Patents

Literature

36results about How to "Riveting realization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

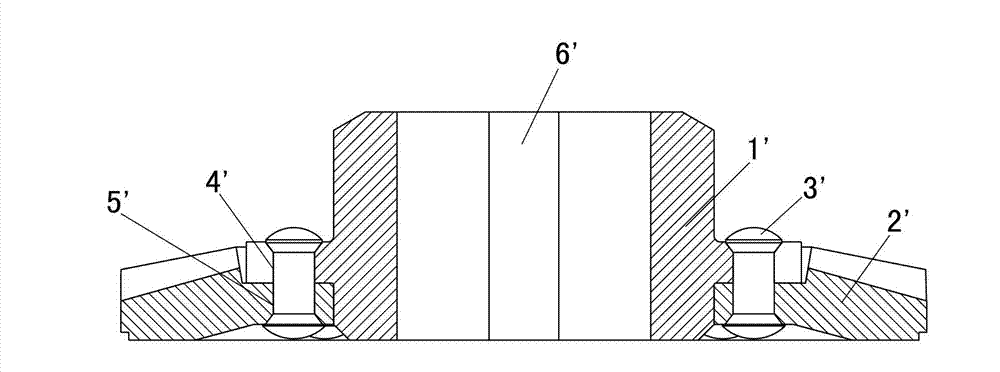

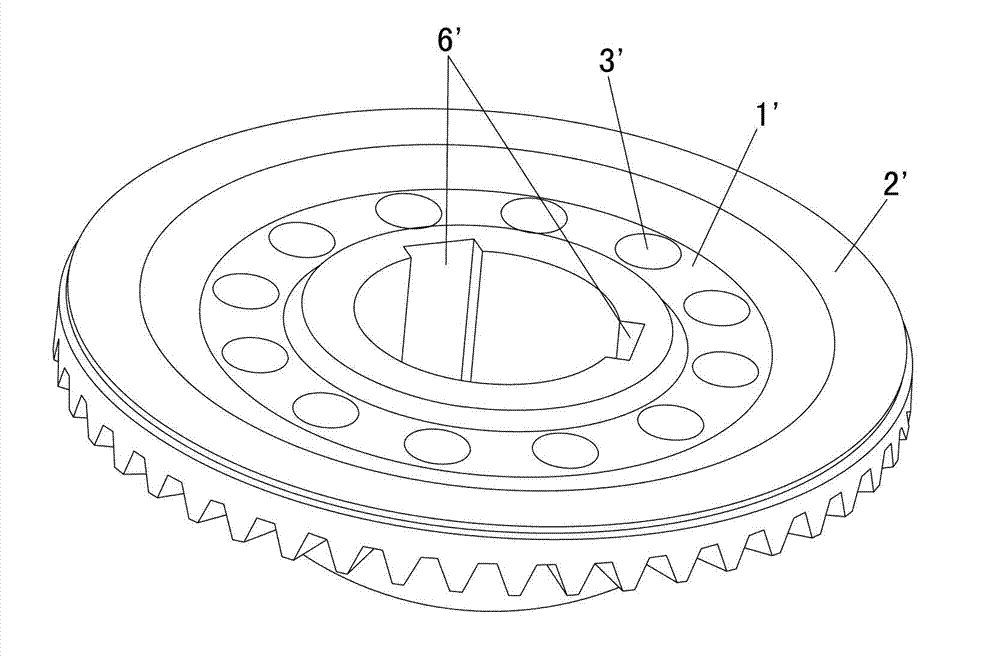

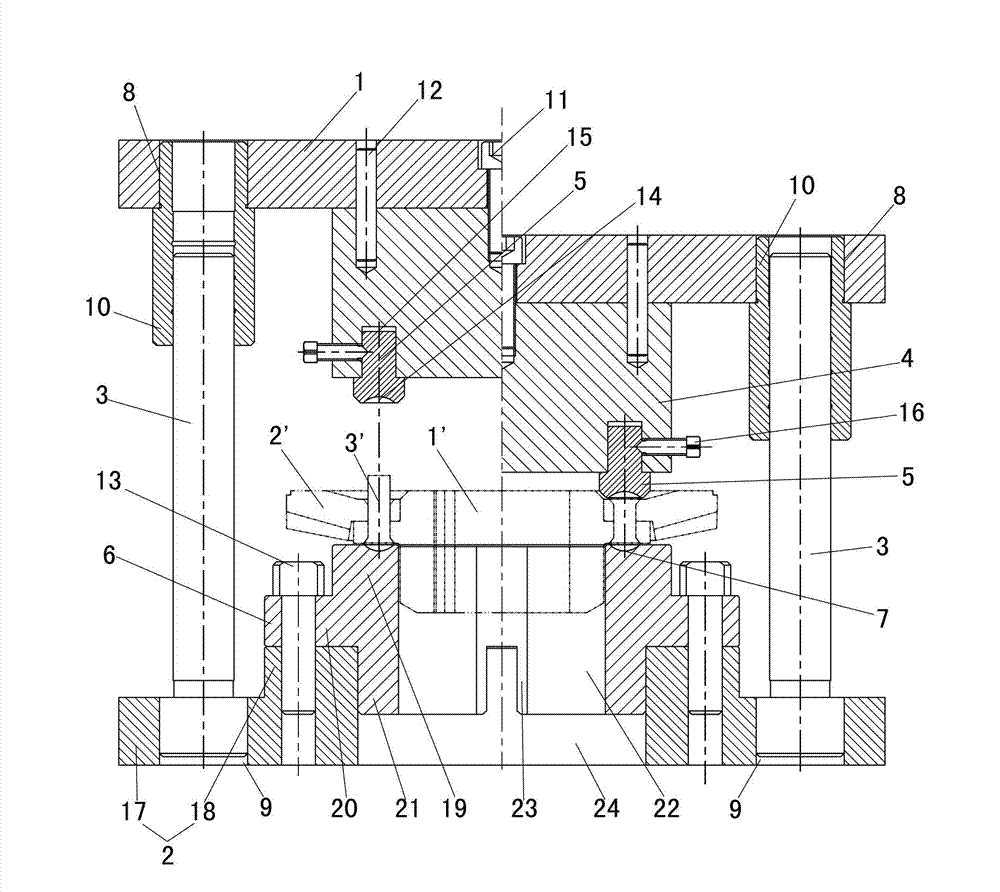

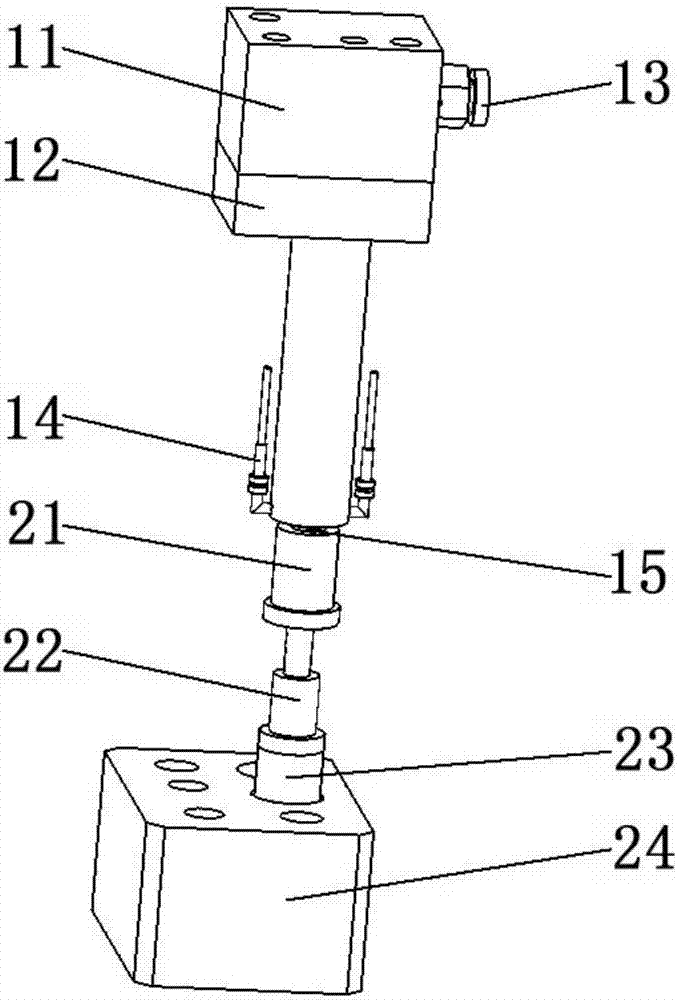

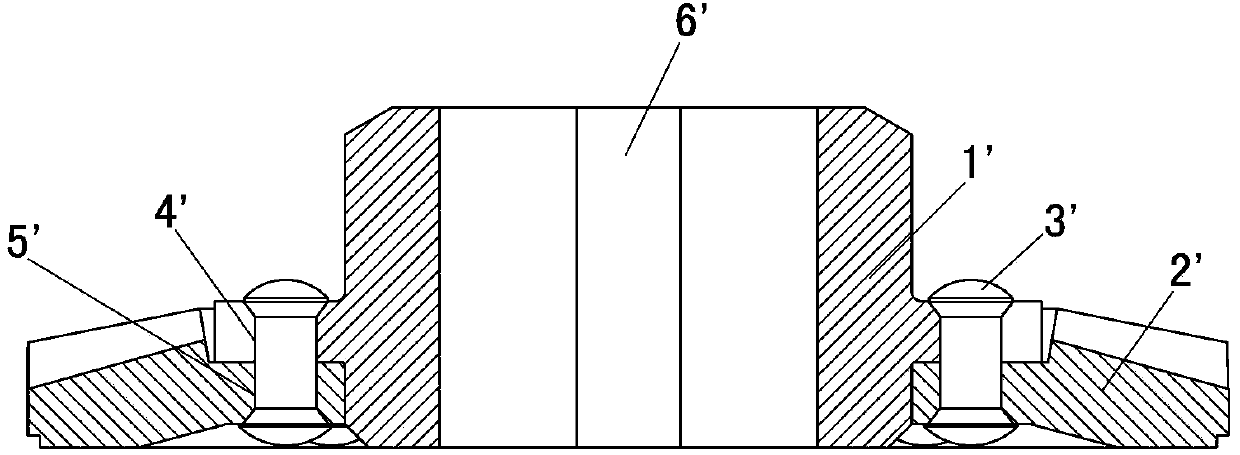

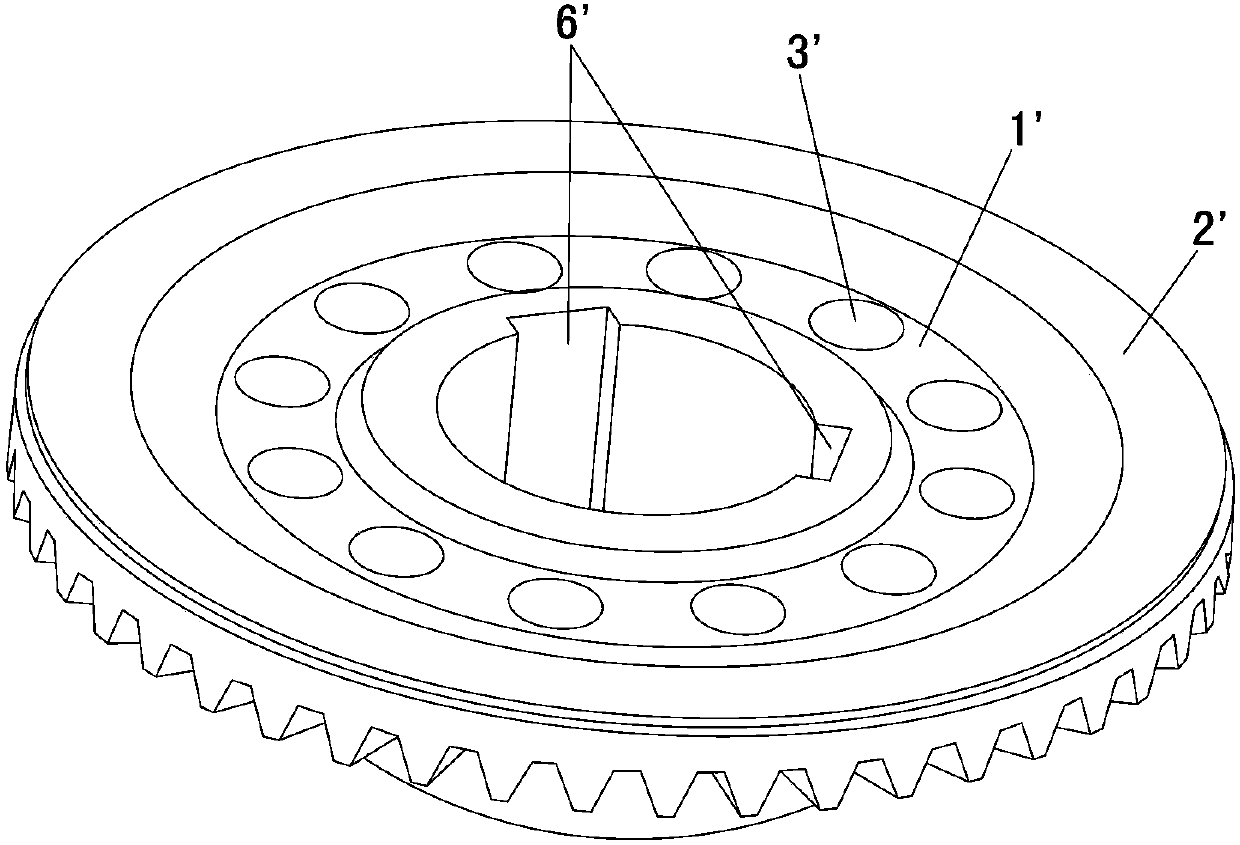

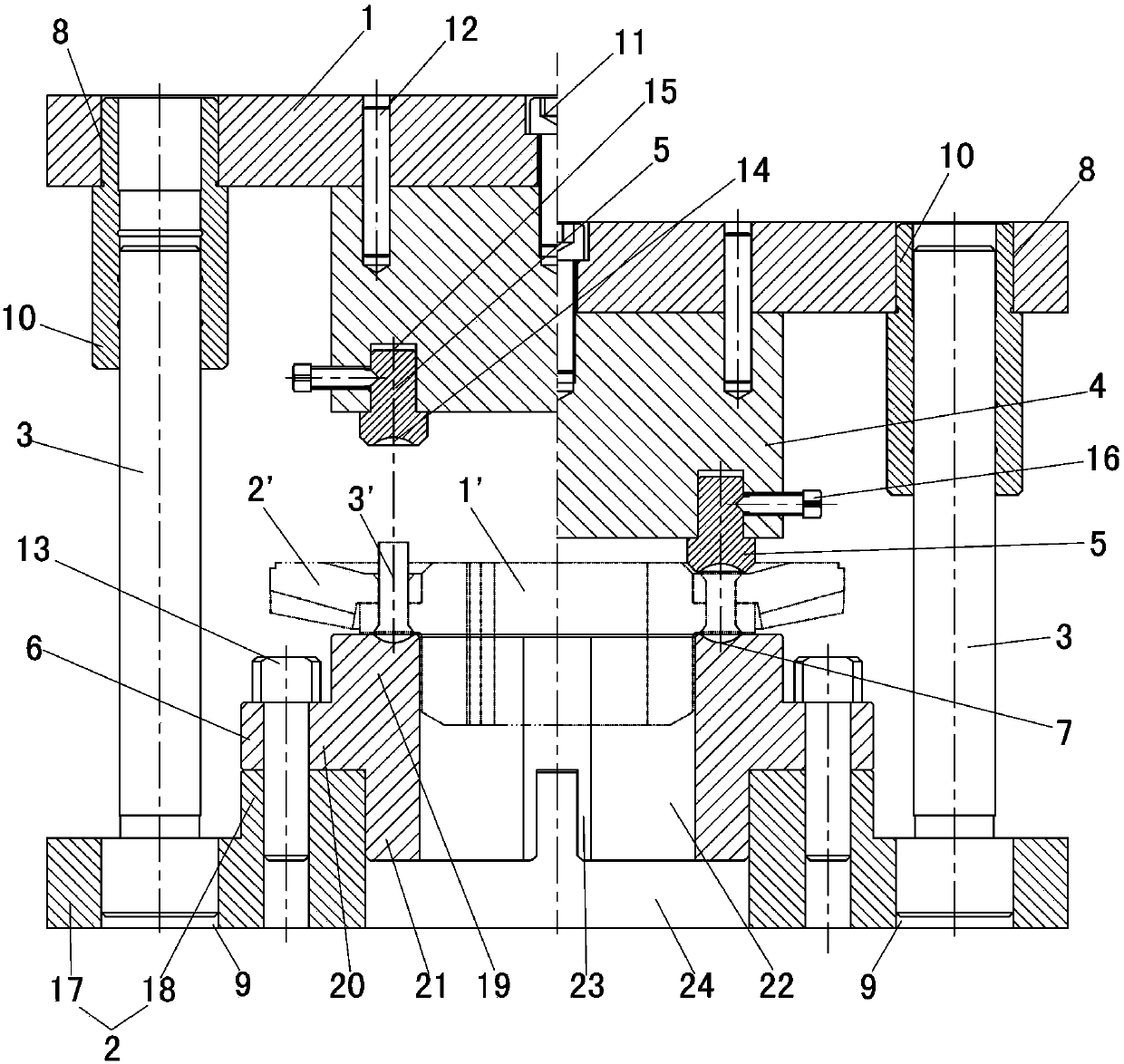

Riveting tool and method for mounting bevel gear components by same

The invention discloses a riveting tool and a method for mounting bevel gear components by the same, and belongs to the technical field of assembling equipment and methods utilizing same. An upper mould plate and a lower mould plate are connected by a plurality of guide pillars, the upper mould plate can slide along the guide pillars up and down, a plurality of press heads are arranged on an upper mould, a plurality of first pits are formed on a lower mould, and the distribution manner and the quantity of the first pins are the same with those of first riveting holes of a hub. During use, the bevel gear components are disposed between the upper mould and the lower mould, two groups of rivets mounted on the bevel gear respectively correspond to the press heads and the first pits, and are respectively pressed between the press heads and the corresponding first pits when the upper mould plate is pressed, so that riveting is achieved and the hub is connected with a large bevel gear. The riveting tool is simple in structure, at least two rivets can be riveted each time when the riveting tool is used for mounting the bevel gear components, and thus, mounting quality is guaranteed, labor intensity of workers when mounting the bevel gear component is reduced, operative technical requirements to operators are reduced, and production efficiency can be increased.

