Patents

Literature

35results about How to "Guaranteed excellent rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

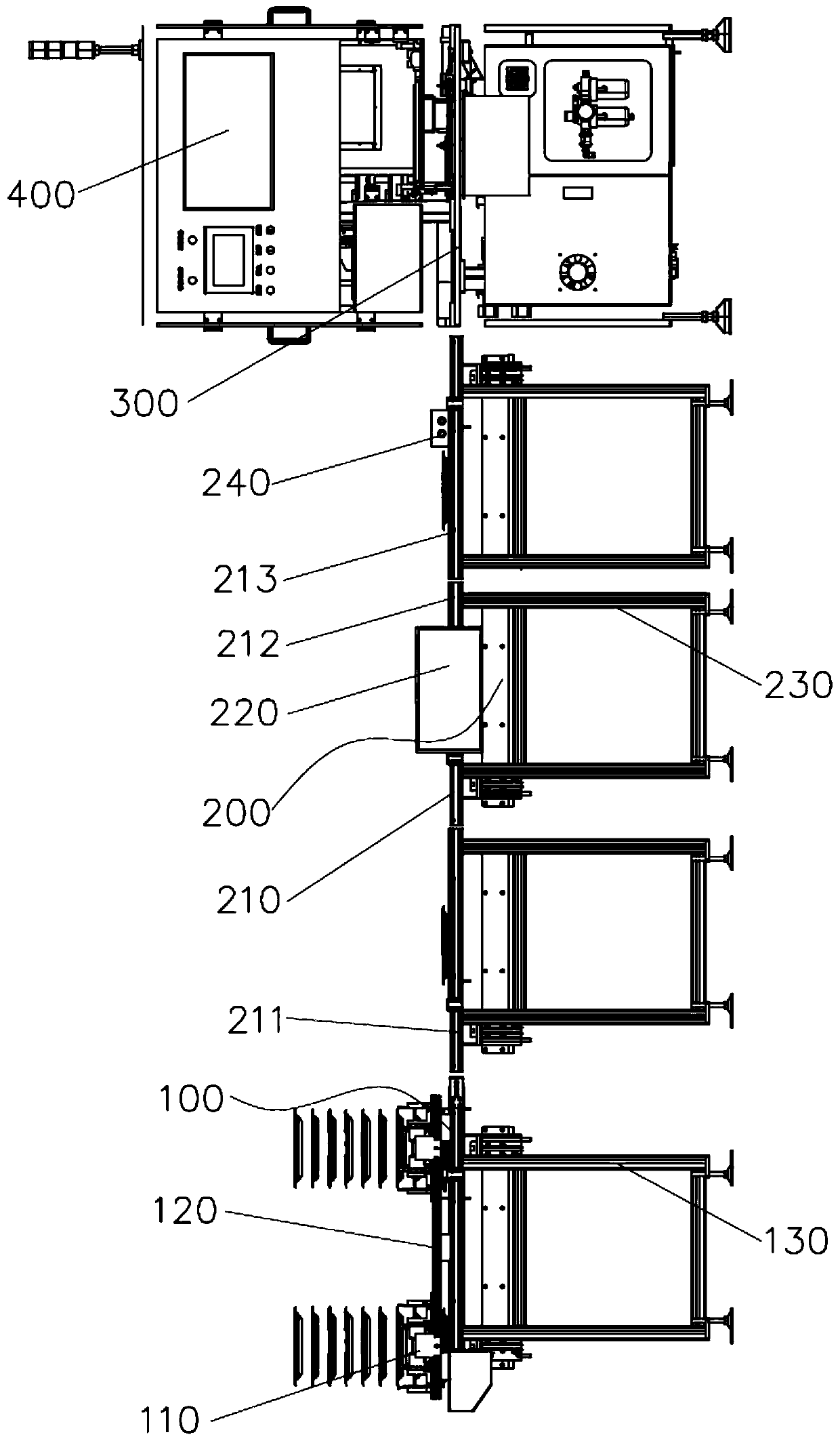

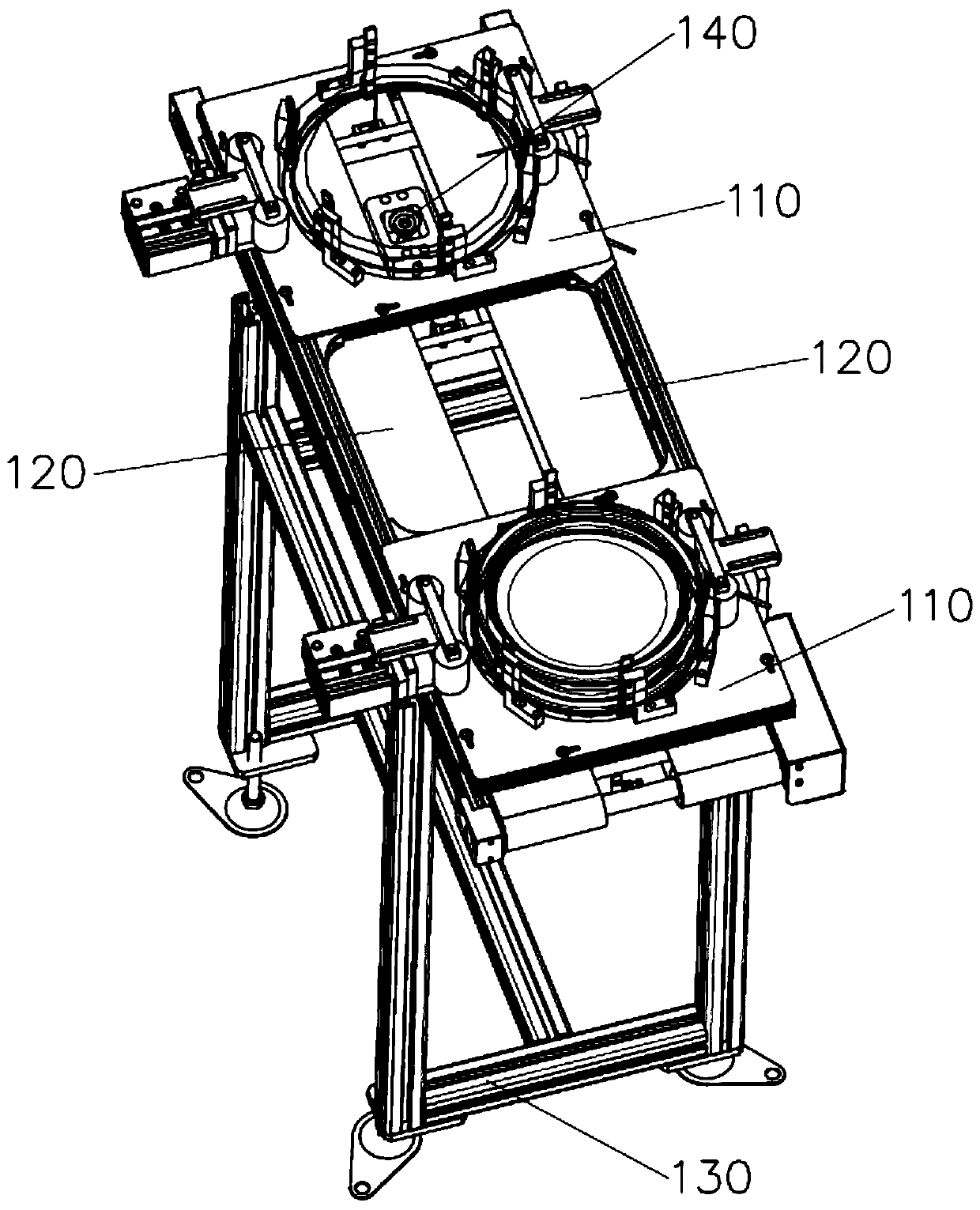

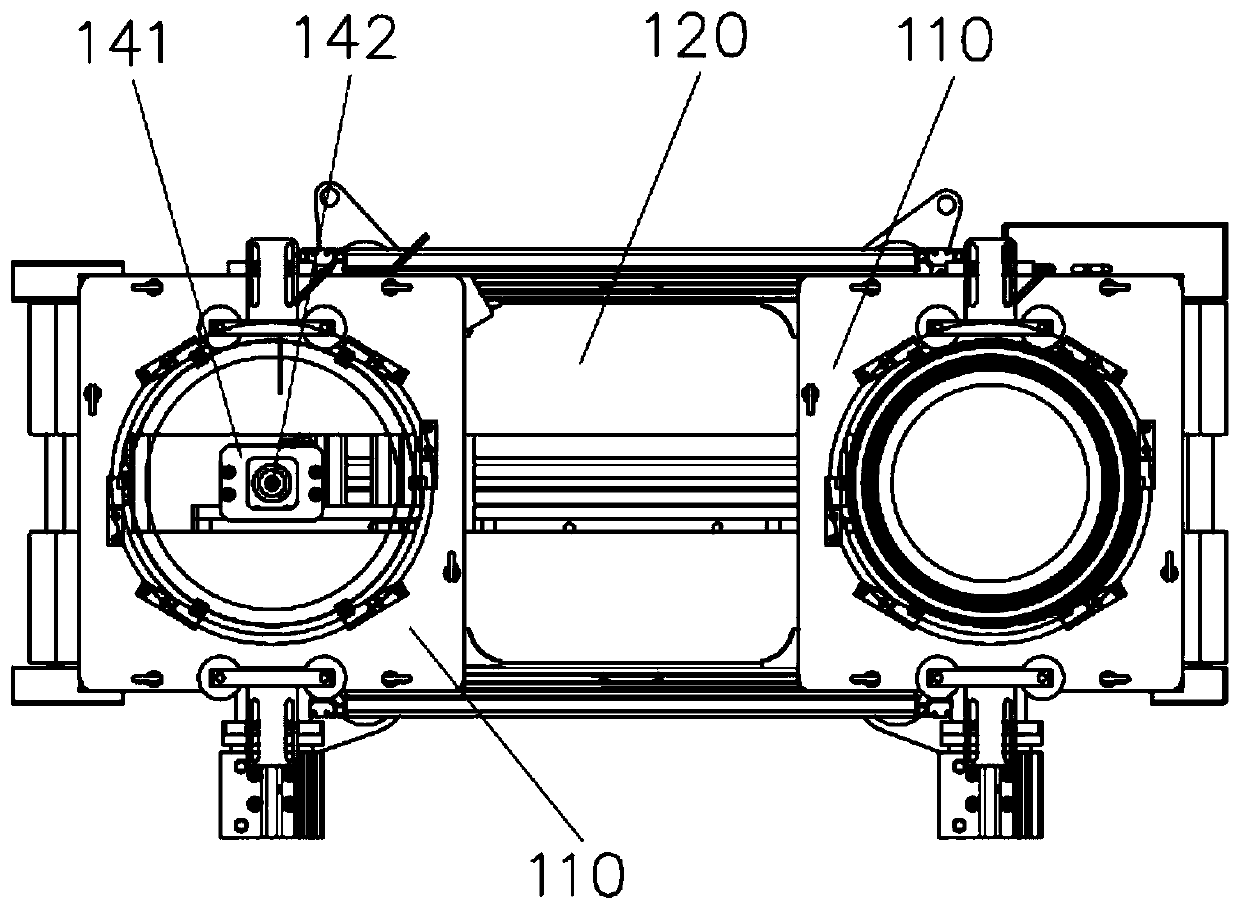

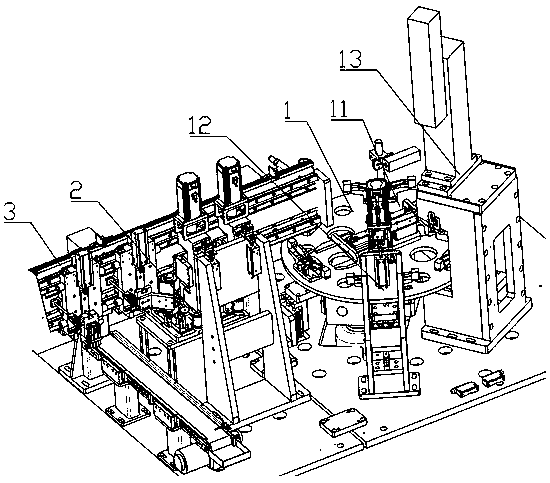

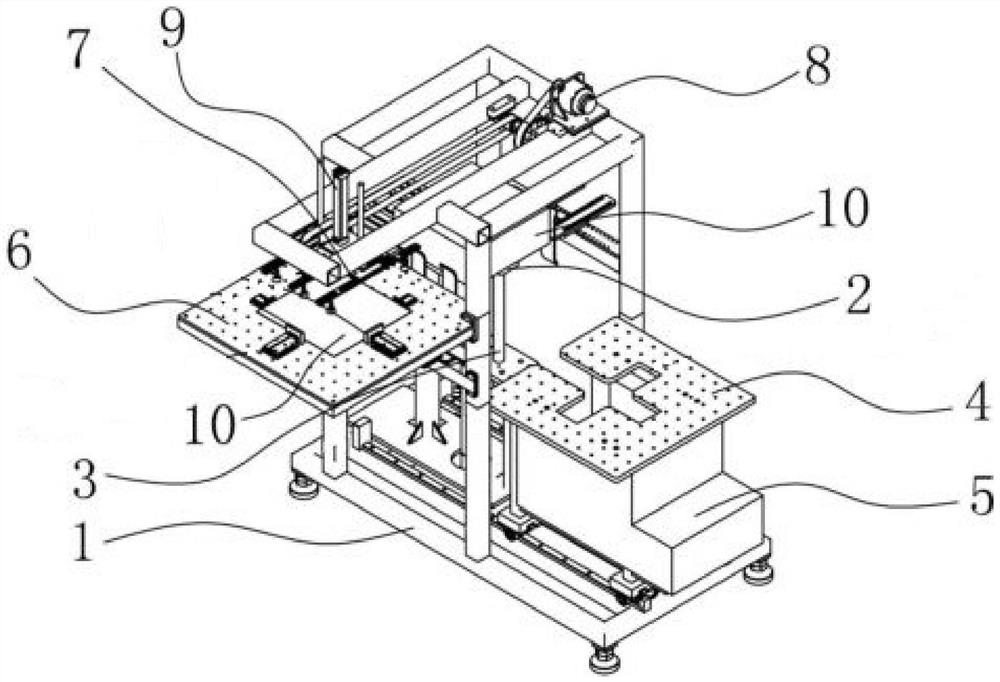

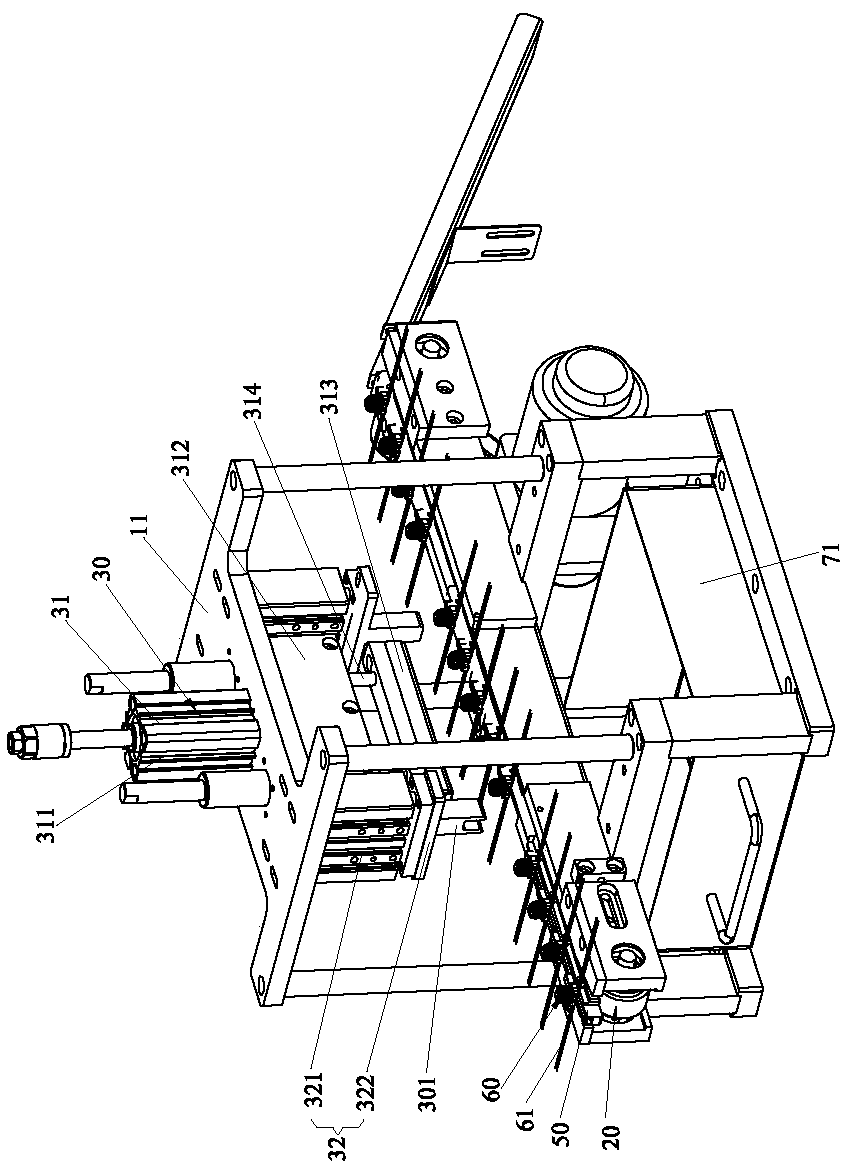

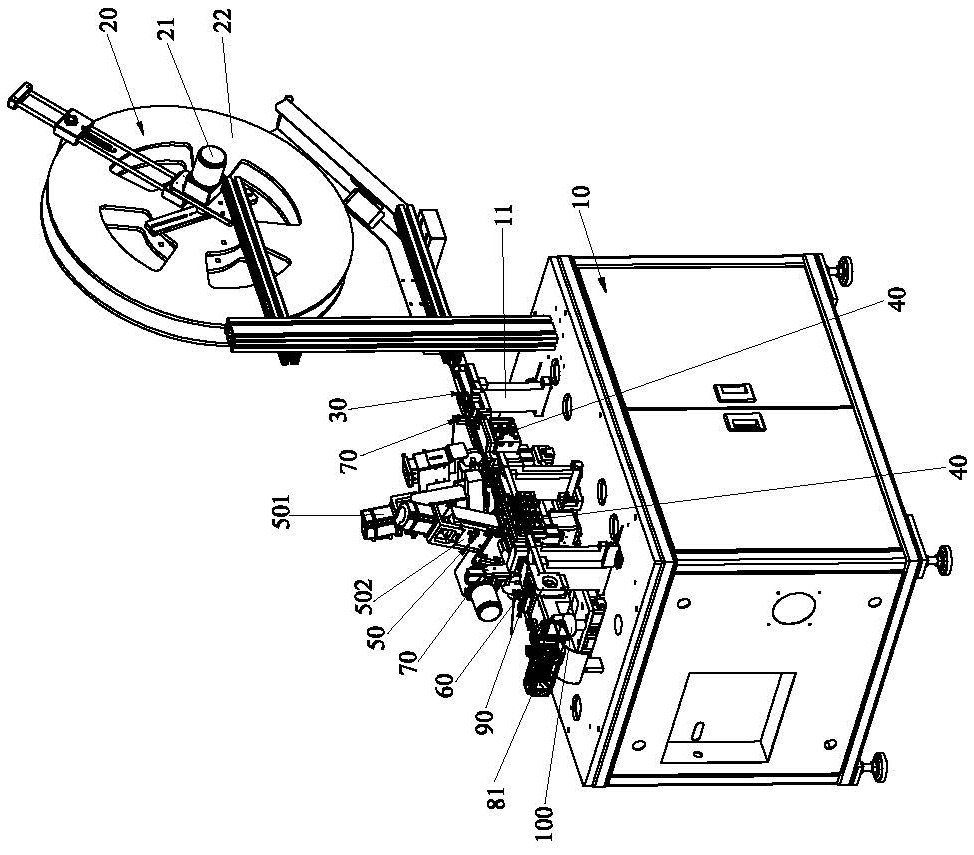

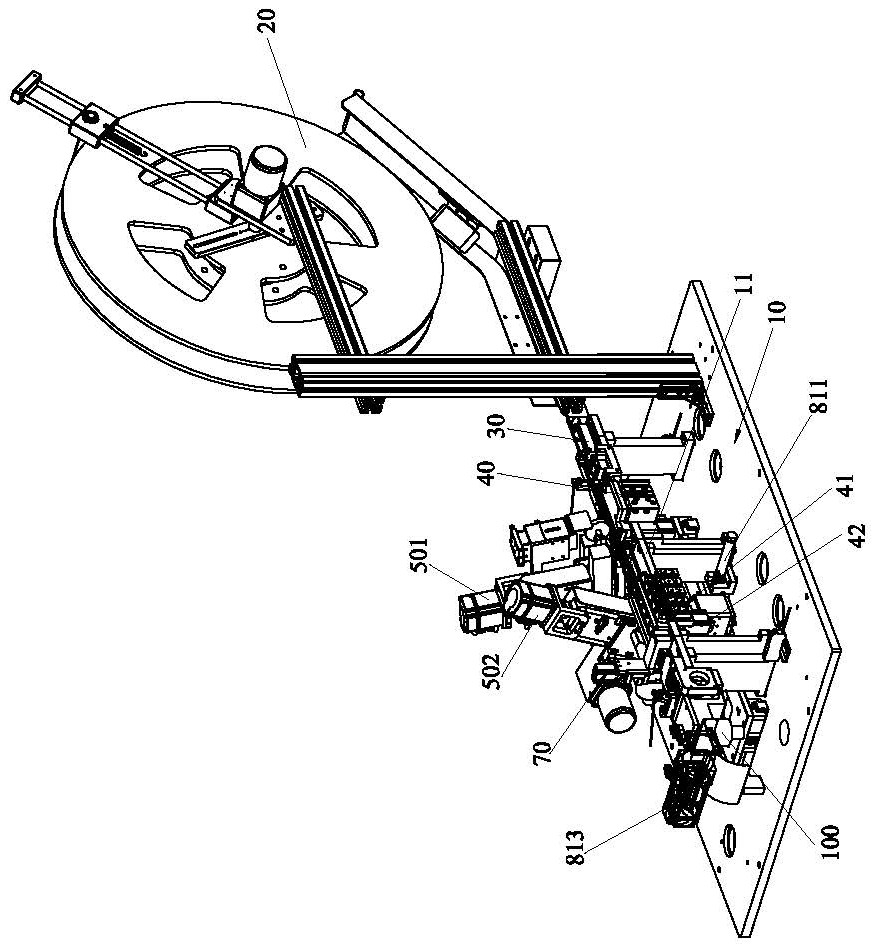

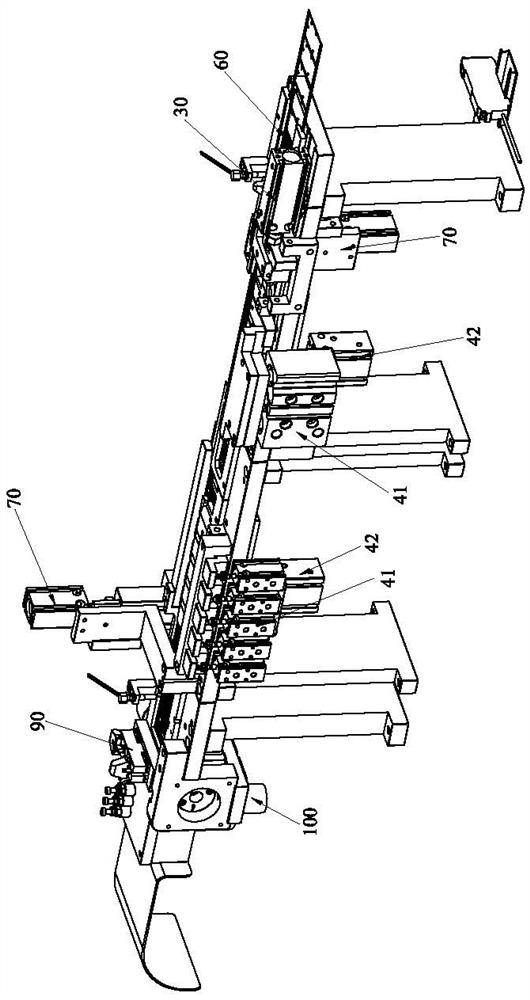

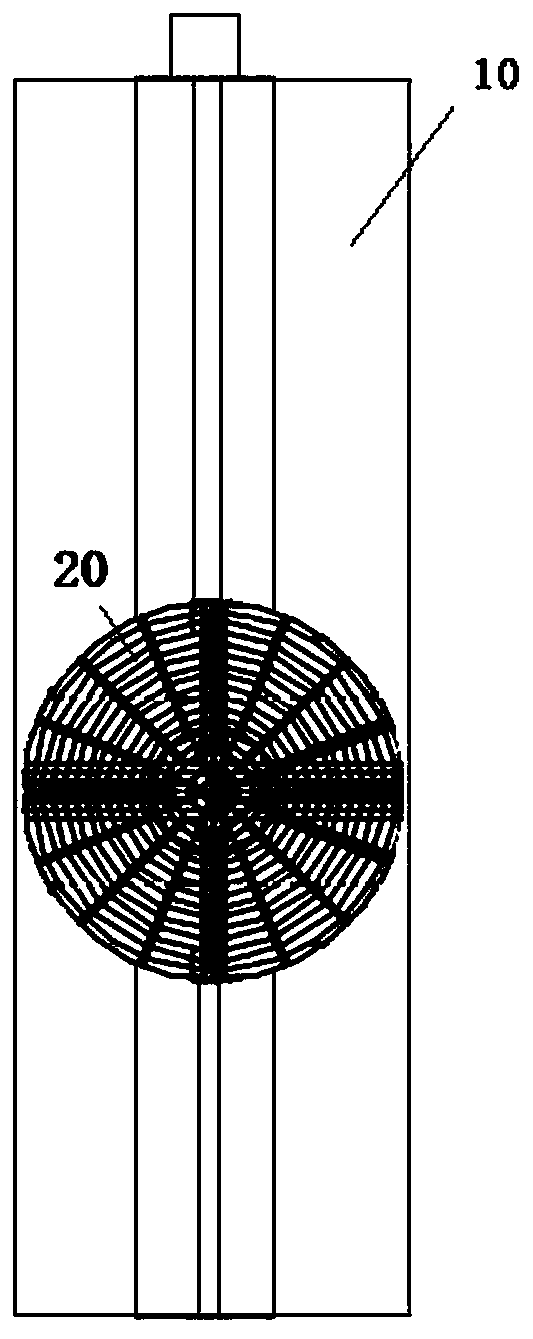

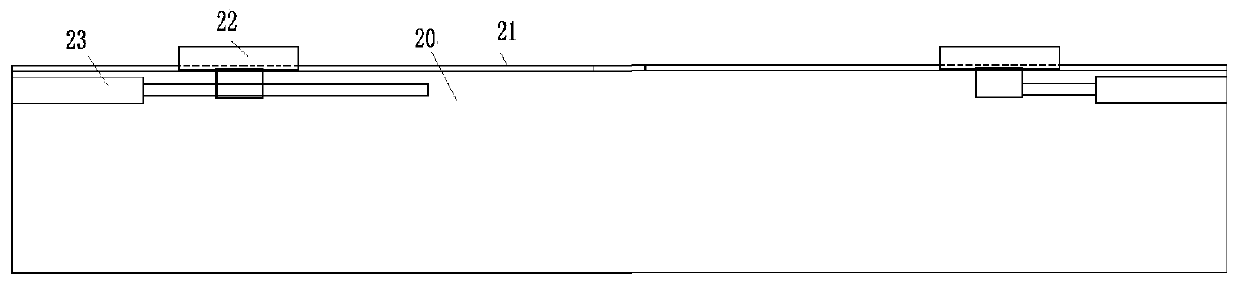

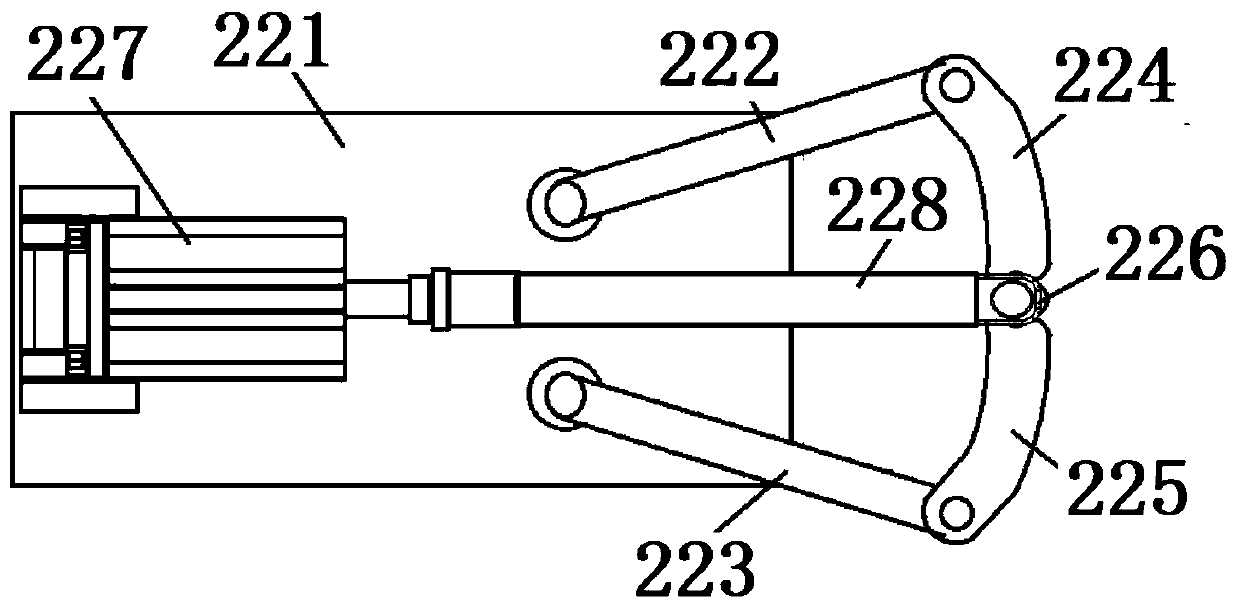

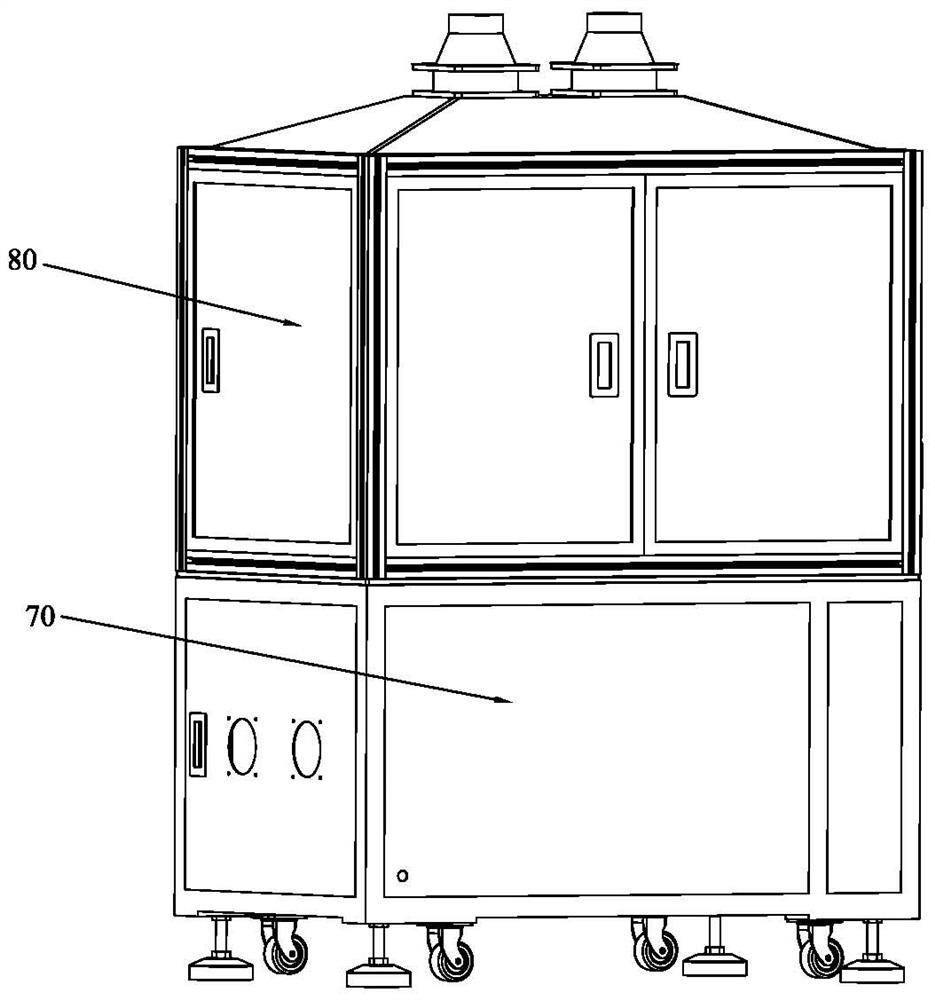

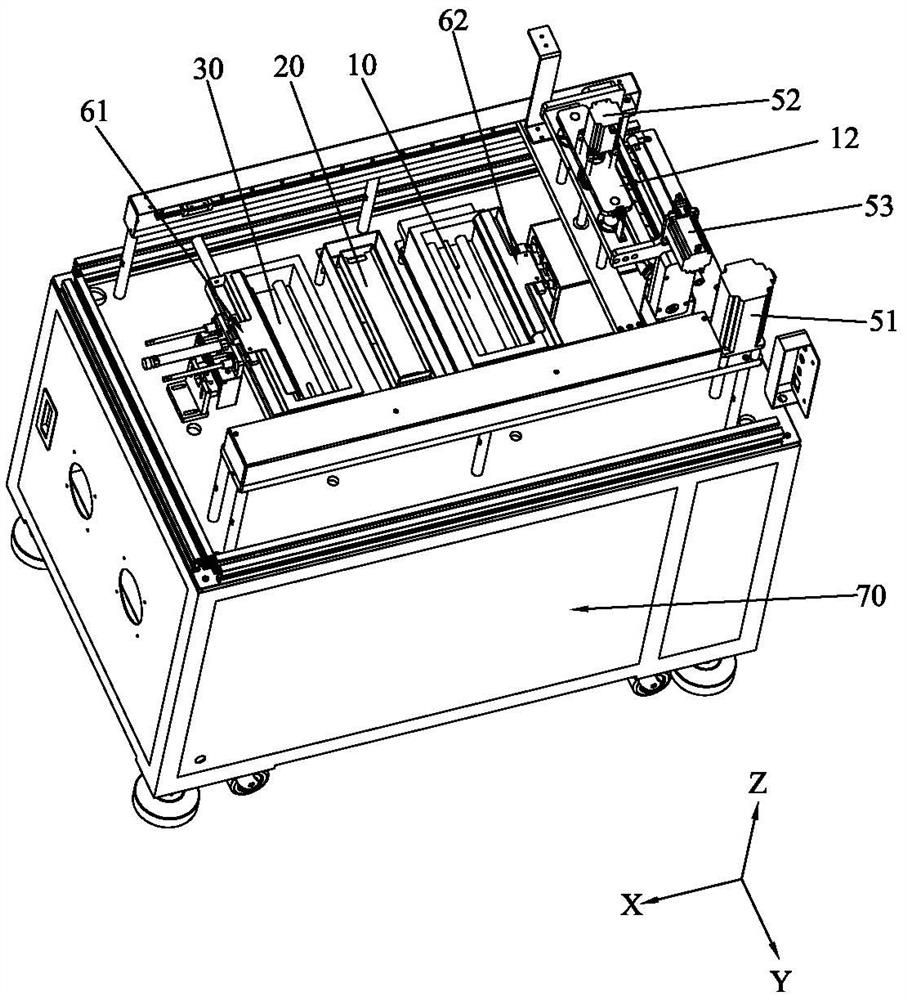

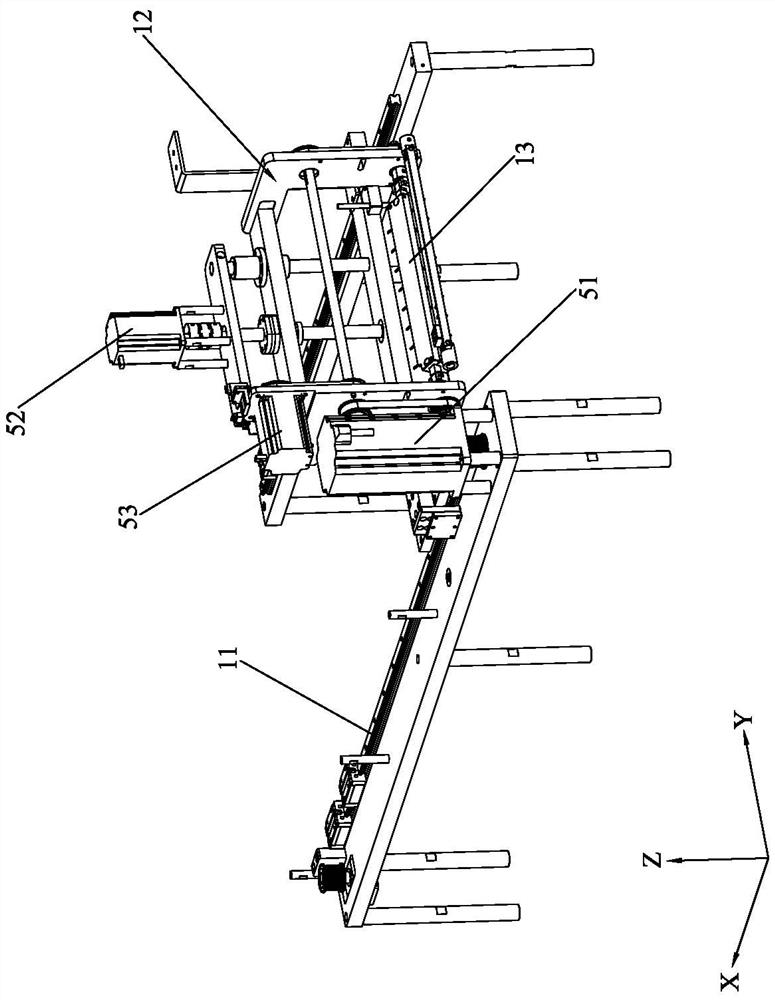

Paper service plate vision detection equipment

PendingCN110116098AImprove detection efficiencyReduce detection error rateSortingDelivery systemPaper sheet

The invention relates to paper service plate vision detection equipment. The paper service plate vision detection equipment comprises a feeding mechanism, a gram weight detection mechanism, a tableware detection conveying mechanism and a vision system; the feeding mechanism comprises a feeding frame; two feeding belts which are arranged in parallel and at intervals and are driven by a motor are arranged below the feeding frame; a weighing conveying belt driven by the motor is arranged at the top of the gram weight detection mechanism; the tableware detection conveying mechanism comprises a tableware detection platform; a front end conveying system and a back end conveying system are arranged on the left side and the right side of the tableware detection platform correspondingly; a detection pushing device is arranged on the front end conveying system; a detection station is arranged between the front end conveying system and the back end conveying system; a front side detection assembly and a back side detection assembly are arranged above and below the detection station correspondingly; and the front side detection assembly and the back side detection assembly are electrically connected with the vision system respectively. The paper service plate vision detection equipment applies the vision system and has high detection efficiency and low detection error rate.

