A ring groove rivet gun automatic feed riveting device

A ring groove rivet and automatic feeding technology, applied in the field of assembly manufacturing or connection, can solve the problem of low degree of automation, achieve the effect of simple operation, ensure the control of moving distance and accuracy, and ensure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

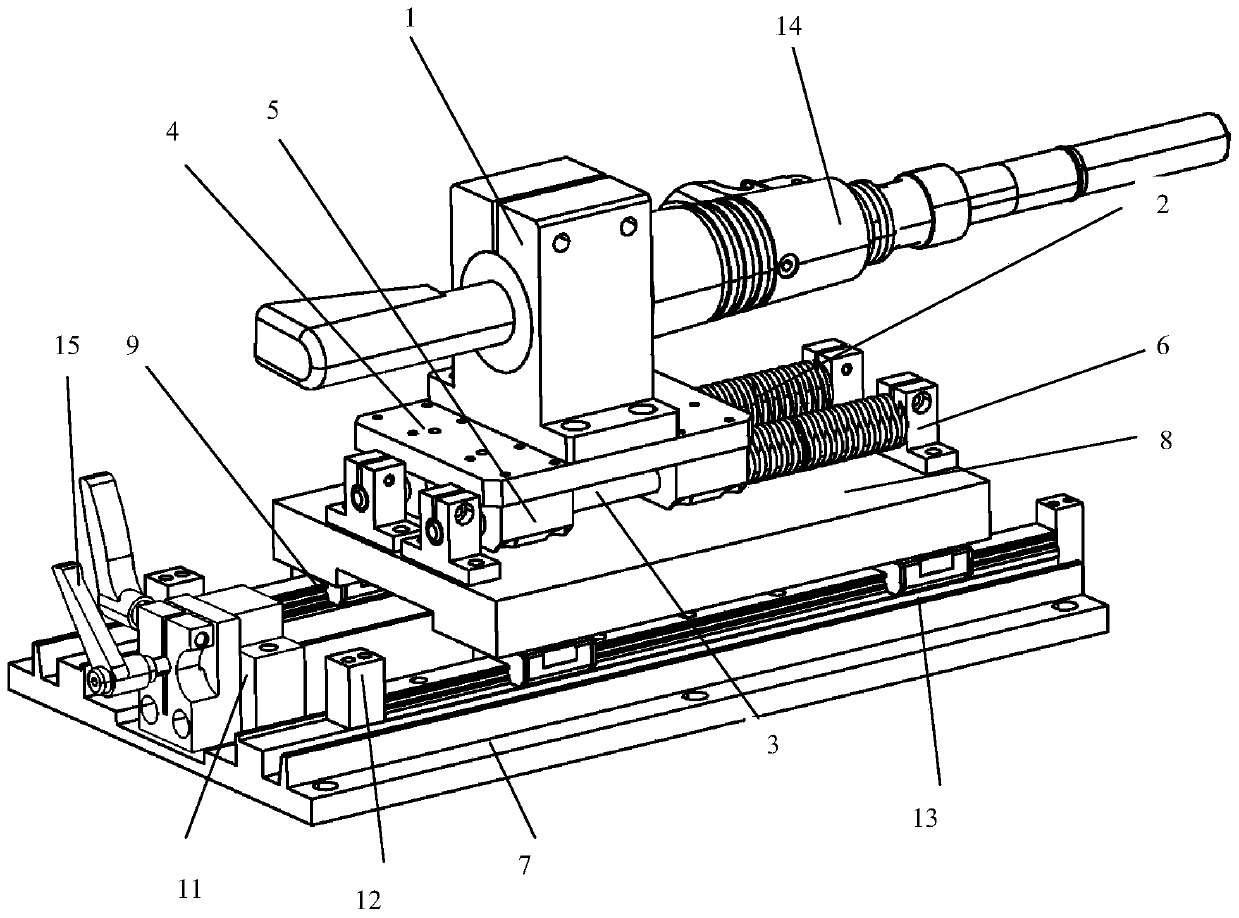

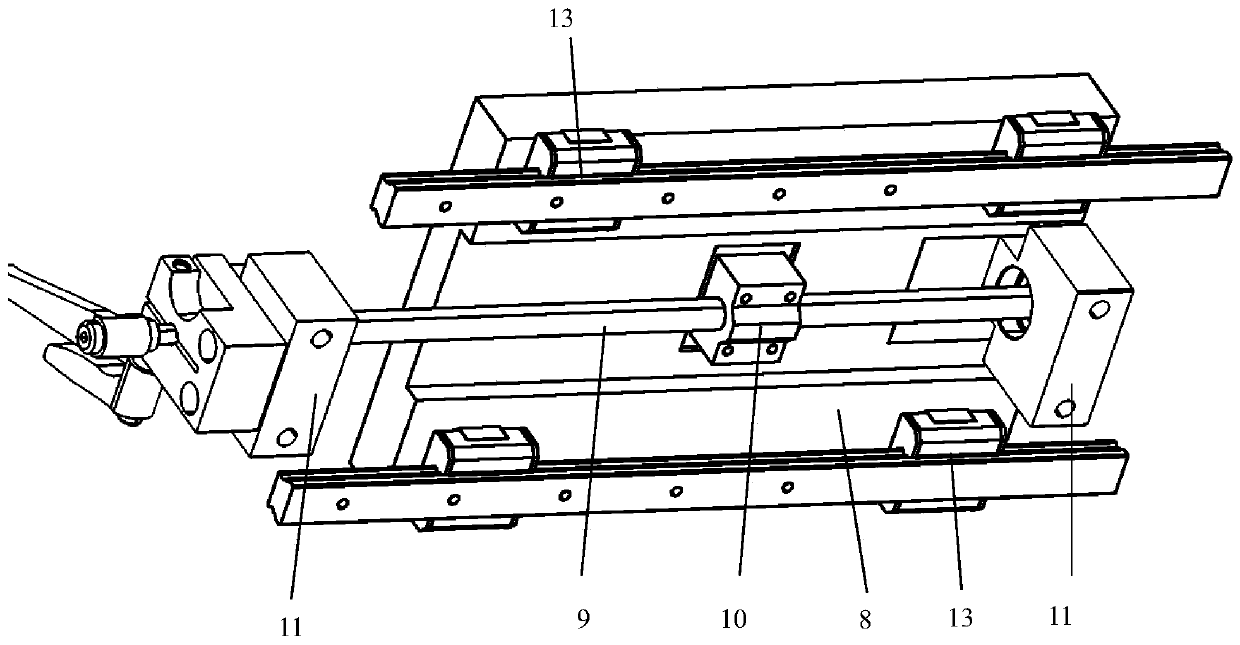

[0027] An automatic feed riveting device for ring groove rivets, which is used in conjunction with the riveter to automatically realize the riveting between ring groove rivets and composite materials; the ring groove rivet gun body 14 can realize the riveting of ring groove rivets, and is a special Riveting process equipment. The riveting device includes a feeding mechanism and a follower mechanism.

