Fully-automatic padlock trademark riveting device

A riveting device and fully automatic technology, which is applied in the field of fully automatic padlock trademark riveting devices, can solve the problems of insufficient riveting and low efficiency, and achieve the effects of increasing riveting efficiency, preventing damage, and preventing safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

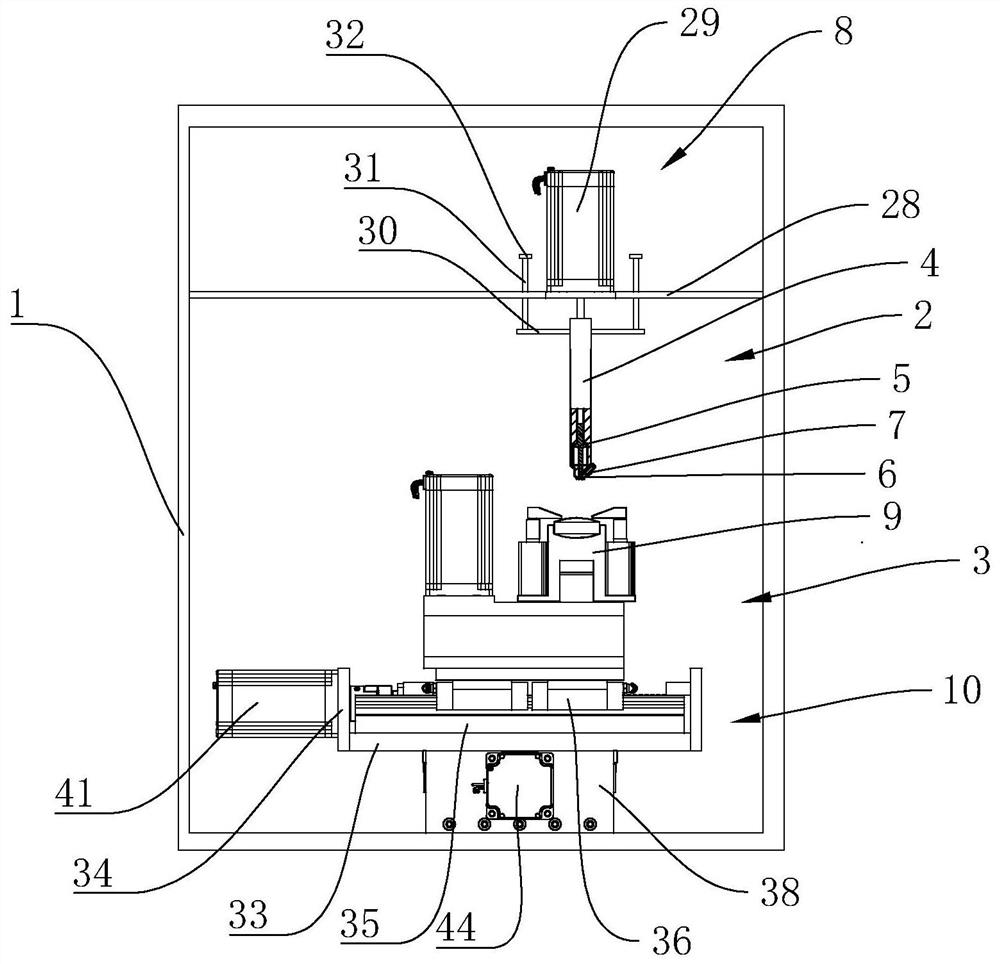

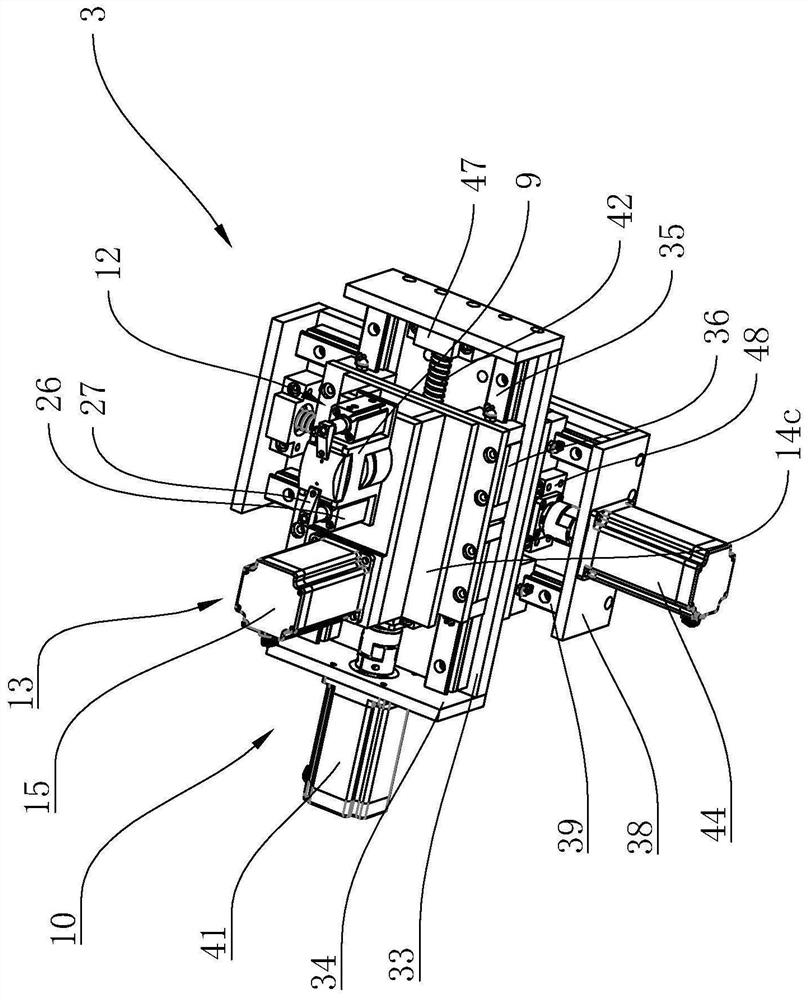

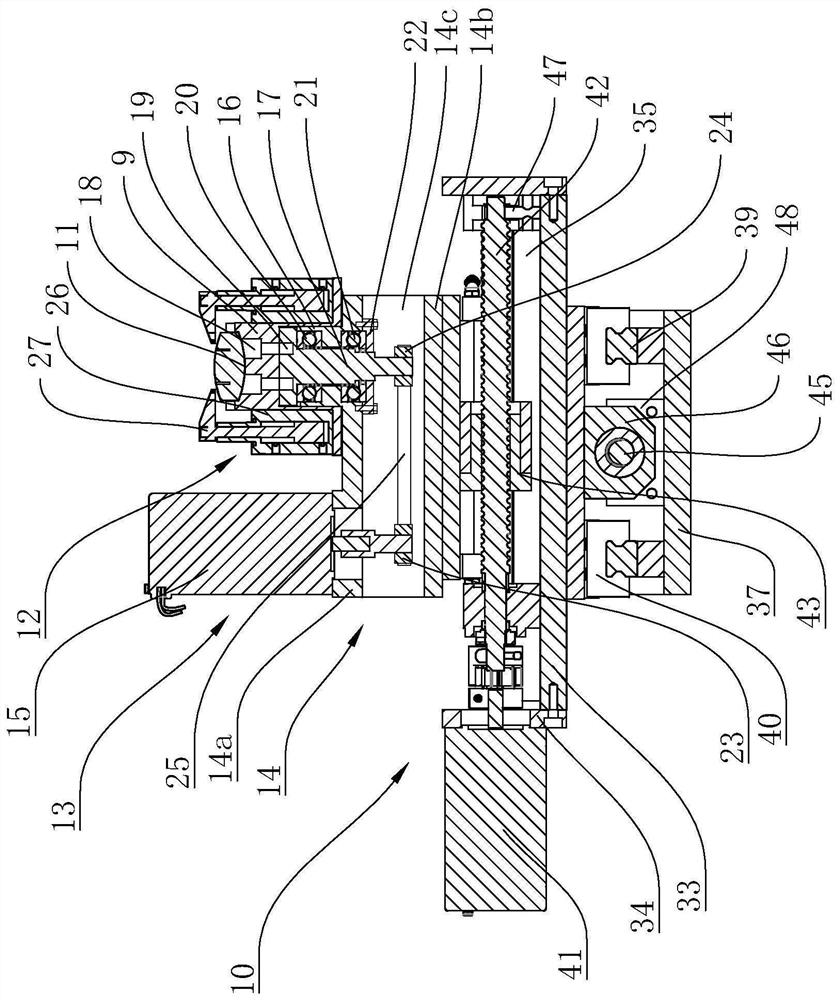

[0028] Such as Figure 1-Figure 3 As shown, a fully automatic padlock trademark riveting device includes a riveting mechanism 2 and a padlock positioning fastening mechanism 3 arranged in a frame 1. The riveting mechanism 2 includes an air hammer 4 and an air hammer connected to the air hammer 4 Lifting assembly 8, the air hammer 4 is provided with a punch 5 with a cross-section in the shape of a Chinese font, the bottom of the air hammer 4 is also provided with a feed channel 6 and the side of the air hammer 4 is also provided with a feed channel 6 A connected feeding pipe 7, the feeding pipe 7 is connected with the rivet feeding mechanism, the bottom of the punch 5 is inserted into the feeding channel 6; the locking position fastening mechanism 3 includes a fixed seat 9 and a fixed seat 9 Connected horizontal moving assembly 10, the fixed seat 9 is in the shape of a few characters, the top of the fixed seat 9 is provided with a padlock groove 11, and the arms on both sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com