Owner:SHAONENG GRP GUANGDONG LVZHOU PAPER MOLD PACKING PROD CO LTD

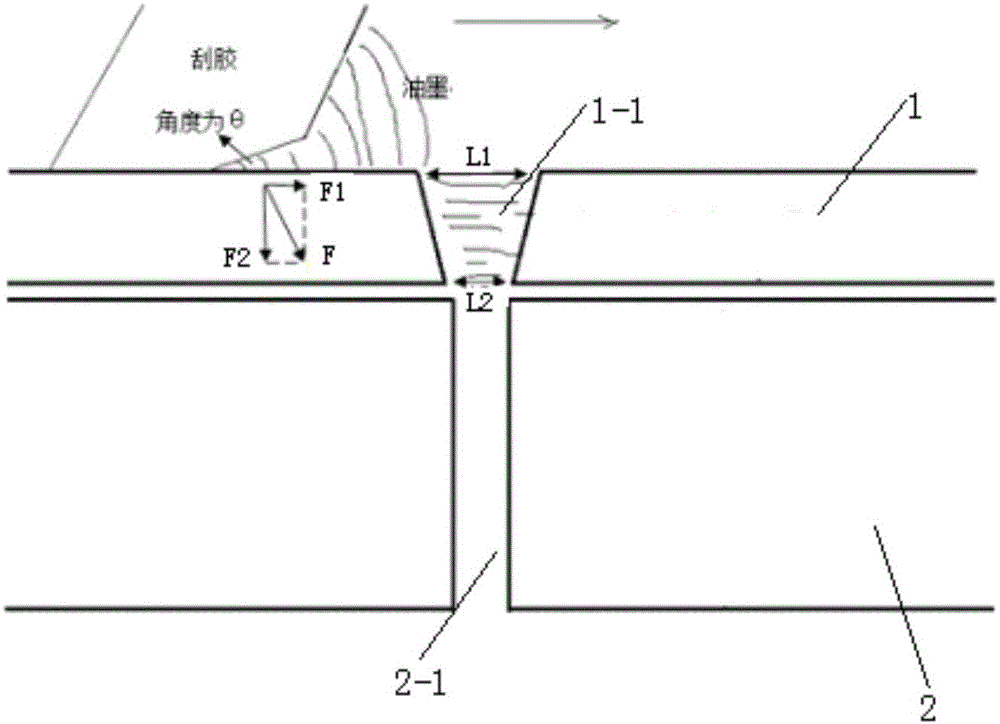

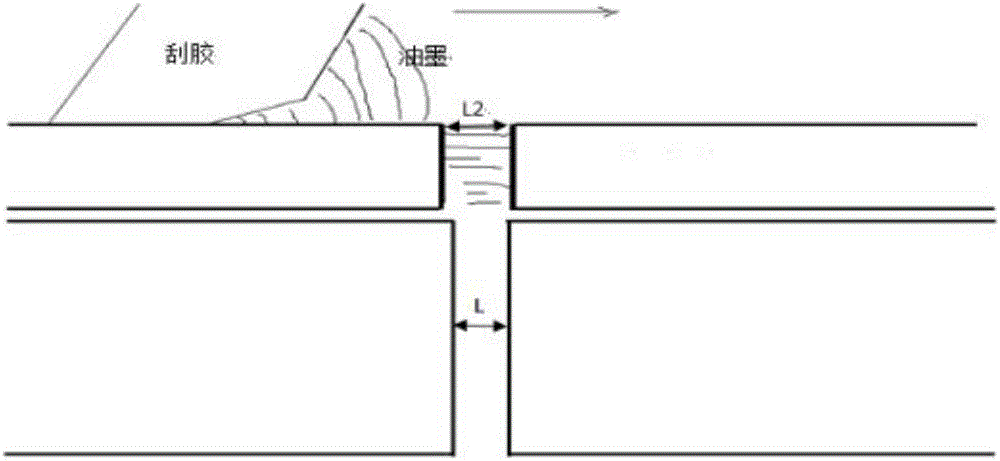

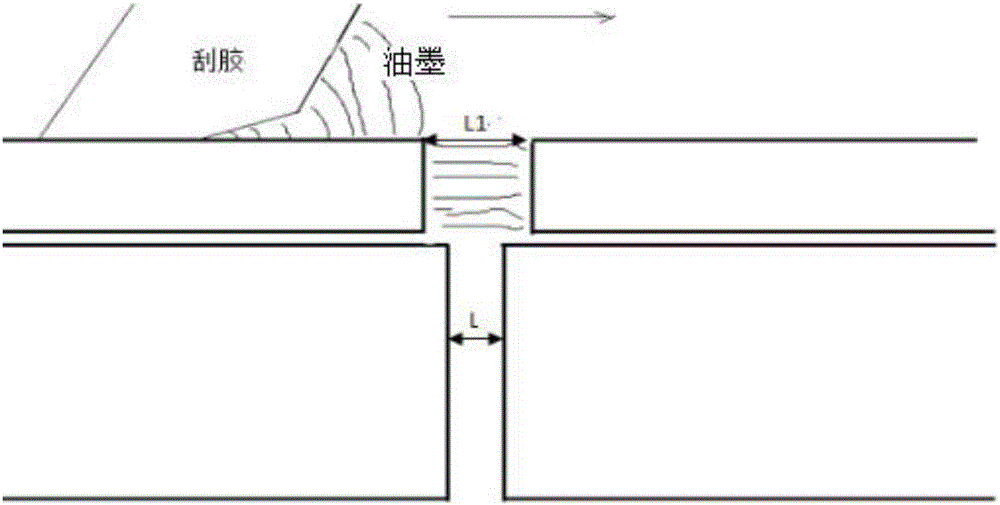

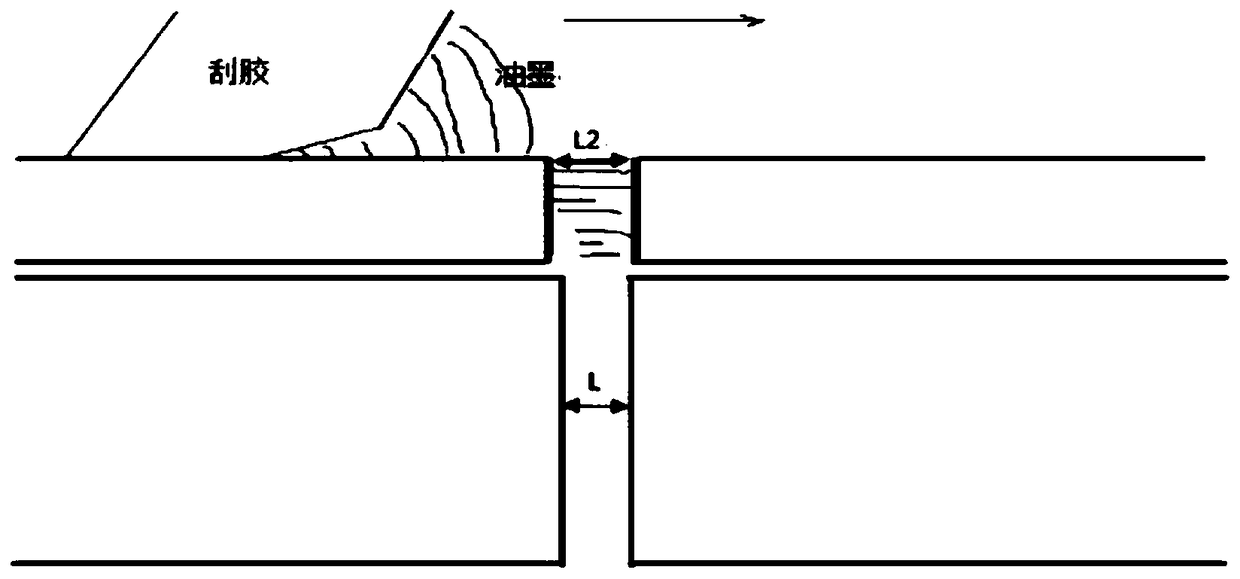

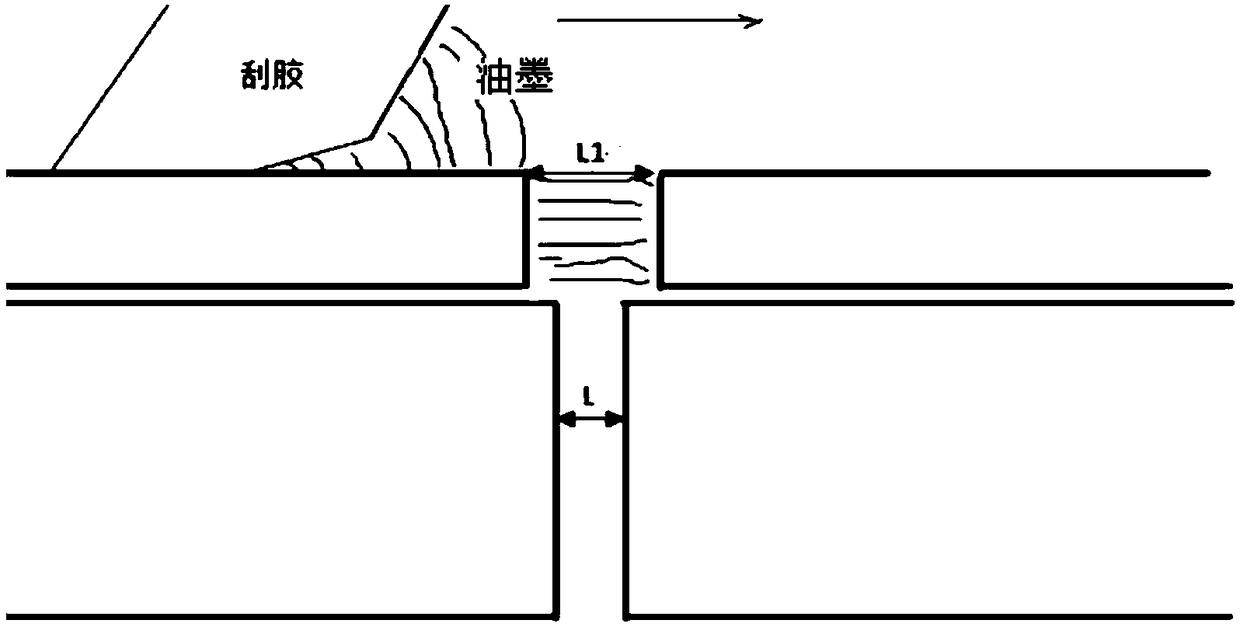

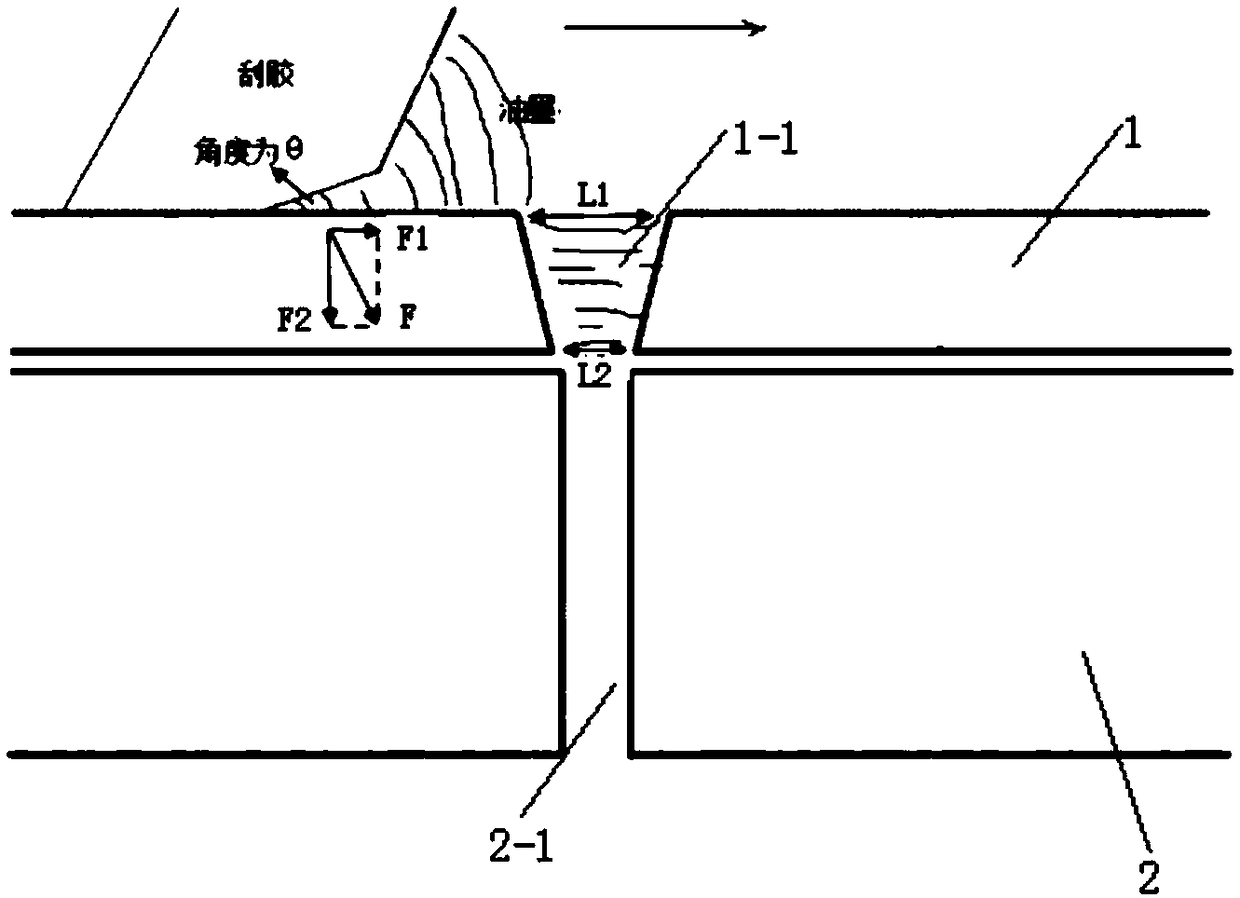

Design method for printing ink hole plugging tool

ActiveCN106211592AGuaranteed excellent rateIncrease the bearing areaPrinted circuit manufacturePrinting inkDesign methods

The invention provides a design method for a printing ink hole plugging tool. The design method comprises the steps that a base plate is placed on a PCB, an inverted-cone-shaped hole is formed in the base plate, the position of the inverted-cone-shaped hole is matched with that of a plug hole formed in the PCB, the size of the lower surface of the inverted-cone-shaped hole is matched with that of the plug hole, the axial section of the inverted-cone-shaped hole has the inclination degree, and therefore printing ink can be subjected to pushing force applying into the inverted-cone-shaped hole when squeegee is screen-printed to the inverted-cone-shaped hole. According to the design method, the hole plugging force is increased, the hole plugging fullness can be effectively guaranteed, the product quality is improved, and the good rate of finished products is guaranteed; the stressed area of the squeegee is increased, the hole plugging efficiency is effectively improved, and the hole plugging time is shortened.