Owner:TRIUMPH HEAVY IND

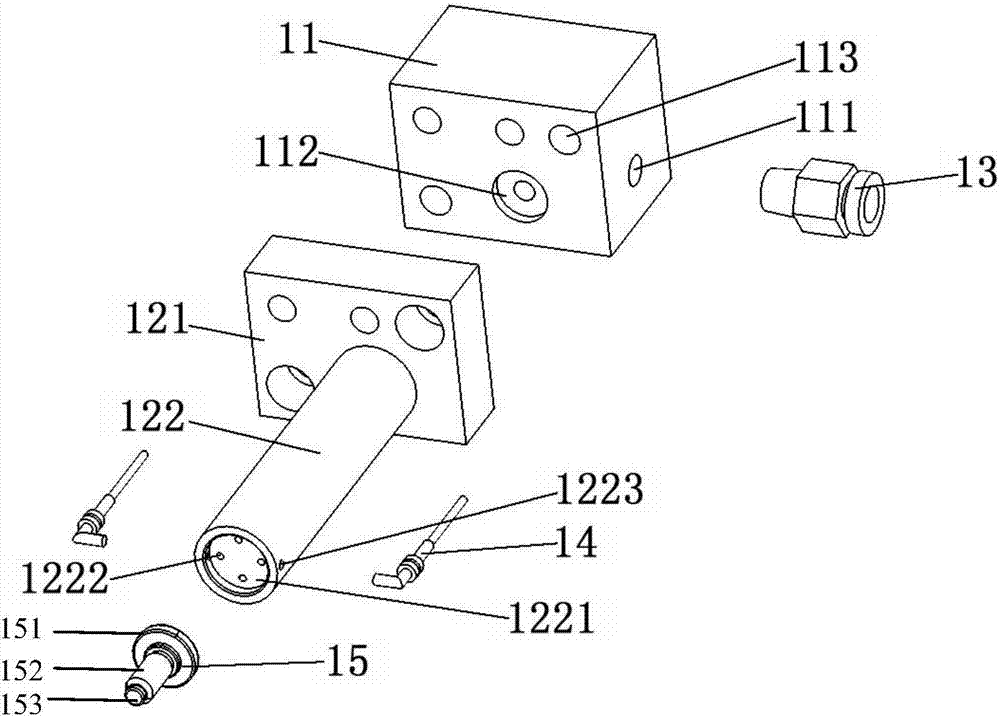

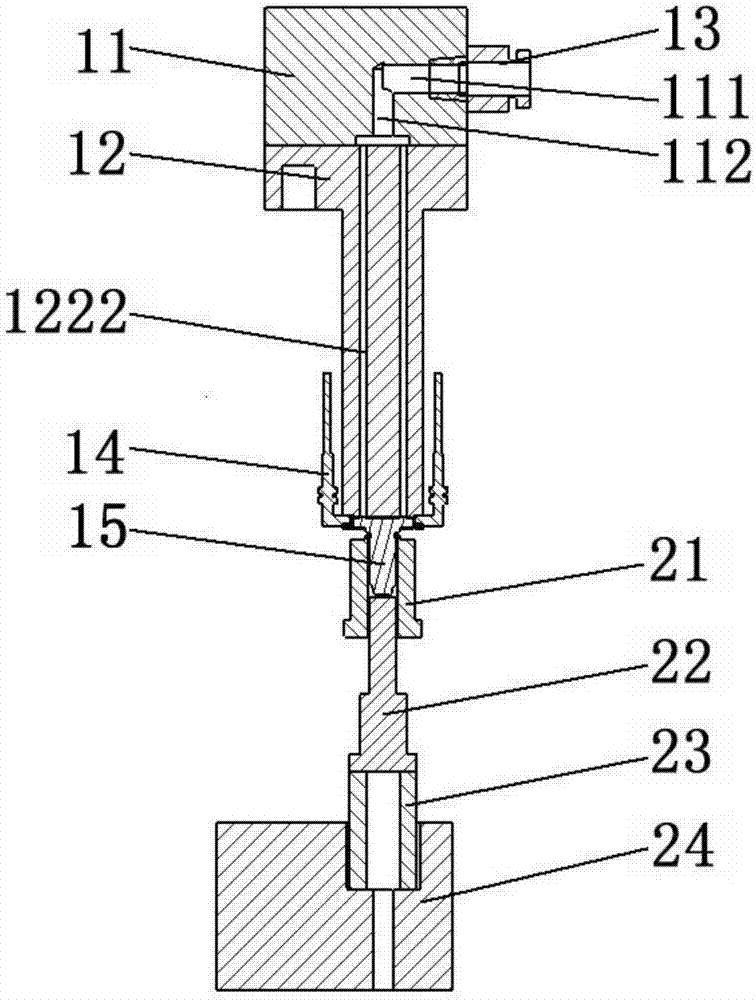

Riveting tool

Owner:GREE ELECTRIC APPLIANCES INC

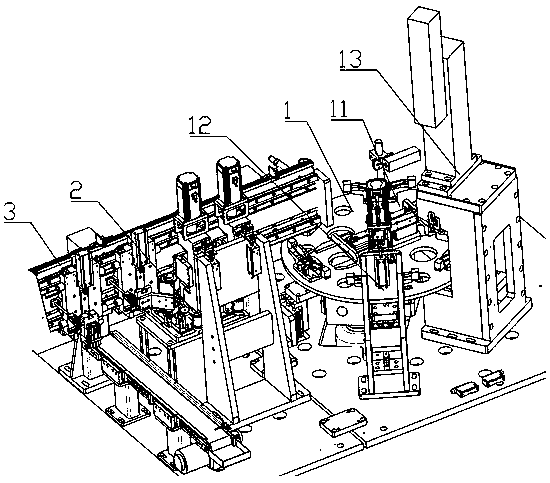

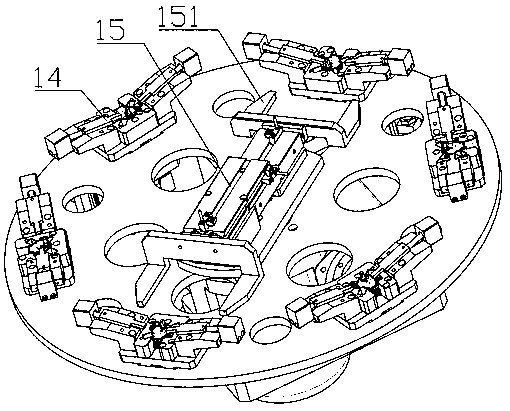

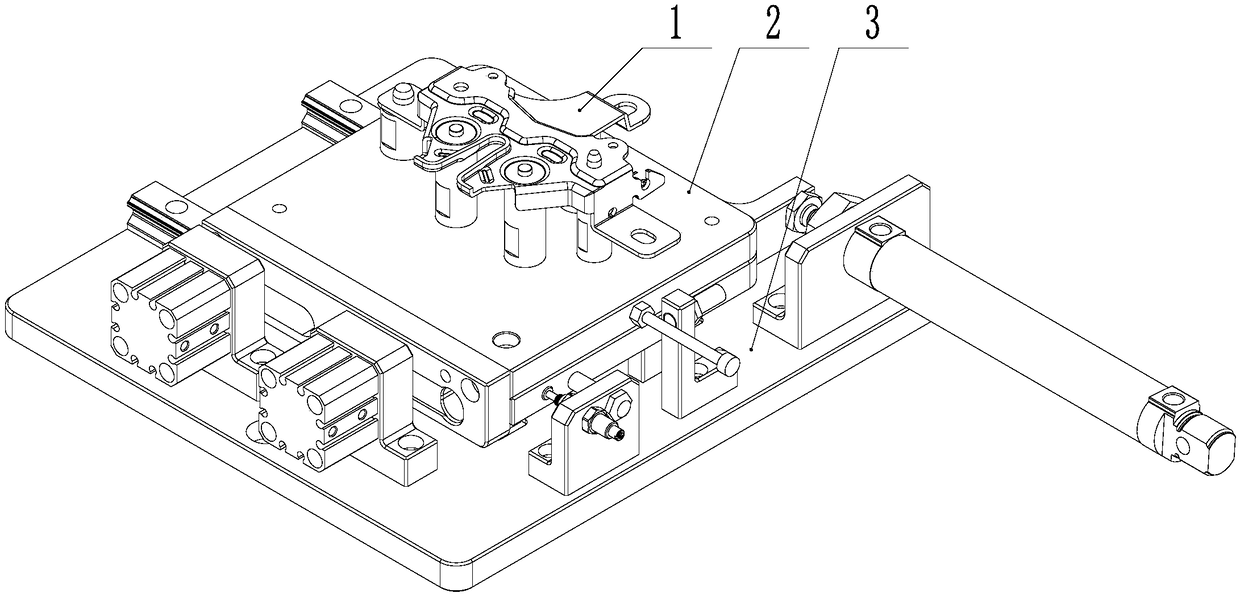

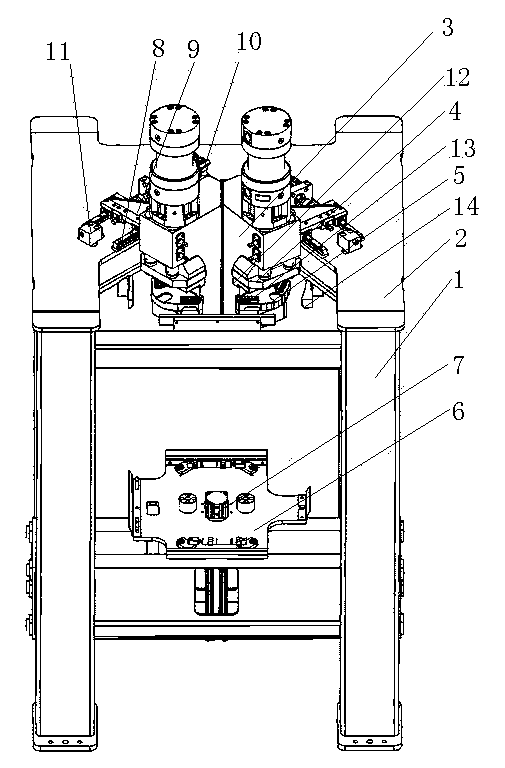

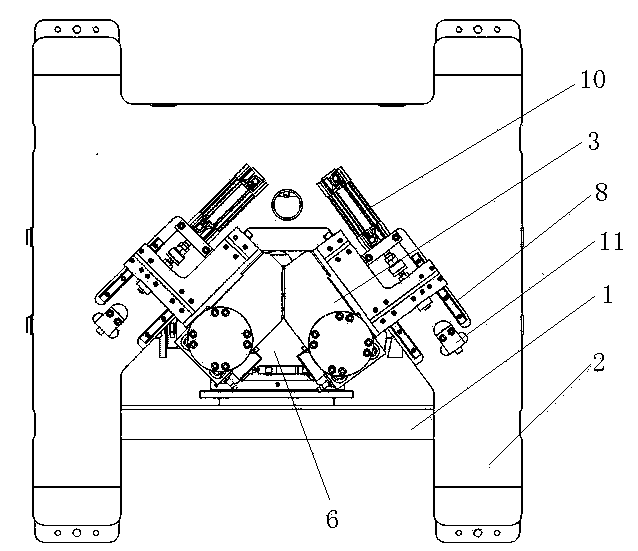

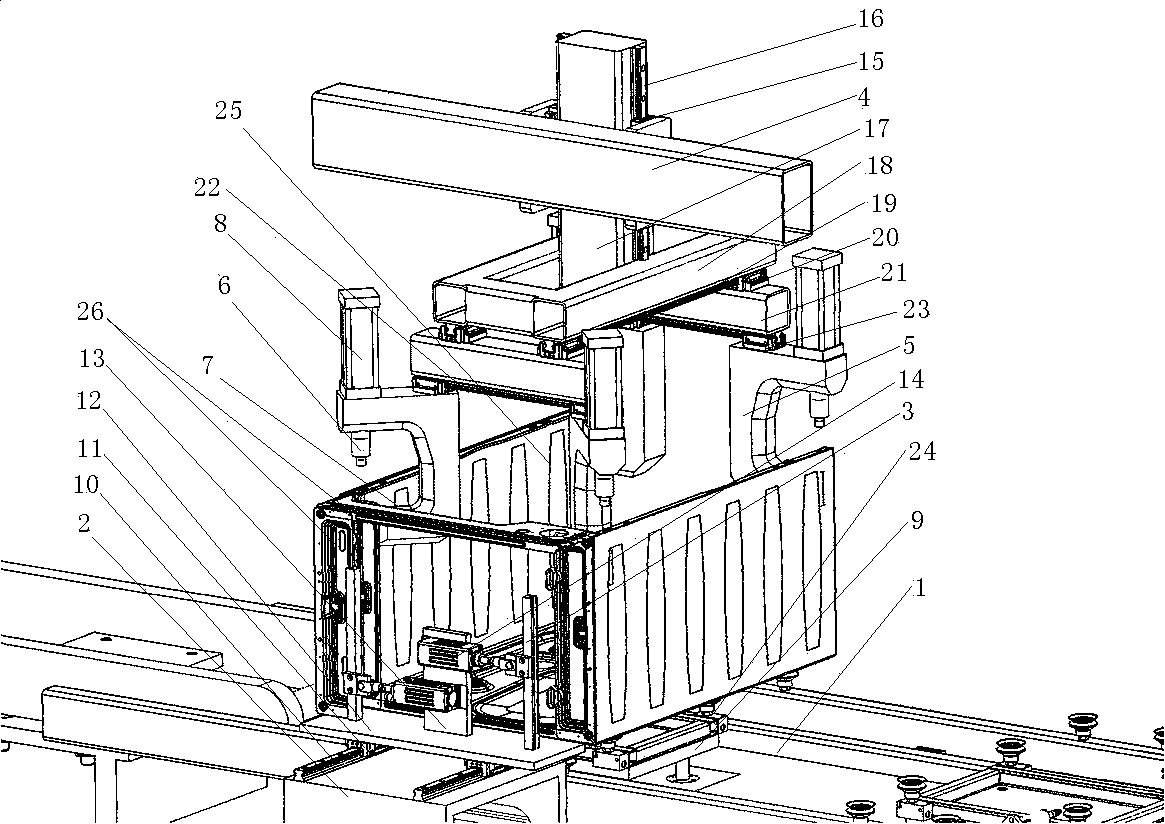

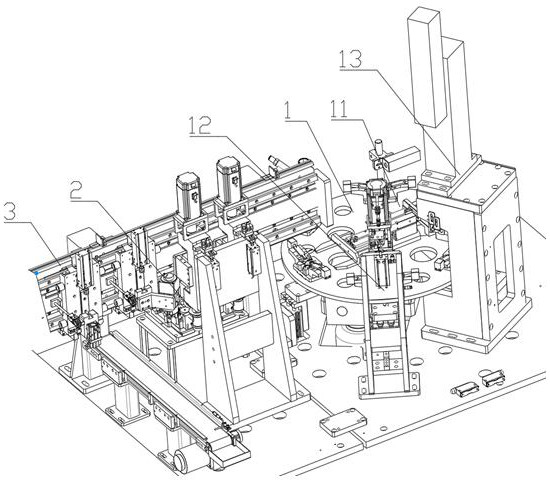

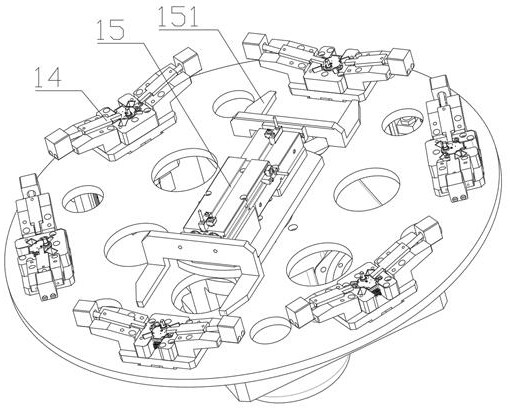

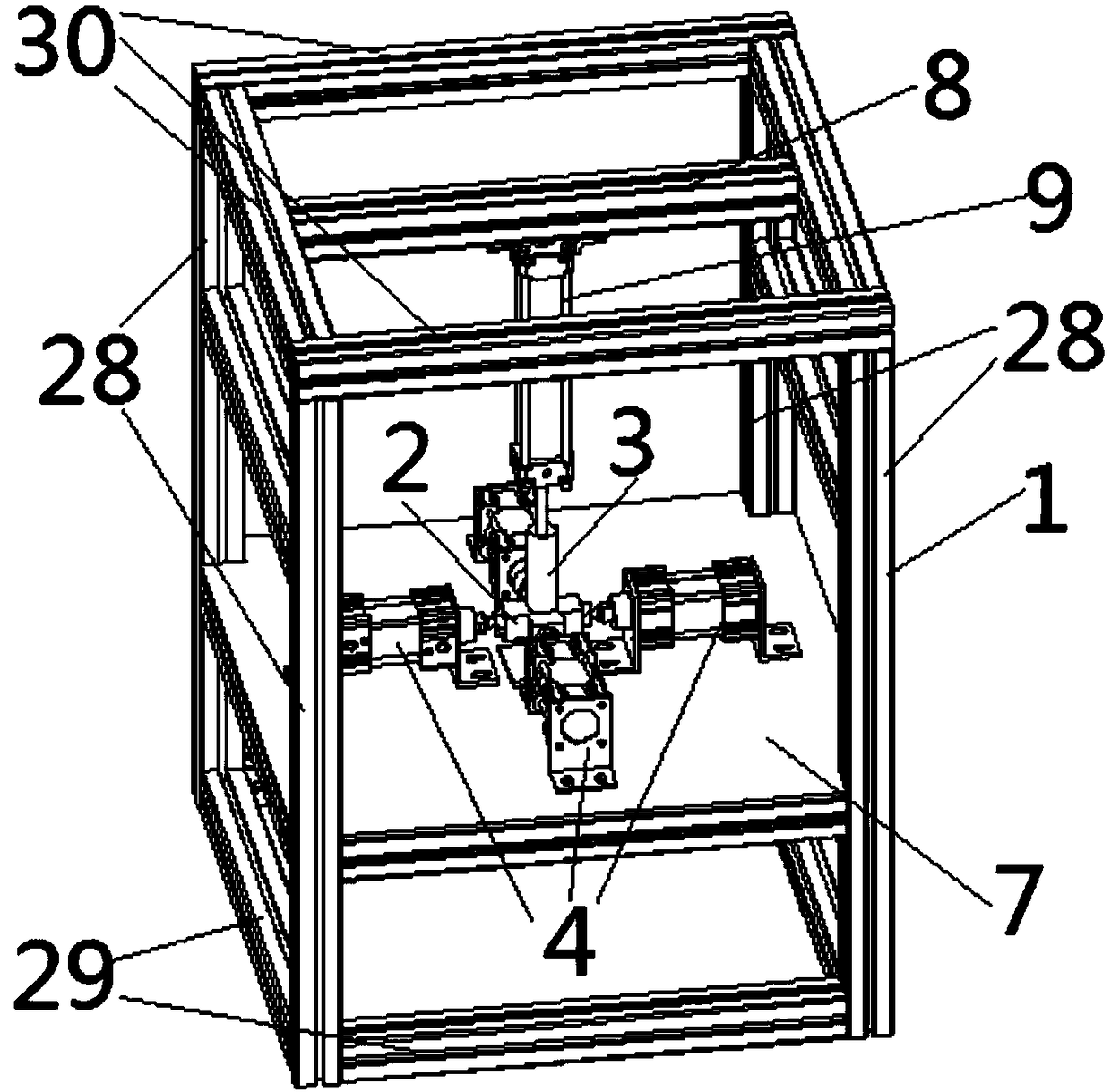

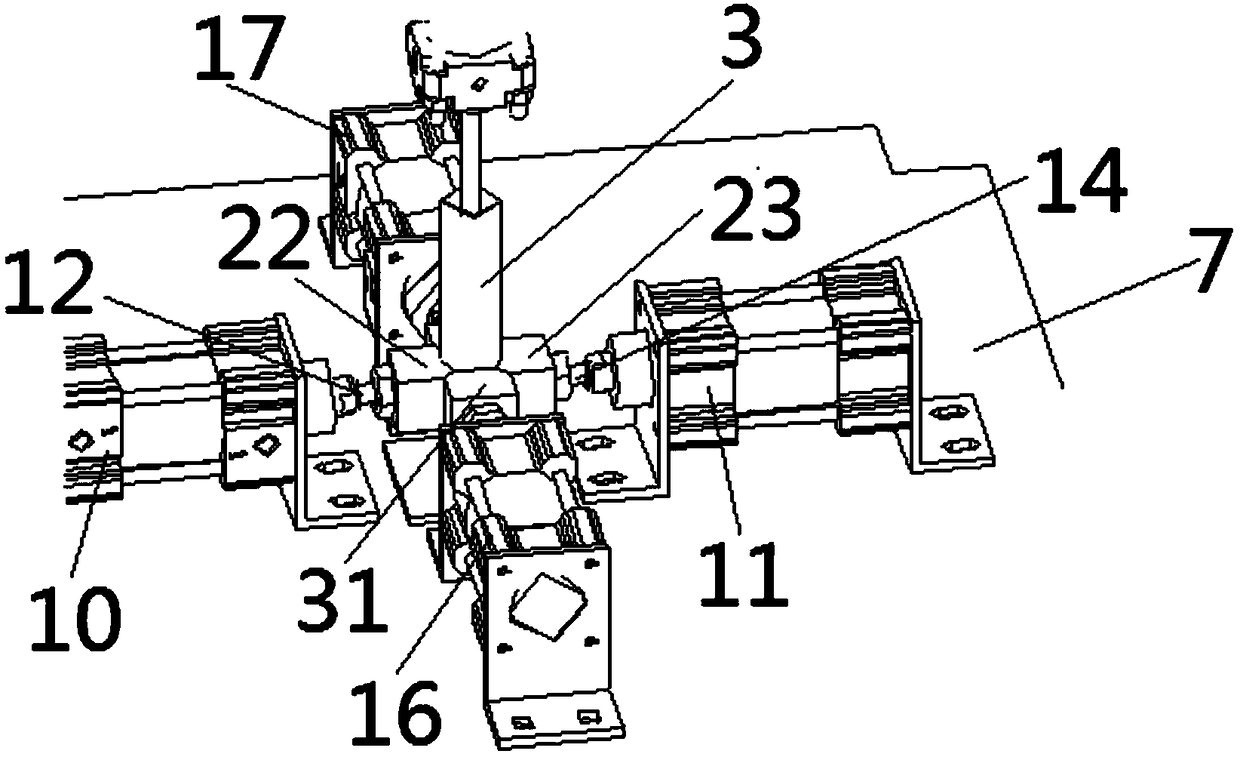

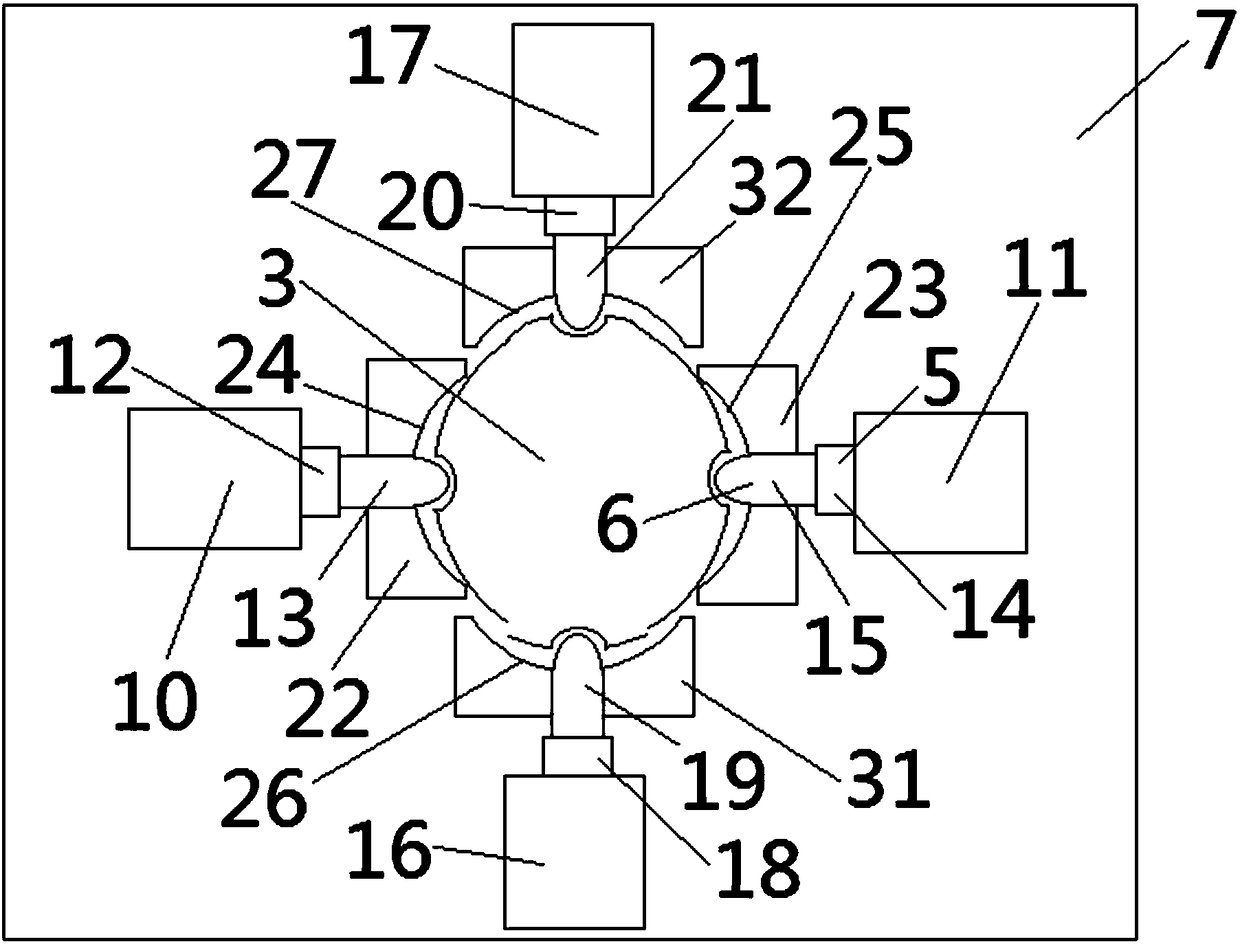

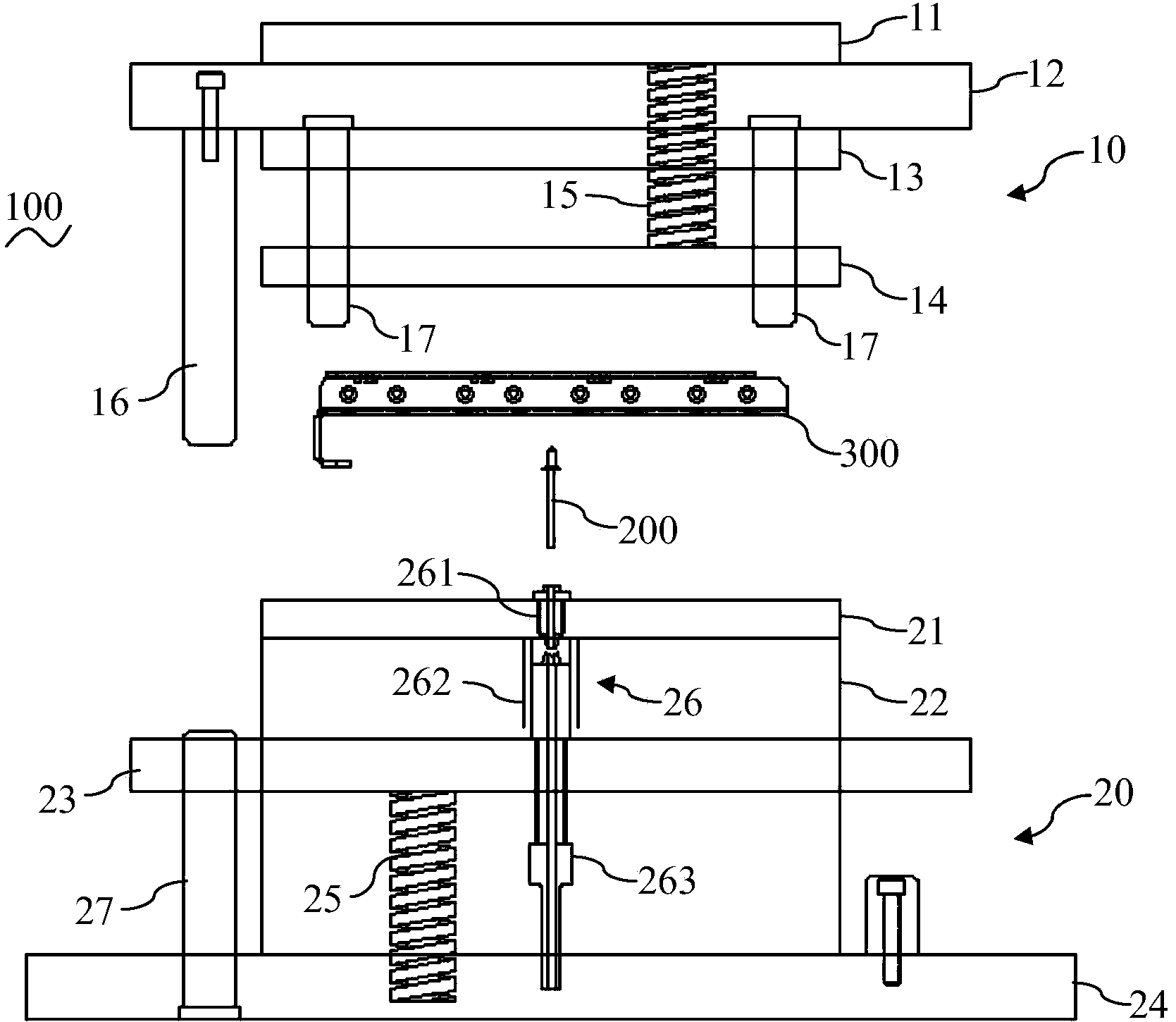

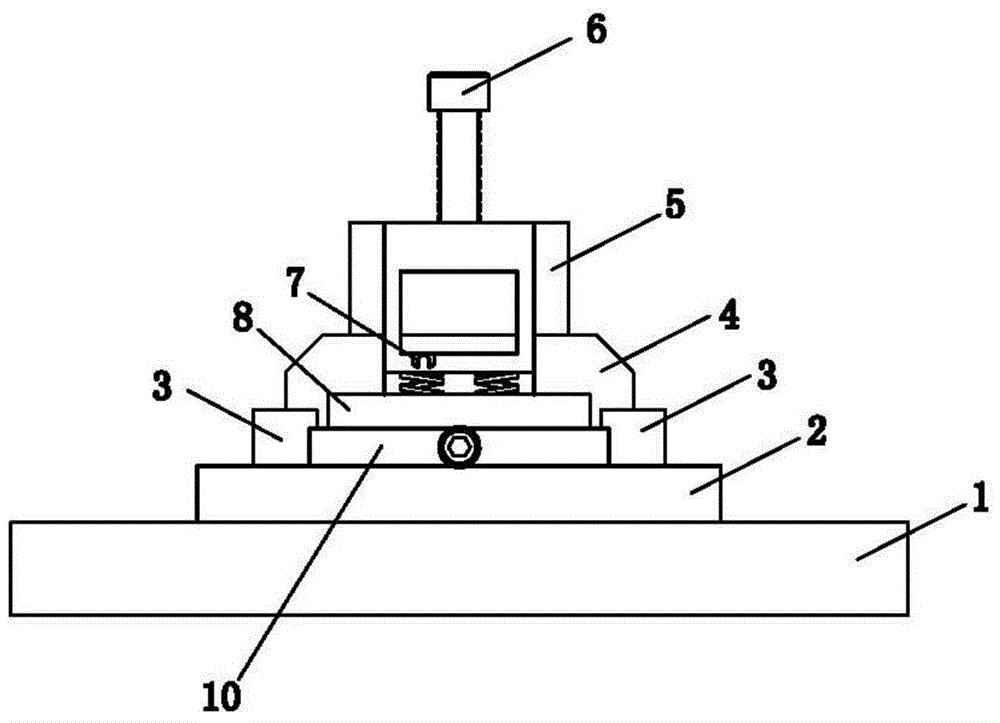

Motor assembly and riveting detecting mechanism

ActiveCN111360167ANovel structureRiveting realizationMetal-working feeding devicesMetal working apparatusElectric machineryStructural engineering

The invention discloses a motor assembly and riveting detecting mechanism. The motor assembly and riveting detecting mechanism is provided with a riveting device, a detecting device and a carrying device, wherein the carrying device is arranged at one side of a machine table; the riveting device and the detecting device are mounted at the other side which corresponds to the machine table; an outerhousing of a motor body and a cover body are pressed by the riveting device, so that the cover body is fixedly arranged on the motor main body; a circuit on a terminal board of the motor is powered on, so that resistance of a rotary shaft of the motor is detected; the riveting device is provided with a rotary disc; a plurality of placing holes for placing a carrier are formed in the rotary disc;the carrier is provided with a carrier base, a placing position for placing the motor main body, fixed wings and a riveting structure; the carrier base is fixedly arranged in the placing holes; the placing holes are fixedly formed in the top of the carrier base; the two fixed wings are separately fixed to the two sides of each placing position; and the riveting structure is mounted onto the fixedwings.

