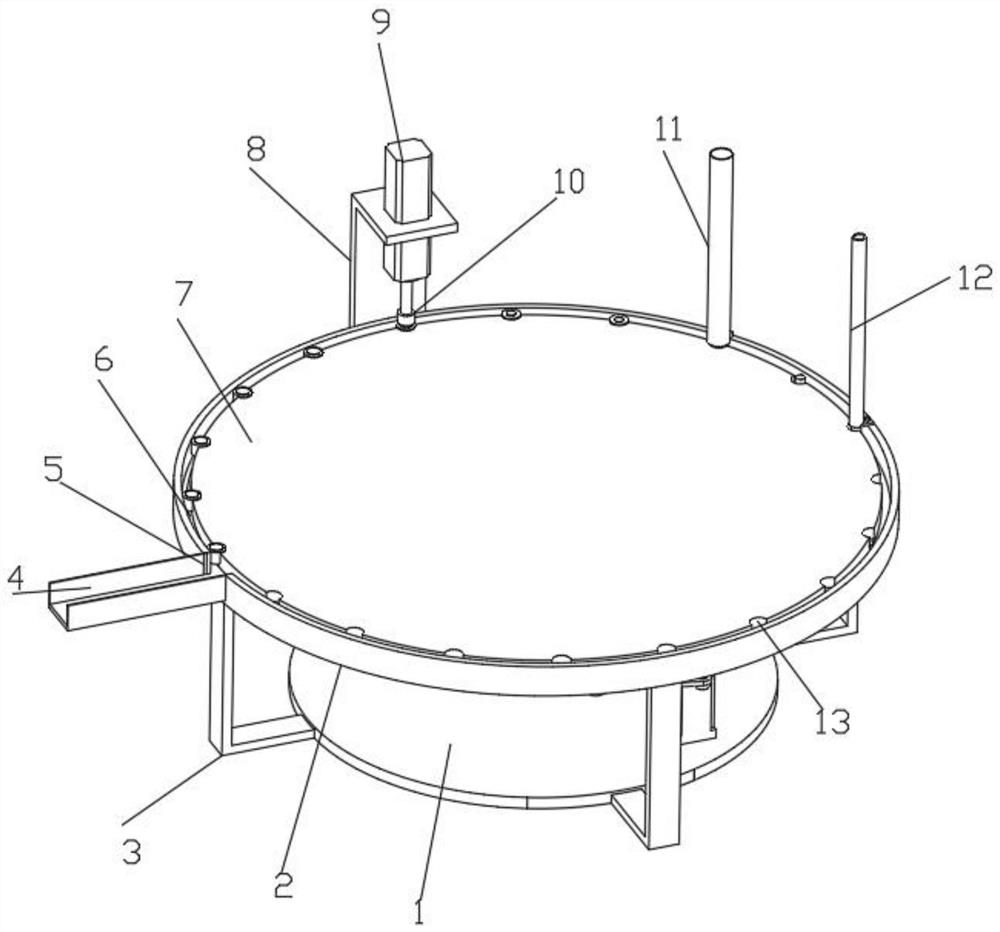

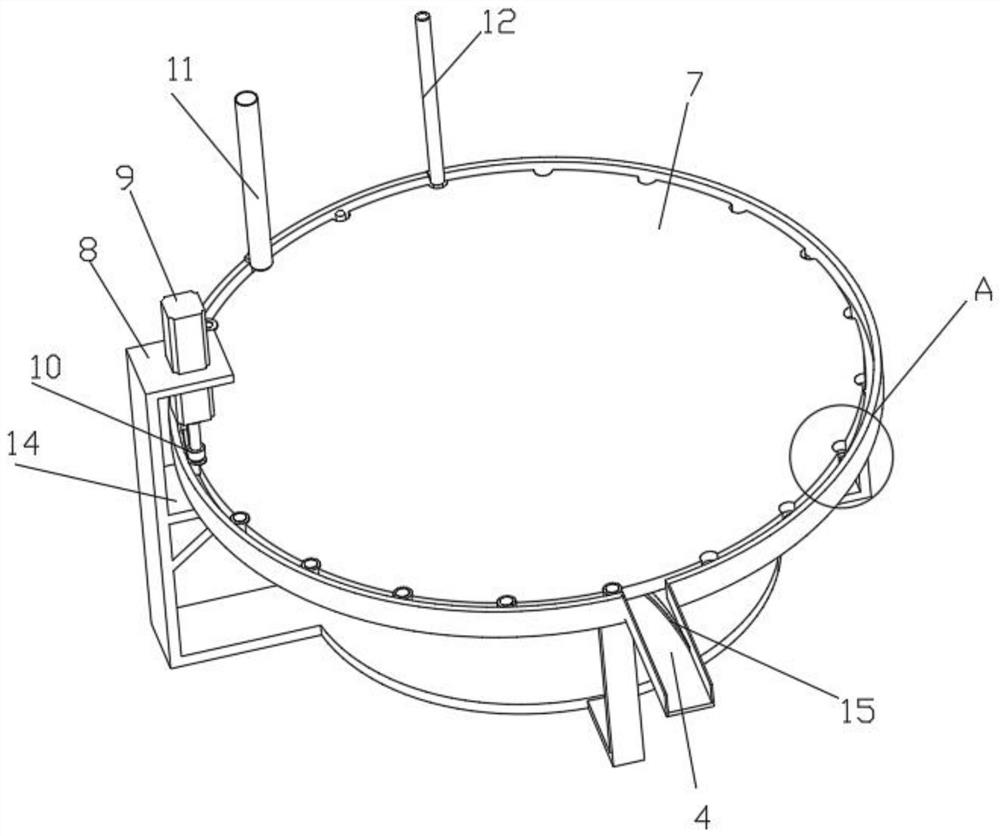

Automatic riveting device for electronic cigarette manufacturing

ActiveCN112355616AGuaranteed normal slidingNormal slideTobaccoMetal working apparatusStructural engineeringElectronic cigarette

