Riveting machine

A riveting machine and riveting technology, applied in the field of riveting machines, can solve the problems of increasing the manufacturing cost of aluminum alloy trucks and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiment of the present invention provides a riveting machine for realizing the riveting of aluminum rivets.

[0032] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described below with reference to the accompanying drawings and specific embodiments.

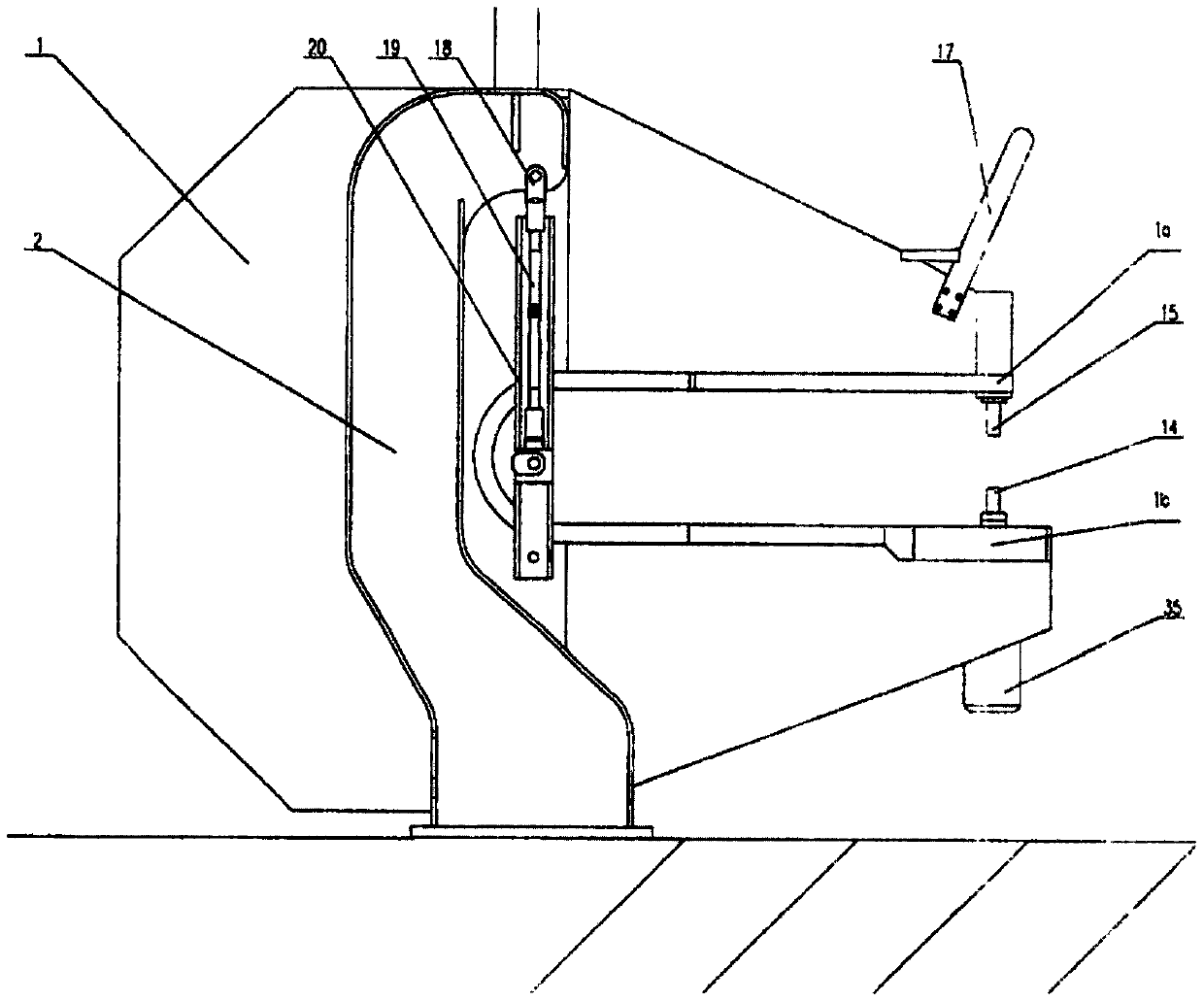

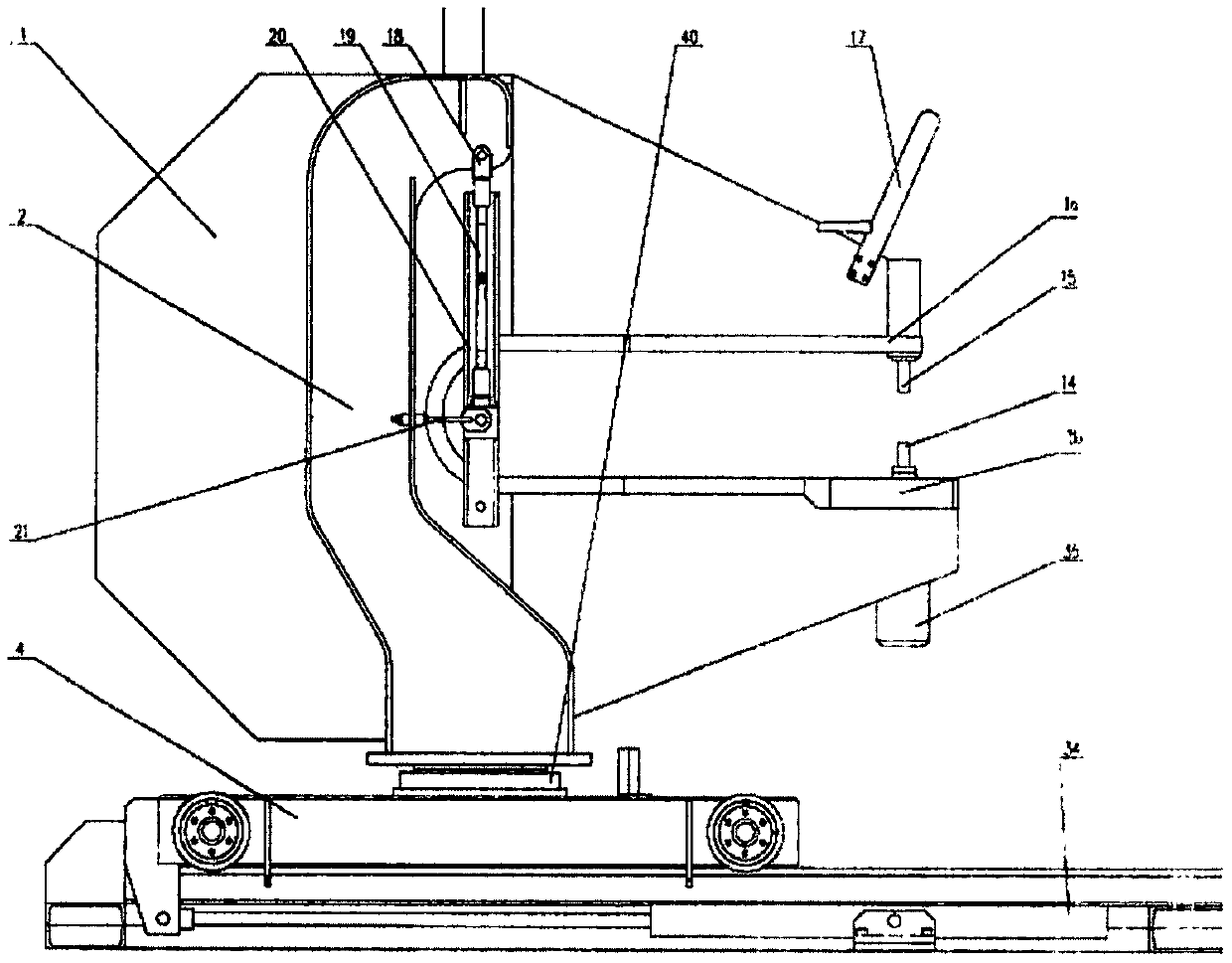

[0033] The first embodiment of the present invention can be referred to figure 1 This figure is a structural diagram of the first embodiment of the present invention.