Owner:深圳市中科创想科技有限责任公司

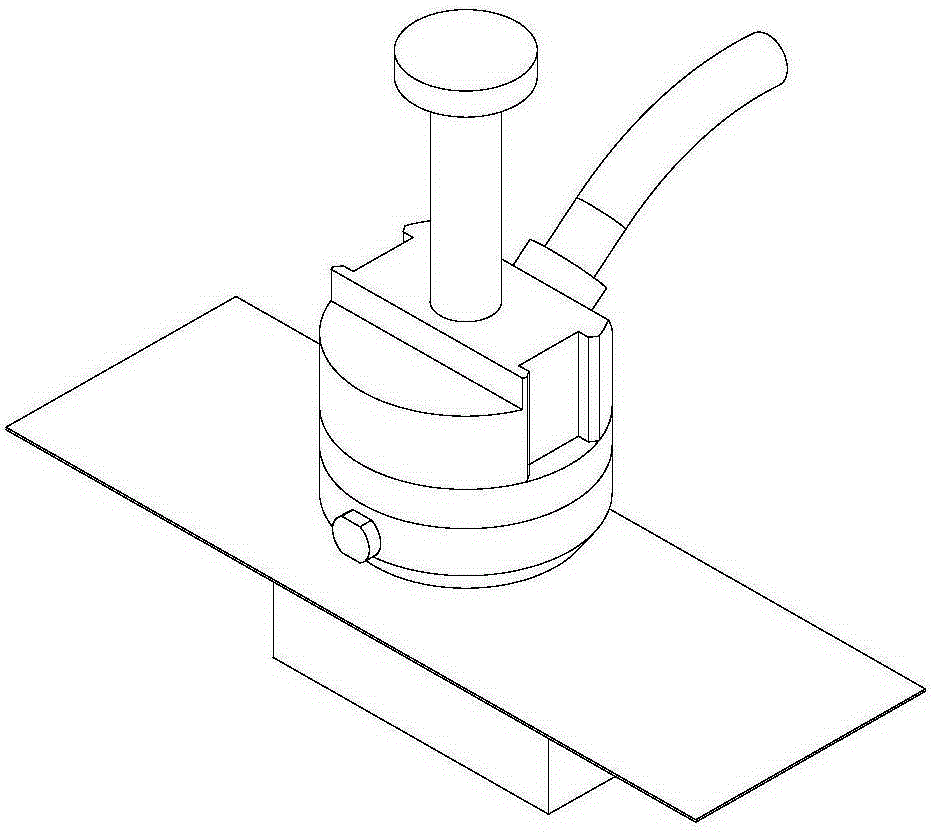

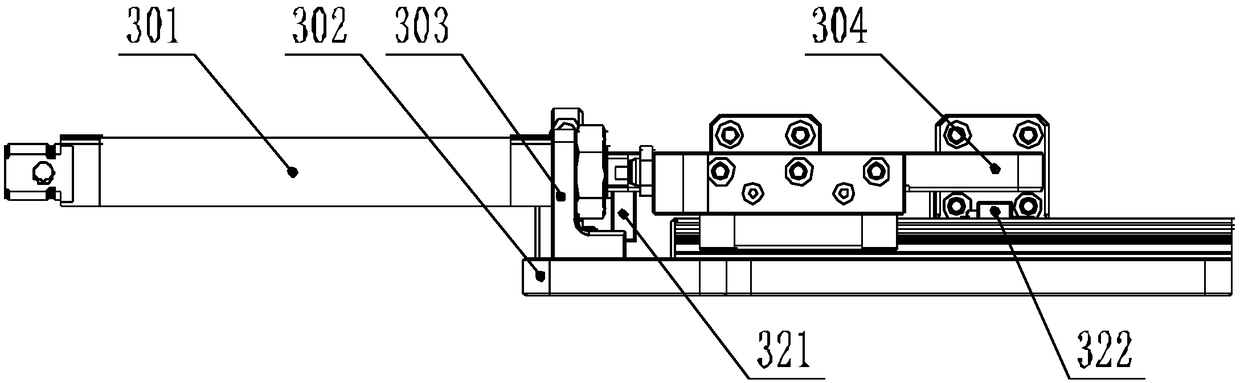

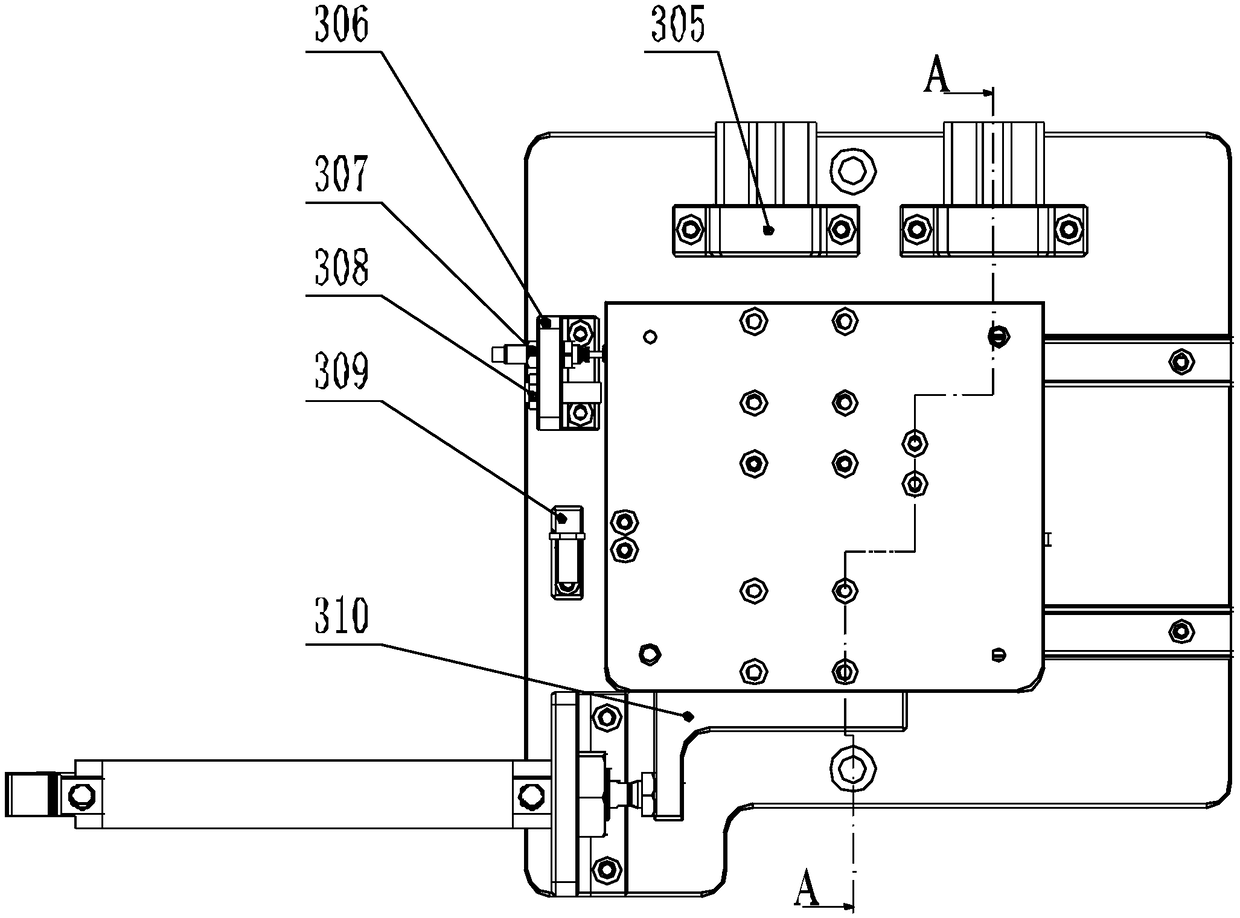

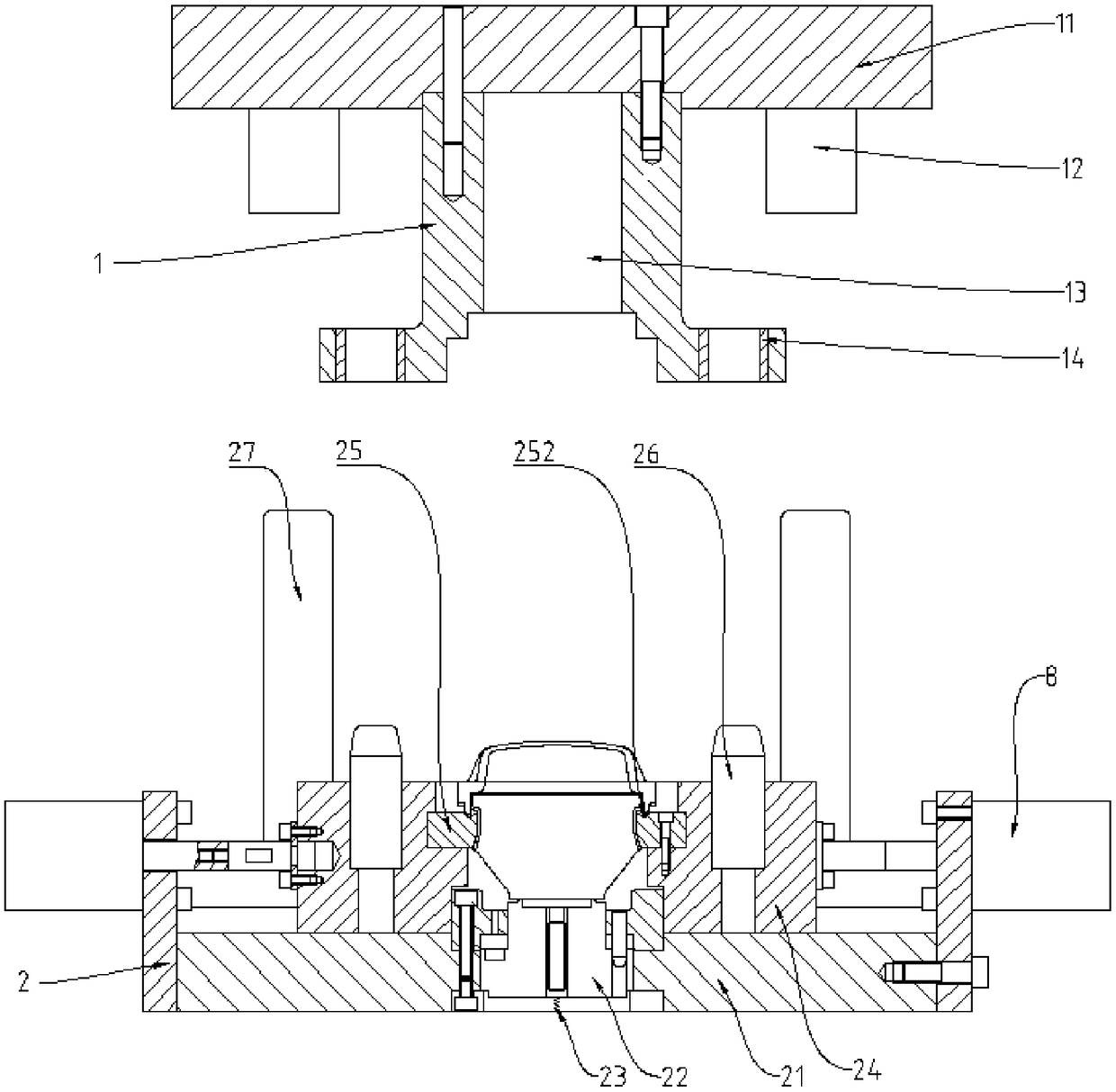

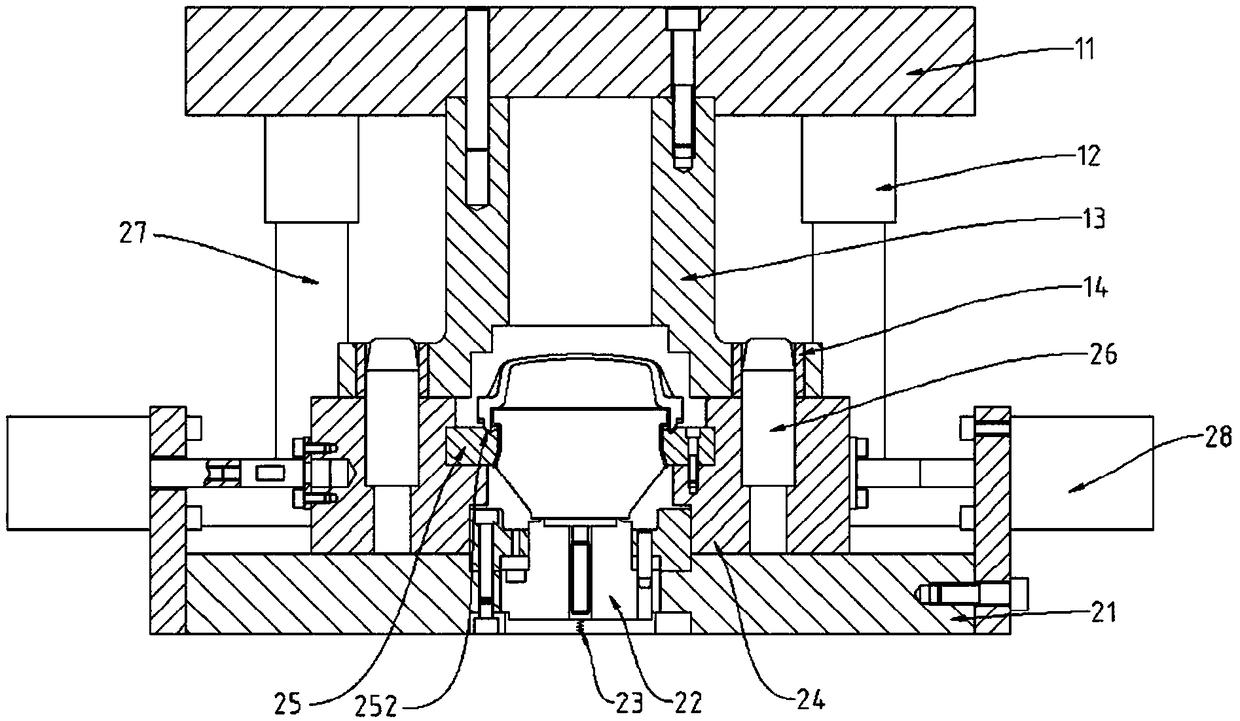

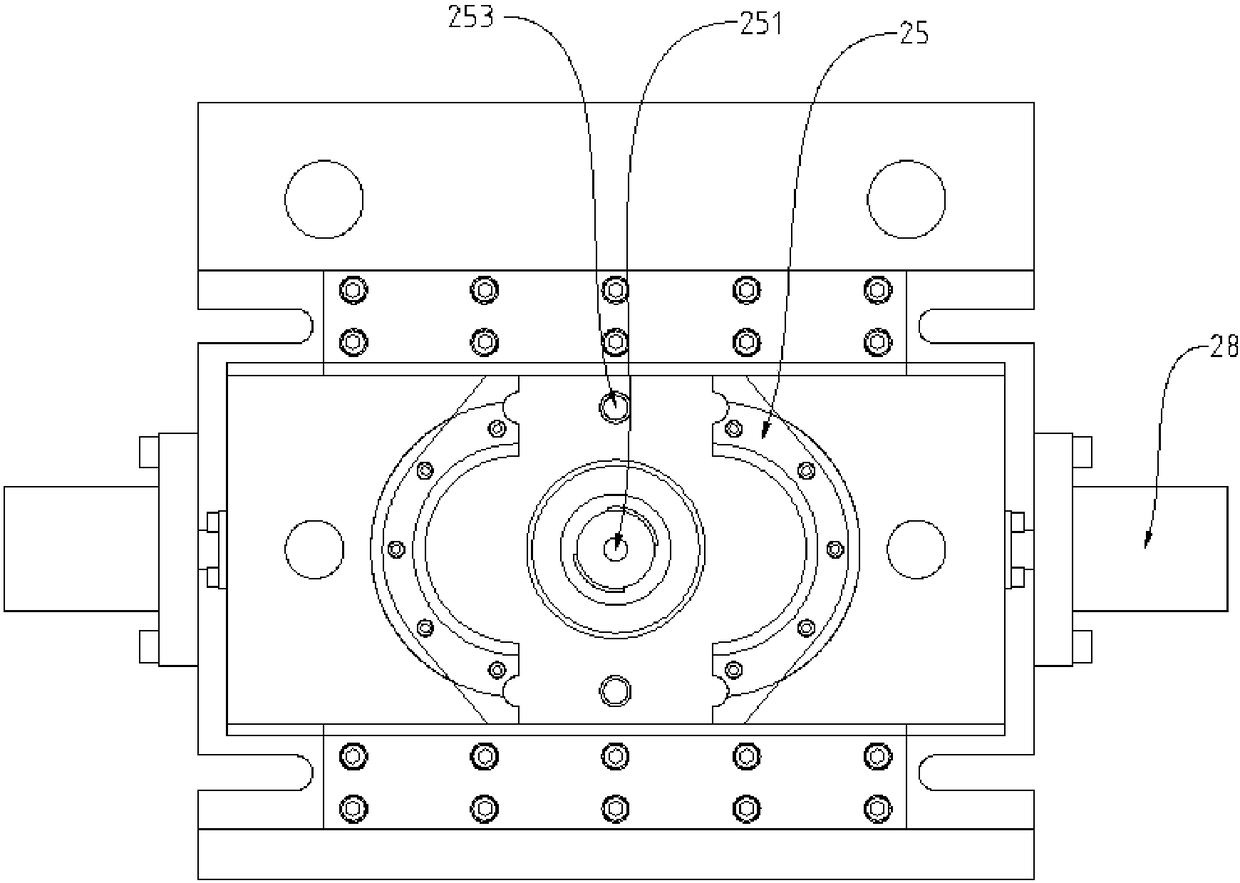

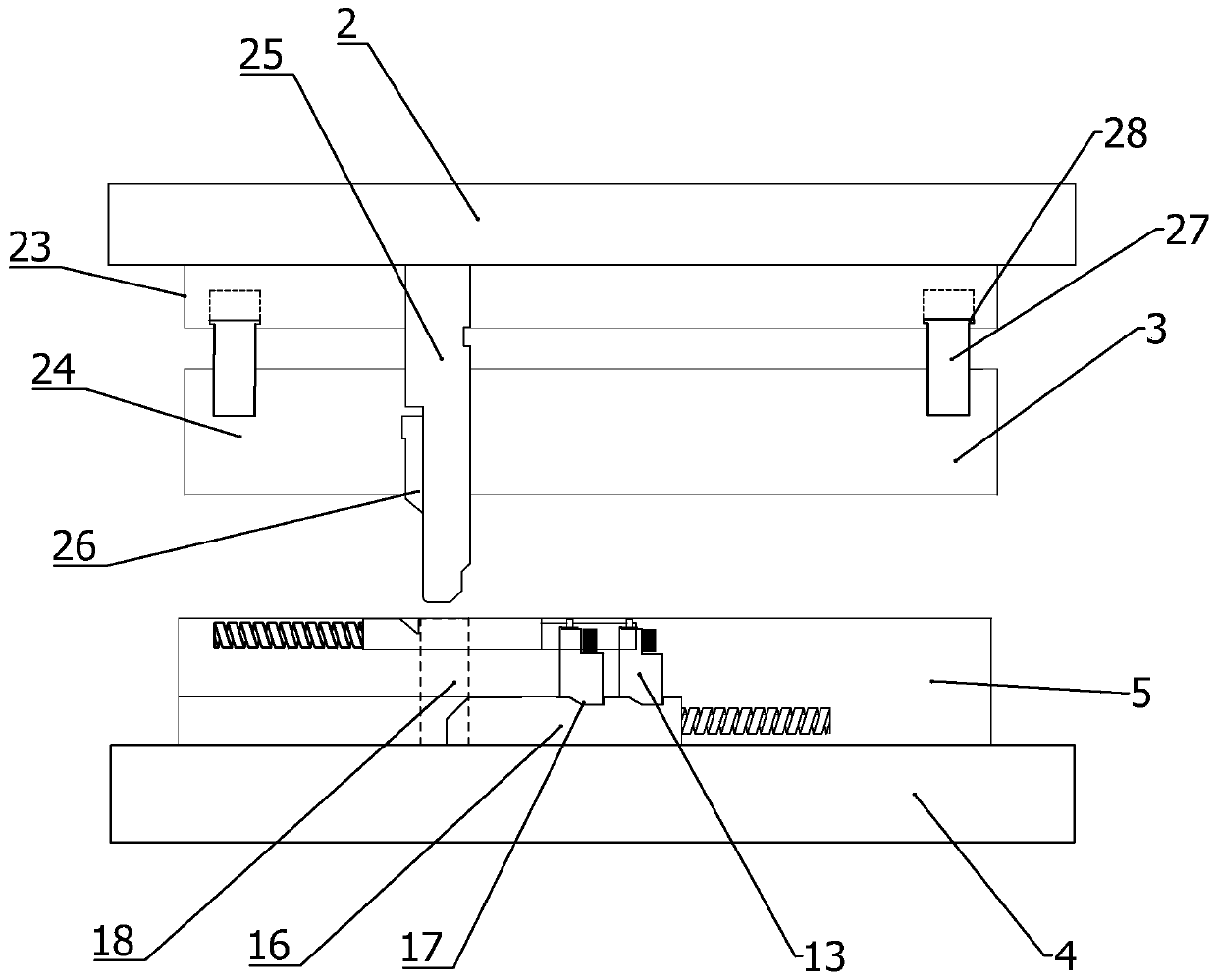

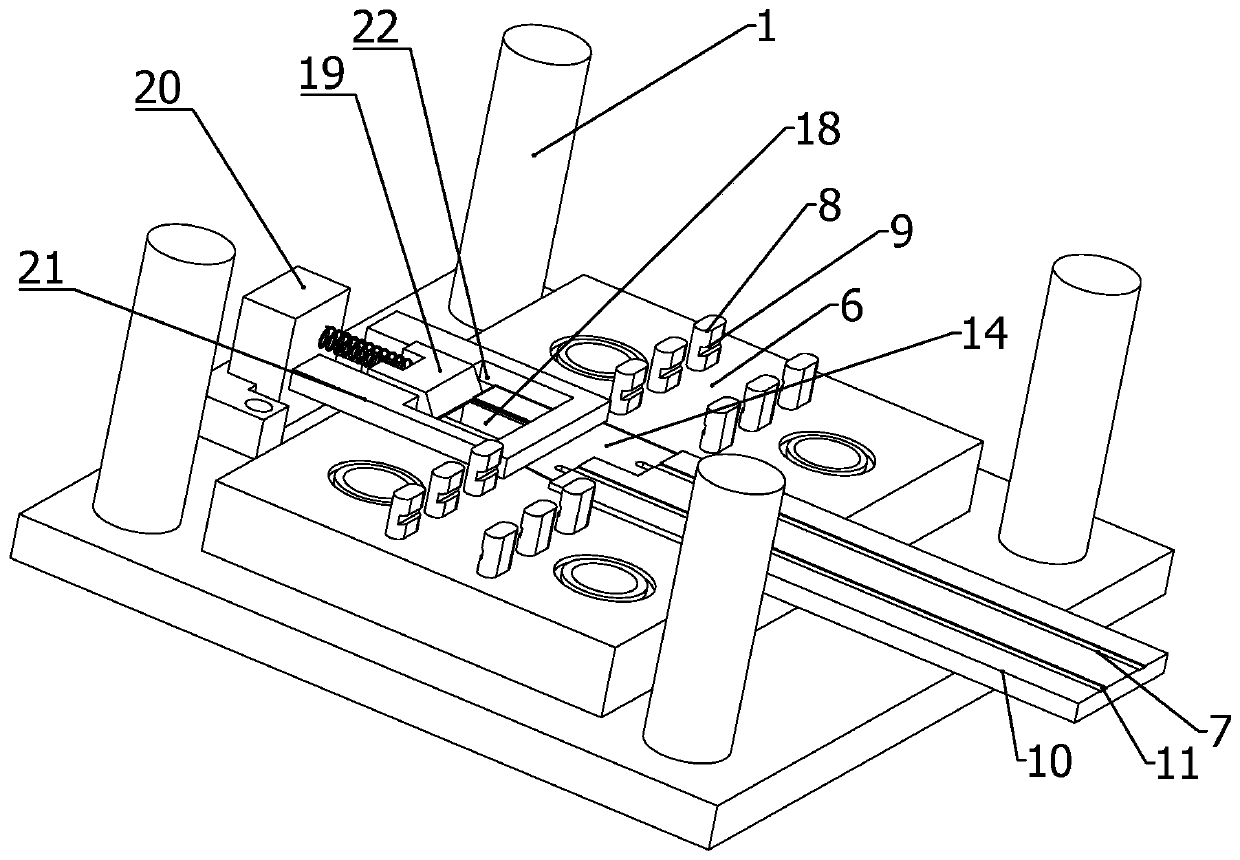

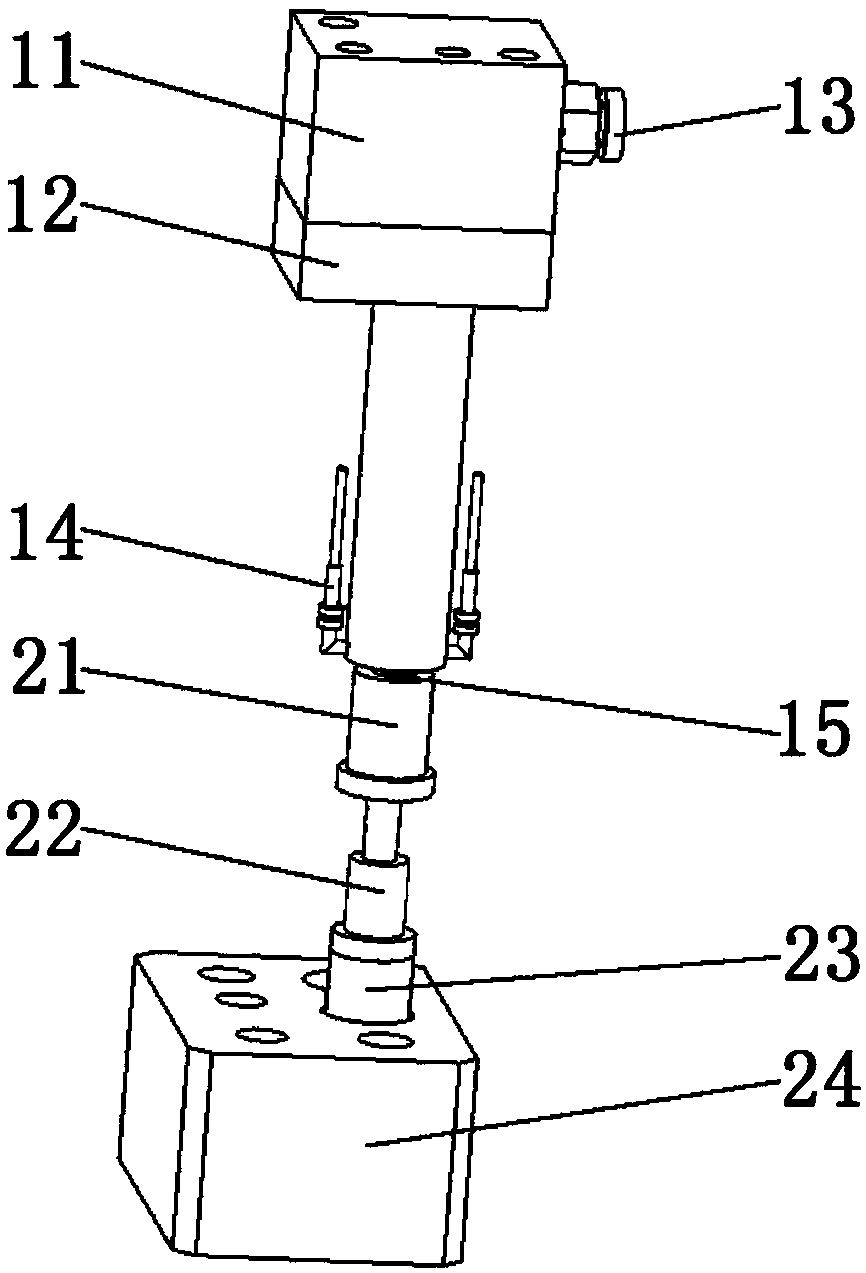

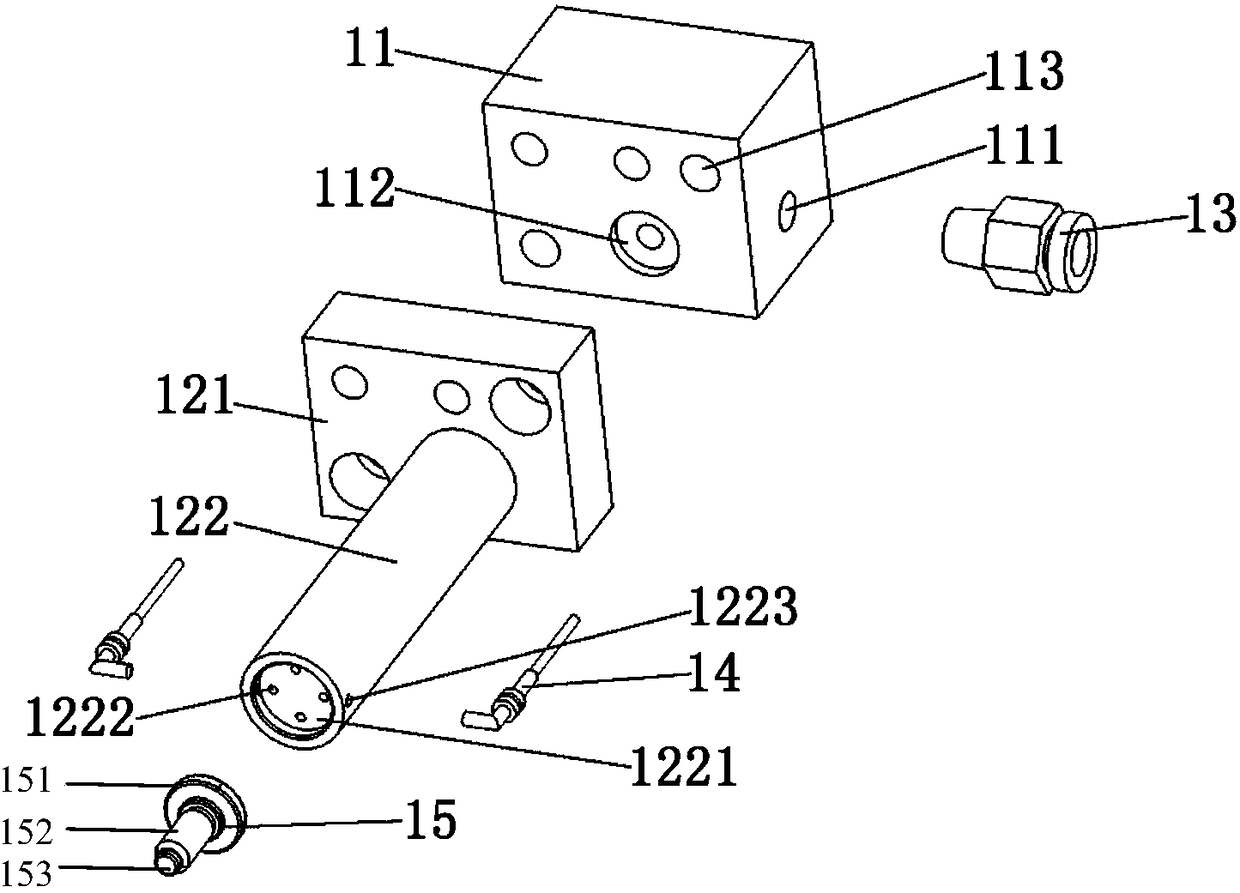

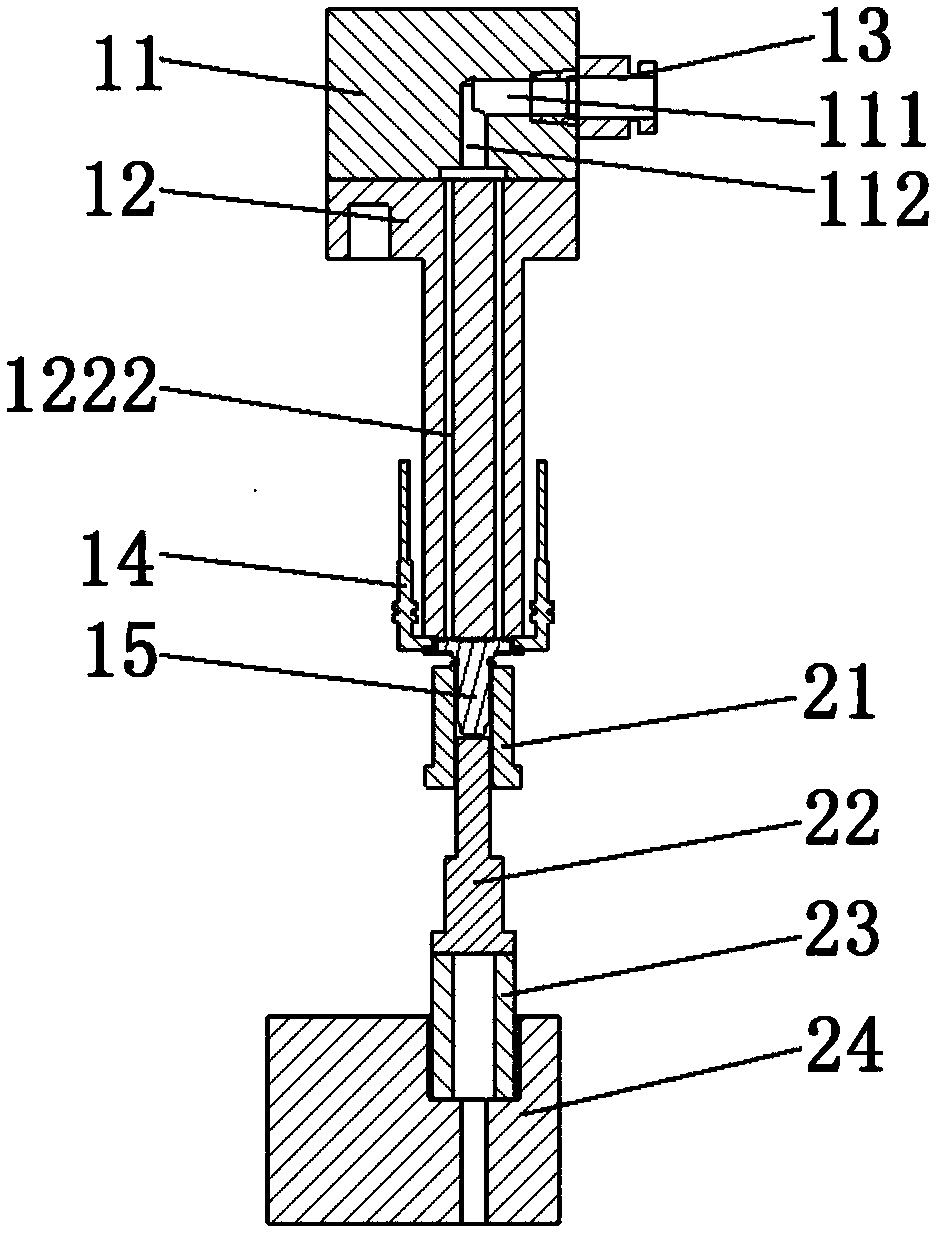

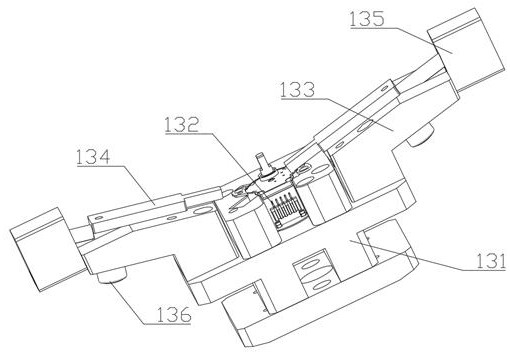

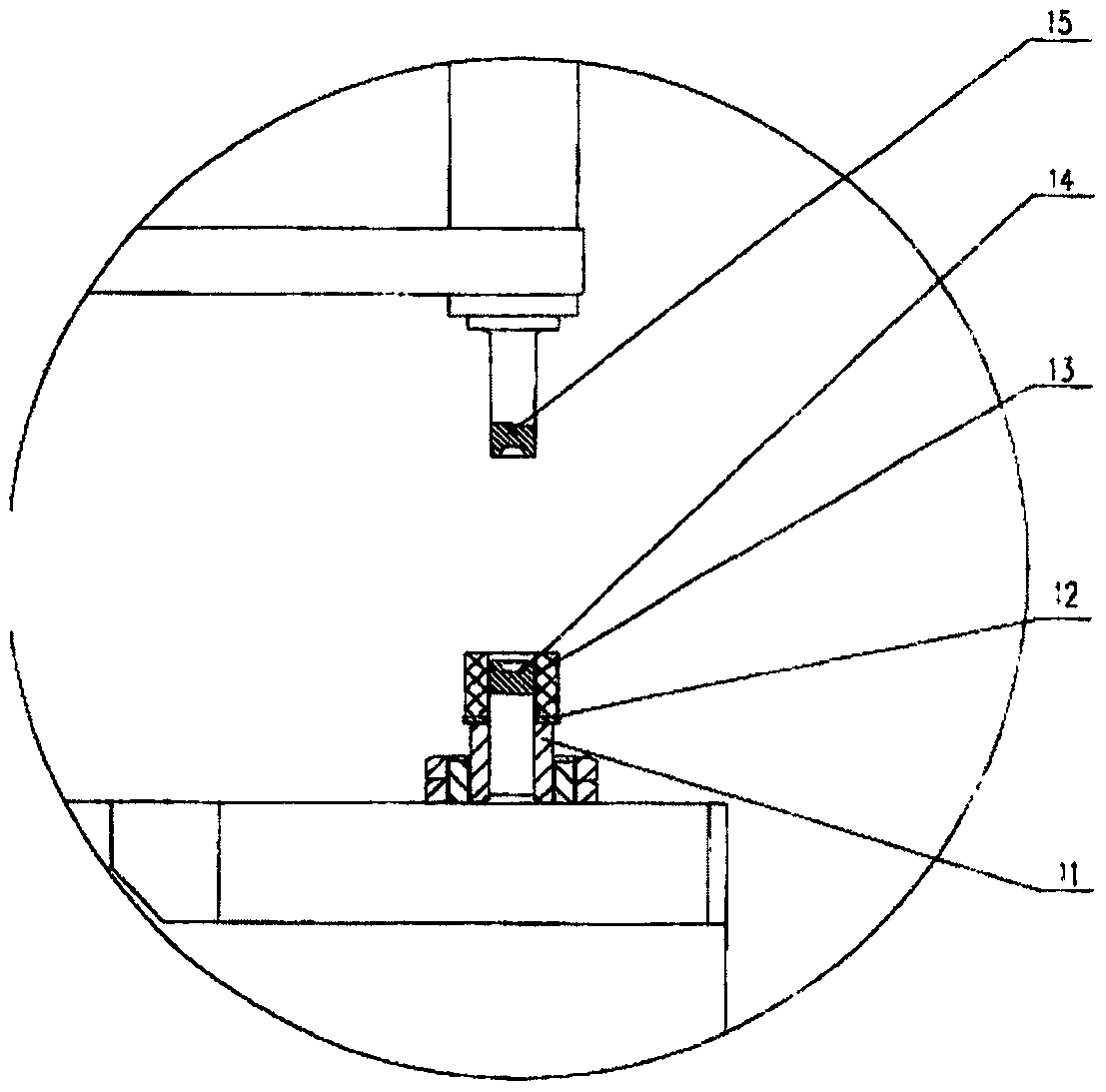

Dual-rivet-point riveting tool

The invention discloses a dual-rivet-point riveting tool. The dual-rivet-point riveting tool comprises a dual-rivet-point tool drive assembly and a dual-rivet-point bracket assembly, wherein the dual-rivet-point drive assembly is fixedly arranged on a riveting machine workbench; the dual-rivet-point bracket assembly is mounted on the dual-rivet-point tool drive assembly; and the dual-rivet-point tool drive assembly drives the dual-rivet-point tool bracket assembly to move to switch to-be-riveted rivet points; and riveting for two rivet points can be completed by placing a riveting workpiece once, and the riveting workpiece is placed on the dual-rivet-point tool bracket assembly.