The invention discloses an automatic riveting device for electronic cigarette manufacturing, and relates to the technical field of electronic cigarette production. The automatic riveting device comprises a supporting plate, a copper core and a sleeve, L-shaped supporting plates are evenly and fixedly connected to the side wall of the supporting plate in the circumferential direction, a supportingring is fixedly connected to the tops of the L-shaped supporting plates, and a circular ring is fixedly connected to the top of the supporting ring; a discharging hole is formed in the left end of thecircular ring, a discharging U-shaped plate used for discharging is fixedly connected to the position, at the discharging hole, of the circular ring, a copper core discharging pipe used for discharging copper cores is fixedly connected to the right end of the circular ring, and a copper core discharging pipe is placed in the copper core discharging pipe; and the circular ring is fixedly connectedwith a sleeve discharging pipe in the anticlockwise direction of the copper core discharging pipe. The automatic riveting device has the advantages that the automatic riveting is realized, the efficiency is higher, meanwhile, the riveting pressure is uniform, the quality is ensured, and the enterprise production is facilitated.

Owner:东莞市拓伸电子科技有限公司

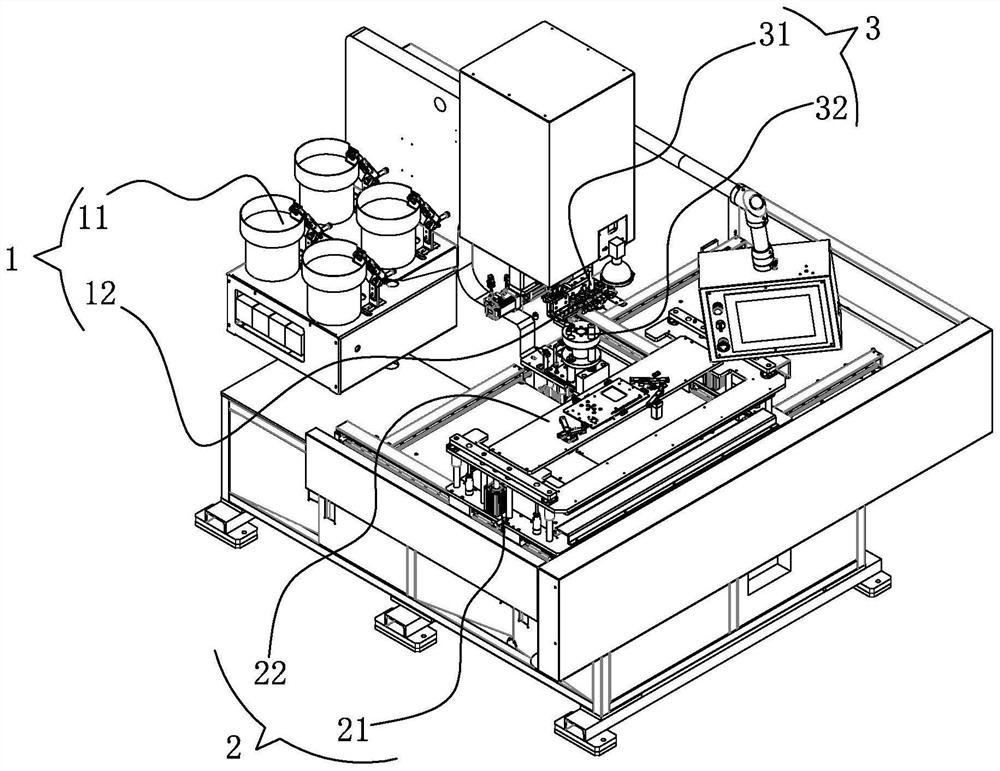

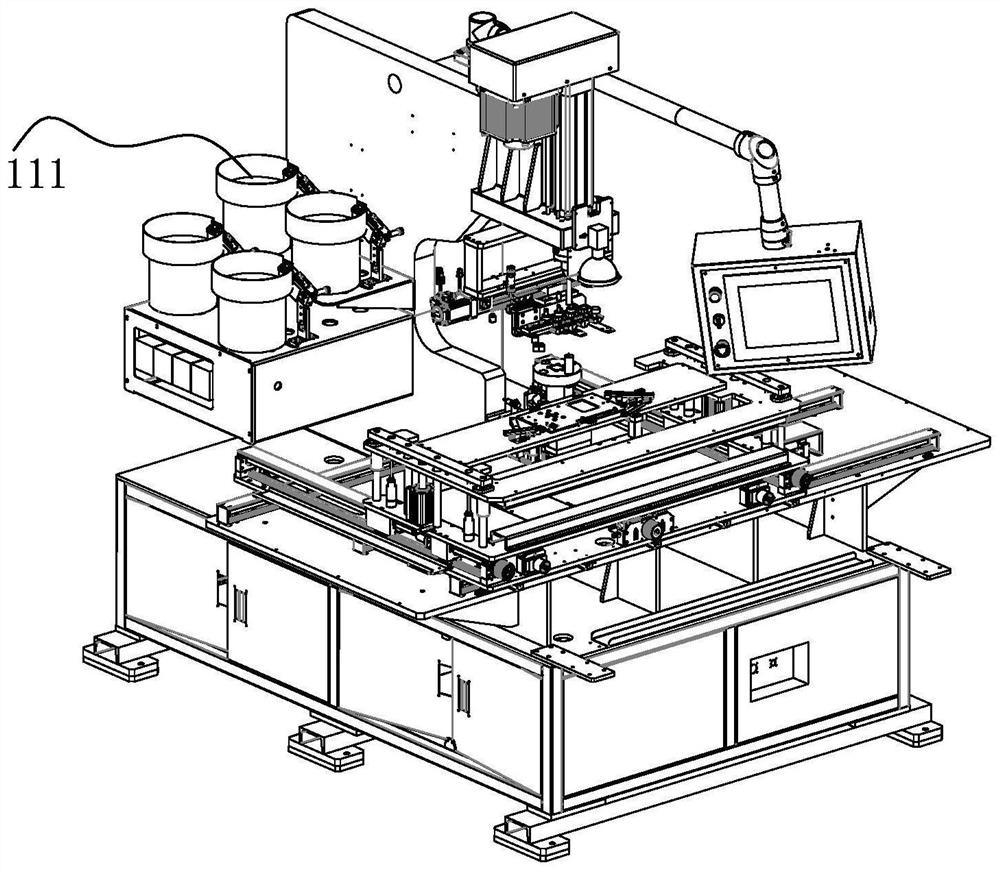

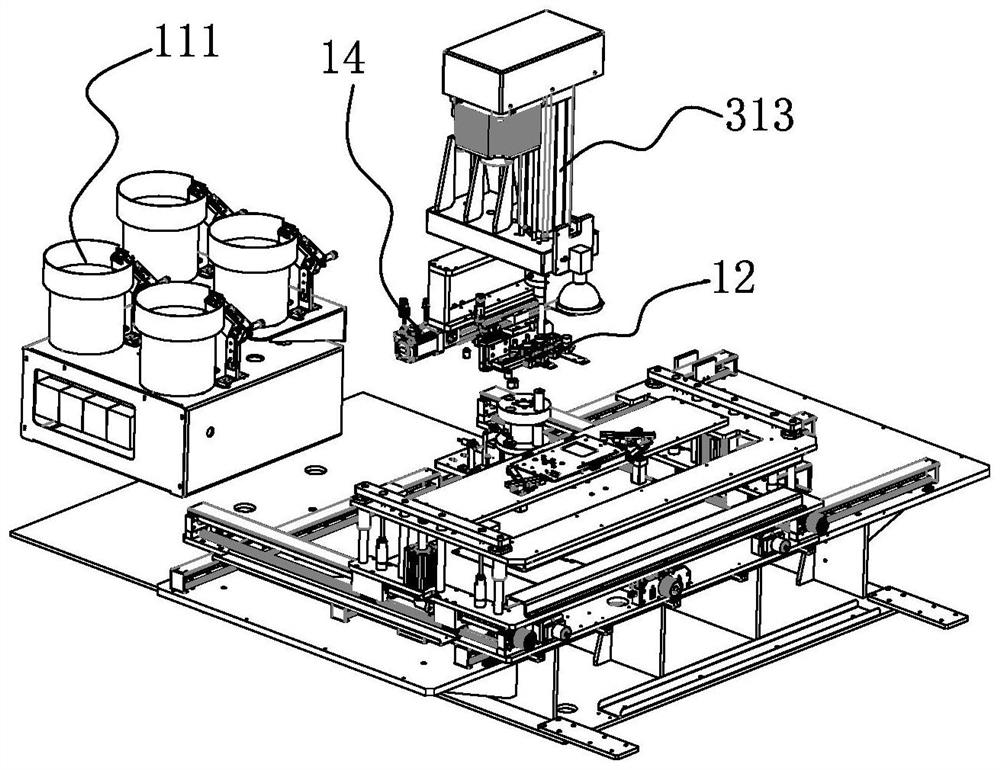

An automatic error-preventing leak riveting method and riveting equipment

ActiveCN114192725BGuaranteed to workAvoid mistakesMetal-working feeding devicesMetal working apparatusEngineeringWork cell

The invention discloses an automatic error-proof and missing riveting method, which comprises the following steps: the riveting part feeding part sends the riveting part to be riveted to a set riveting position; the workpiece clamping and moving part sends the workpiece to be riveted to a set position The position of the workpiece; the riveting part rivetes the riveting part at the set riveting position to the workpiece at the setting position; it is characterized in that: the riveting part includes an upper riveting module device and a lower riveting module device , wherein, the upper riveting module device is provided with an air pressure module, and the air pressure module includes an air suction working unit and an air pressure change monitoring unit; the upper riveting module device and the lower riveting module device cooperate with each other to rivet the riveting parts to the workpiece , the air suction working unit produces air suction on the rivet at the set position of the rivet, and the air pressure change monitoring unit monitors the change of the air pressure value, and judges whether it is adsorbed to the rivet to be riveted or whether the adsorption is judged by the change of air pressure. To what kind of rivet. The invention also discloses an automatic error-preventing leakage riveting equipment.