[0028] Such as figure 1 As shown, the follow-up mechanism includes a gun body holding device 1, a spring 2, a guide column 3, an upper plate 4, a guide sleeve 5, and a mounting seat 6;

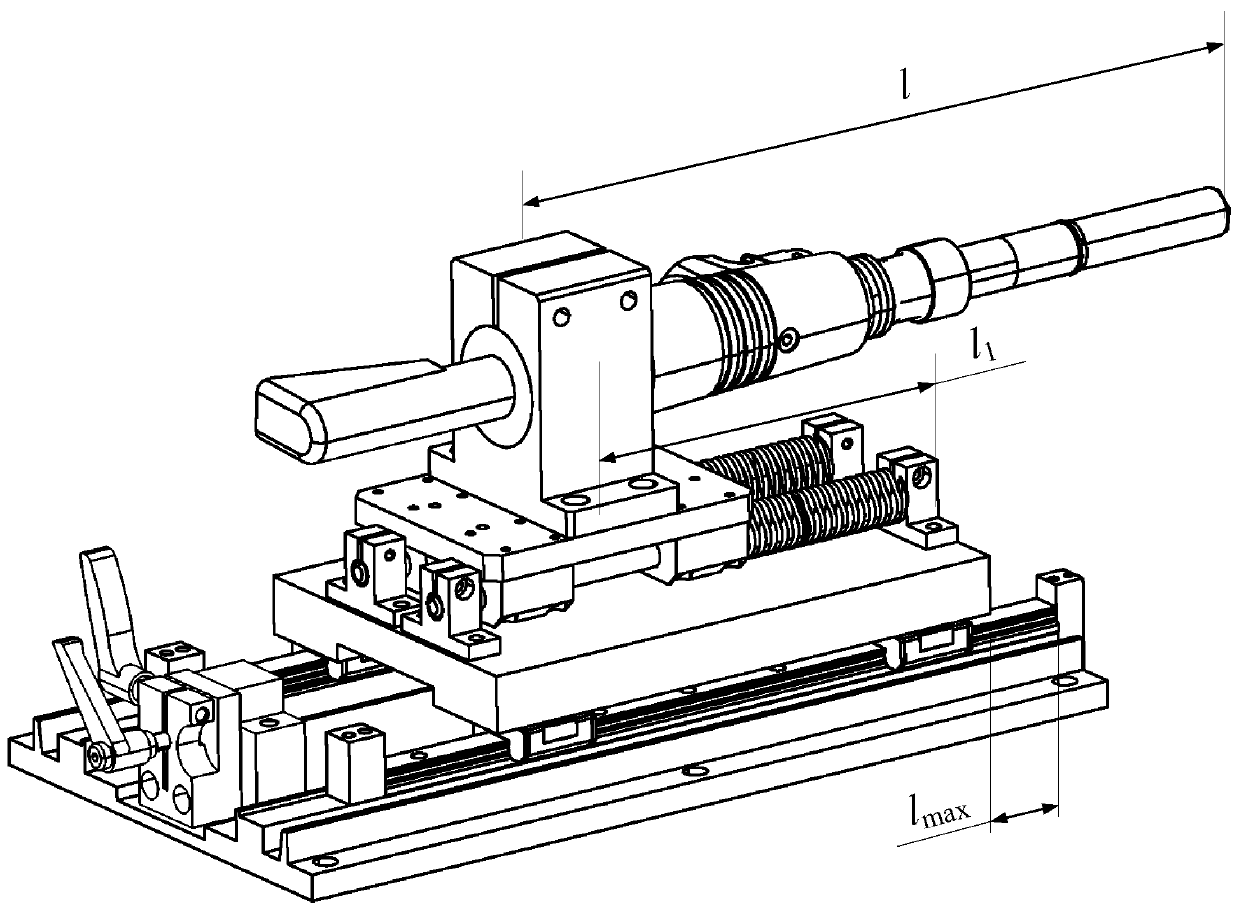

[0029] Such as figure 1 , figure 2 As shown, the upper surface of the upper plate 4 is fixed with the gun body holding device 1; the gun body holding device 1 can clamp and fasten the riveting gun gun body, and the position for clamping the riveting gun gun body should be before the nail outlet of the riveting gun, Optimally, the following requirements should be met: position l of the gun bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com