Owner:AOSHIKANG TECH CO LTD

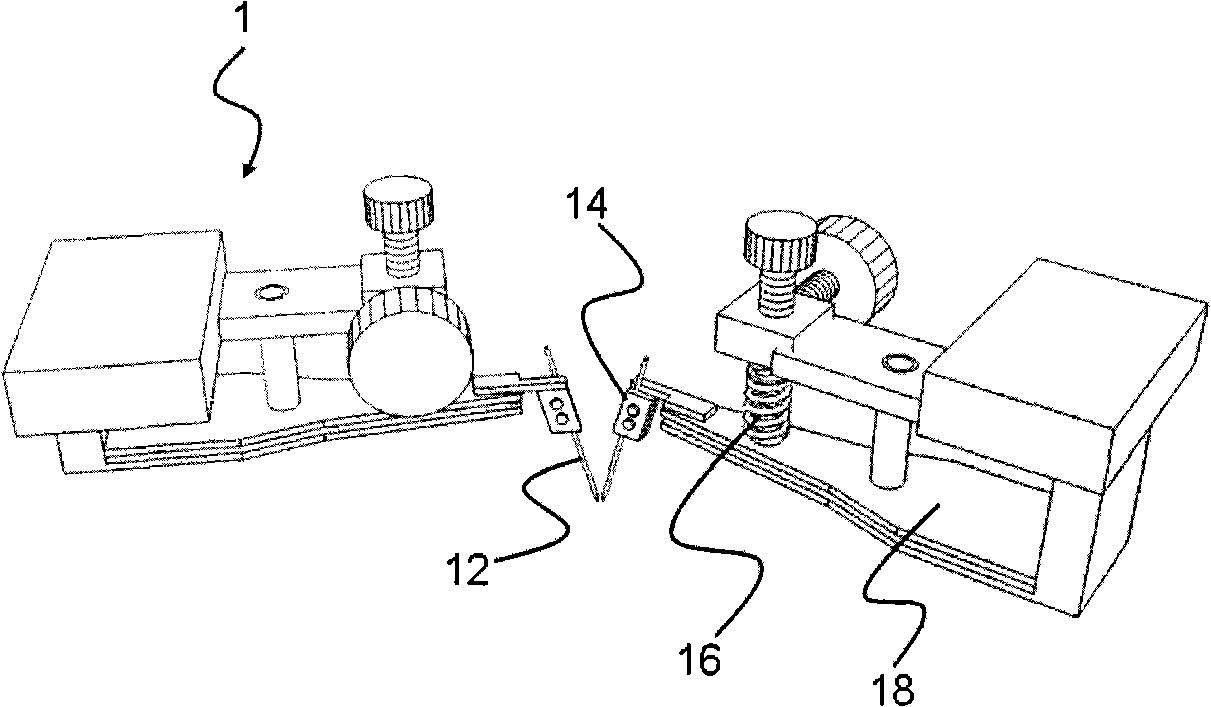

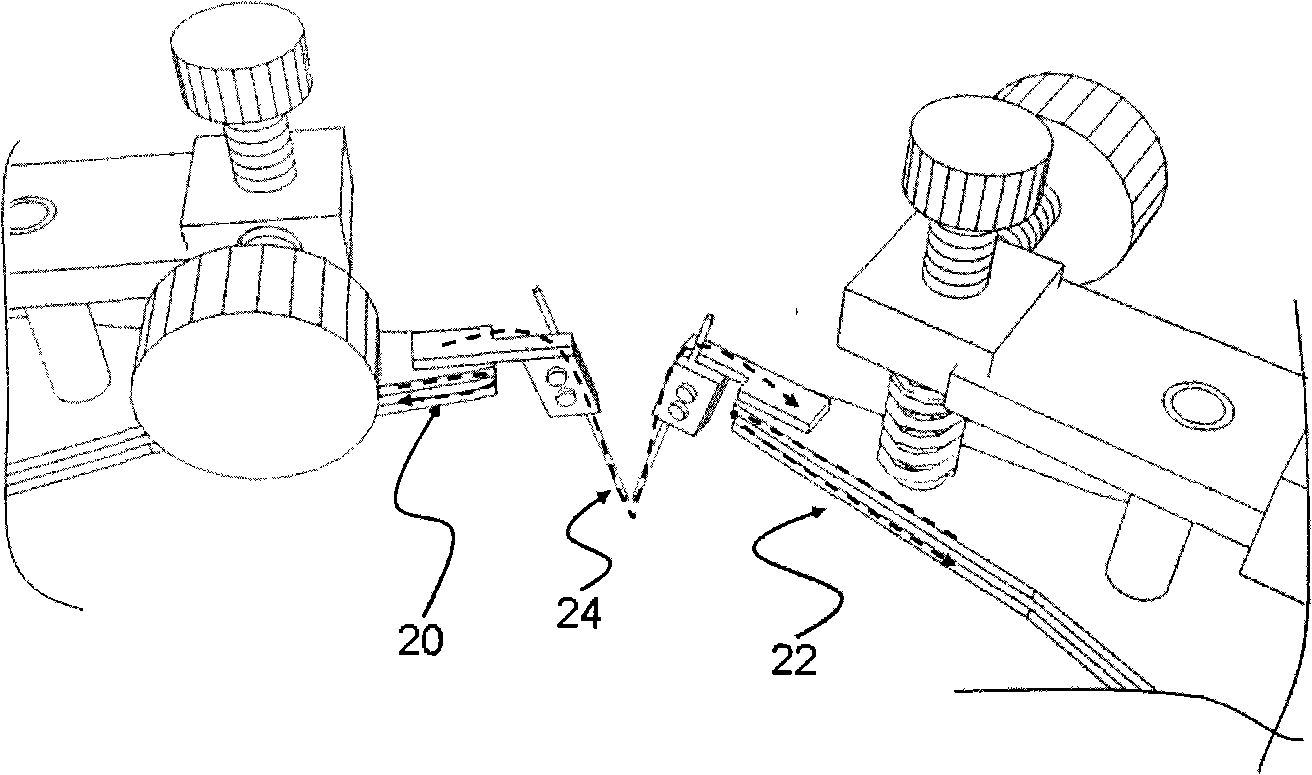

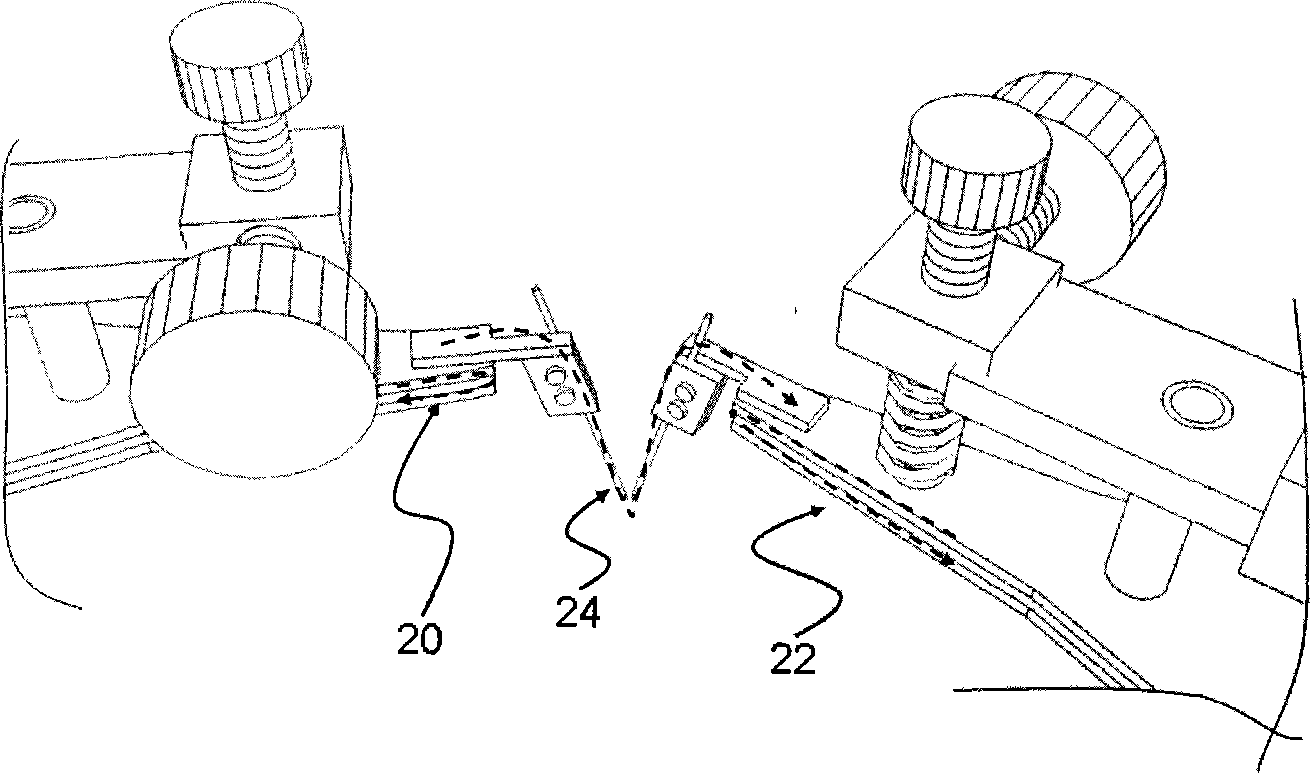

Detection machine station with contact impedance detection device

InactiveCN101581742AImprove disadvantagesReduce the risk of errorsElectronic circuit testingResistance/reactance/impedenceContact impedanceTransfer switch

The invention is suitable for the technical field of circuit component tests, and provides a detection machine station with a contact impedance detection device, used for detecting a circuit component to be tested. The detection machine station comprises a pressure conduction connecting device, an electric signal supply sensing device and the contact impedance detection device which comprises a set of standard components with known electric characteristics and a set of transfer switches, wherein the transfer switches are used for switching the pressure conduction connecting device to the standard components by electric connection, is provided for the electric signal supply sensing device to sense, and comprises contact impedance of an electric circuit of the pressure conduction connecting device and the standard components.

Owner:CHROMA ELECTRONICS SHENZHEN

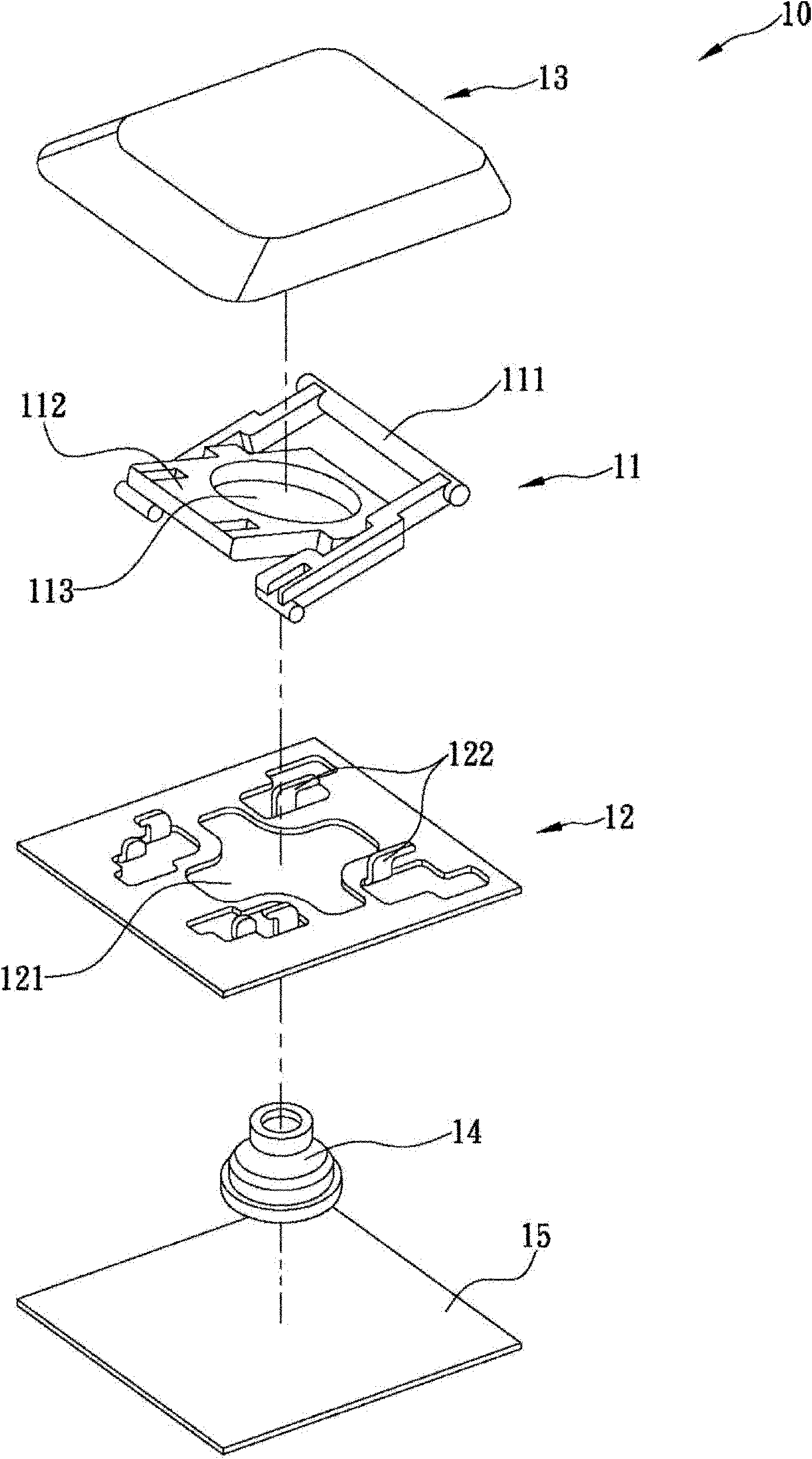

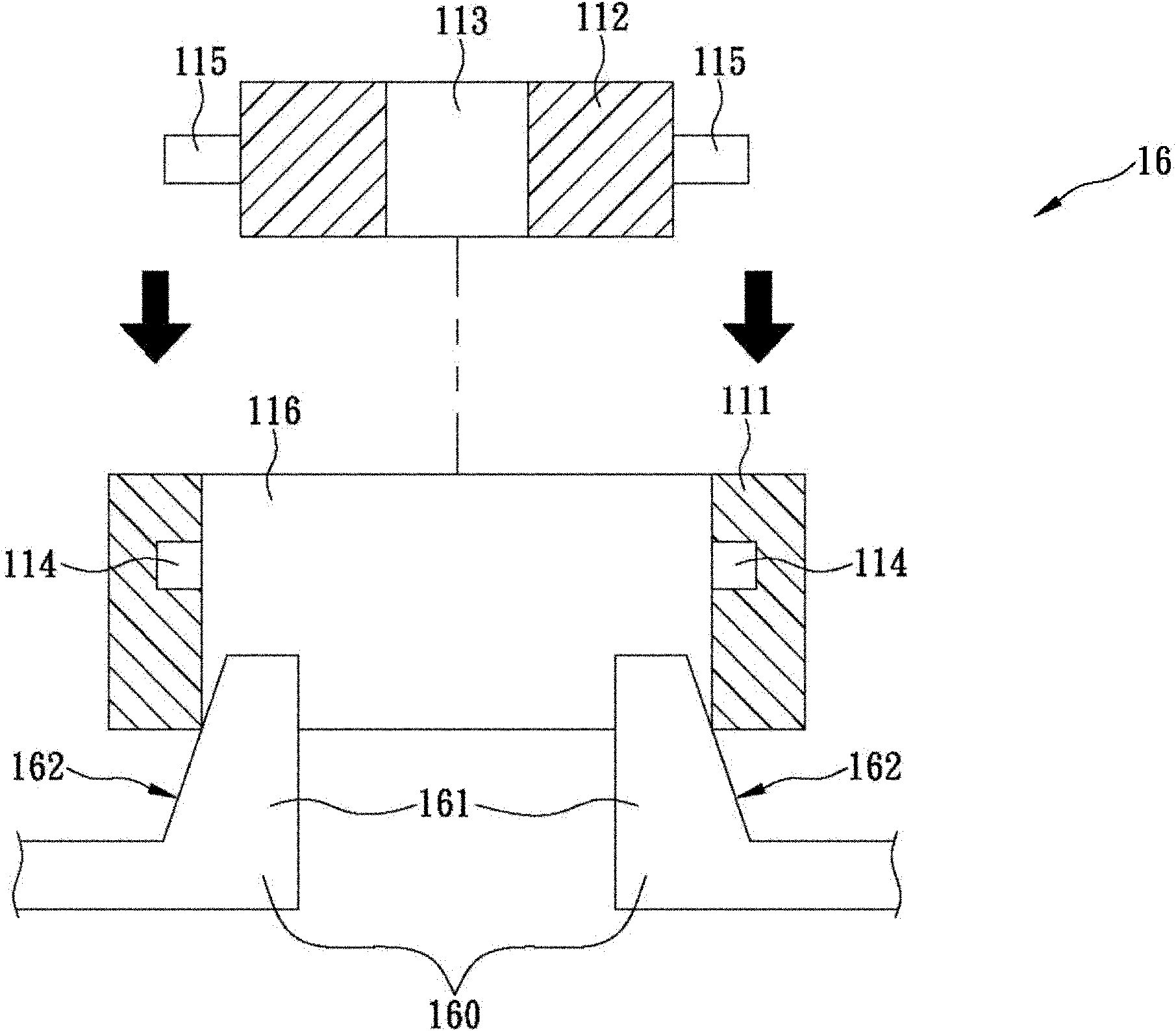

Pushing and clamping type assembling cabinet for pin joint structures of press keys

InactiveCN102403143AReduce manufacturing costGuaranteed excellent rateElectric switchesKey pressingEngineering