Owner:睿恩特智能装备(东莞)有限公司

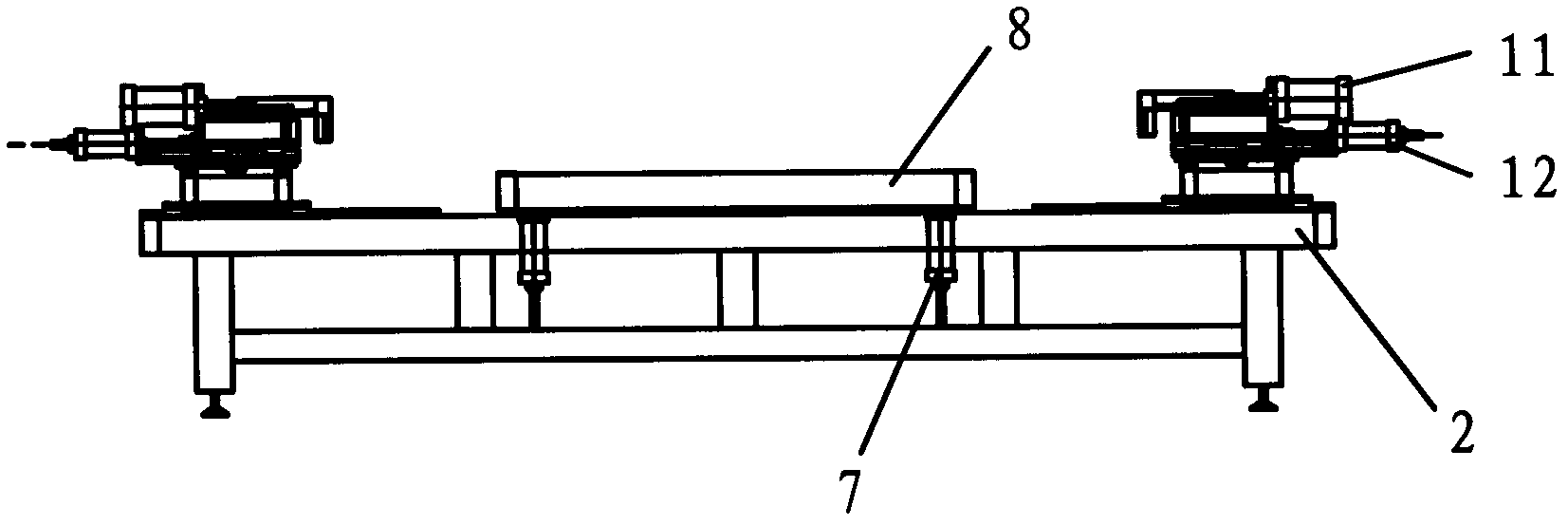

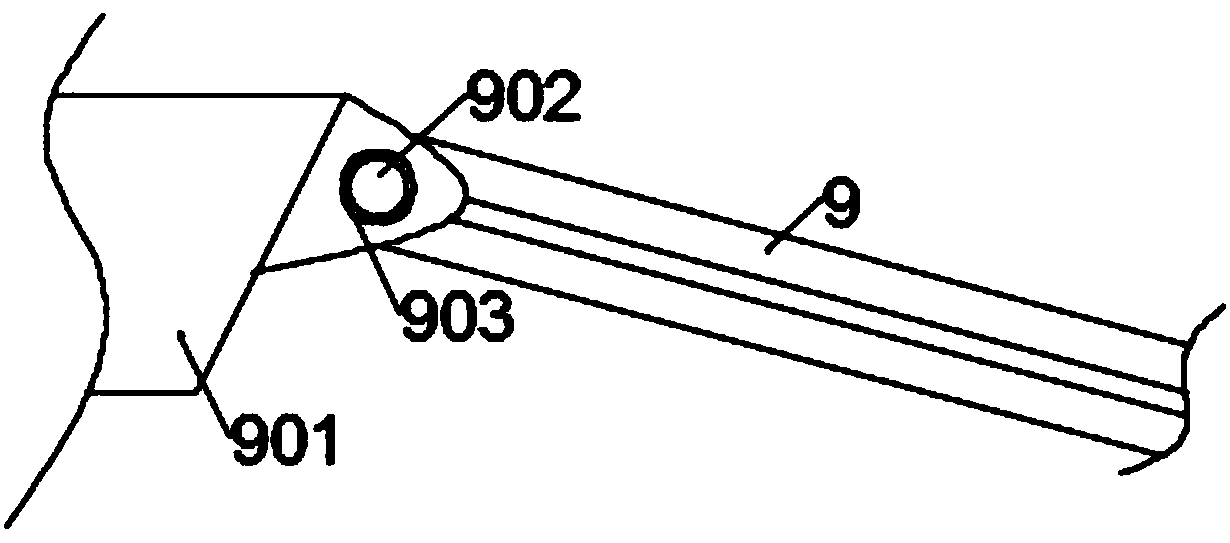

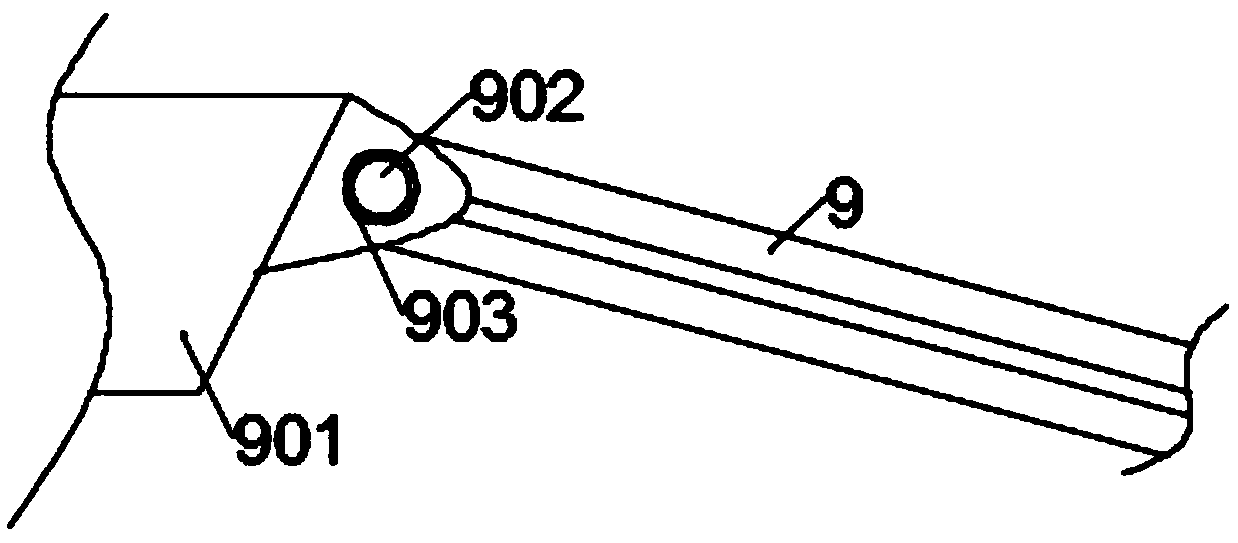

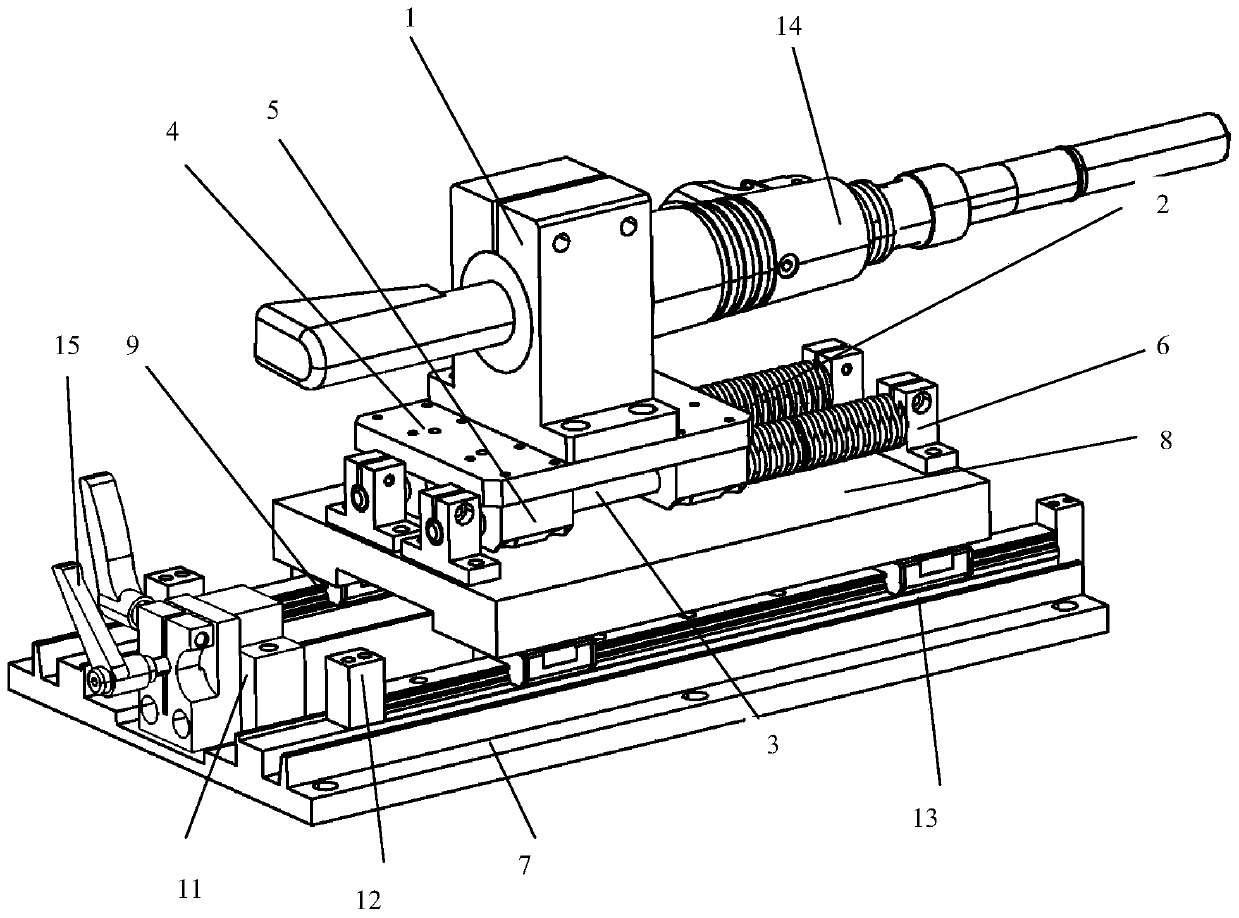

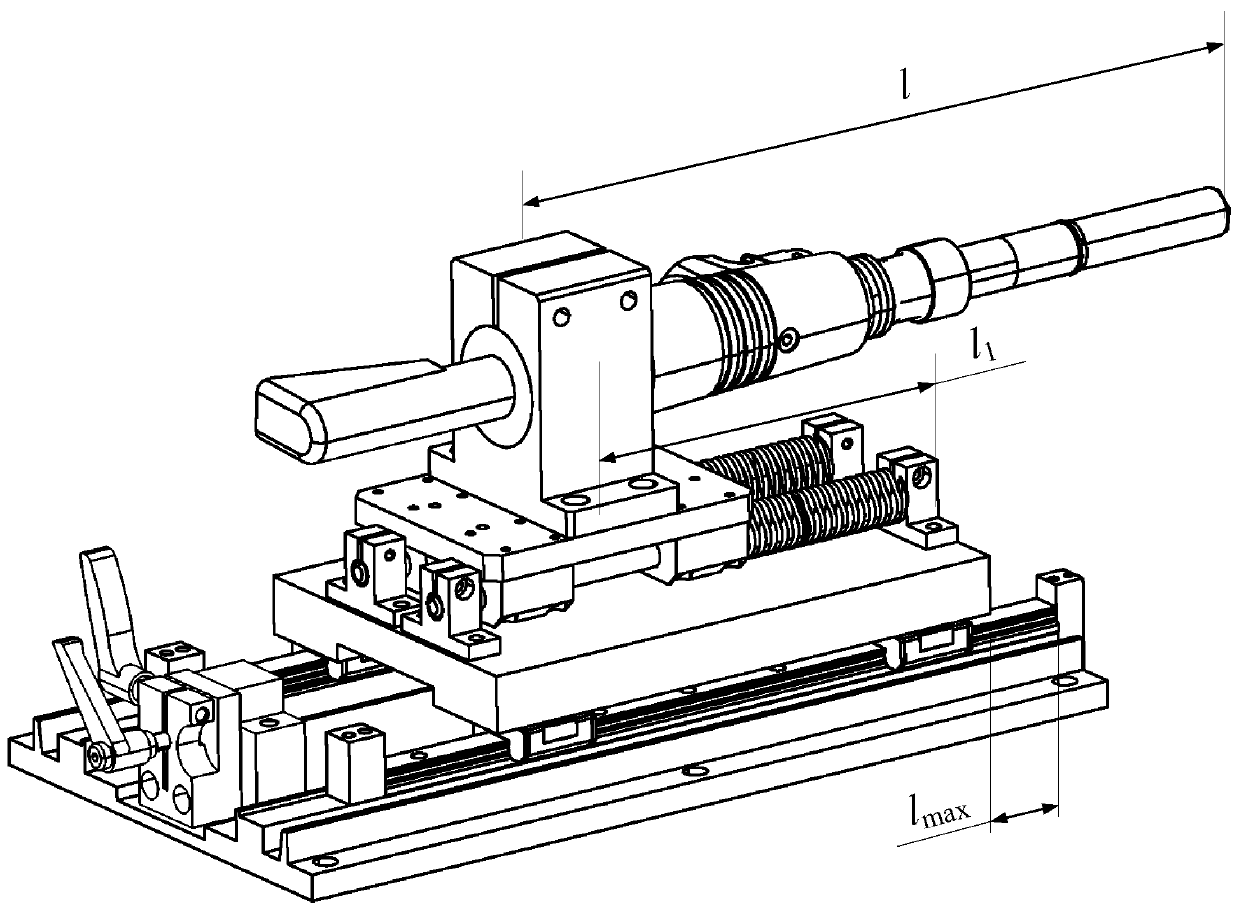

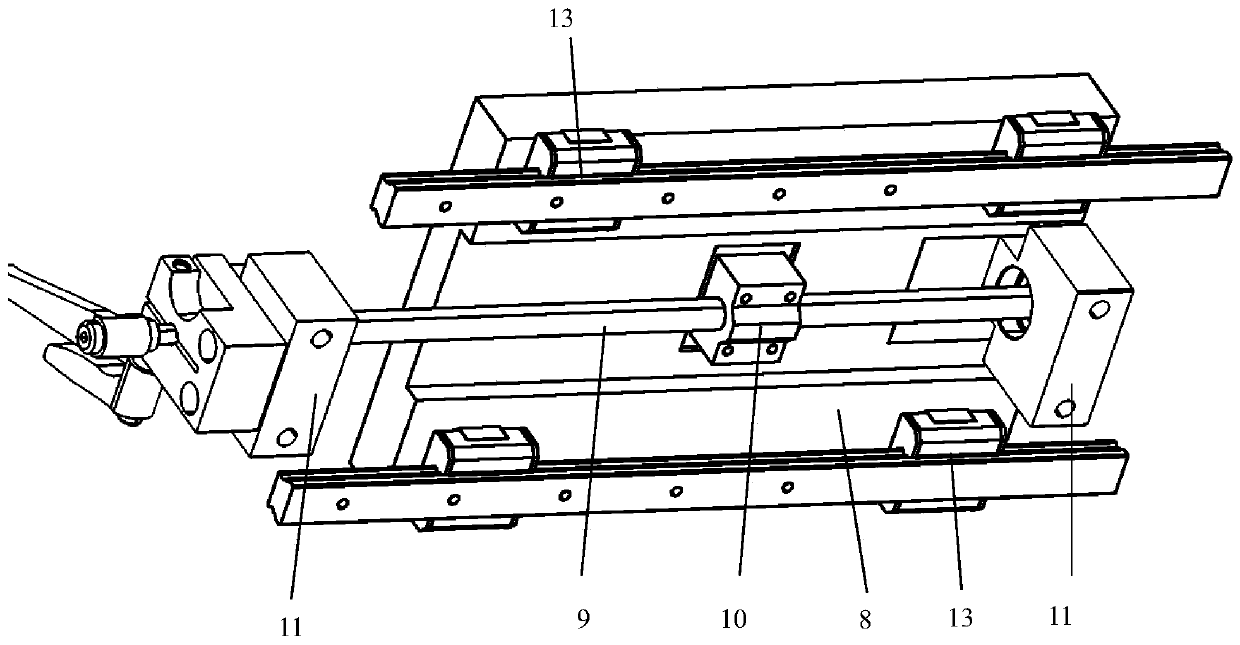

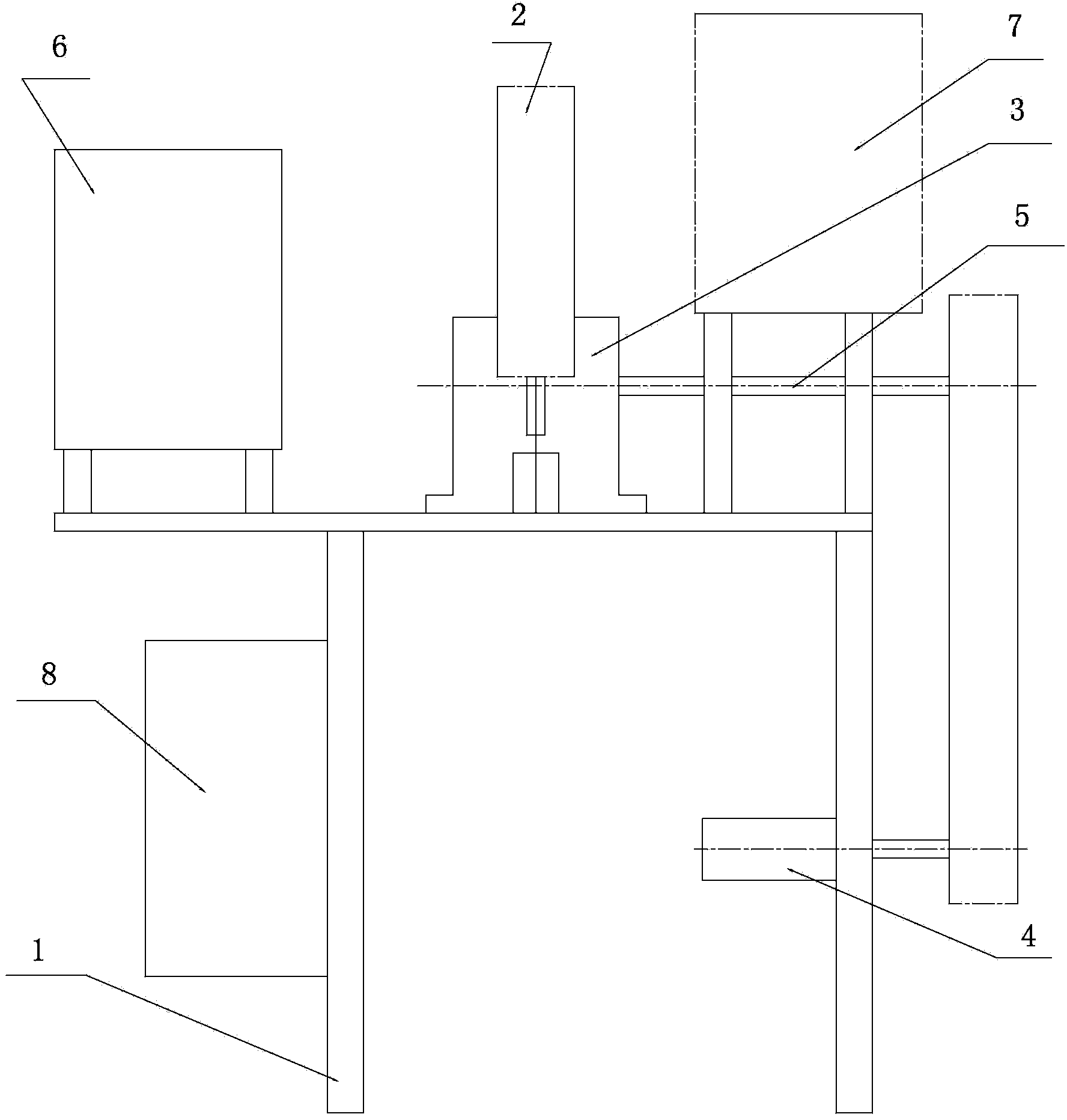

A ring groove rivet gun automatic feed riveting device

The invention relates to a device for automatic feeding and riveting of a circular groove rivet riveter. The device mainly consists of a circular groove rivet riveter body, a riveter body retaining device, a feeding mechanism, a resetting device, a manual feeding