Automatic assembly production device provided with detection device for automotive lock catches

A technology of production device and detection device, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of complex structure, poor environmental protection and high consumption cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0031] The proximity sensor 607 (model LJ24A3-12-Z / BY(AY)) mentioned in the present invention can be obtained through private customization or market purchase.

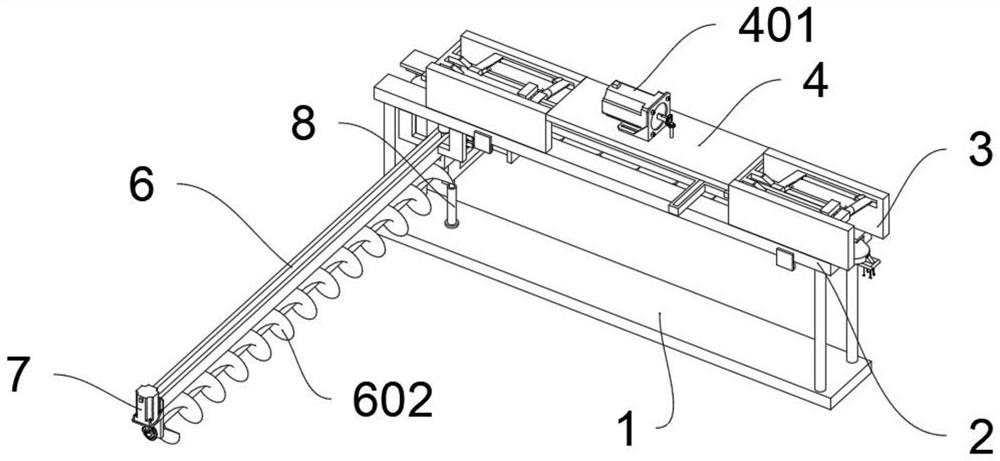

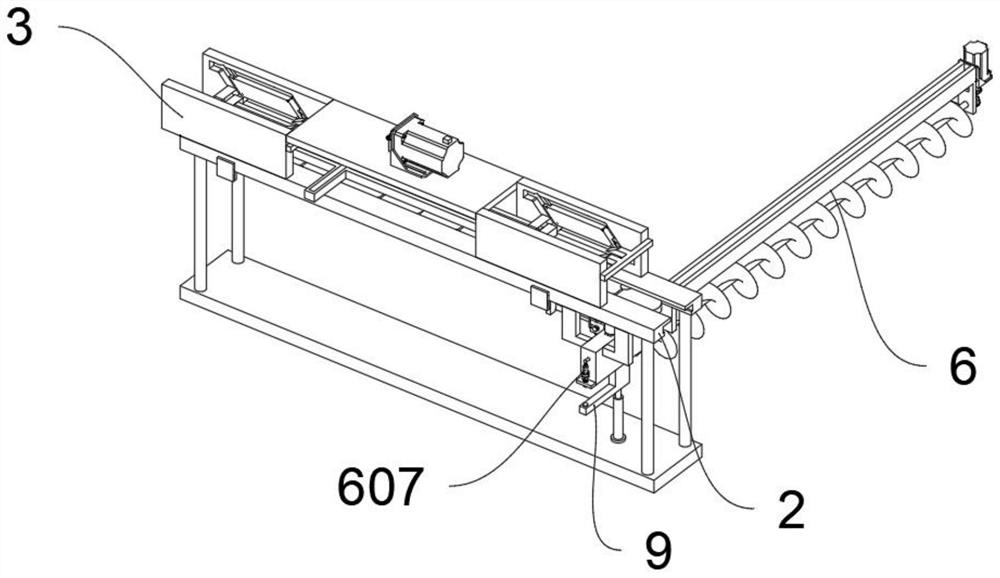

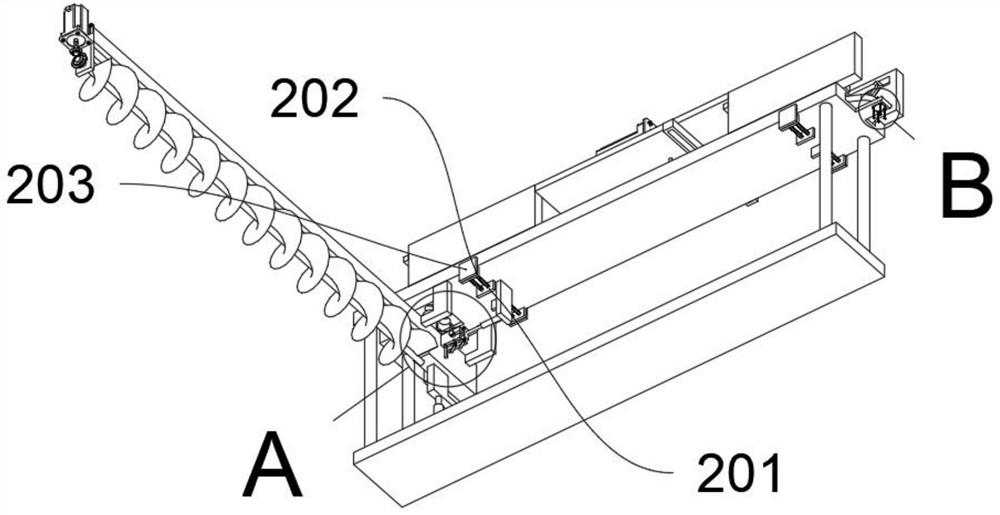

[0032] see Figure 1 to Figure 8, an embodiment provided by the present invention: a kind of automatic production device for automobile lock assembly assembly with a detection device, including a base 1; the top of the base 1 is fixed with a feed slideway 2 through a bracket; the feed slideway 2 also includes There are connecting pieces 201, spring rods A202, and positioning parts 203; two sets of bump structures are fixedly arranged on both sides of the bottom of the feed slideway 2; Springs are sleeved on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com