Owner:上海乾庾智能科技有限公司

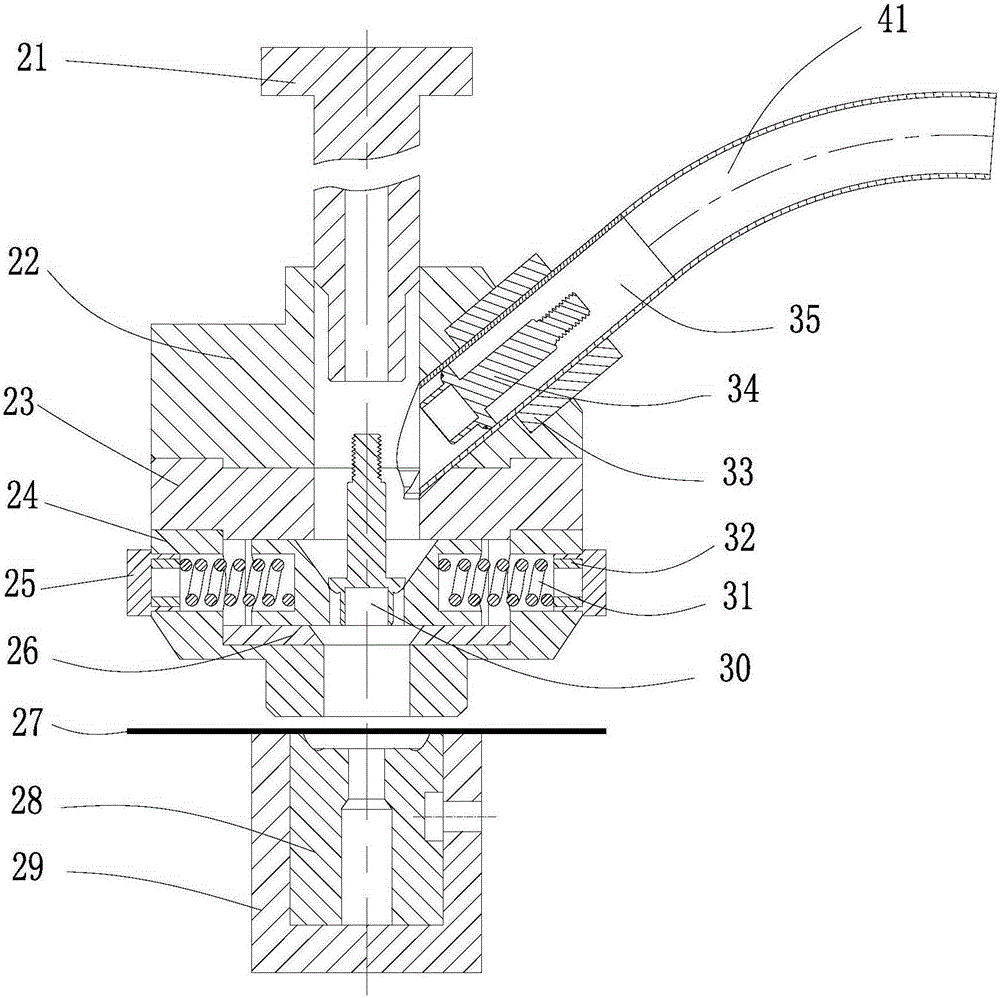

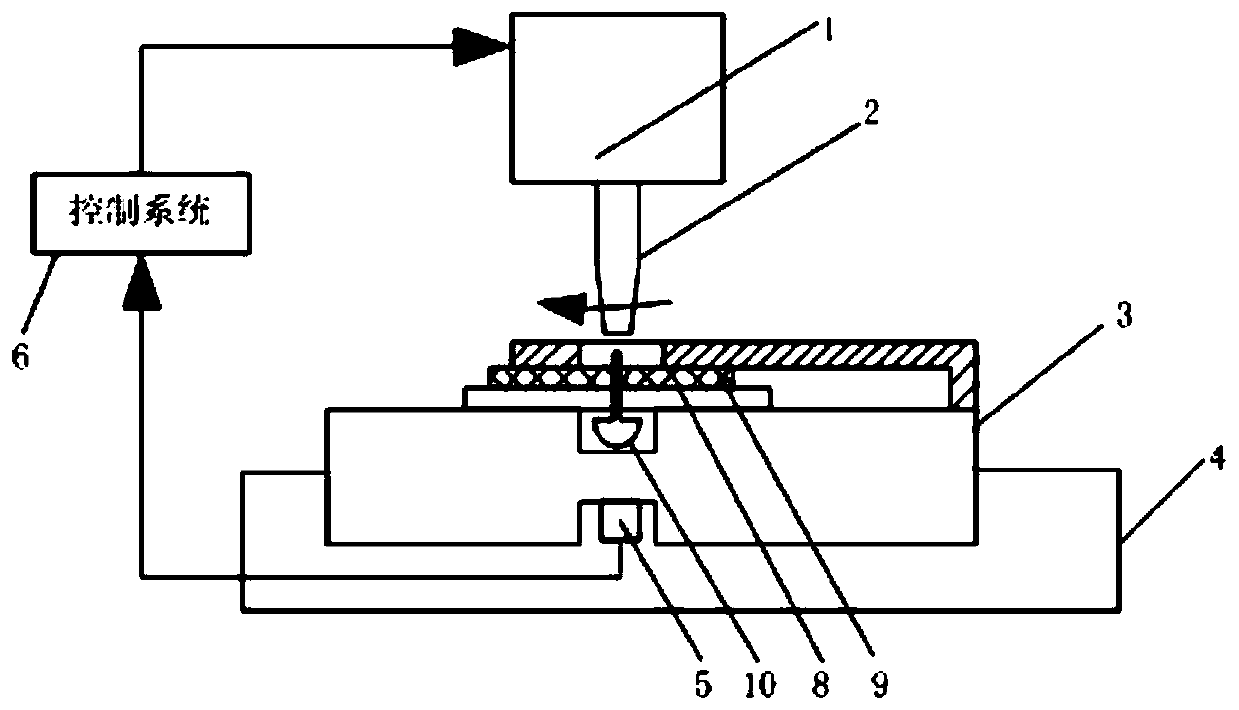

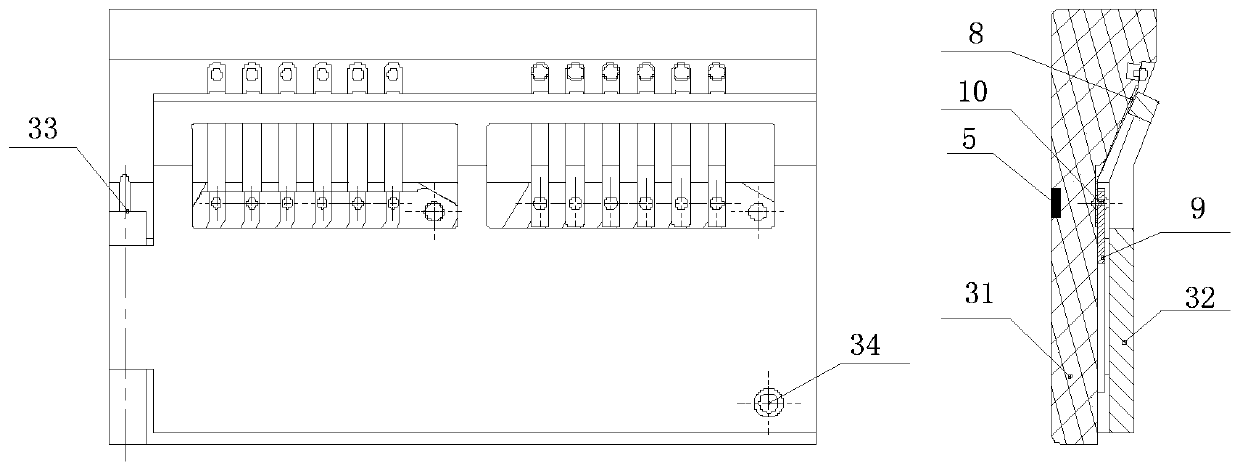

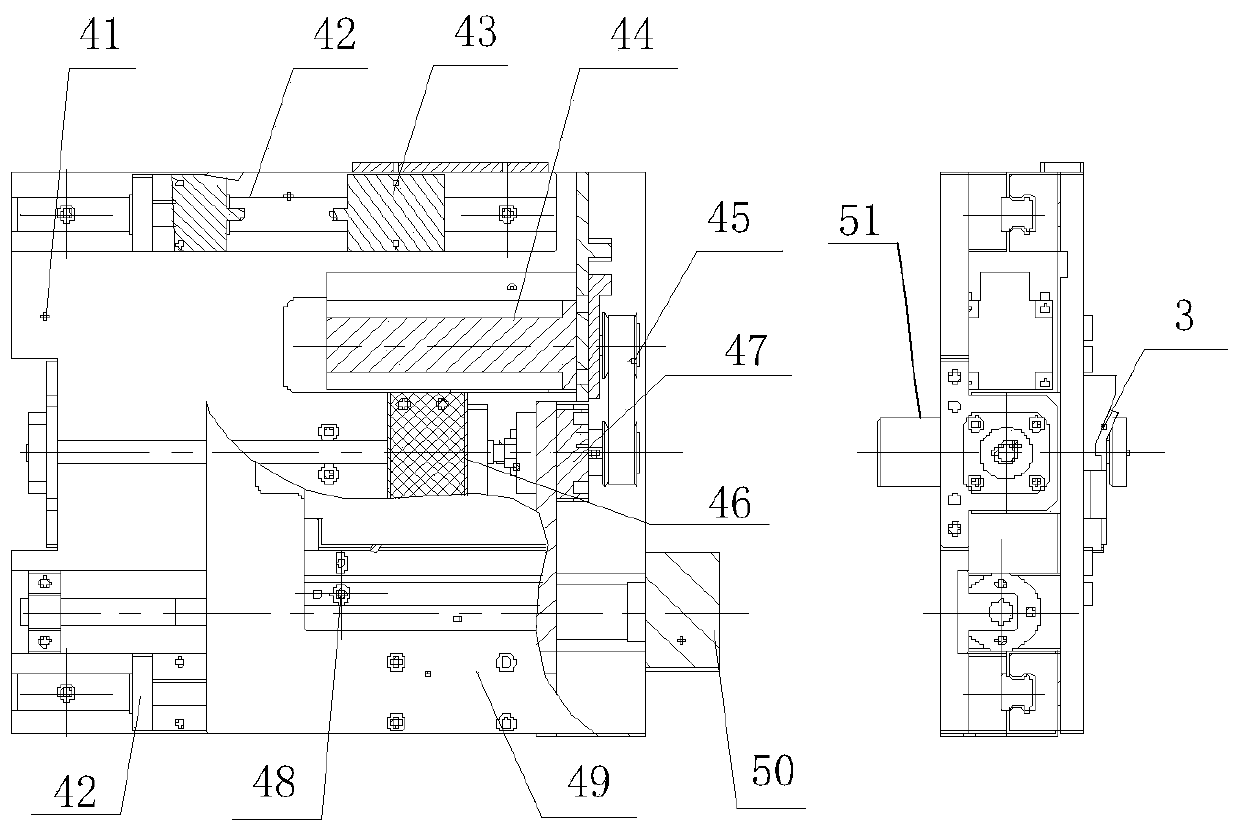

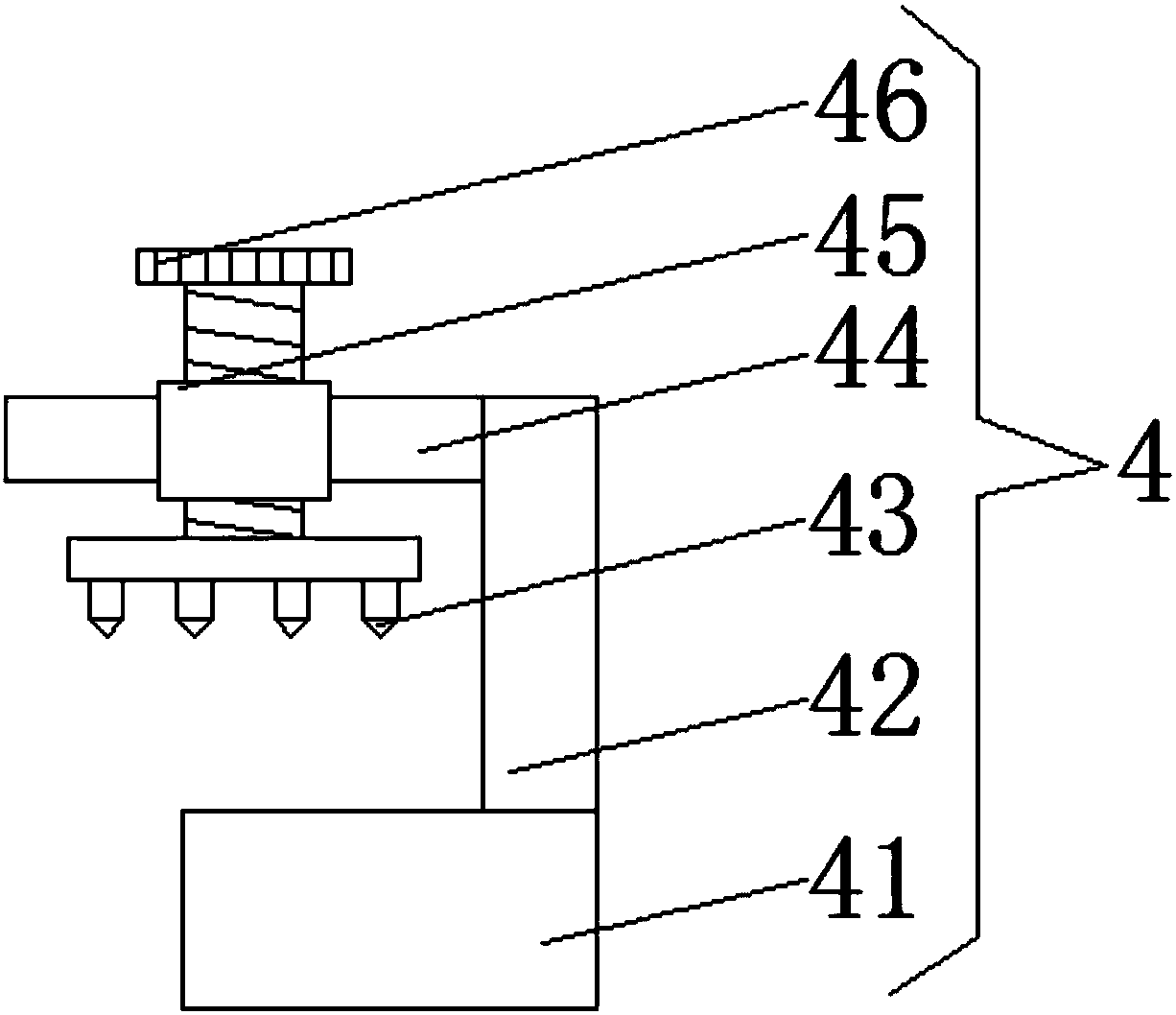

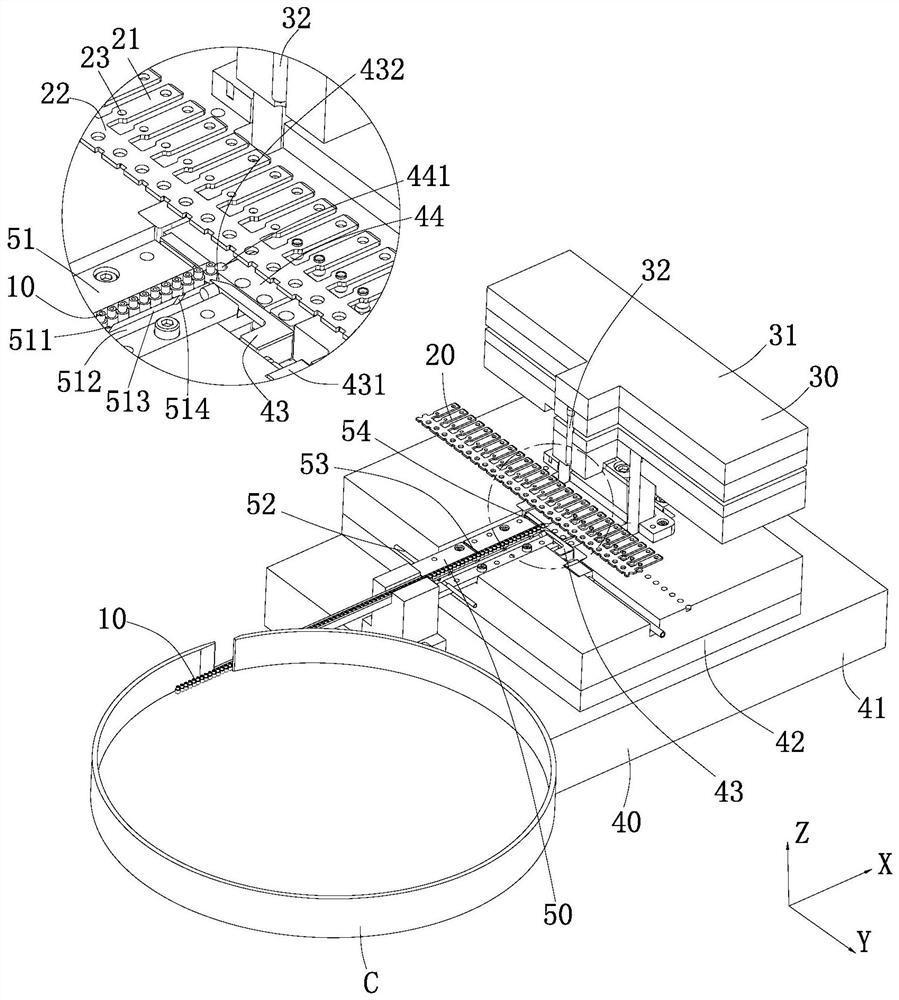

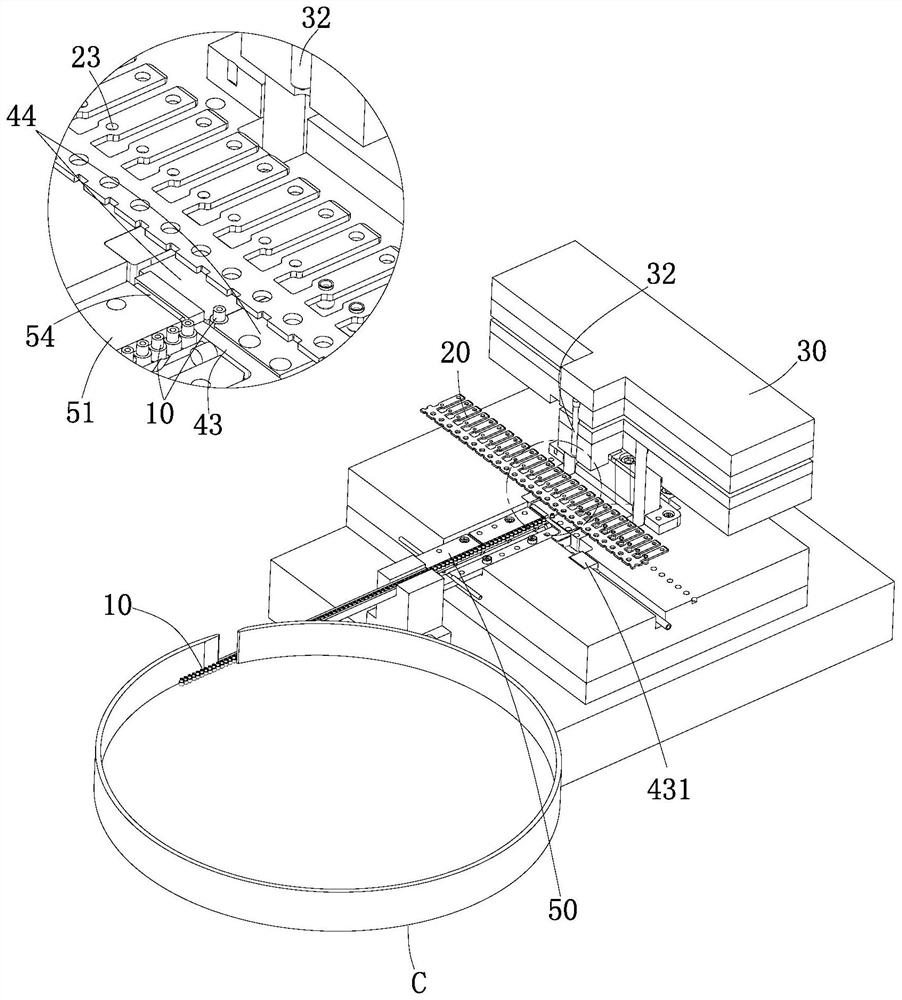

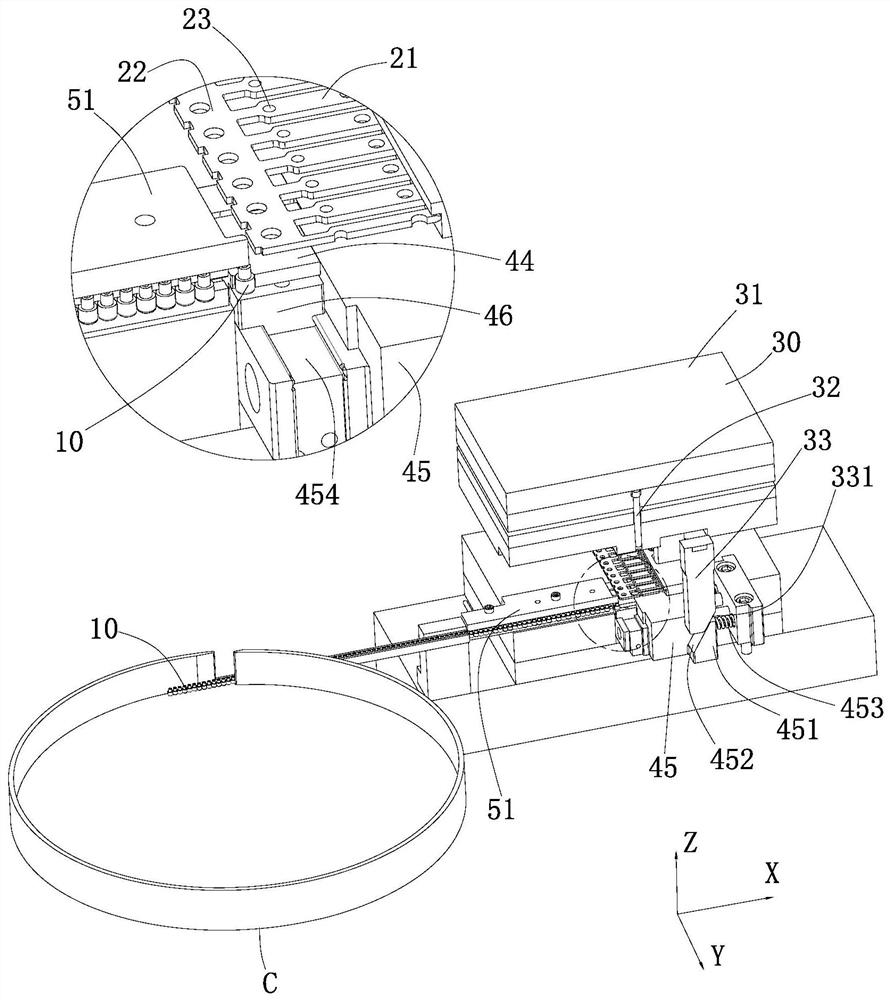

Automatic riveting device suitable for satellite disc type conductive slip ring ultra-thin reed

ActiveCN110504609AAutomatic riveting realizationImprove molding efficiencyBrushes manufactureControl systemEngineering

The invention relates to an automatic riveting device suitable for a satellite disc type conductive slip ring ultra-thin reed. The device comprises a riveting machine, a riveting head, a riveting fixed clamping tool, a precise driving platform, a sensor, a control system and the like. A rivet, the reed and a printed brush plate are accurately positioned through the riveting fixed clamping tool; the riveting machine is controlled by the control system, the riveting head is tightly absorbed by means of magnetic force, and the riveting head is pressed to a certain position through high-speed rotation; the sensor is used for feeding back riveting force to the control system in real time to finally achieve riveting of a fixed force value; after one point is riveted, the control system is used for controlling the precise driving platform to accurately move to a next riveting point, and the operation is repeated, so as to realize automatic riveting of the reed. According to the automatic riveting device in the invention, positioning and fastening of the reed are realized, through force feedback control, the pressing quality consistency of the riveting points is guaranteed to be good, andthe reliability is guaranteed to be high; and through the precise driving platform, automatic riveting of a group of reeds is realized, and the product quality precision and efficiency are improved.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

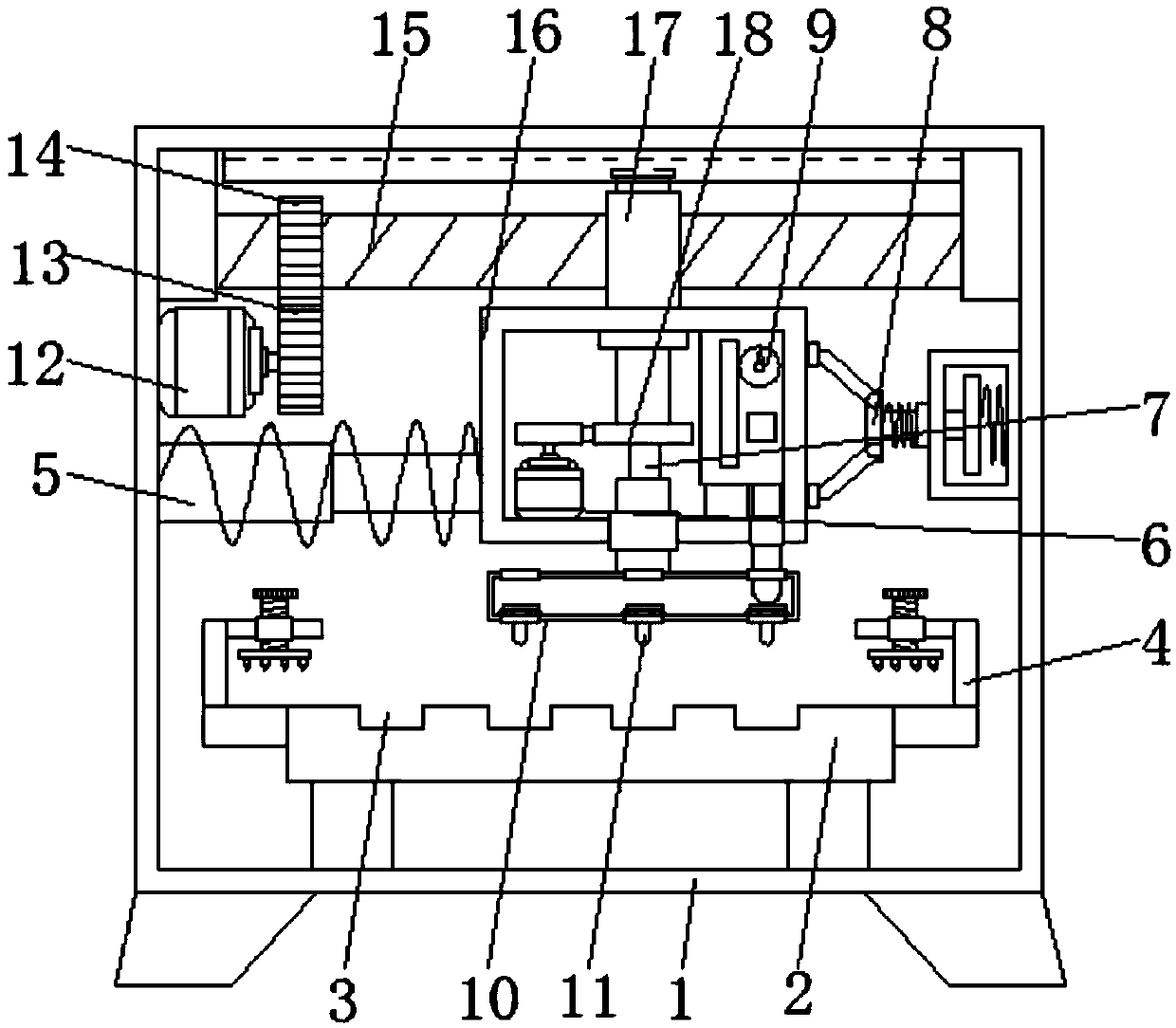

Continuous hydraulic riveting machine

The invention discloses a continuous hydraulic riveting machine, and relates to the technical field of riveting machines. The continuous hydraulic riveting machine comprises an outer frame. The bottomof the inner wall of the outer frame is fixedly connected with a riveting plate through a supporting column. Fixing devices are fixedly connected to the two sides of the top of the riveting plate. Aspring rod is fixedly connected to the left side of the inner wall of the outer frame. The right end of the spring rod is fixedly connected with an inner frame. The left side of the inner wall of theouter frame is fixedly connected with a first motor. A first gear is fixedly connected to one end of an output shaft of the first motor. The top of the first gear is engaged with a second gear. The continuous hydraulic riveting machine achieves the purpose of conveniently fixing workpieces, workpiece movement during riveting is prevented, and riveting proceeding is guaranteed; the riveting qualityis improved, riveting can be conveniently achieved for different positions, usage is convenient for people, rivets do not need to be added at every time of riveting, batched adding can be conducted,and the burden of workers is relieved; and the stability of the device is improved, the service life of the device is prolonged, and the production cost is reduced.

Owner:陈颖

Box corner riveting device for washing machine box body

The invention relates to the technical field of riveting, in particular to a box corner riveting device for a washing machine box body. The box corner riveting device can achieve location accurately, achieve riveting of box corners conveniently and improve the riveting efficiency. The box corner riveting device comprises a main frame, a top supporting plate is arranged at the upper end of the main frame and provided with a riveting base, the riveting base is provided with a stamping base and a locating base, and a box body supporting base is arranged on the bottom of the main frame and connected with a lifting air cylinder.

Owner:WUXI AMTEX AUTOMATION TECH

U shaped riveted joint and riveting gun joint

The invention discloses a U-shaped rivet joint, which is characterized in that the rivet joint takes a shape of an inverted U-shaped structure, a bayonet is arranged downwards, the lower end of the tail of the rivet joint is provided with a connecting hole, and the side wall which is axially opposite to the connecting hole is provided with a screwed hole. The invention also discloses a connector used for connecting the U-shaped rivet joint and a rivetter, which is characterized in that the connector takes a shape of a column-table structure, the head of the connector is a column which is provided with a key slot and in transition fit with the connecting hole on the U-shaped rivet joint in a transition way, the tail of the connector is a round table which has one concave station respectively at the left side and the right side which are matched with two bosses at the tail of the U-shaped rivet joint, and the radial center of the round table is provided with a screwed hole. As the bayonet of the U-shaped rivet joint can escape from the non-open part, the riveting of the non-open part can be realized; the U-shaped rivet joint and the connector adopt the transition fit connection, as the two can move relatively, the rebound problem of the rivet joint can be solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

Riveting device for box corner reinforcing part of washing machine box body

The invention relates to the technical field of riveting, in particular to a riveting device for a box corner reinforcing part of a washing machine box body. The riveting device can achieve riveting between the reinforcing part and the box corners of the washing machine box body conveniently, ensures the stability in the subsequent conveying process of the box body, and is easy and convenient to operate. The riveting device comprises a base, a locating base is arranged on one side of the base and provided with a locating block, a support is arranged at the upper end of the base, a riveting base is arranged around the bottom of the support and provided with a riveter and box corner supporting blocks, the riveter is connected with a riveter air cylinder, and a supporting base is arranged on the base at the lower end of the support.

