Automatic riveting device for electronic cigarette manufacturing

An electronic cigarette, riveting pressure technology, applied in the direction of manufacturing tools, tobacco, metal processing equipment, etc., can solve the problems of unfavorable enterprise production, high defective rate, high riveting pressure, etc., to facilitate cutting, ensure quality, and riveting pressure. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

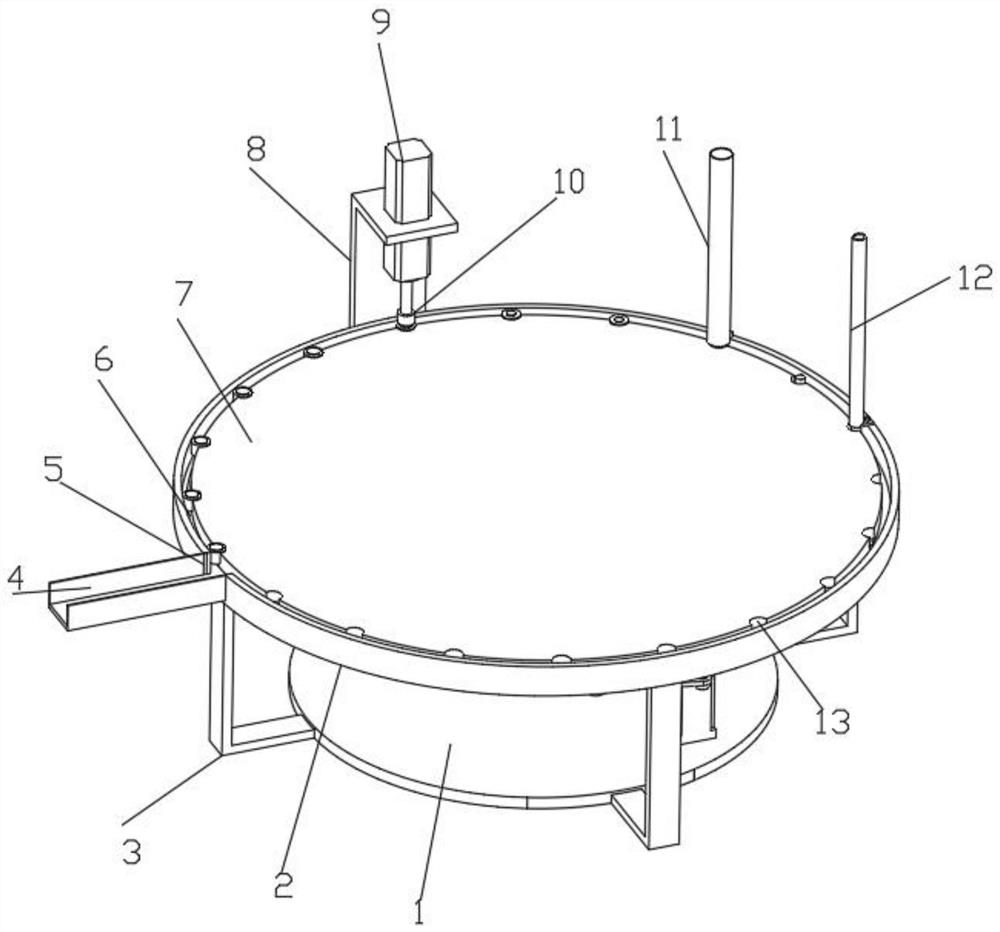

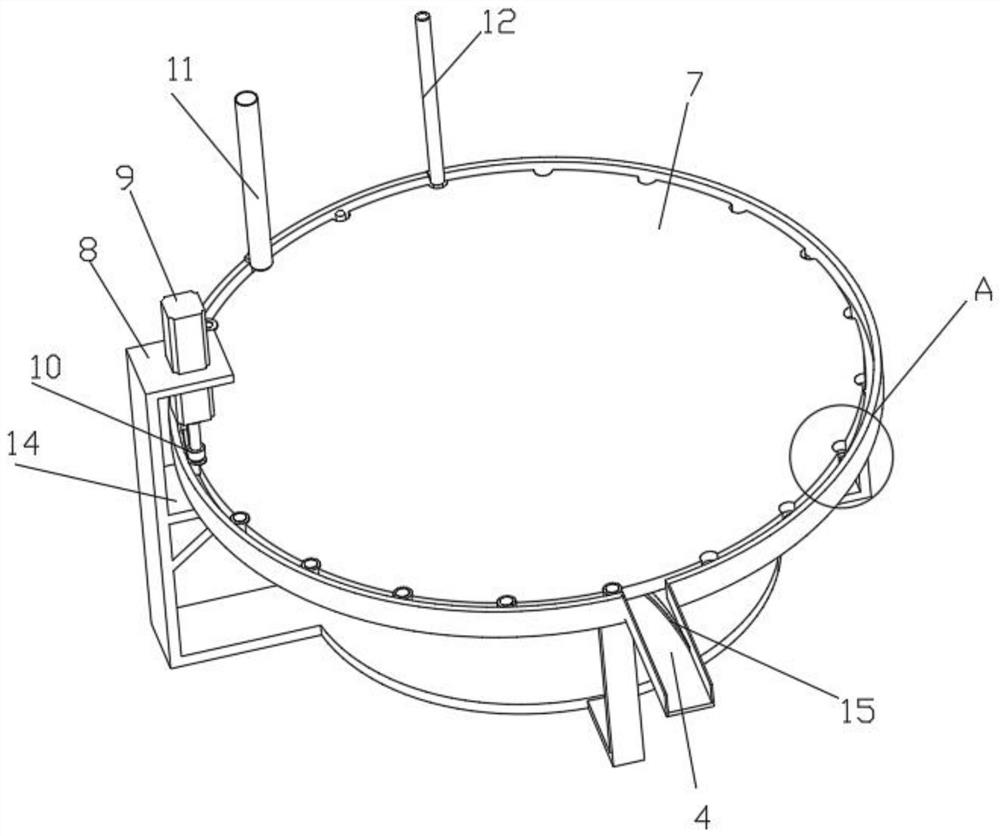

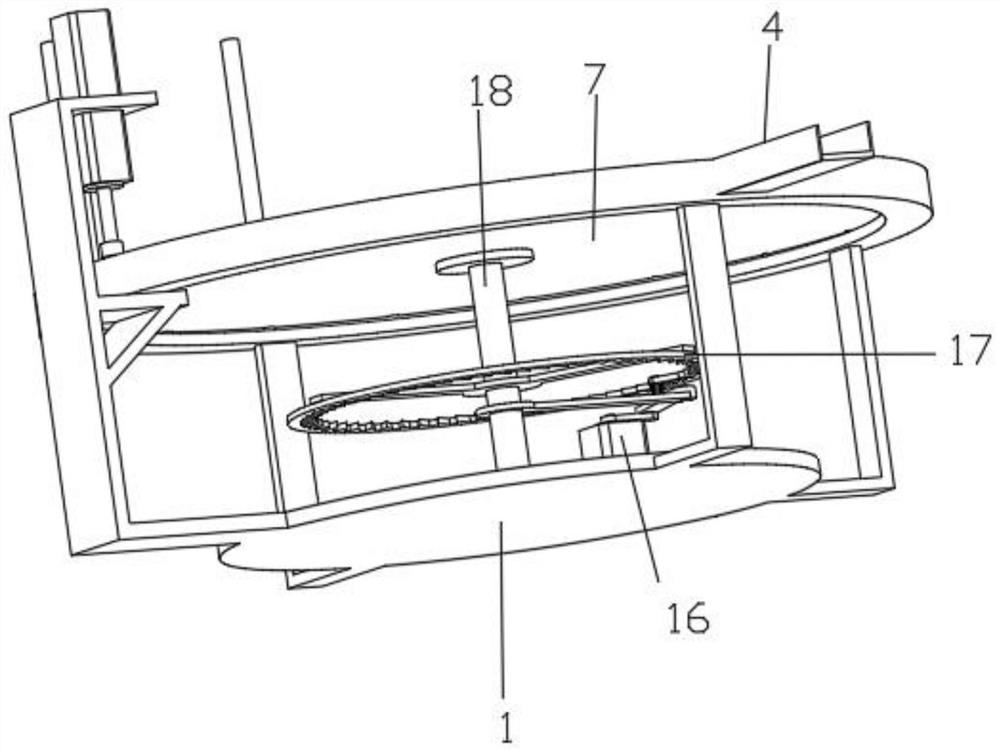

[0031] Such as figure 1 , 2 , an automatic riveting device for electronic cigarette manufacturing as shown in 3, 4, and 6, including a support plate 1, a copper core 30 and a sleeve 31, and the side wall of the support plate 1 is evenly fixed and connected with an L-shaped support along the circumferential direction Plate 3, the top of the L-shaped support plate 3 is fixedly connected with a support ring 6, the top of the support ring 6 is fixedly connected with a ring 2, and the left end of the ring 2 is provided with a discharge hole 5, and the ring 2 is at the discharge hole 5 A discharge U-shaped plate 4 for blanking is fixedly connected, the inner wall of the discharge U-shaped plate 4 is fixedly connected with an arc-shaped guide plate 15 for guiding the finished product to move into the discharge U-shaped plate 4, and the inner end of the arc-shaped guide plate 15 Fixedly connected with the top of the support ring 6, the arc-shaped guide plate 15 is convenient for movi...

Embodiment 2

[0034] Embodiment 2 is a further improvement to Embodiment 1.

[0035] Such as figure 1 , 5 The adjustment structure shown comprises a support arc plate 28 and an oblique guide plate 29, the support arc plate 28 and the oblique guide plate 29 are all fixedly installed on the top of the discharge U-shaped plate 4, and the oblique guide plate 29 is arranged on the support arc. The right end of the plate 28, when the copper core 30 is in contact with the inclined guide plate 29, pushes the top of the copper core 30 to move upwards and pushes the riveting position of the copper core 30 to move to the top of the sleeve 31, and 10 is set in the middle of the supporting arc plate 28. At the top of the end, because the top of the sleeve 31 is flush with the top of the copper core 30 to ensure that the copper core 30 slides normally under the sleeve feeding tube 11, the top of the copper core 30 needs to be adjusted to the top of the sleeve 31 when riveting. At the top, the sleeve 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com