cranking bar and limiting stoppers; linear movement of the riveter body is realized by the feeding mechanism consisting of a T-shaped screw rod and linear guide tracks; and relative position precision of a riveter head of the riveter body is guaranteed by mechanical calibration, and control over movement distance and precision is ensured. The device is capable of realizing feeding movement by an automatic or manual machine; when the device is used for riveting with a circular groove rivet, the riveter body automatically does linear feeding movement to finish automatic riveting of the circular groove rivet; and the device is simple to operate, convenient and capable of guaranteeing precise feeding movement during automatic riveting of the circular groove rivet.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

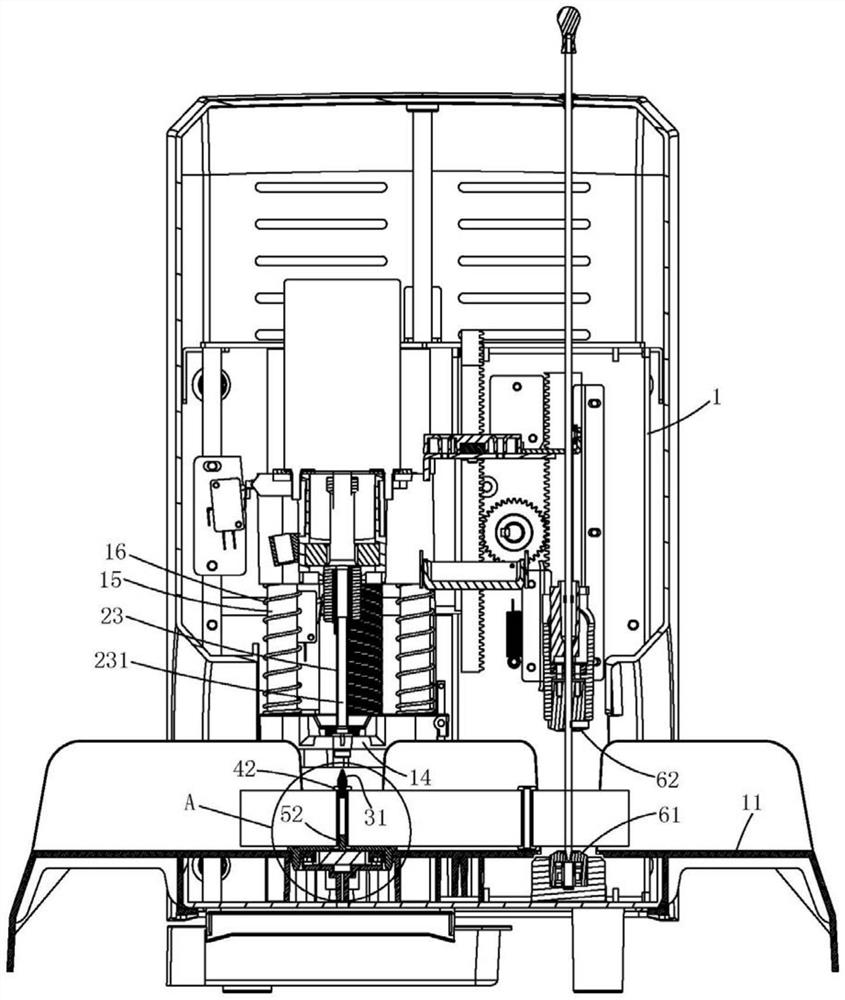

Mushroom fastener riveting machine

InactiveCN102599689BRealize automatic rivetingIncrease productivityClothes buttonsMotor driveMushroom

The invention discloses a mushroom fastener riveting machine. The riveting machine includes a rack, a first vibration disk, a second vibration disk, a transmission system, a motor, a main shaft and a riveting mechanism, the transmission system is arranged on the rack, the motor drives the main shaft to rotate, the main shaft outputs power to the transmission system, the transmission system drives the riveting mechanism to move, the riveting mechanism includes a support base, two slideways that are parallel from top to bottom are arranged inside the support base, two ejector rods are arranged on a top base, the two ejector rods are respectively arranged inside the two slideways, an upper riveting piece support is arranged at the exit of the upper slideway, a lower riveting piece support is arranged at the exit of the lower slideway, an upper mould is arranged above the upper riveting piece support, a lower mould is arranged below the lower riveting piece support, the upper mould and the lower mould are arranged below the riveting mechanism. In the invention, the automatic riveting of mushroom fasteners can be achieved, the production efficiency of mushroom fasteners can be greatly improved, during the riveting process, the fitting between the upper part and the lower part of mushroom fasteners can effectively guarantee the relative position of the two parts, so that the qualified rate of products is greatly increased.

Owner:SHENZHEN LIANDA BUTTON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com