Owner:WUXI AMTEX AUTOMATION TECH

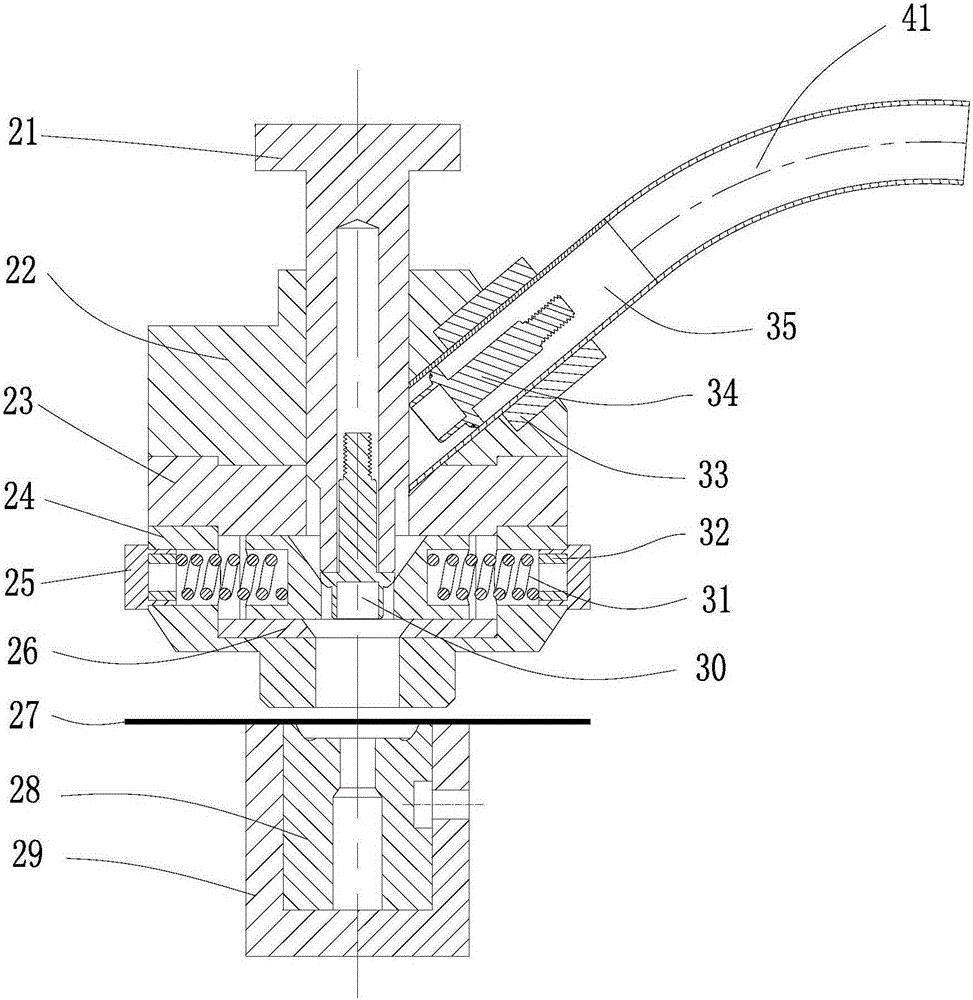

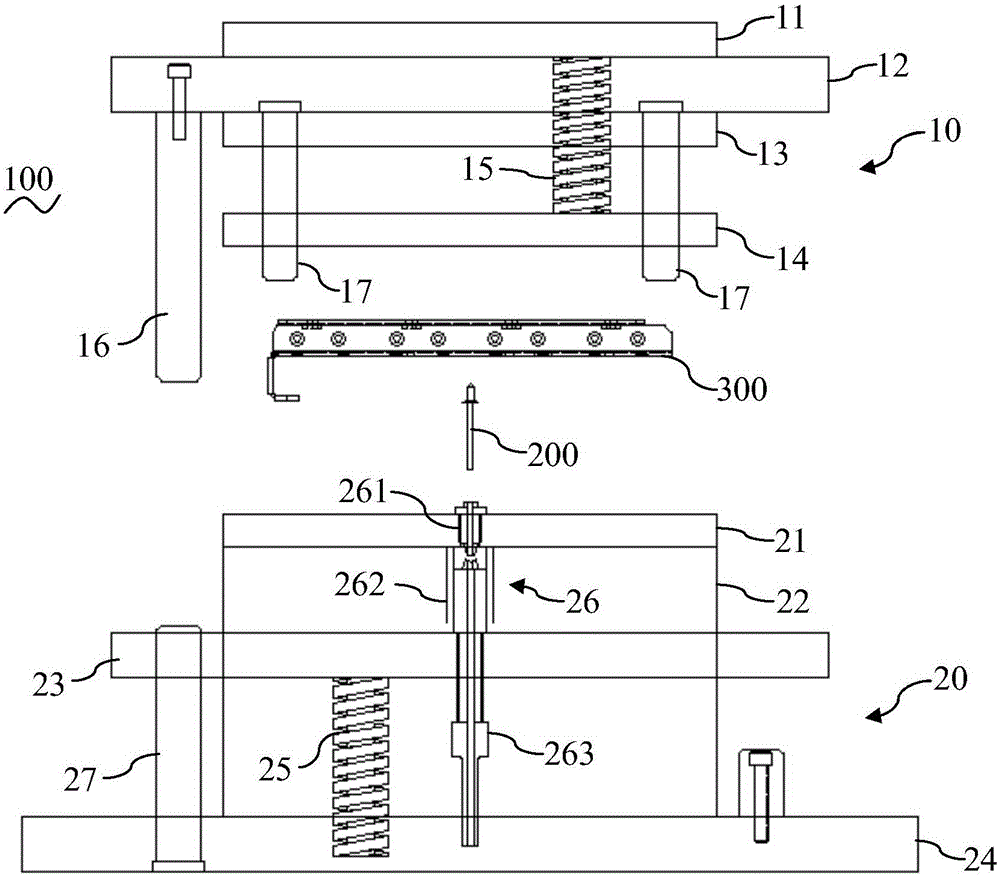

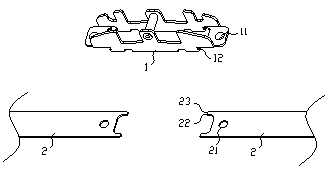

Internal riveting mechanism

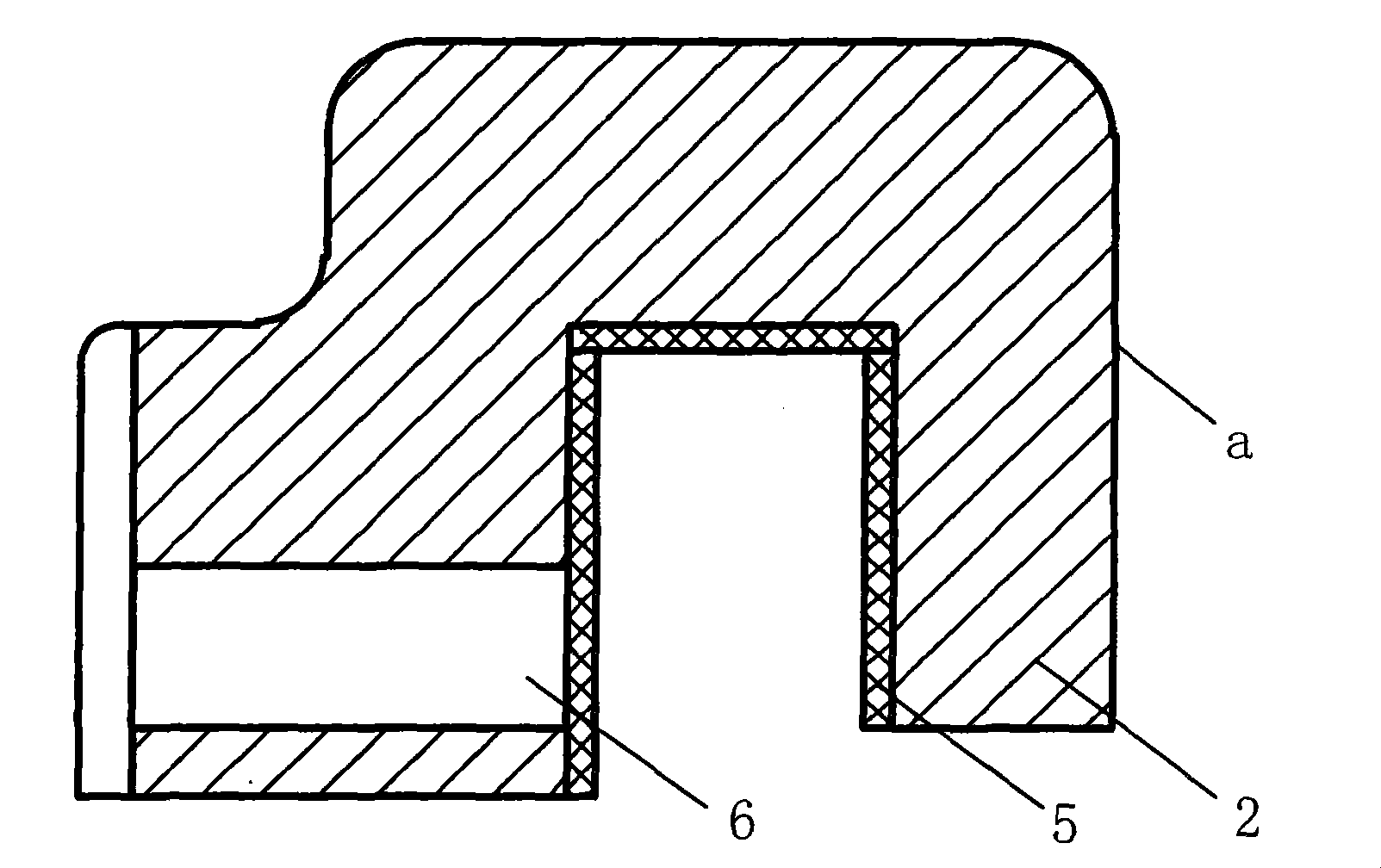

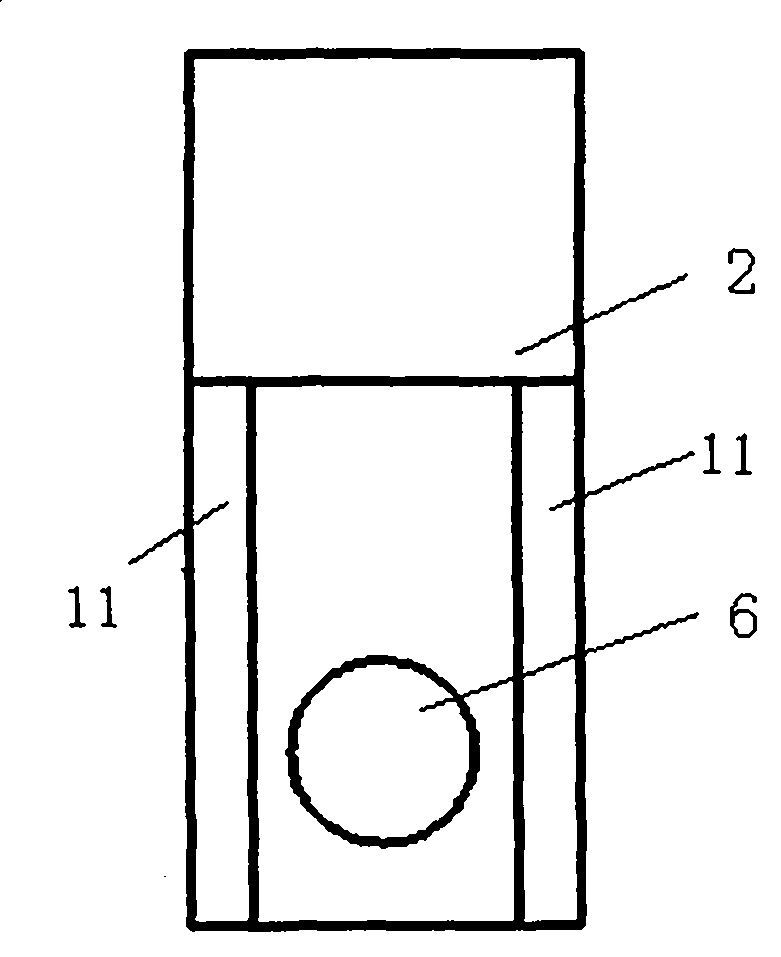

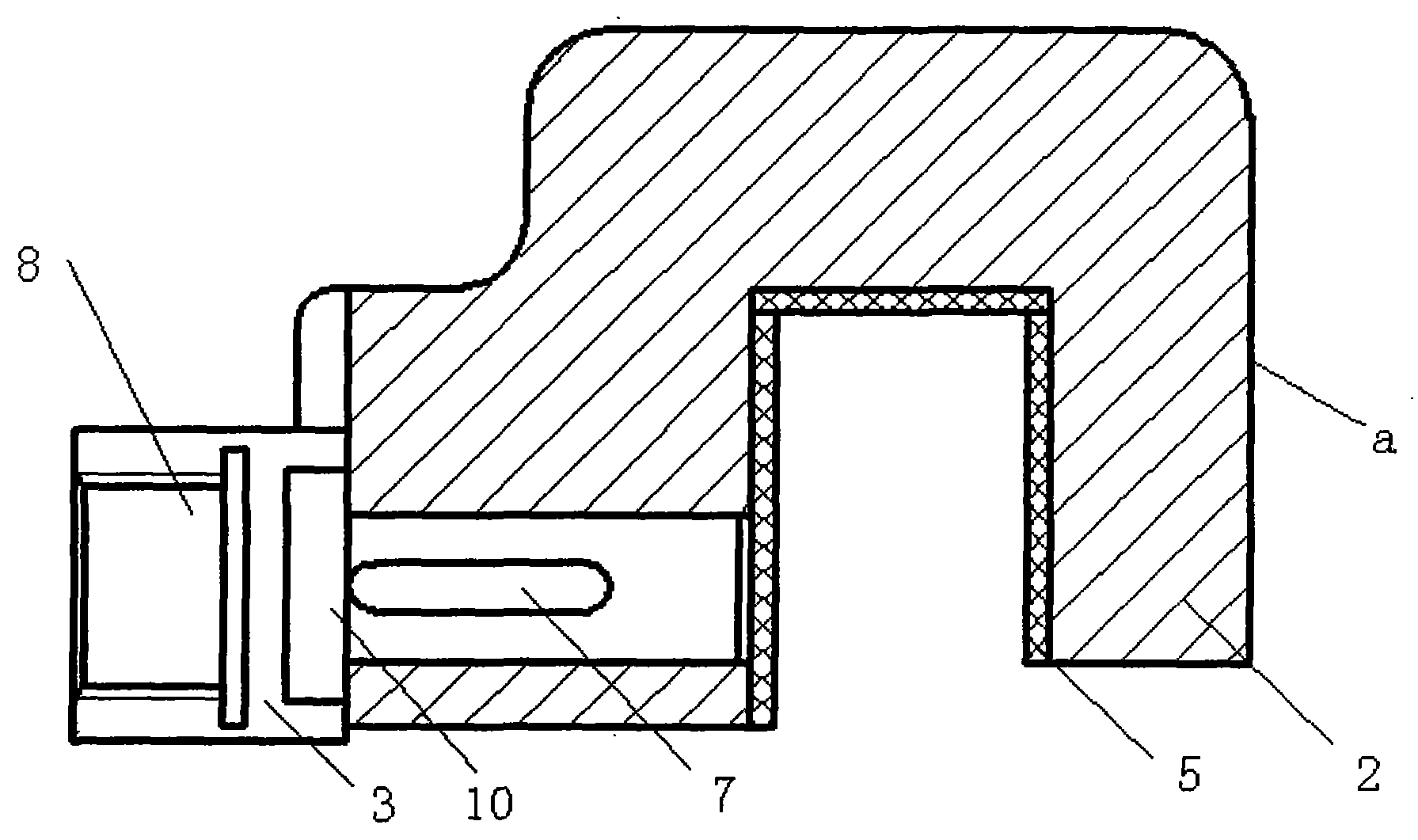

PendingCN108326162AOvercoming external tensionRiveting realizationShaping toolsEngineeringMechanical engineering

The invention discloses an internal riveting mechanism. The mechanism comprises an upper die structure and a lower die structure, wherein the upper die structure comprises an upper die plate, outer guide sleeves are symmetrically arranged on the two sides below the upper die plate, pressing blocks are arranged in the middles of the outer guide sleeves, each pressing block is in a capital omega shape, the two ends of the capital omega shape of each pressing block are provided with locking sleeves, the lower die structure comprises a lower die plate, a lower ejection block is arranged in the middle of the lower die plate, the lower ejection block is embedded into the lower die plate, the lower part of the lower ejection block is connected with the lower die plate through a spring, side pushing blocks are arranged on the two sides of the lower ejection block, riveting heads are symmetrically arranged at the positions, opposite to the central axis of the lower ejection block, of the innerside faces of the side pushing blocks on the two sides, locking guide columns are arranged in the middles of the side pushing blocks on the two sides, outer guide columns matched with the outer guidesleeves are arranged above the side pushing blocks on the two sides, and side pushing air cylinders are arranged on the outer side surfaces of the side pushing blocks on the two sides. According to the mechanism, a riveting part with the riveting point at a sunken part of a product is riveted, the overall performance is high, the locking force is large, the structure is stable, popularization andapplication are facilitated.

Owner:无锡微研中佳精机科技有限公司

Rivet pressing stamping die

The invention discloses a rivet pressing stamping die. The rivet pressing stamping die comprises a cushion block, a rivet fixing block and a riveting female die, wherein the cushion block is fixedly arranged on an upper die; the rivet fixing block is provided with a fixing and assembling part and a rod part; the fixing and assembling part is connected with the cushion block; one end of the rod part is connected with the fixing and assembling part, and the other end is provided with an assembly groove used for assembling the rivet; the riveting female die is arranged on a lower die; the top surface, facing to the rivet fixing block, of the riveting female die is provided with a through hole through which the rivet can penetrate and a boss surrounding the through hole; the cushion block is arranged on the upper die, and the riveting female die is arranged on the lower die; the rivet which is arranged on the rivet fixing block which is arranged on the cushion block is matched with the riveting female die, so that riveting of a workpiece is realized; the riveting can be directly realized by assembly of the upper die and the lower die of a current die, so that the riveting technique is applied to other techniques which are realized through assembly of the upper die and the lower die such as punching, edging, stamping and the like; and meanwhile, the rivet is fixed in the assembly groove through air pressure, so that the rivet pressing stamping die is convenient, flexible and easy to change.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

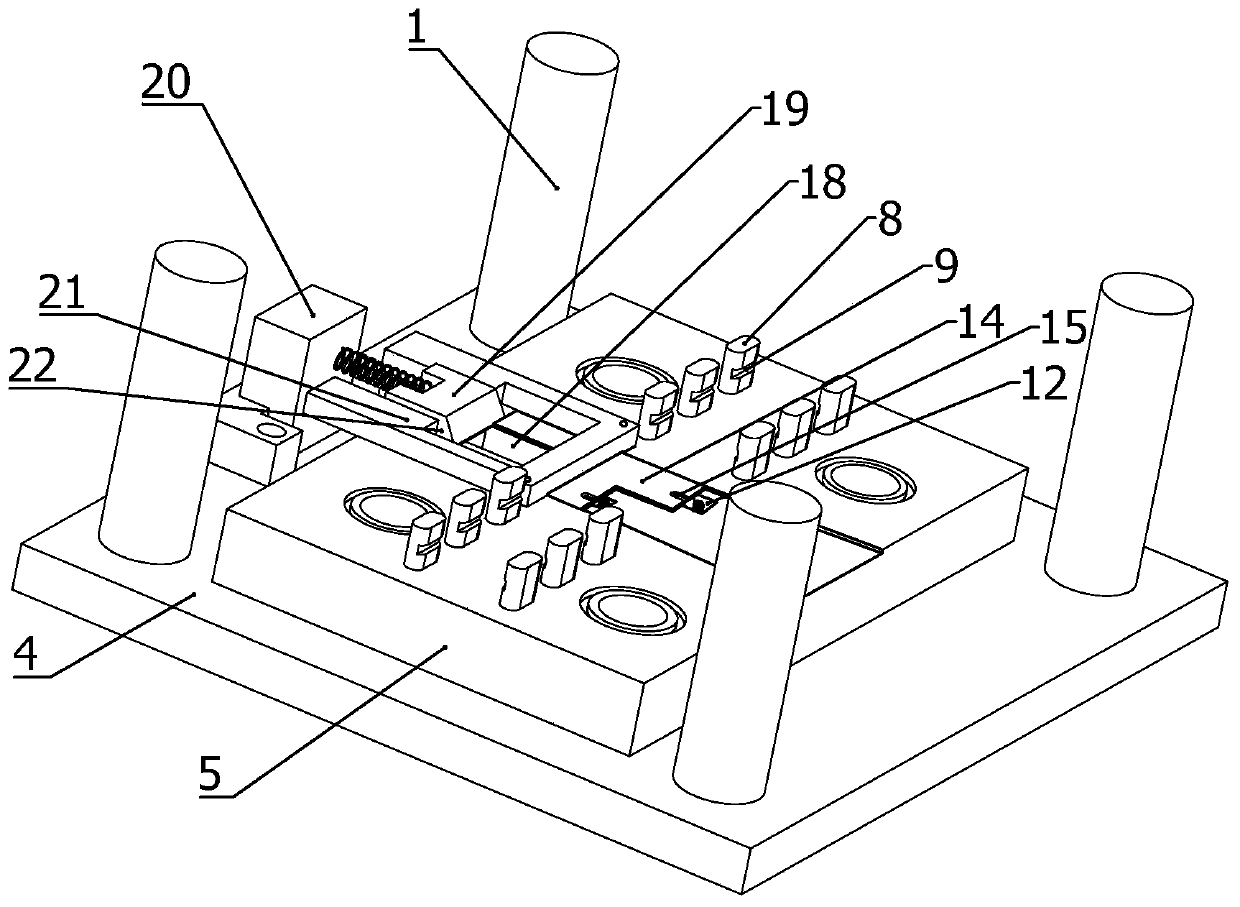

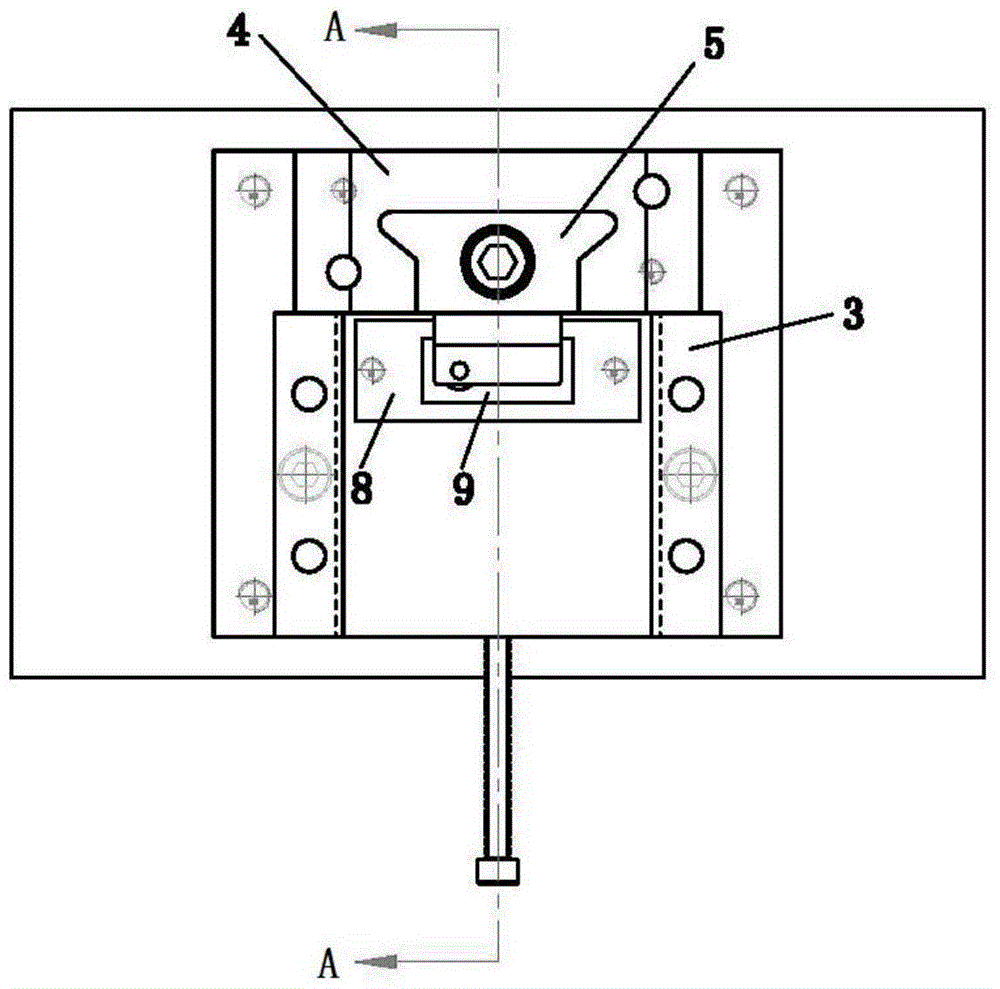

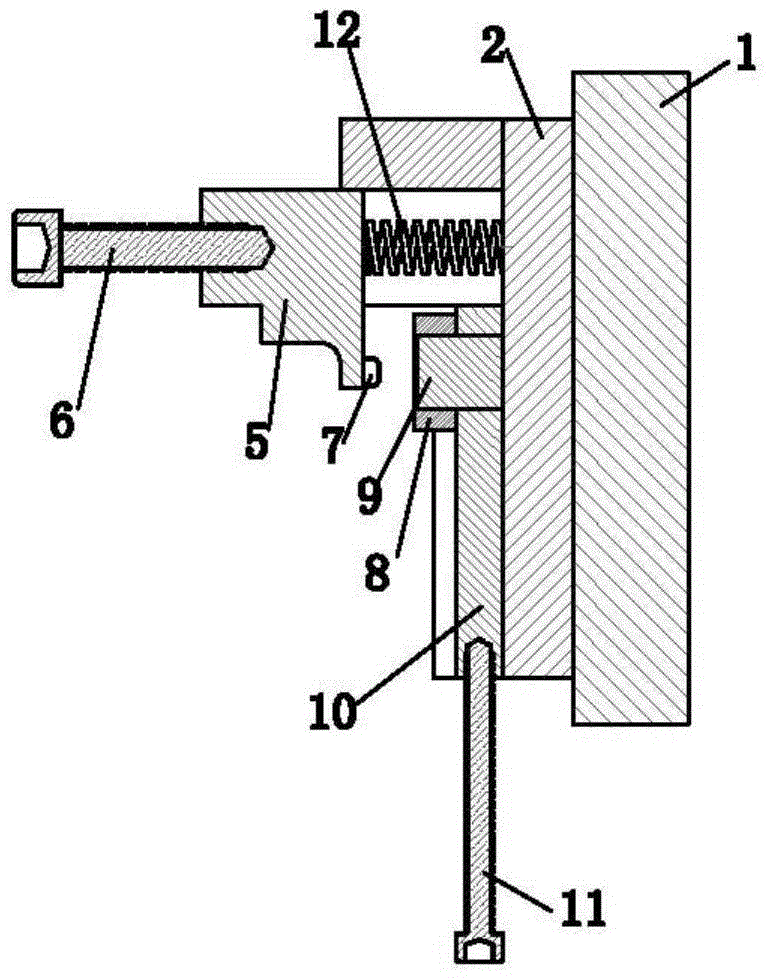

In-mold riveting die for riveting punch press

The invention discloses an in-mold riveting die for a riveting punch press. The technical scheme is characterized in that the in-mold riveting die comprises an upper die assembly, a lower die assemblyand guide columns, wherein the upper die assembly comprises an upper die plate and an upper die holder, the lower die assembly comprises a lower die plate and a lower die holder, and a discharging channel and a feeding channel are formed in the lower die holder; an accommodating groove is formed in the lower die holder; a slider is arranged in the accommodating groove; the lower end of the slideris inclined; a moving block is arranged at the lower end of the slider; a stagger groove matched with the lower end of the slider is formed in the upper end surface of the moving block; a spring is arranged on the rear side of the moving block, and an oblique plane is formed on the front side; an opening is formed in the lower die holder opposite to the oblique plane of the moving block; a firstinserting column is arranged on the upper die holder; an oblique plane matched with the oblique plane above the moving block is formed at the lower end of the first inserting column. The in-mold riveting die for the riveting punch press has the characteristics of being simple to operate and convenient to use.