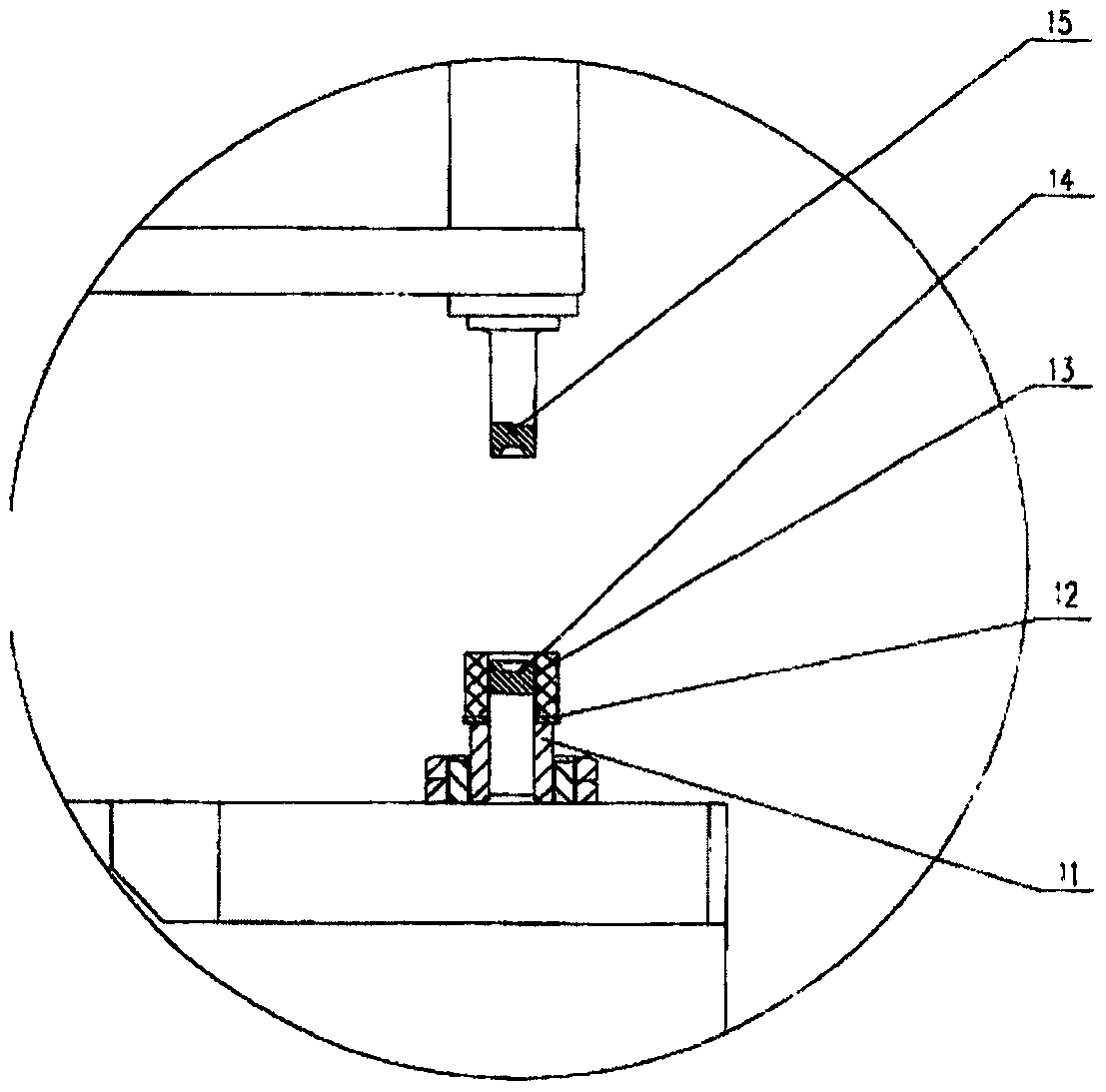

[0034] Due to the different properties of aluminum rivets and steel rivets, the rivet rod of aluminum rivets will become thicker during the riveting process and will penetrate into the gap between the two workpieces. Therefore, the workpiece must be clamped during the riveting process of aluminum rivets. Rivet riveting does not need to clamp the workpiece.

[0035] The aluminum rivet riveting machine according to the first embodiment of the present invention includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com