Owner:欣厚精密工业(苏州)有限公司

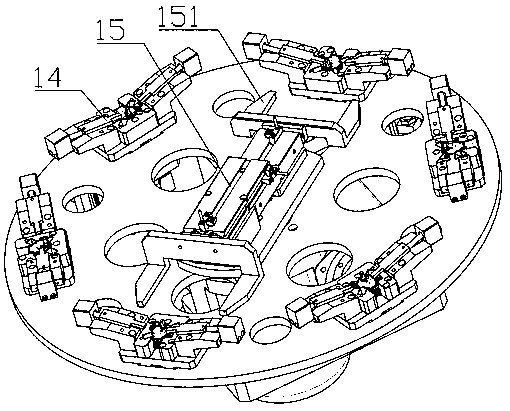

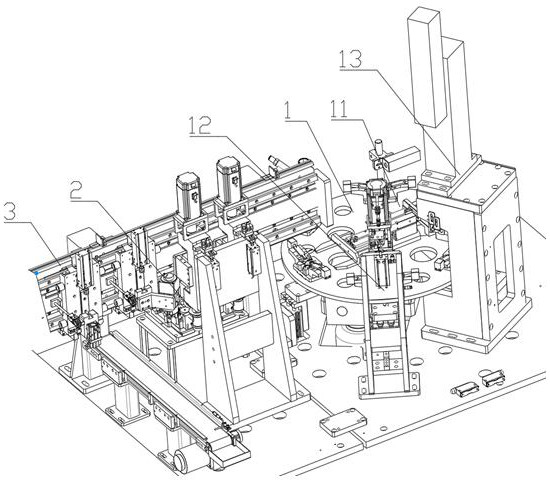

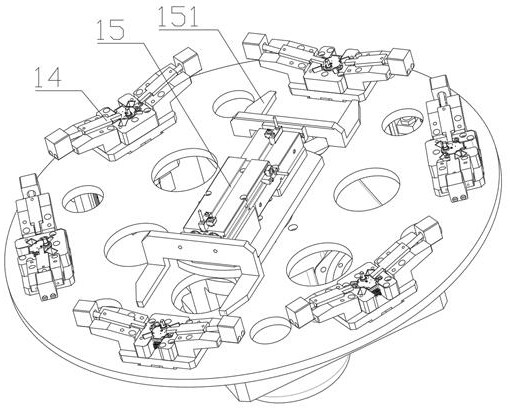

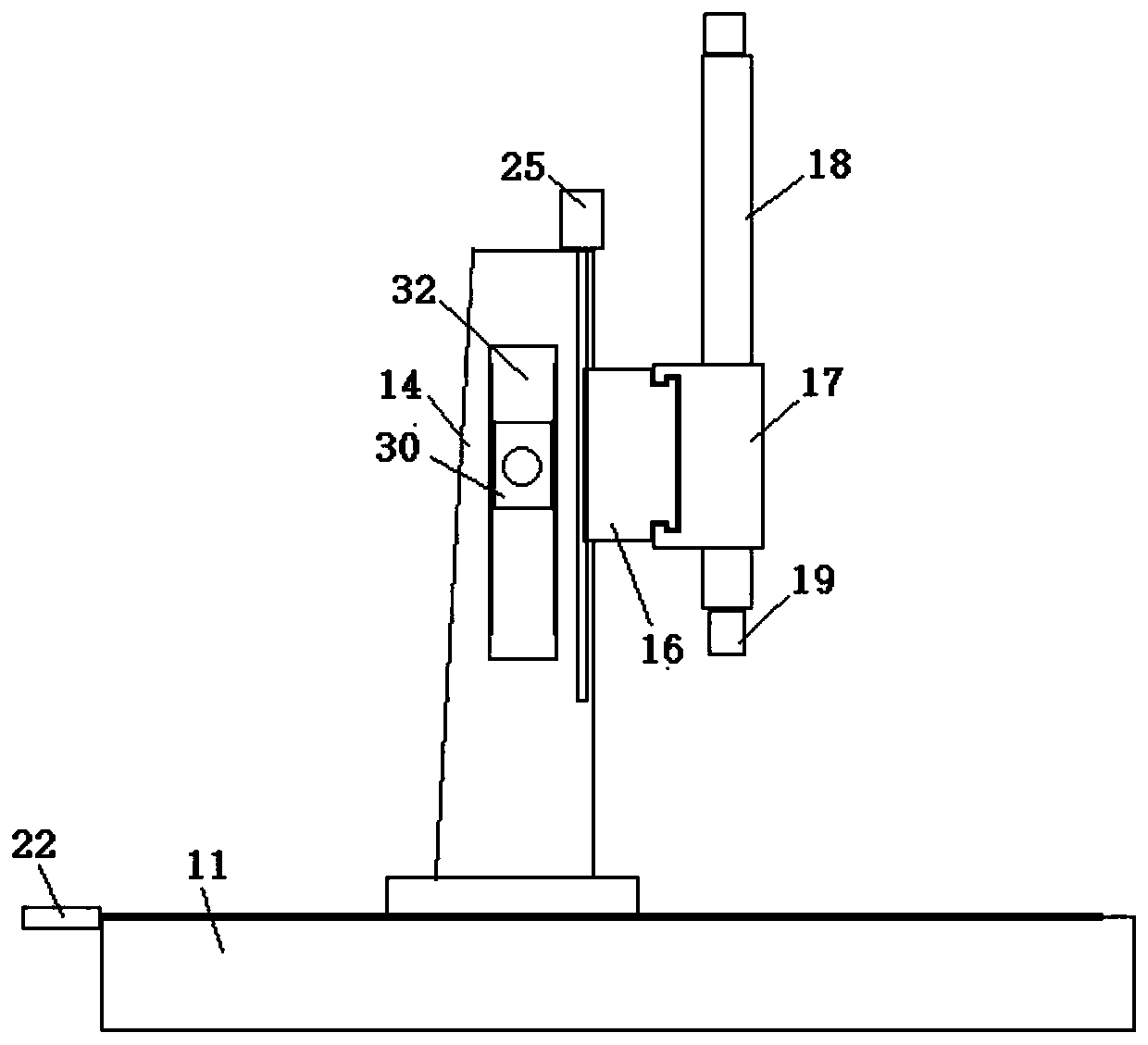

Motor assembly and riveting detecting mechanism

ActiveCN111360167ANovel structureRiveting realizationMetal-working feeding devicesMetal working apparatusElectric machineryStructural engineering

The invention discloses a motor assembly and riveting detecting mechanism. The motor assembly and riveting detecting mechanism is provided with a riveting device, a detecting device and a carrying device, wherein the carrying device is arranged at one side of a machine table; the riveting device and the detecting device are mounted at the other side which corresponds to the machine table; an outerhousing of a motor body and a cover body are pressed by the riveting device, so that the cover body is fixedly arranged on the motor main body; a circuit on a terminal board of the motor is powered on, so that resistance of a rotary shaft of the motor is detected; the riveting device is provided with a rotary disc; a plurality of placing holes for placing a carrier are formed in the rotary disc;the carrier is provided with a carrier base, a placing position for placing the motor main body, fixed wings and a riveting structure; the carrier base is fixedly arranged in the placing holes; the placing holes are fixedly formed in the top of the carrier base; the two fixed wings are separately fixed to the two sides of each placing position; and the riveting structure is mounted onto the fixedwings.

Owner:深圳市中科创想科技有限责任公司

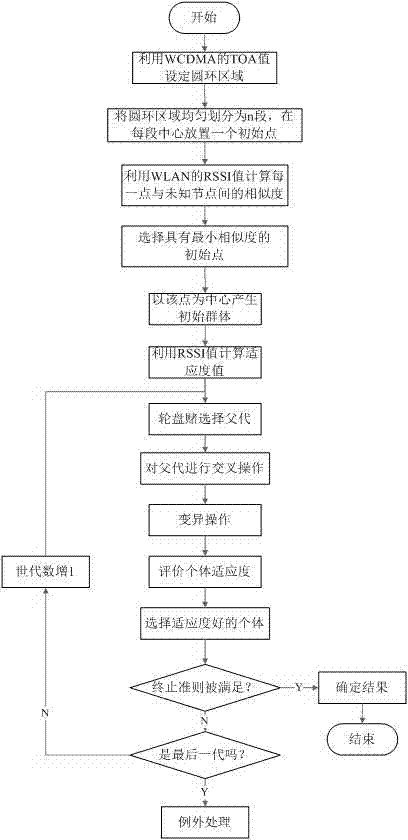

Genetic positioning algorithm under environment of single-base-station heterogeneous network

InactiveCN102970746ASmall amount of calculationHigh positioning accuracyPosition fixationWireless communicationLocal optimumCode division multiple access

The invention relates to a genetic positioning algorithm under the environment of single-base-station heterogeneous network and particularly relates to the technical field of heterogeneous network technology. Aiming at coexisting heterogeneous networks of a wireless local area network (WLAN) and a wideband code division multiple access (WCDMA) network and a scene that the edge of the WCDMA network cannot be positioned, a algorithm, namely the genetic positioning algorithm under the environment of the single-base-station heterogeneous network, for achieving a positioning function by combining with the WLAN network is provided. Due to the fact that in most cases, initial groups selected by the algorithm through similarity are always close to real nodes to be positioned, the situation that genetic searching results are converged to local optimal points occurs rarely.

Owner:江苏学府医疗科技有限公司

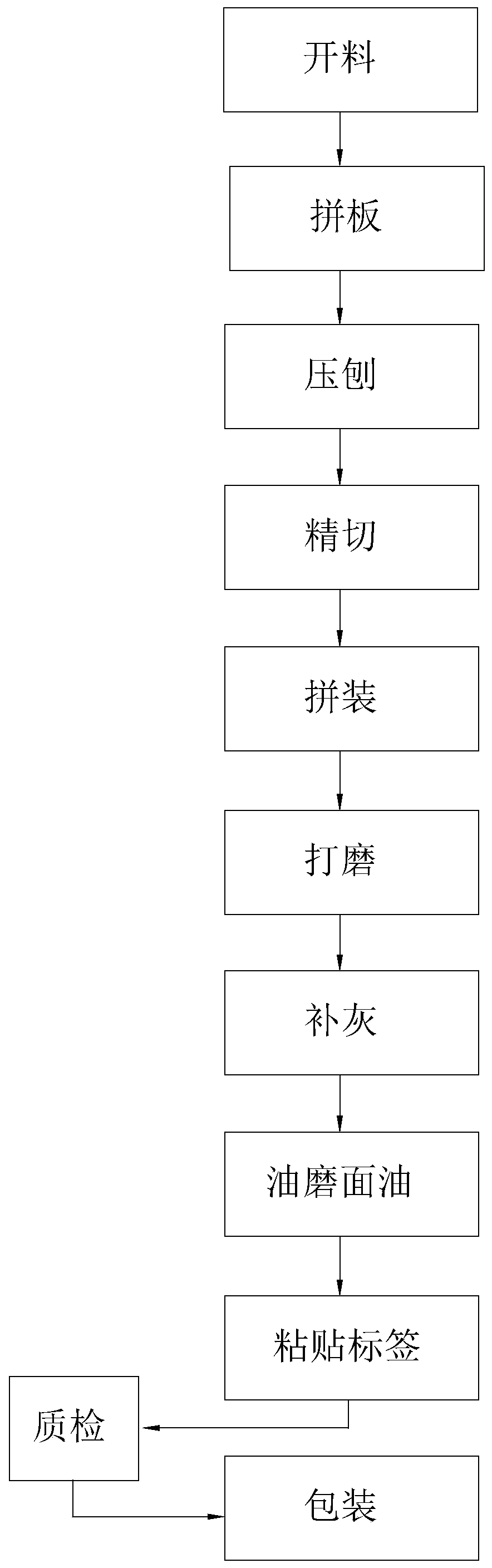

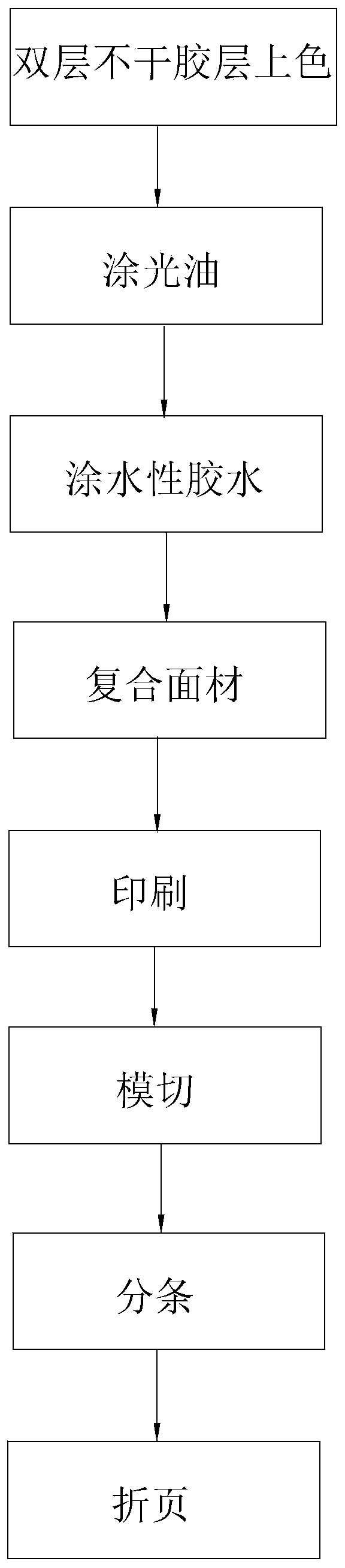

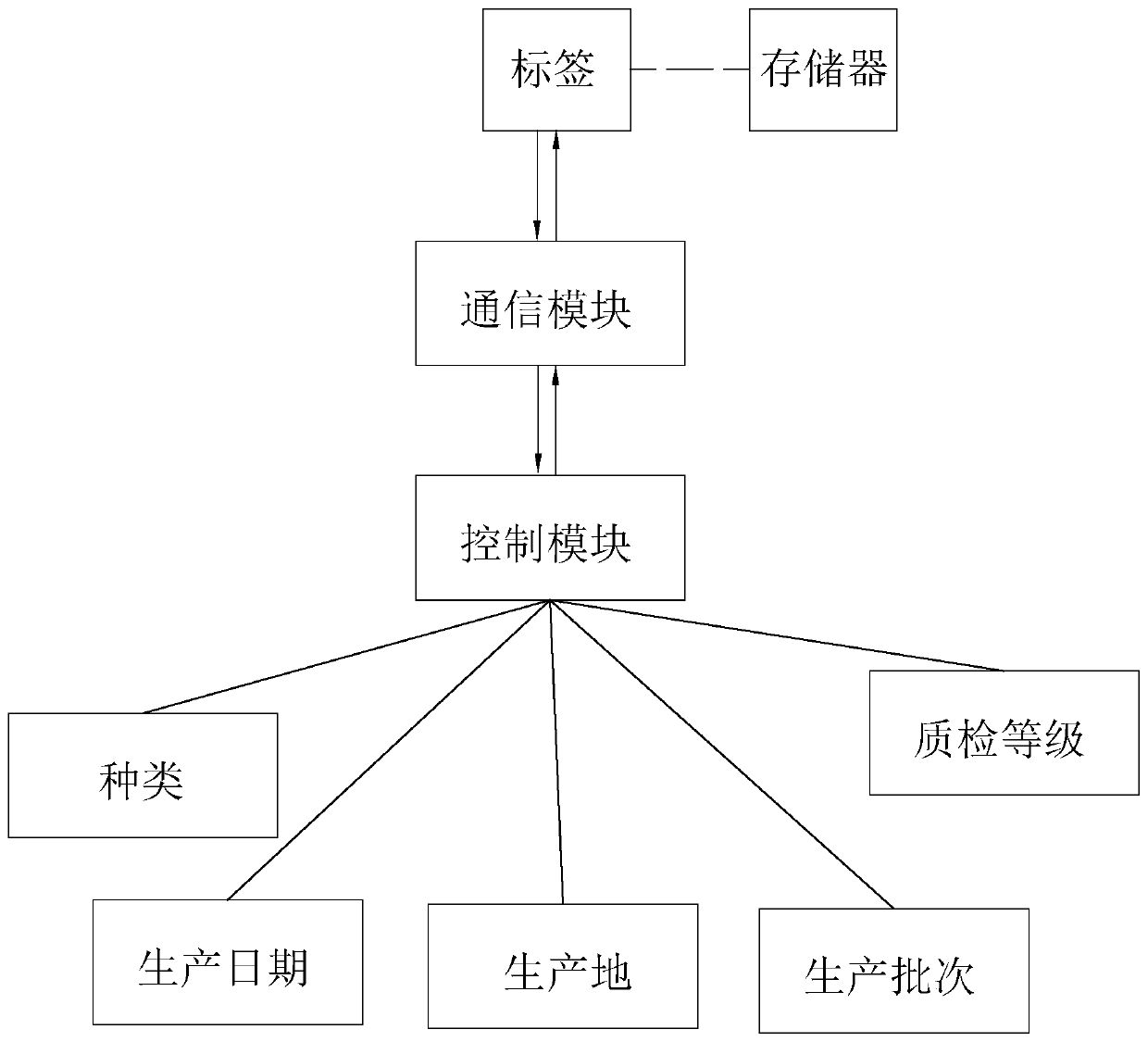

Panel processing technology

InactiveCN111098376ALong data transmission distanceImprove anti-interference abilityWood working apparatusLabelling machinesPolishingMachining process

The invention relates to the field of panel product processing, and aims to provide a panel processing technology. The panel processing technology comprises the following steps that material cutting is conducted, specifically, a panel is selected and cut according to specifications to form battens; panel splicing is conducted, specifically, the specification battens are pressed into required panels through a press machine; planing is conducted, specifically, the pressed panels are planed and sanded to the preset thickness; fine cutting is conducted, specifically, the angle of the panels is cutby a cutting machine; assembly is conducted, specifically, the panels are assemble into the preset shape; polishing is conducted, specifically, the assembled panels are polished by a trimming machine; ash supplementing is conducted, specifically, the surfaces of the panels are subjected to ash supplementing; surface oil oil-grinding is conducted, specifically the panels are subjected to surface oil oil-grinding; label pasting is conducted, specifically, labels storing the panel information are pasted on the surfaces of the panels; and packaging is conducted. According to the panel processingtechnology, the obtained panels are corrosion-resistant, moisture-proof, solid and durable; and meanwhile the labels storing the panel information pasted on the panels are convenient for obtaining thepanel information, the management method is standardized and facilitated, and the effect of reducing human error is achieved.