Owner:浙江亿金电器有限公司

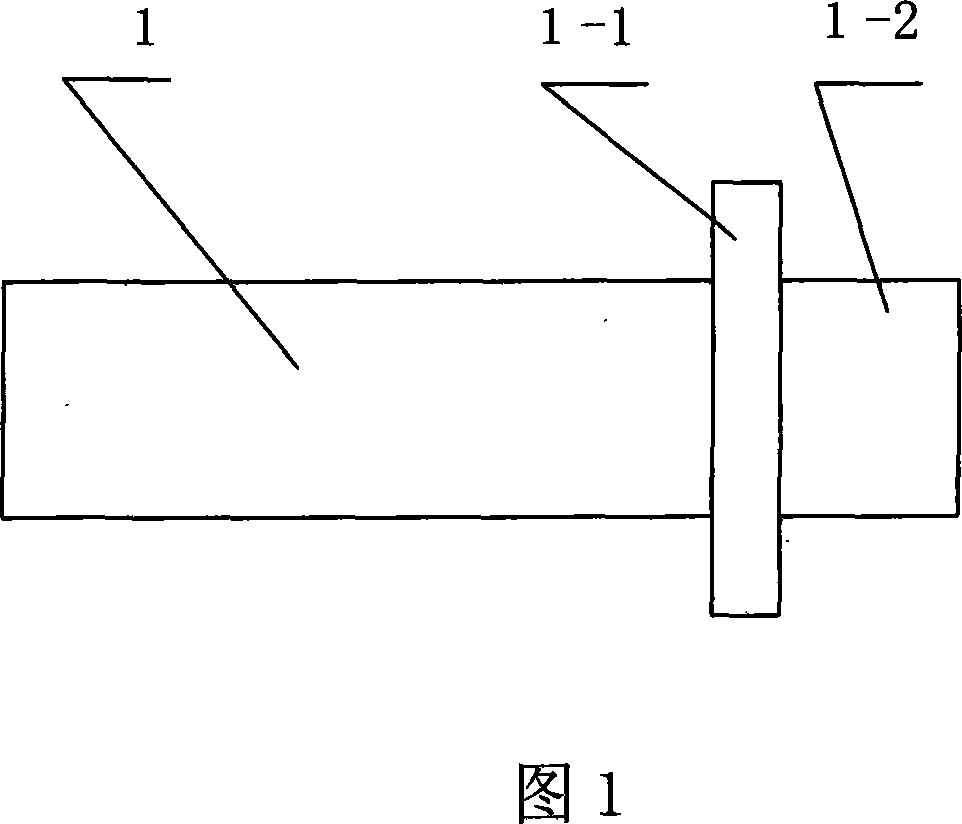

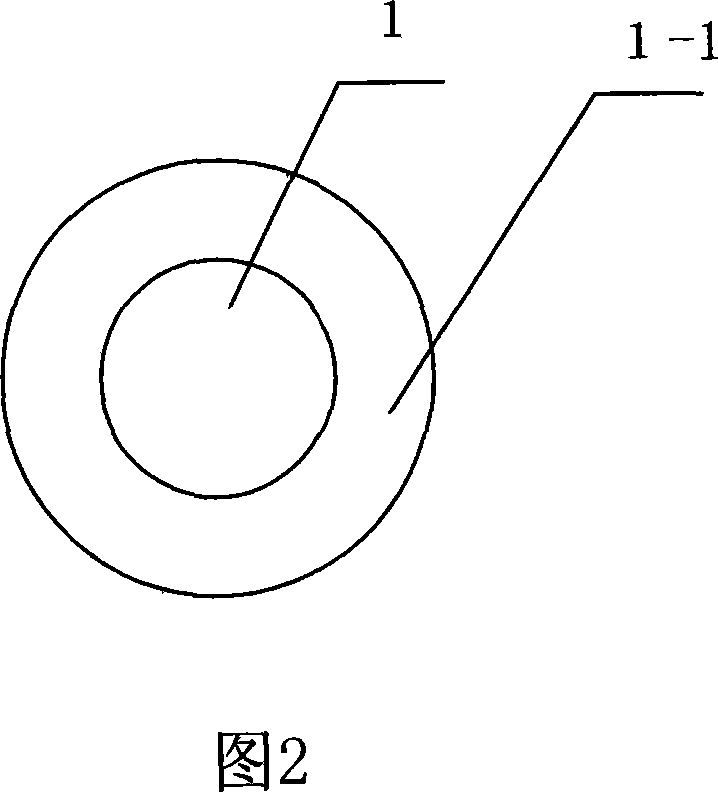

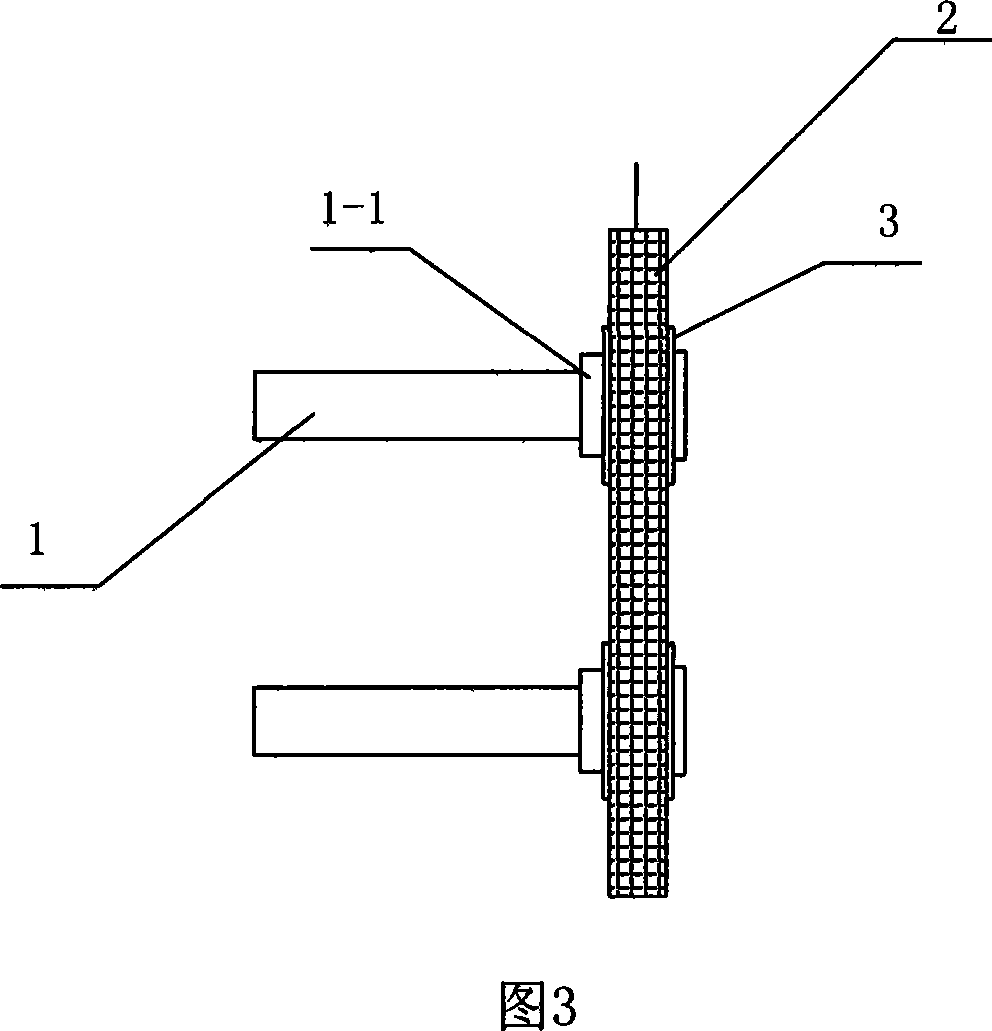

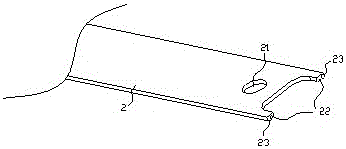

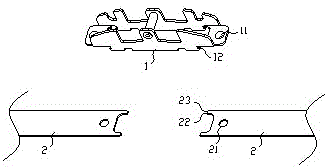

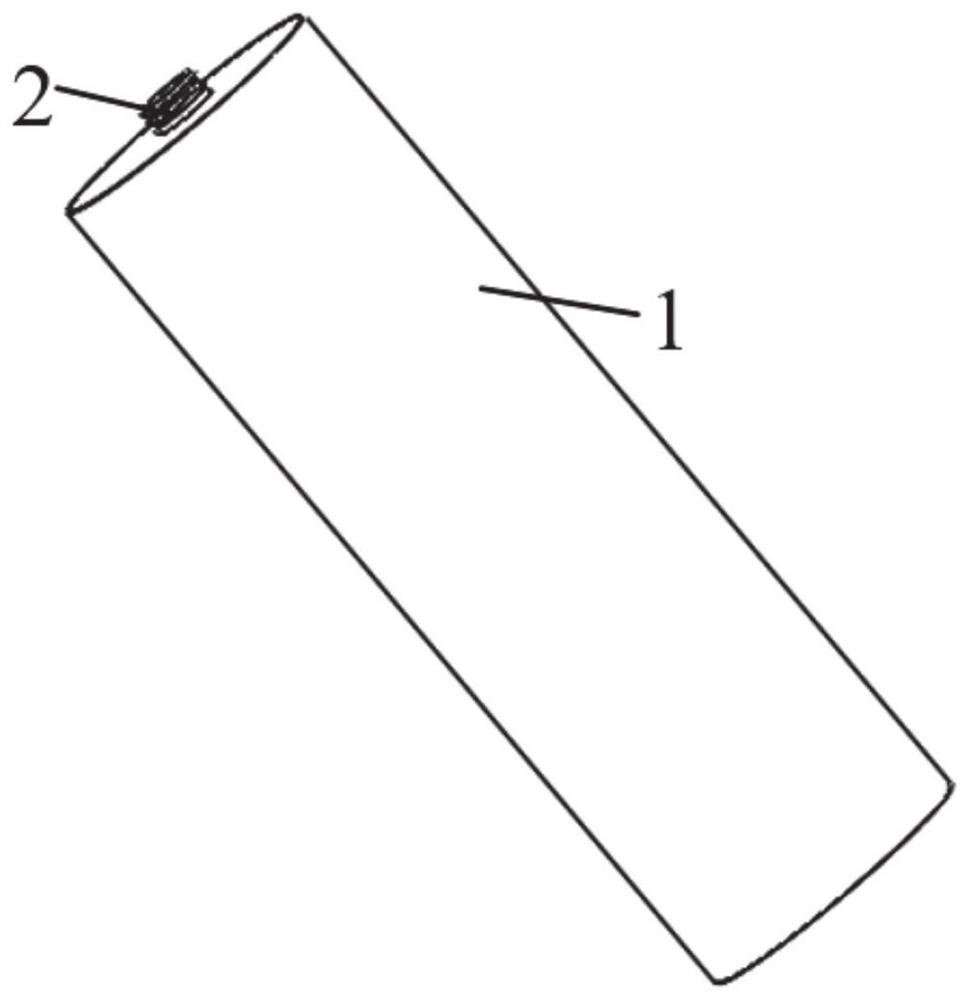

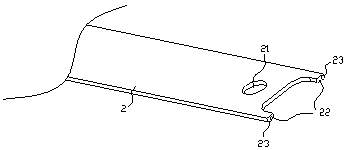

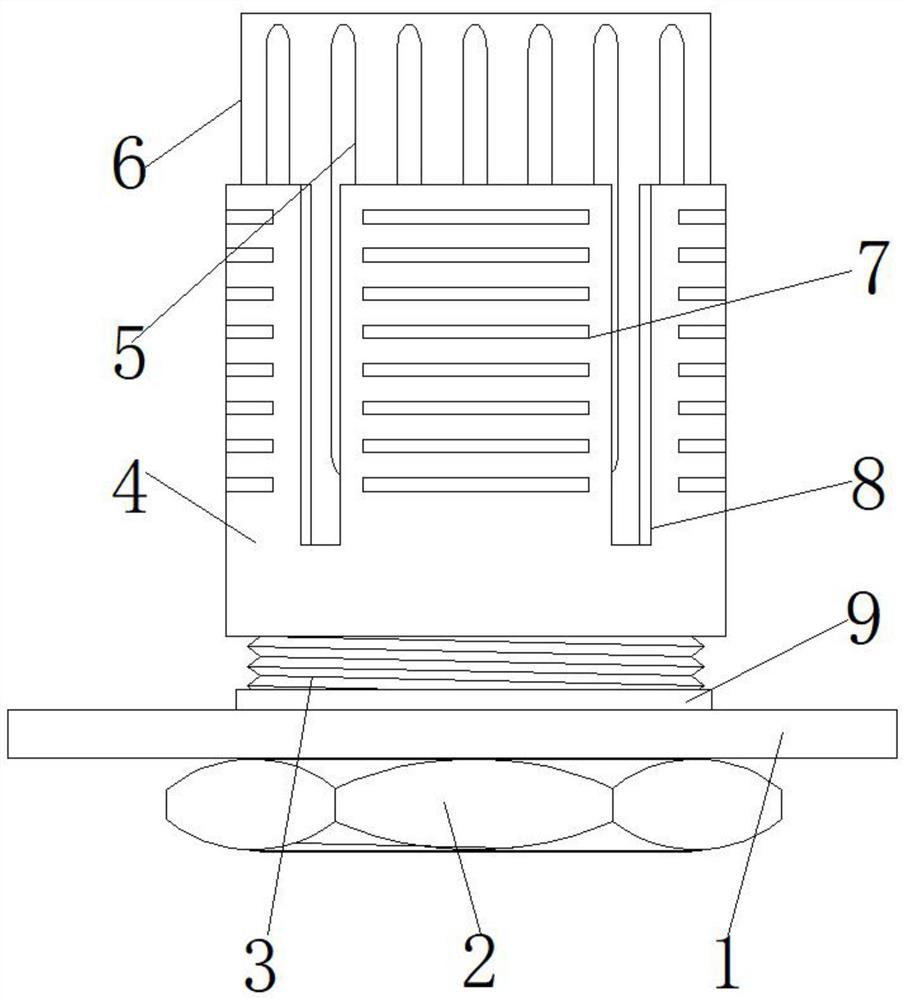

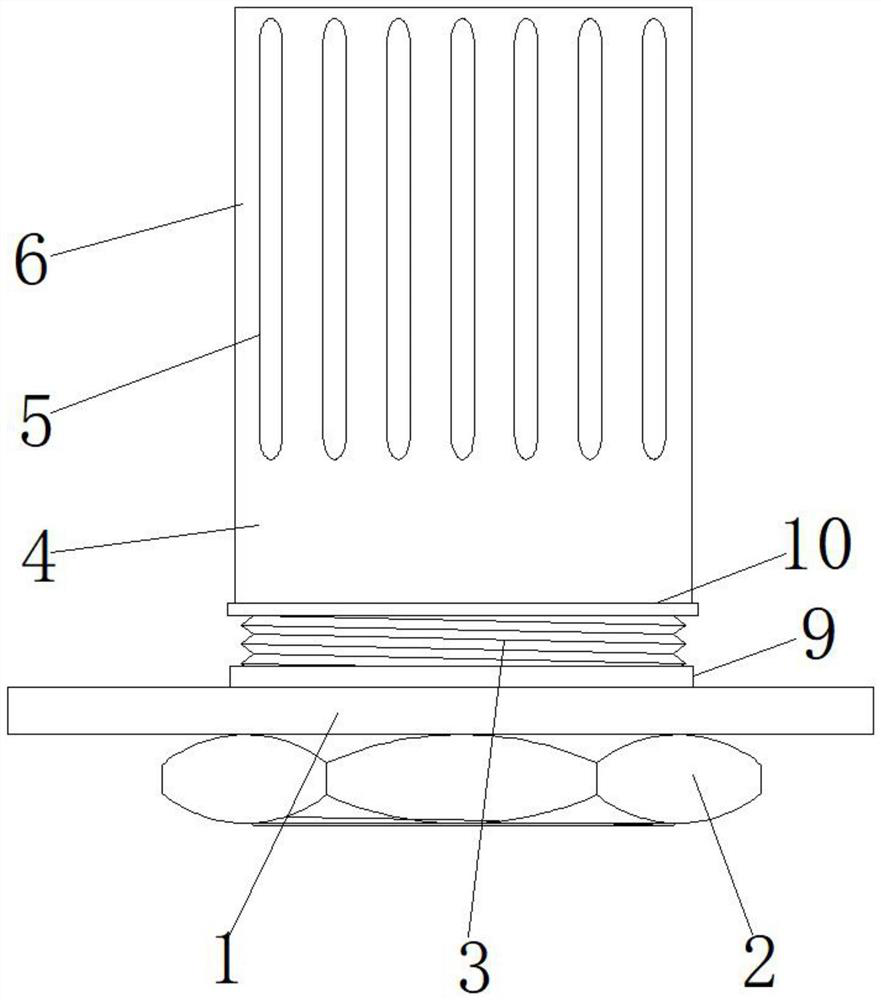

Microphone pin and method for connection it with printed circuit board

InactiveCN101048013ARiveting facilitates realizationRiveting realizationMouthpiece/microphone attachmentsEngineeringPrinted circuit board

The invention relates to a kind of pins of microphone, including a pin-body (1), a connectivity part (1-2) for connecting with the printed circuit board, a convex shoulder (1-1). The invention also provides a method for connecting the microphone pin and the printed circuit board shows as follow: It inserts the front-end of the microphone into the printed circuit board reserved pin-hole by transition fit, and exposes the front-end out of the reserved pin-hole, and then, it rivets the front-end with the printed circuit board through riveting.

Owner:赵年东

Pressure riveting stamping die

The invention discloses a rivet pressing stamping die. The rivet pressing stamping die comprises a cushion block, a rivet fixing block and a riveting female die, wherein the cushion block is fixedly arranged on an upper die; the rivet fixing block is provided with a fixing and assembling part and a rod part; the fixing and assembling part is connected with the cushion block; one end of the rod part is connected with the fixing and assembling part, and the other end is provided with an assembly groove used for assembling the rivet; the riveting female die is arranged on a lower die; the top surface, facing to the rivet fixing block, of the riveting female die is provided with a through hole through which the rivet can penetrate and a boss surrounding the through hole; the cushion block is arranged on the upper die, and the riveting female die is arranged on the lower die; the rivet which is arranged on the rivet fixing block which is arranged on the cushion block is matched with the riveting female die, so that riveting of a workpiece is realized; the riveting can be directly realized by assembly of the upper die and the lower die of a current die, so that the riveting technique is applied to other techniques which are realized through assembly of the upper die and the lower die such as punching, edging, stamping and the like; and meanwhile, the rivet is fixed in the assembly groove through air pressure, so that the rivet pressing stamping die is convenient, flexible and easy to change.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

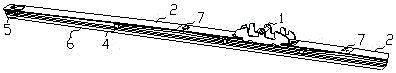

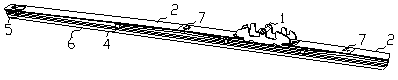

Connecting structure and wiper using connecting structure

ActiveCN106347302AEasy rivetingAchieve connectionVehicle cleaningEngineeringElectrical and Electronics engineering

Owner:DANYANG UPC AUTO PARTS

Motor assembly riveting detection mechanism

ActiveCN111360167BNovel structureRiveting realizationMetal-working feeding devicesMetal working apparatusElectric machineControl engineering

Owner:深圳市中科创想科技有限责任公司

Stamping progressive die capable of riveting

The invention discloses a stamping progressive die capable of riveting. The stamping progressive die capable of riveting comprises a punching machine, a stamping station and a riveting station, the stamping station and the riveting station are sequentially arranged in the transverse direction, a metal plate enters the riveting station to be riveted with a rivet after being stamped and formed intoa product connected through a material belt through the stamping station, and the same punching action of the punching machine can at least achieve punching forming of one product and riveting of oneproduct and the rivet. According to the stamping progressive die capable of riveting, the cost can be reduced, and the punching machine can be used more efficiently.

Owner:NEW AMERIOCEAN TECH CO LTD

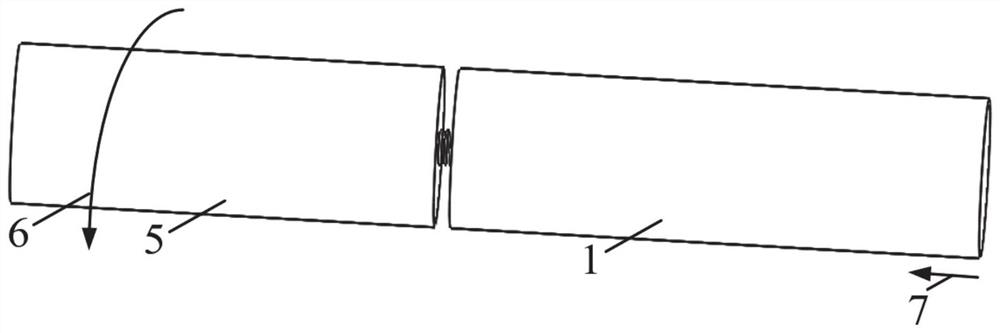

Riveting-assisted rotary friction welding process for dissimilar metal bar and application

The invention provides a riveting-assisted rotary friction welding process for preparing a high-strength dissimilar metal bar structure. The riveting-assisted rotary friction welding process is particularly suitable for preparing the dissimilar metal structure with high performance and large hardness difference. According to the method, the process advantages of rotary friction welding can be fully exerted, meanwhile, the interface bonding performance of a central area is improved by utilizing a riveting mode, on the basis that the production cost is not obviously increased, the performance of the composite structure of the dissimilar metal bar can be remarkably improved, and the high-performance dissimilar metal bar structural part can be directly obtained.

Owner:SHANDONG UNIV

Riveting tool and method for mounting bevel gear components by same

Owner:TRIUMPH HEAVY IND

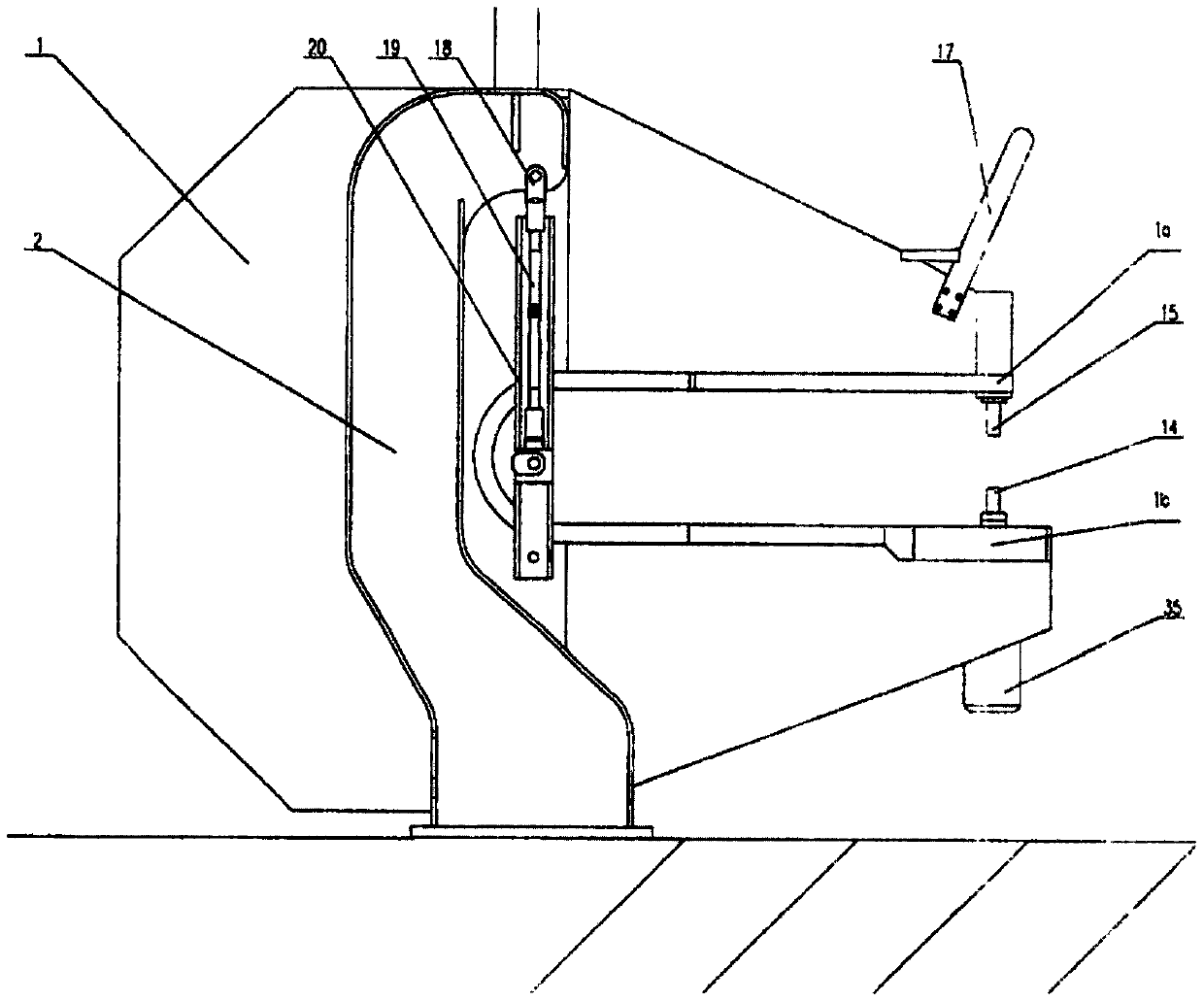

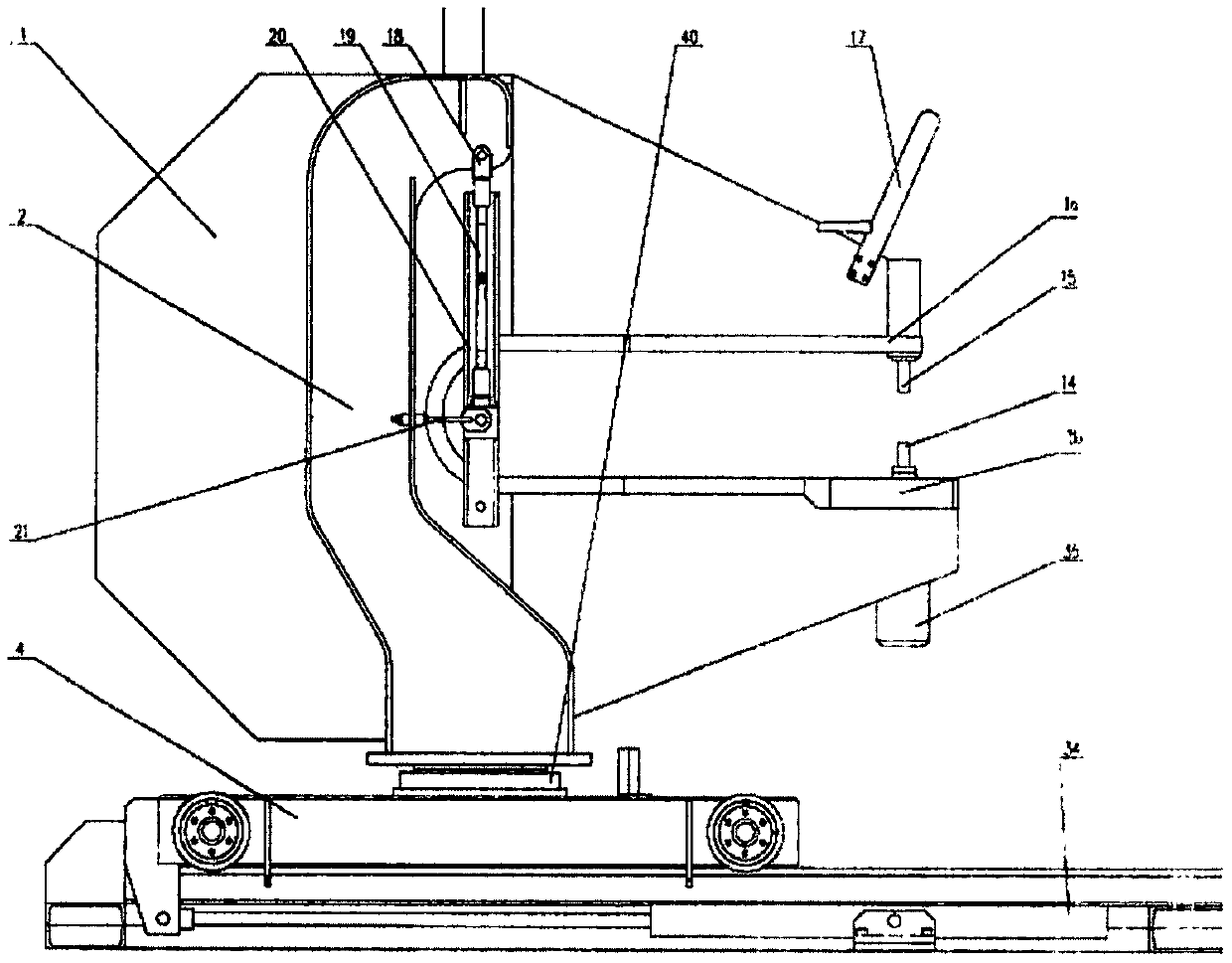

Riveting machine

The invention discloses a riveting machine. The riveting machine comprises a rivet cavity head, a clamp body, a clamp body support for hanging the clamp body and a hydraulic device; the clamp body support is fixed to the ground, a clamping device used for clamping a machined workpiece is arranged on the clamp body, a rivet cavity head is divided into a rivet upper cavity head and a rivet lower cavity head, the rivet upper cavity head is fixedly arranged on the lower end of an upper clamp opening of the clamp body, the rivet lower cavity head is arranged at the position, aligned with the rivetupper cavity head, of the upper end of the lower clamp opening of the clamp body, a riveting oil cylinder of the hydraulic device is fixedly arranged below the lower clamp opening of the clamp body, the rivet lower cavity head and a piston of the riveting oil cylinder are linked, the hydraulic device drives the piston of the riveting oil cylinder to move, and the rivet lower cavity head moves relative to the rivet upper cavity head. The riveting machine is provided, and used for riveting of aluminum rivets.

