An automatic riveting machine for packaging box production

A technology of a riveting machine and a packaging box is applied in the field of packaging box production and manufacturing machinery and equipment to achieve the effects of being convenient to use, reducing economic losses and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

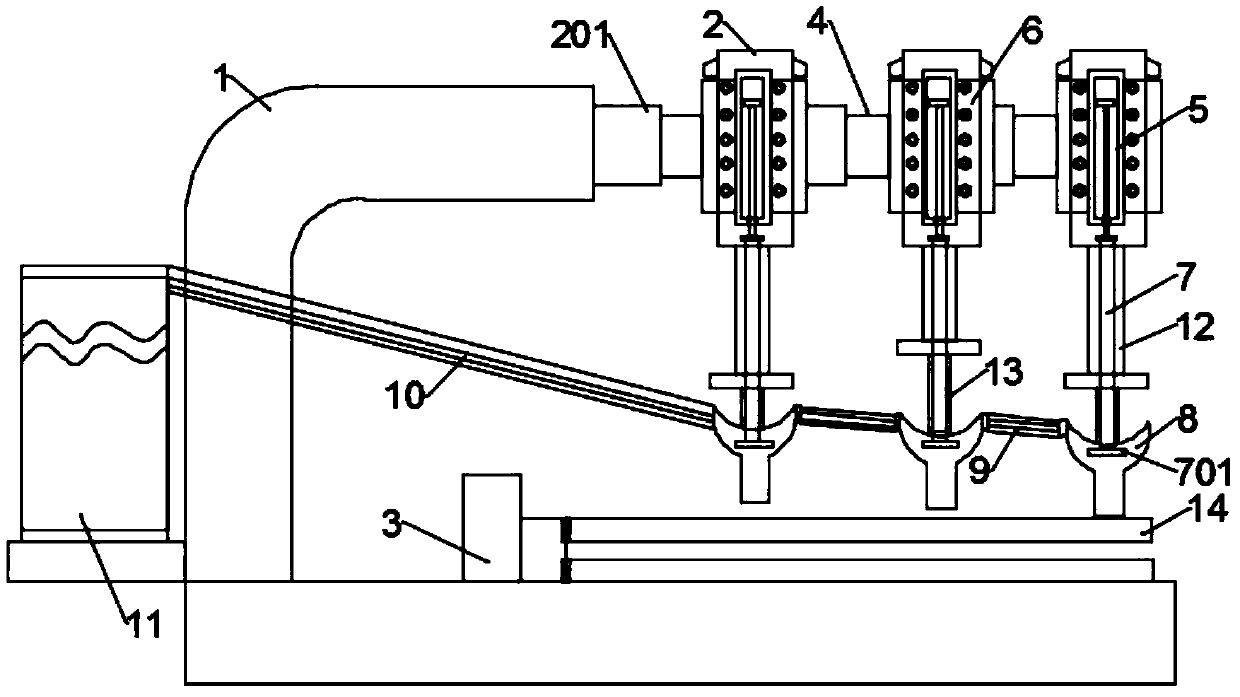

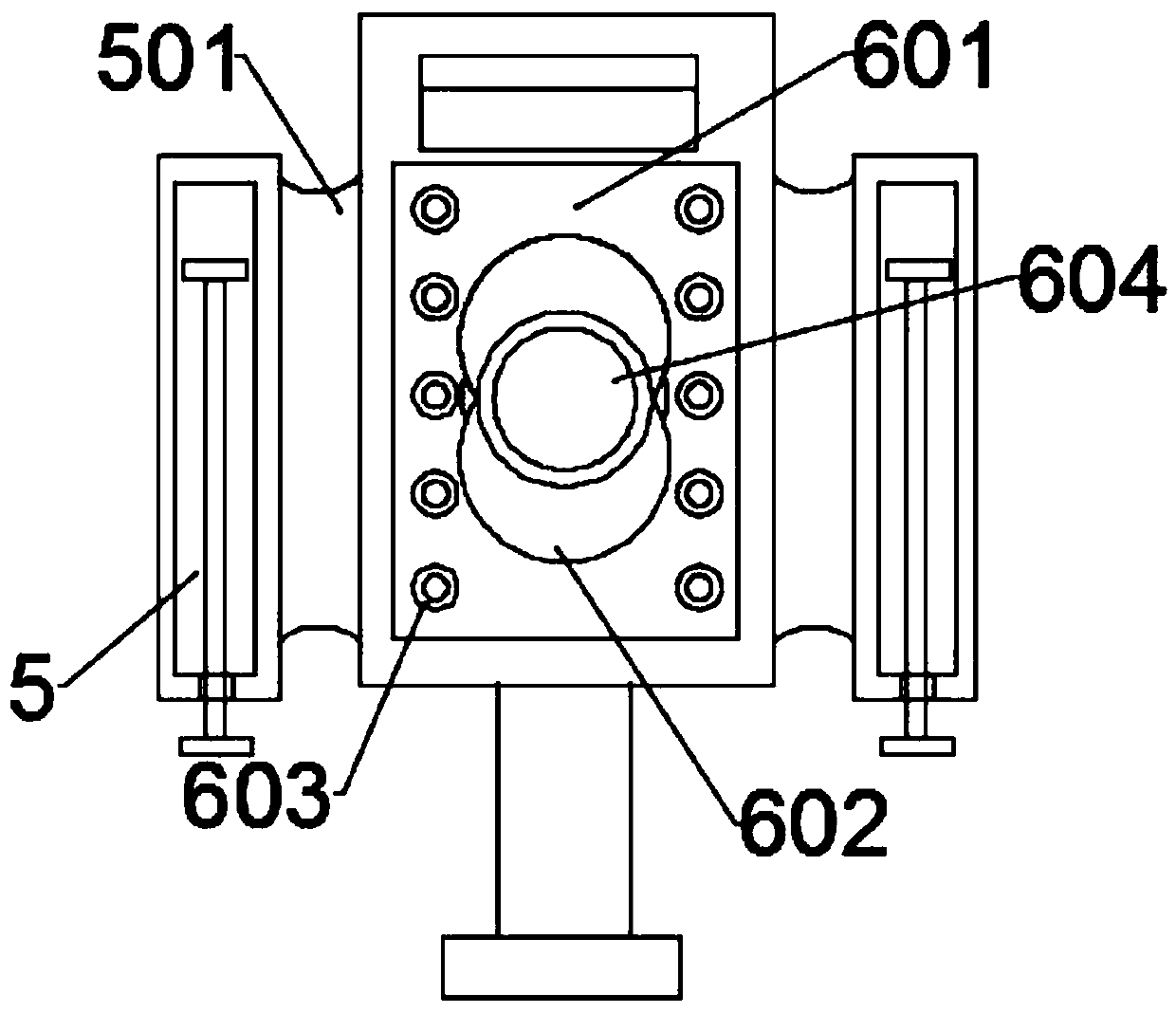

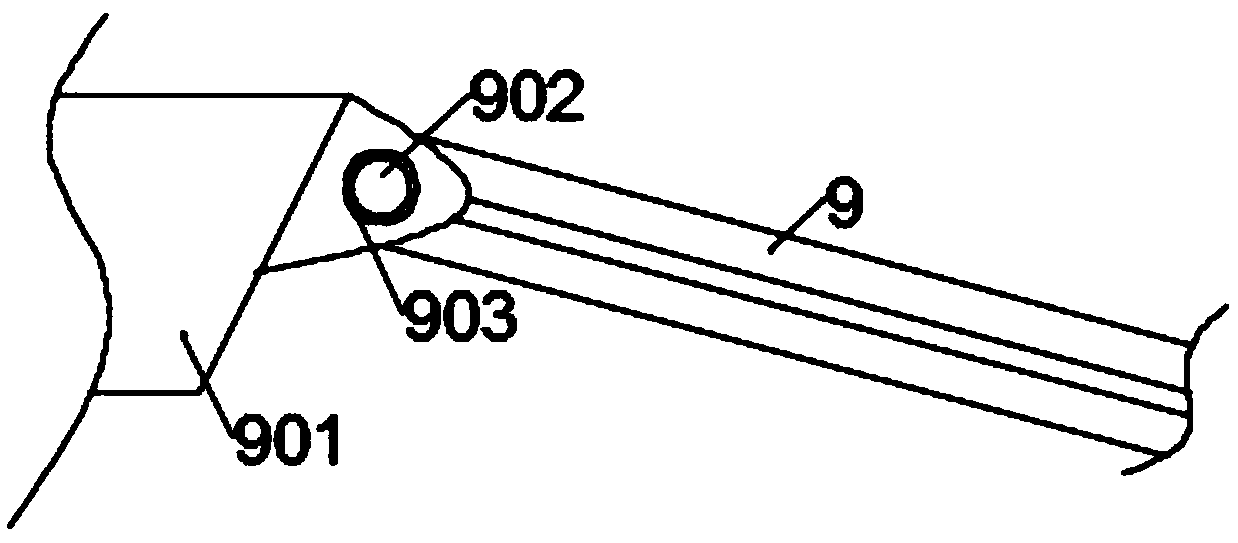

[0023] Such as figure 1 and figure 2 As shown, the present invention provides an automatic rivet machine for packaging box production, including a rivet frame 1, three pressing cylinders 2 and a load holding frame 3, the rivet frame 1 is a C-shaped structure, And the two ends of the rivet frame 1 are connected with a compression cylinder 2 and a load holding frame 3, and the three compression cylinders 2 are connected through a telescopic column 4, wherein the compression cylinder 2 is telescopic through the base The column 201 is connected to one end of the rivet frame 1, and the horizontal distance between the three compression cylinders 2 can be changed by adjusting the length of the telescopic column 4 and the base telescopic column 201, so as to meet the riveting requirements of the packaging box board and reduce the There is little need to adjust the position of the packing box board, and two adjustable air cylinders 5 are symmetrically installed on the front and rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com