Owner:广州市鼎好家具有限公司

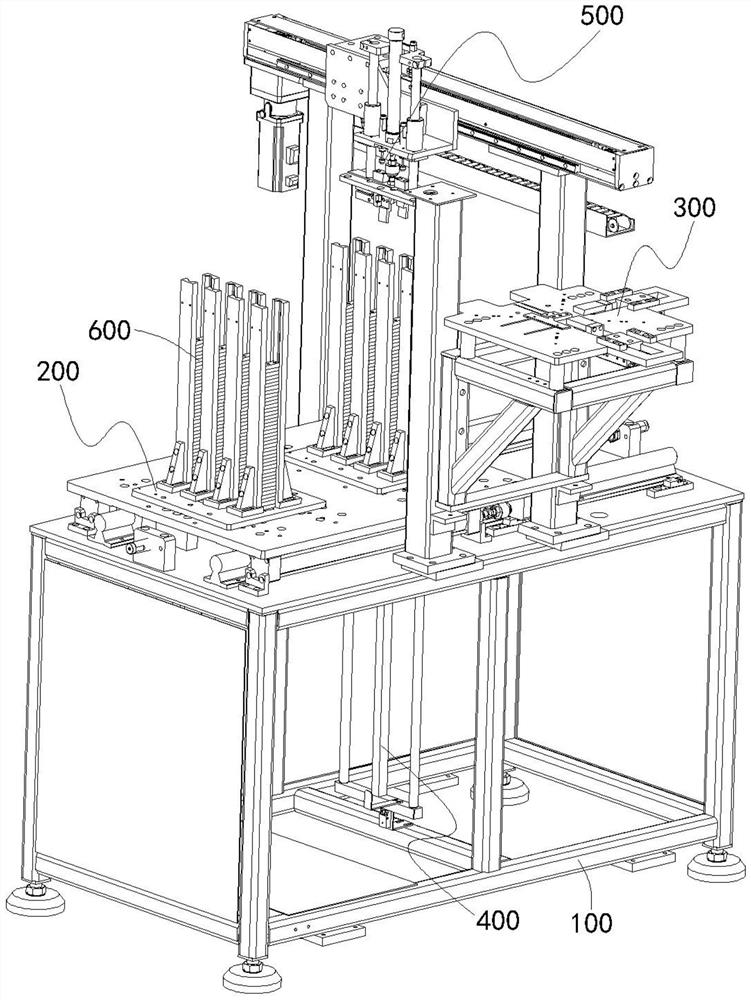

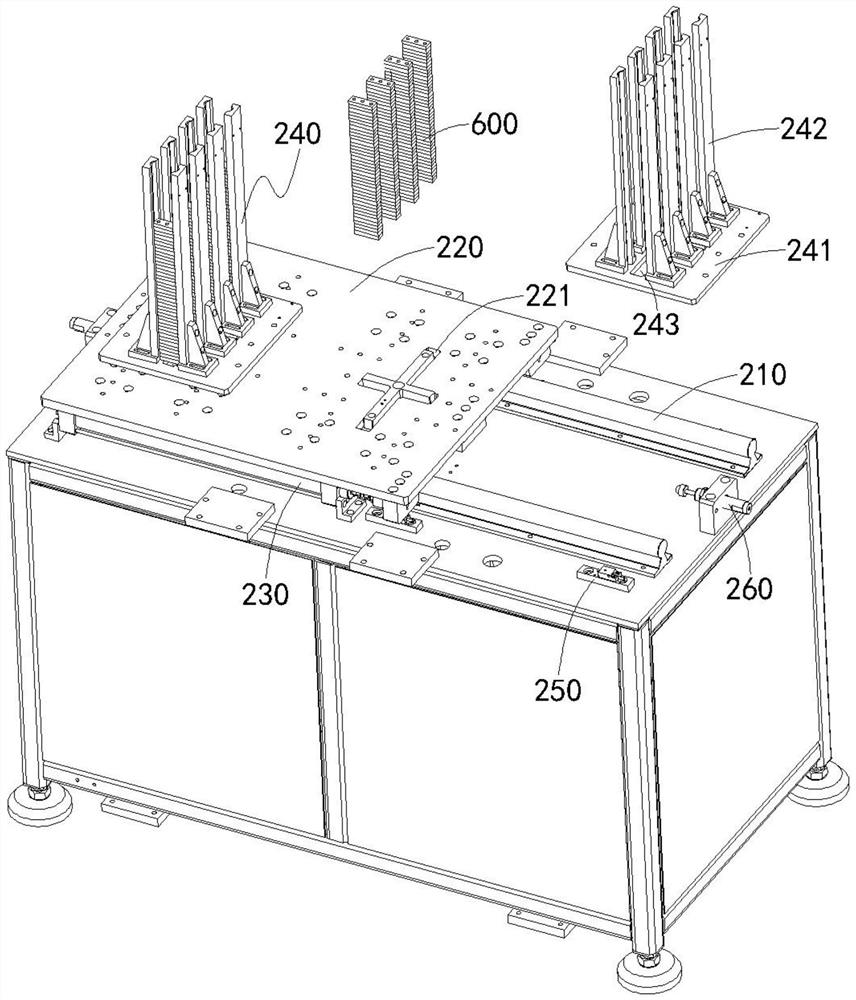

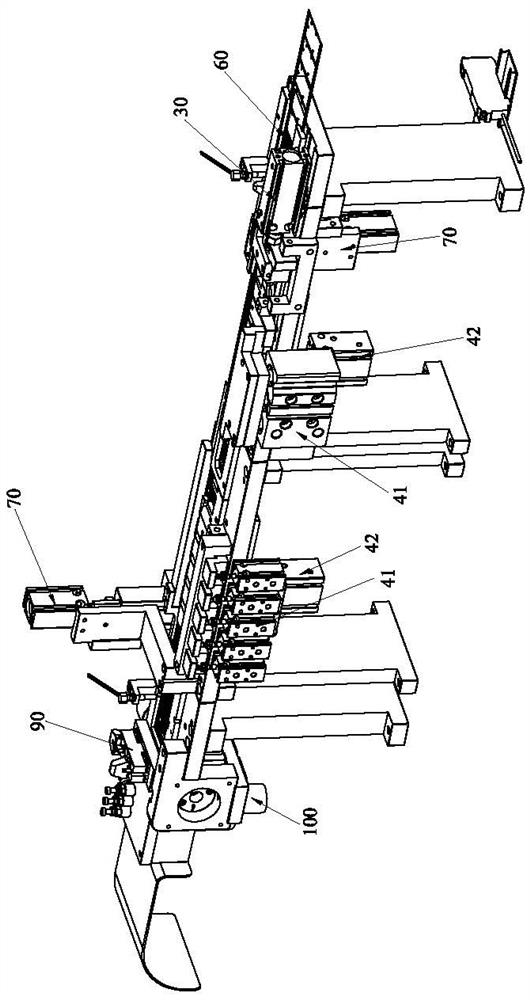

Feeding device and feeding method

InactiveCN111703883AReduce lossesSmall footprintDe-stacking articlesConveyor partsEngineeringMechanical engineering

The invention relates to a feeding device and a feeding method. The feeding device comprises a storage assembly, a supply assembly, a feeding assembly and a taking assembly, wherein the storage assembly is used for placing workpieces; the supply assembly is located on one side of the storage assembly and used for positioning the workpieces from the storage assembly; the feeding assembly is locatedbelow the storage assembly and used for ejecting the workpieces on the storage assembly one by one from bottom to top; the taking assembly is located above the storage assembly and the feeding assembly and used for carrying the workpieces on the storage assembly to the supply assembly; the taking assembly comprises a clamping module, a first driving module and a second driving module, the clamping module abuts against side faces of the workpieces to clamp the workpieces, the first driving module is used for driving the clamping module to move back and forth between the storage assembly and the supply assembly in the horizontal direction, and the second driving module is used for driving the clamping module to ascend and descend back and forth in the vertical direction. The feeding methodadopts the feeding device for feeding.

Owner:伯朗特机器人股份有限公司

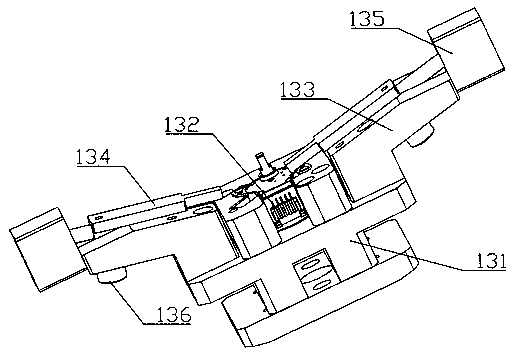

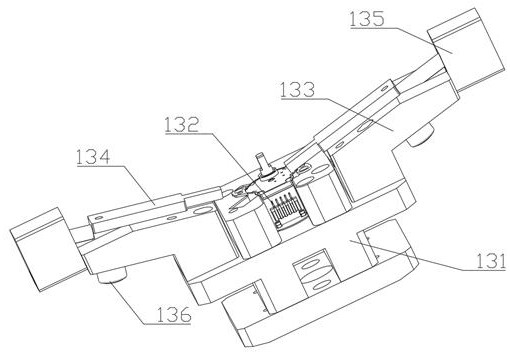

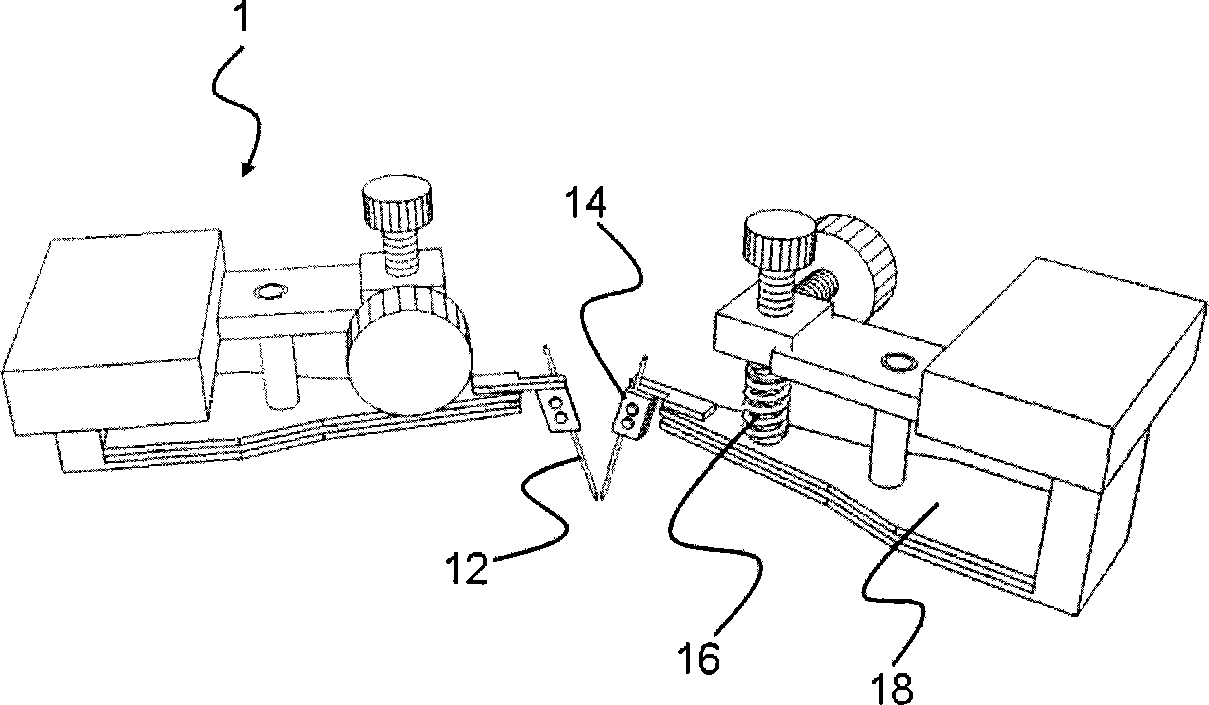

Automatic wire pulling machine for transformer

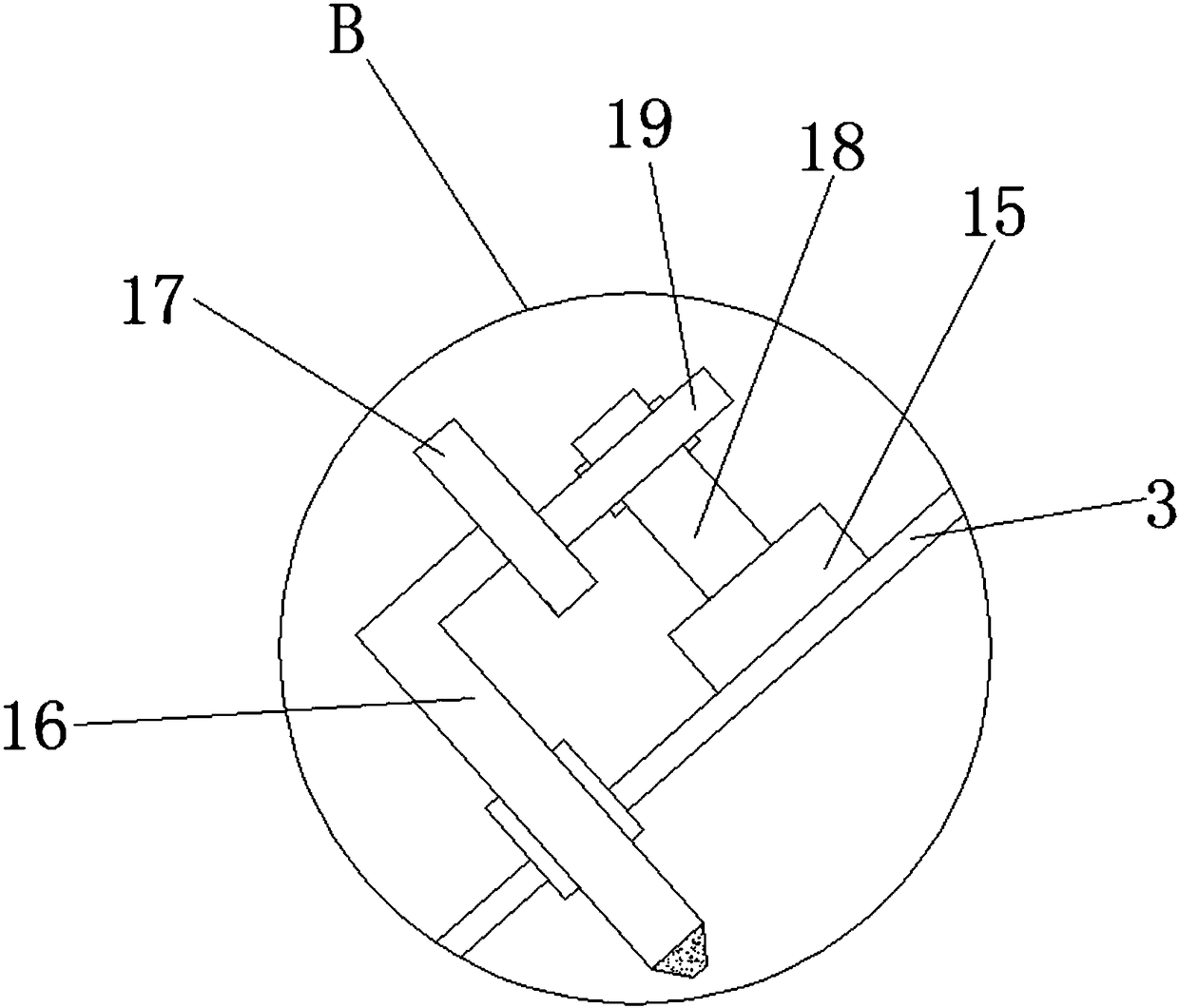

PendingCN110289159AGuaranteed excellent rateReduce manual labor intensityInductances/transformers/magnets manufactureTransformerEngineering