Owner:王杰

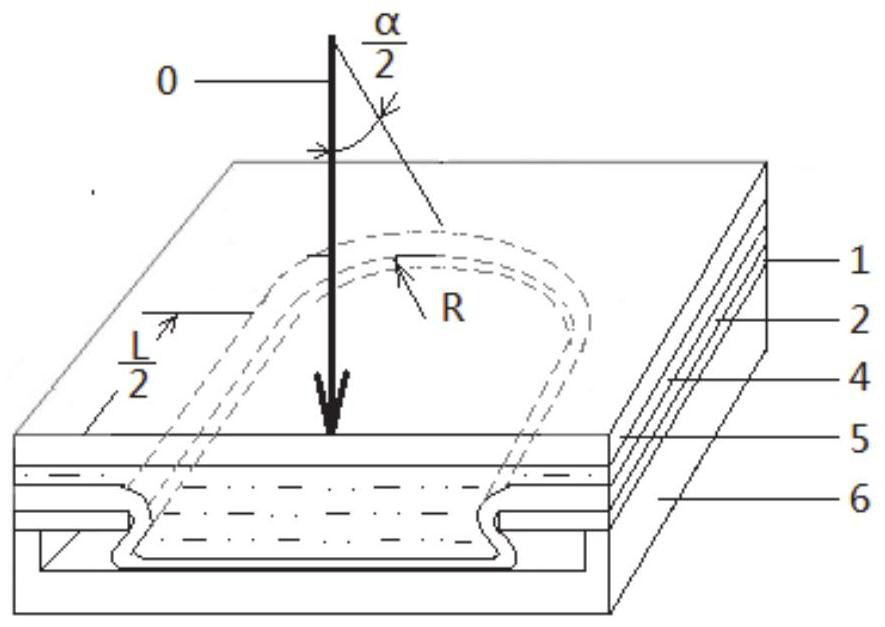

Special-shaped rivet-free riveting structure and forming device and method

ActiveCN113172163AGuaranteed riveting effectExpand the scope of processingLap jointUltimate tensile strength

The invention discloses a special-shaped rivet-free riveting structure, and a forming device and method, which solves the problem of low connection strength of rivet-free riveting in the prior art, and has the beneficial effect of improving the strength of a plate riveting area. The specific scheme is as follows: the special-shaped rivet-free riveting structure comprises a first plate and at least one layer of second plate which are riveted; the first plate is provided with a special-shaped hole, and the second plate is provided with a concave part; the non-concave part of the second plate is in lap joint above the first plate, the concave part protrudes out of the special-shaped hole of the first plate, and the depth of the concave part is larger than the sum of the thickness of the first plate and the thickness of the second plate; and the length of the bottom surface of the concave part is greater than that of the open side of the top of the concave part, and / or the width of the bottom surface of the concave part is greater than that of the open side of the top of the concave part.

Owner:SHANDONG UNIV

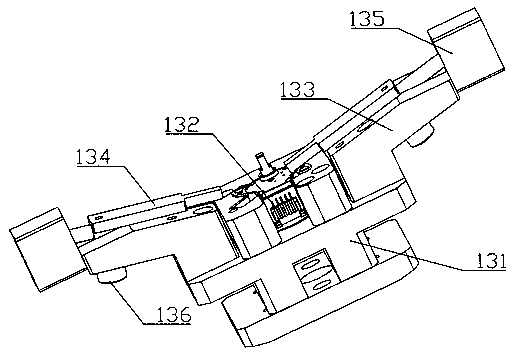

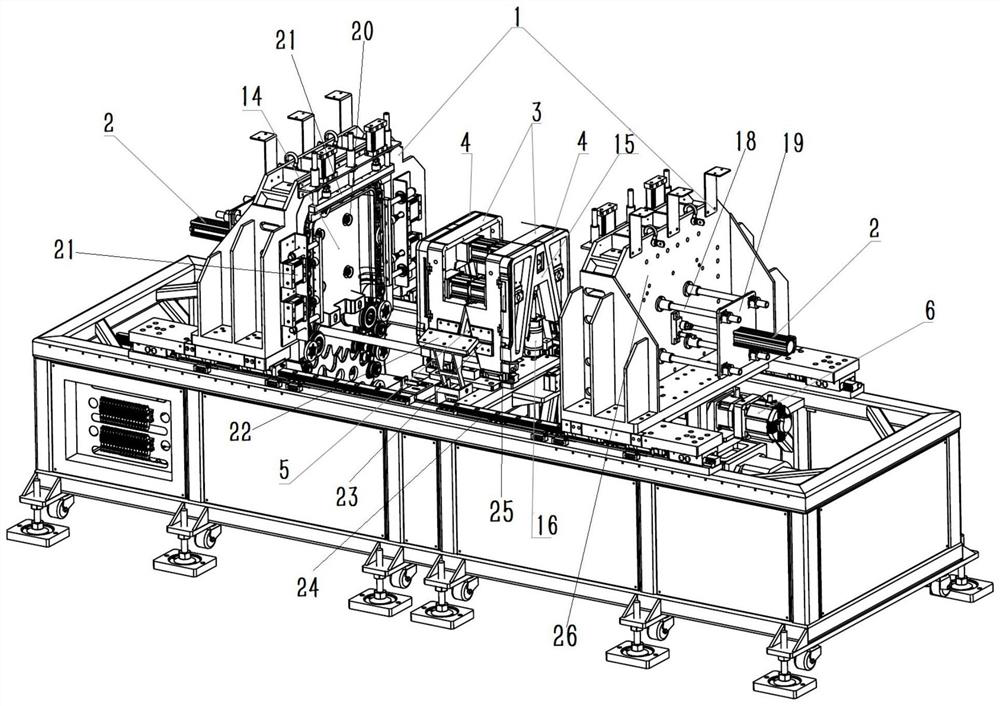

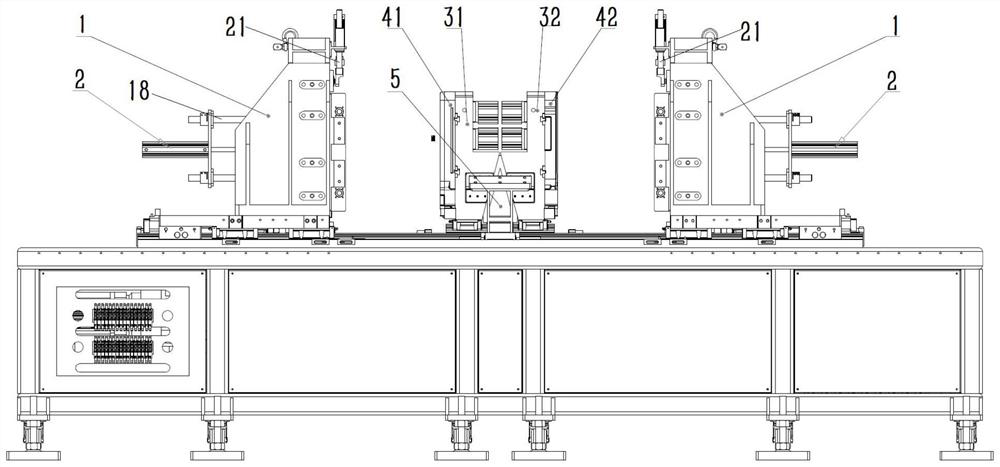

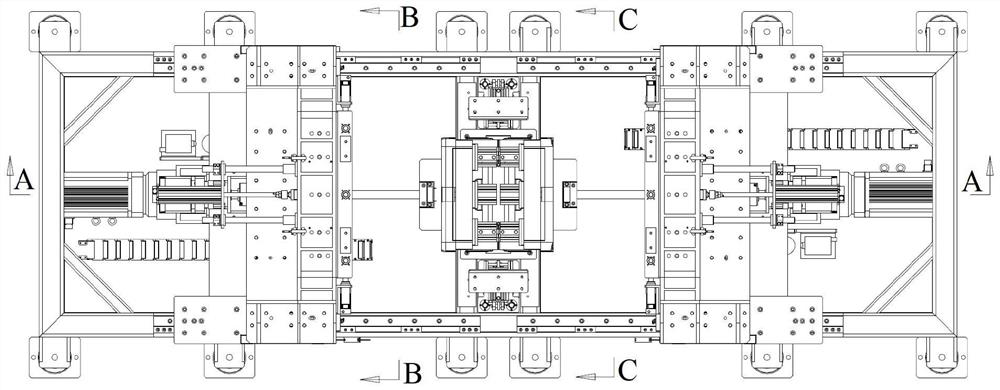

Split groove piece orbit determination loop chain hob roll riveting splicing equipment

PendingCN114653840ARiveting realizationAchieve contactMetal-working feeding devicesPositioning devicesClassical mechanicsEngineering

The invention relates to split groove piece orbit determination loop chain hob roll riveting splicing equipment. A split groove piece comprises a middle frame needing to be riveted and cover plates on the two sides of the middle frame. The fixed-orbit loop chain hob roll riveting splicing equipment comprises a supporting jig assembly, a guide rail assembly and rolling modules on the two sides of the supporting jig assembly. The middle frame and the cover plate are supported through the supporting jig assembly in the riveting process. The rolling module moves along the guide rail assembly through the driving assembly, and riveting or separation is achieved. The rolling module comprises a body, a cover plate cavity and a rolling assembly, wherein the cover plate cavity and the rolling assembly are arranged on the body. The size, the shape and the height of the cover plate cavity are consistent with those of the cover plate, the rolling assembly can rotate on the outer side of the cover plate cavity, a plurality of hobs are arranged on the rolling assembly, and the hobs can rivet split groove pieces in the rotating process of the rolling assembly. In the whole riveting process, the supporting jig assembly and the rolling modules on the two sides of the supporting jig assembly are automatically combined into a whole, operation is easy, the automation degree is high, the reject ratio of products can be reduced, and the product quality can be improved.

Owner:HANGZHOU TAISHANG INTELLIGENT EQUIP CO LTD

High-efficiency rivet riveting device

The invention relates to an efficient pop-rivet pulling-riveting device which comprises an upper die mechanism, a lower die mechanism and a driving mechanism. The upper die mechanism comprises an upper cover plate, an upper die base, an upper clamping plate, an upper stripping plate, a material pressing elastic piece and a limiting pillar, the upper cover plate, the upper die base and the upper clamping plate are arranged in sequence from top to bottom, the upper stripping plate is arranged below the upper clamping plate, the material pressing elastic piece is arranged between and is connected with the upper cover plate and the upper stripping plate, and the limiting pillar is arranged on and perpendicular to the upper die base. The lower die mechanism comprises a female die plate, a lower base plate, a lower die base, a lower back plate, a reset elastic piece and multiple pulling-riveting assemblies, the female die plate, the lower base plate and the lower die base are arranged in sequence from top to bottom, the lower back plate is arranged below the lower die base, and the reset elastic piece is arranged between the lower die base and the lower back plate. The efficient pop-rivet pulling-riveting device can achieve pulling and riveting of multiple pop-rivets at the same time, riveting efficiency is high, and the yield of production and machining is improved.

Owner:昆山力盟机械工业有限公司

Connecting structure and wiper device using it

ActiveCN106347302BEasy rivetingAchieve connectionVehicle cleaningElectrical and Electronics engineering

Owner:DANYANG UPC AUTO PARTS

A riveting device for automobile tailgate electric support rod pipe fittings

Owner:WUHU MOTIONTEC AUTOMOTIVE

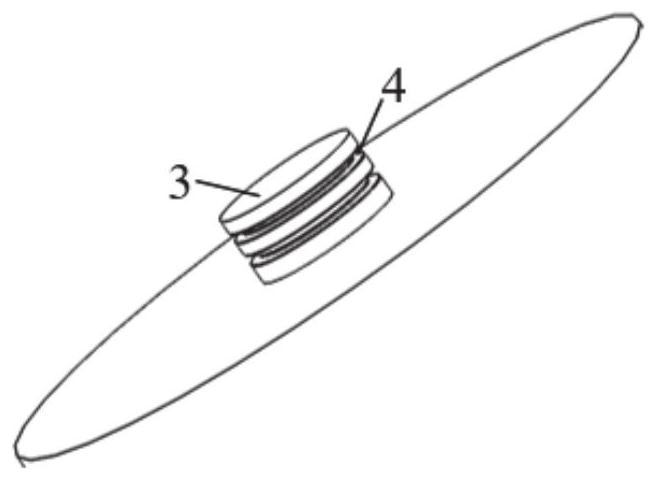

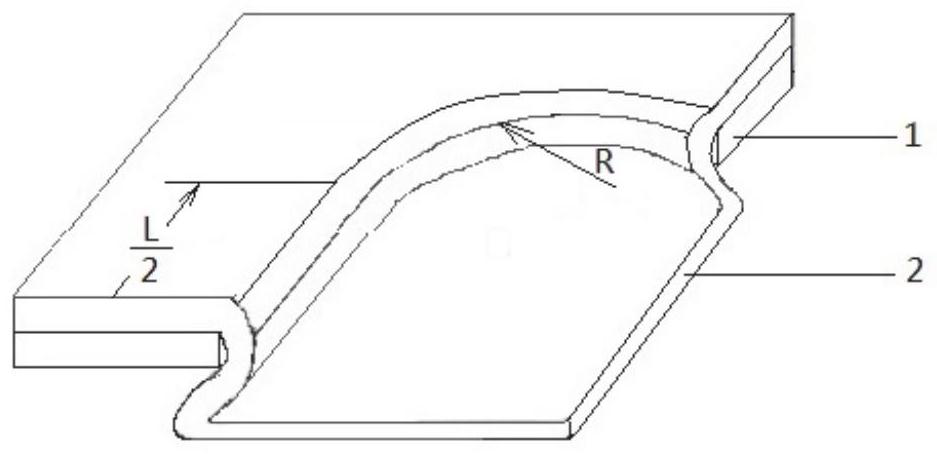

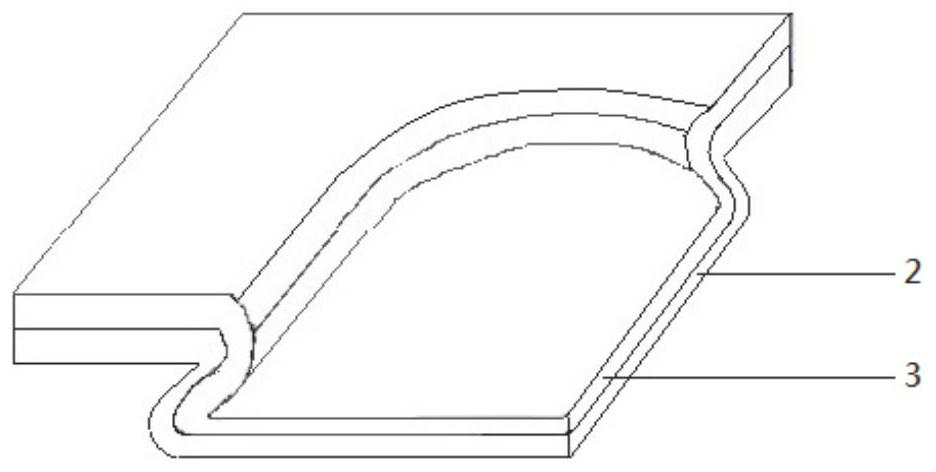

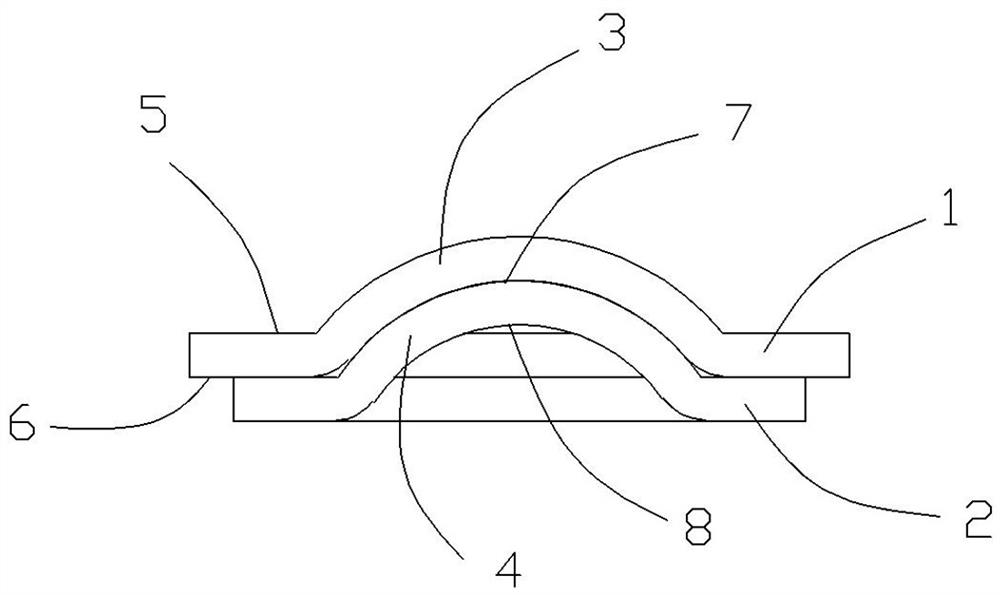

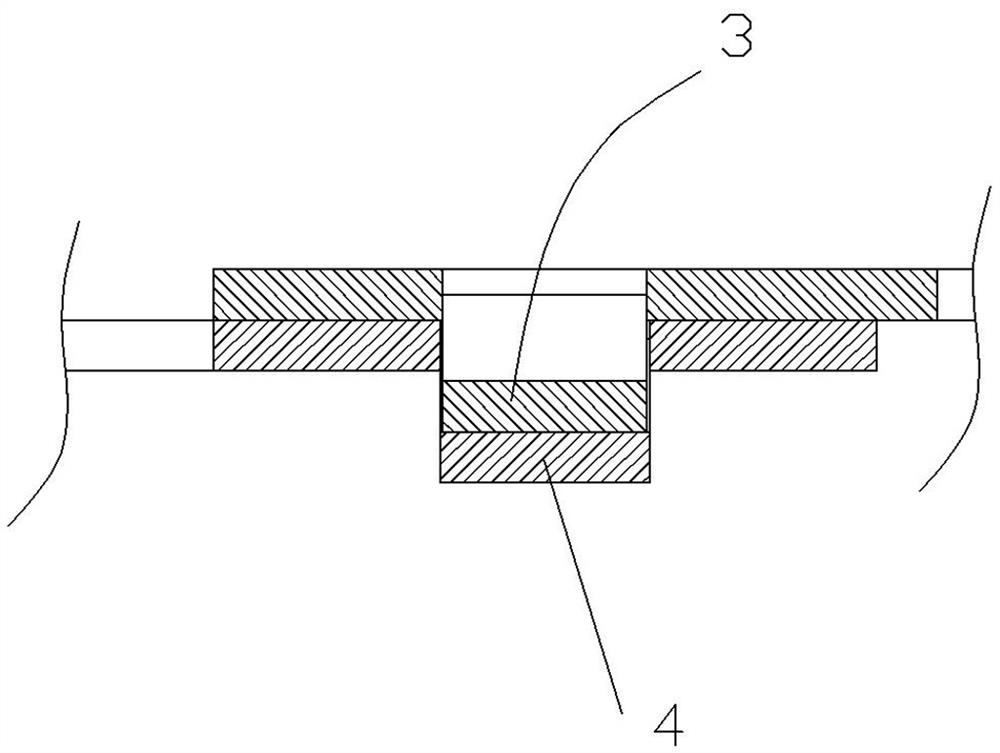

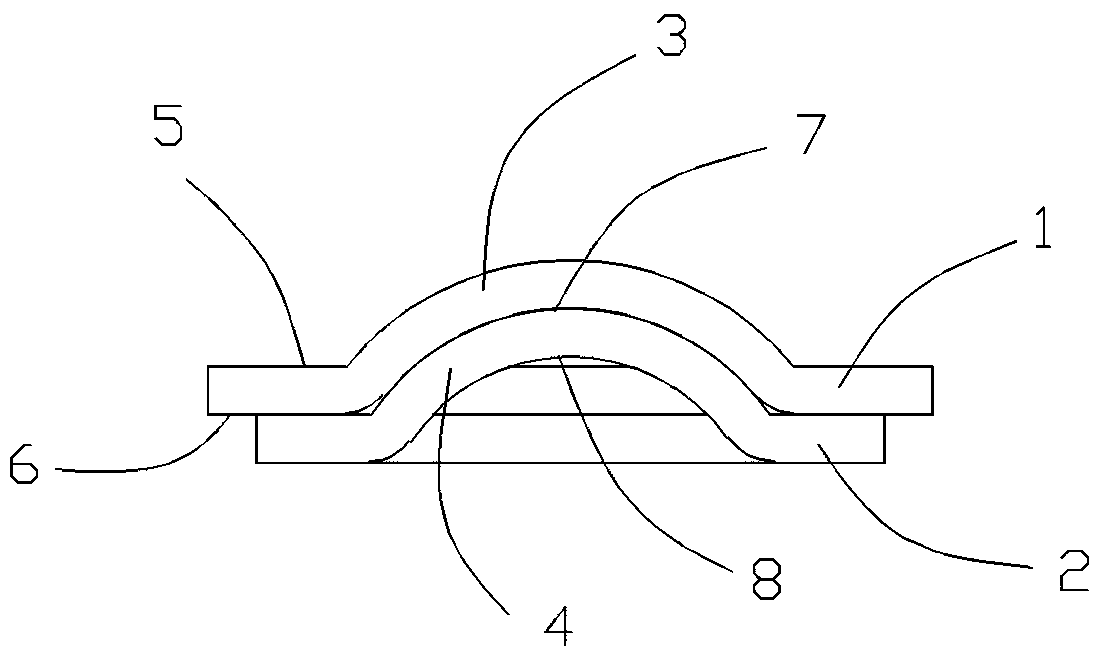

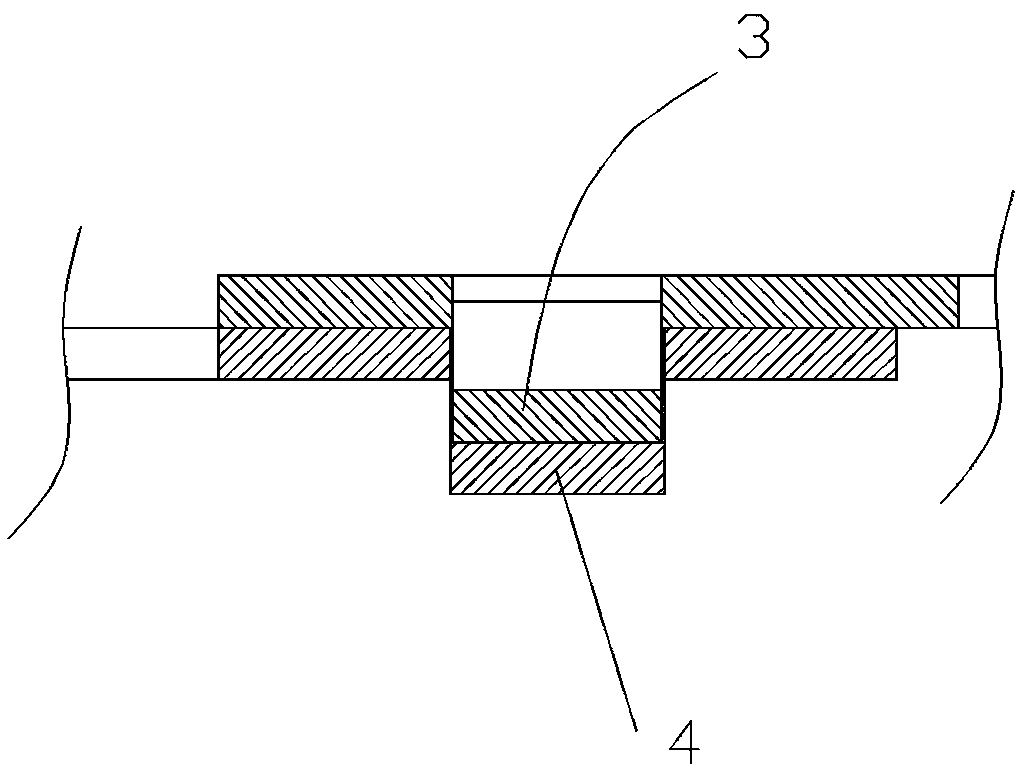

A metal riveting process

The present invention relates to a metal piece riveting process, including the first metal piece 1 and the second metal piece 2 that need to be riveted. The second arc-shaped protrusion assembles the second arc-shaped protrusion 4 of the second metal piece in the concave cavity formed by the first arc-shaped protrusion, and the first arc-shaped protrusion and the assembled first metal piece The second arc-shaped protrusion of the second metal part is riveted and extruded, and the first metal part and the second metal part are riveted together through the first arc-shaped protrusion and the second arc-shaped protrusion. The invention realizes rivetless riveting through a new riveting method, and compared with other existing rivetless riveting, the strength of the riveting structure is enhanced.

Owner:CIXI HANDE ELECTRICAL APPLIANCES

Efficient pop-rivet pulling-riveting device

The invention relates to an efficient pop-rivet pulling-riveting device which comprises an upper die mechanism, a lower die mechanism and a driving mechanism. The upper die mechanism comprises an upper cover plate, an upper die base, an upper clamping plate, an upper stripping plate, a material pressing elastic piece and a limiting pillar, the upper cover plate, the upper die base and the upper clamping plate are arranged in sequence from top to bottom, the upper stripping plate is arranged below the upper clamping plate, the material pressing elastic piece is arranged between and is connected with the upper cover plate and the upper stripping plate, and the limiting pillar is arranged on and perpendicular to the upper die base. The lower die mechanism comprises a female die plate, a lower base plate, a lower die base, a lower back plate, a reset elastic piece and multiple pulling-riveting assemblies, the female die plate, the lower base plate and the lower die base are arranged in sequence from top to bottom, the lower back plate is arranged below the lower die base, and the reset elastic piece is arranged between the lower die base and the lower back plate. The efficient pop-rivet pulling-riveting device can achieve pulling and riveting of multiple pop-rivets at the same time, riveting efficiency is high, and the yield of production and machining is improved.

Owner:昆山力盟机械工业有限公司

A high-efficiency riveting nut

Owner:柳州博纳汽车科技有限公司

Metal piece riveting technology

The invention relates to a metal piece riveting technology. A first metal piece 1 and a second metal piece 2 which need to be riveted are included. The first metal piece 1 and the second metal piece 2are punched and torn into a first arc protrusion and a second arc protrusion, then the second arc protrusion 4 of the second metal piece is assembled in a concave cavity formed by the first arc protrusion, the first arc protrusion of the assembled first metal piece and the second arc protrusion of the second metal piece are riveted and extruded, and the first metal piece and the second metal piece are riveted together through the first arc protrusion and the second arc protrusion. Through a novel riveting method, non-rivet riveting is achieved; and compared with existing other non-rivet riveting, the strength of a riveting structure is enhanced.

Owner:CIXI HANDE ELECTRICAL APPLIANCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com