The invention discloses an automatic wire pulling machine for a transformer. The automatic wire pulling machine comprises a frame, a control mechanism, a conveying mechanism, a jig fixing mechanism, a wire pulling mechanism and a transformer jig. The jig fixing mechanism is arranged on the frame and located over the conveying mechanism. The wire pulling mechanism is arranged on the frame and located beside the jig fixing mechanism. The wire pulling mechanism comprises a first driving device, a movable frame, a second driving device and a wire head clamping device. The transformer jig is placed on the conveying mechanism, a plurality of transformer mounting stations are arranged on the top surface of the transformer jig, and a blade part used for cutting a wire head is formed at the corner of the top surface of the transformer jig. Through the integrated arrangement of the control mechanism, the conveying mechanism, the jig fixing mechanism and the wire pulling mechanism and the cooperative use of the transformer jig, the automatic wire pulling machine achieves the automatic conveying, fixing and wire pulling of a transformer. Compared with traditional manual wire pulling, the automatic wire pulling machine achieves the mechanical wire pulling, guarantees the excellent rate of products, reduces the labor intensity of workers and the labor cost, and improves the production efficiency.

Owner:DONGGUAN JIALONG HAIJIE ELECTRONICS TECH CO LTD

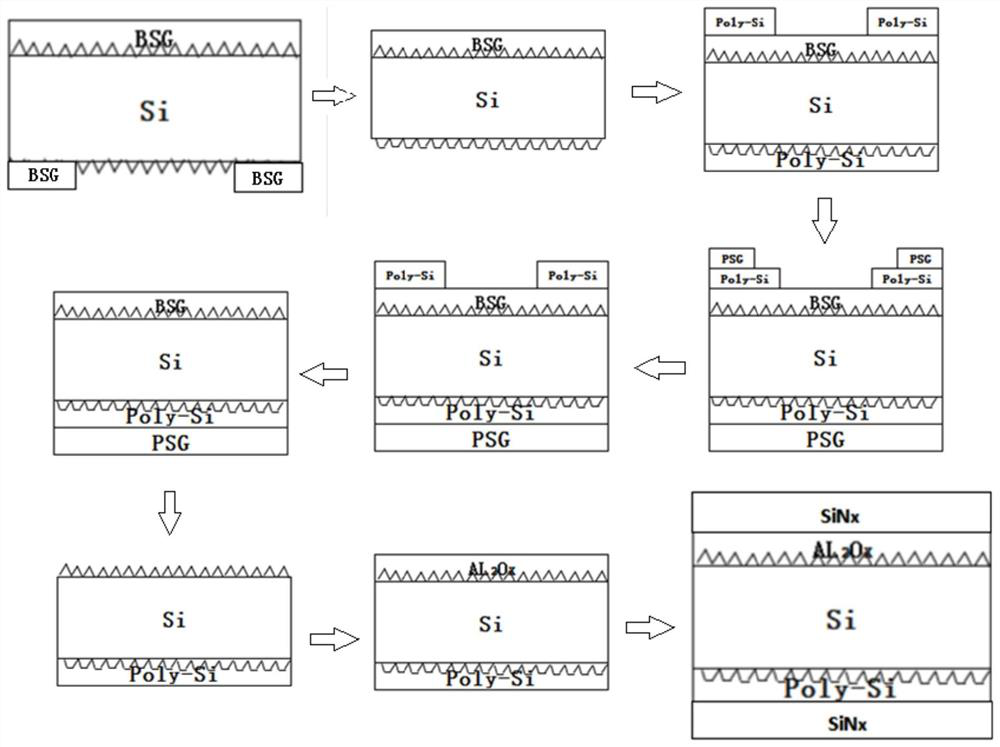

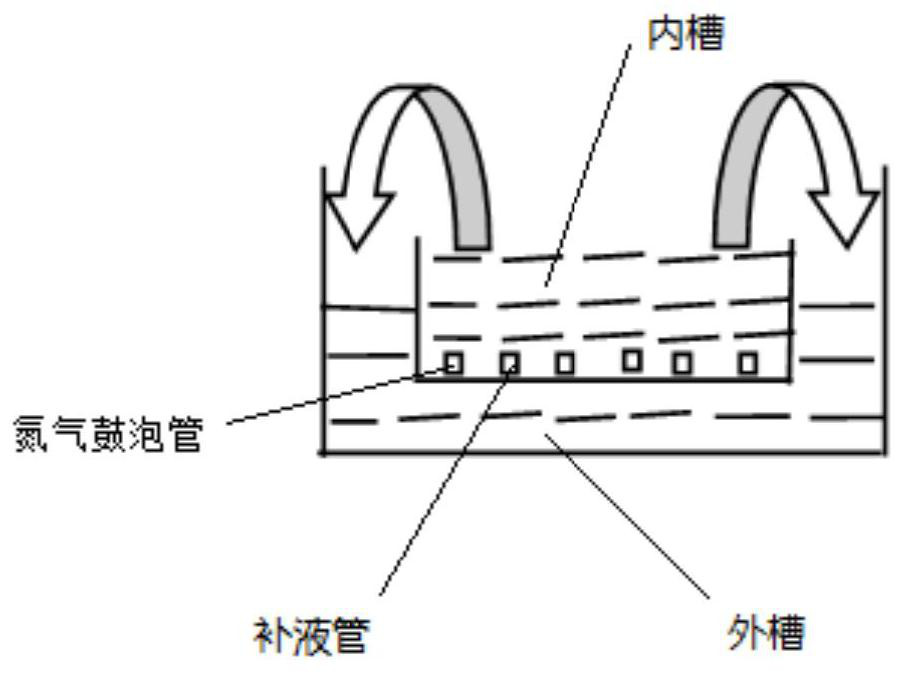

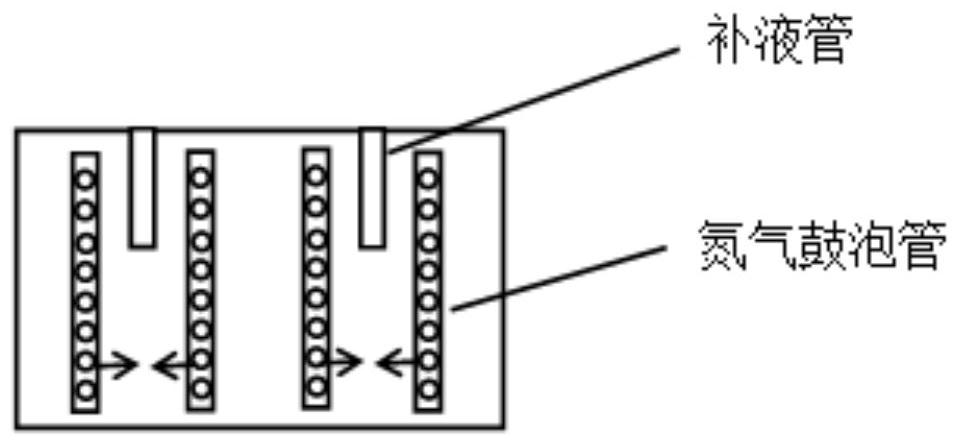

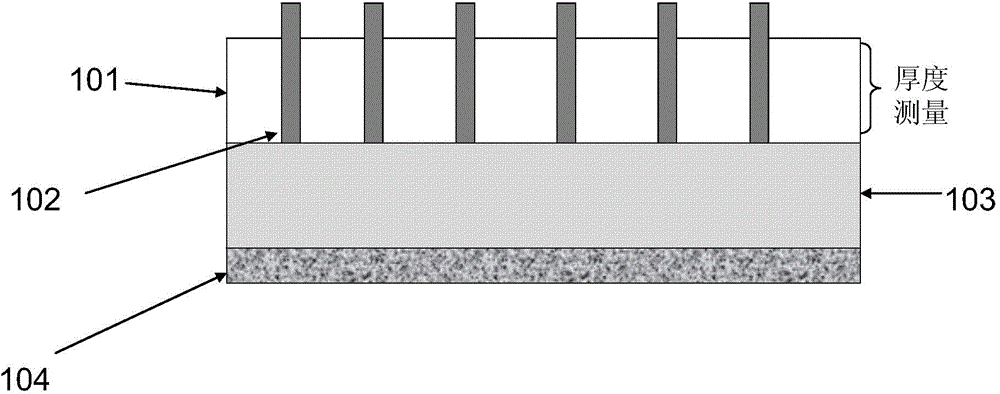

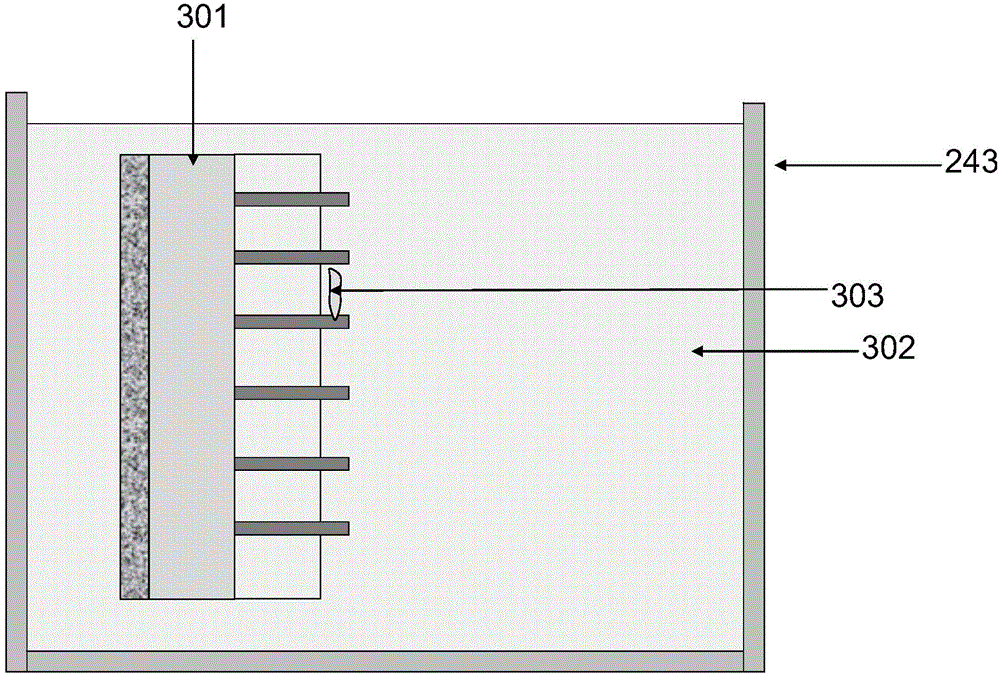

De-winding plating method for TOPCon battery and preparation method of TOPCon battery

ActiveCN112349584AGood removal effectNot volatileFinal product manufactureSemiconductor/solid-state device manufacturingHydrofluoric acidPhysical chemistry

The invention relates to the technical field of solar cells, and particularly discloses a winding and plating removing method for a TOPCon cell and a preparation method of the TOPCon cell. The methodcomprises the following steps: manufacturing a water film on the back surface of a phosphorus-doped silicon wafer, and removing phosphorus-doped layers wound and plated on the front surface and the side surface by using a hydrofluoric acid solution; soaking the obtained silicon wafer in a KOH solution or NaOH solution containing an additive, removing polycrystalline silicon on the front surface ofthe silicon wafer, taking out the silicon wafer, and washing with water; placing the obtained silicon wafer in a KOH or NaOH and H2O2 mixed solution to be soaked and then placing the silicon wafer ina hydrochloric acid solution to be soaked after washing, taking out the silicon wafer to be washed, completing the soaking treatment in a corresponding reaction tank, and arranging two sets of circulating bubbling systems in the reaction tank. According to the winding-plating-removing method provided by the invention, the winding plating phenomenon of the TOPCon battery can be effectively solved,the excellent rate of products is ensured, the appearance problem and EL disqualification problem caused by winding plating are solved, and the battery conversion efficiency is improved.

Owner:YINGLI ENERGY CHINA +1

Pleione bulbocodioides seed tissue cultivation method

InactiveCN110972956AReduce the impactGuaranteed excellent ratePlant tissue cultureHorticulture methodsPleione bulbocodioidesPleione

The invention relates to the technical field of pleione bulbocodioides planting, and discloses a pleione bulbocodioides seed tissue cultivation method. The method comprises the following steps: removing unnecessary parts of collected pleione bulbocodioides seeds, carefully cleaning required parts, and then cutting the seeds to an appropriate size. According to the pleione bulbocodioides seed tissue cultivation method, through tissue cultivation, the large-scale tissue cultivation of pleione bulbocodioides can be performed in a large-scale pleione bulbocodioides planting base, so that the seedling survival rate of pleione bulbocodioides is improved, the excellent and good rate of pleione bulbocodioides is ensured, the reproduced progeny is neat and consistent, excellent characters of the original variety can be maintained, and rot or necrosis cannot appear after sterilization during the process of seed multiplication and rhizome culture of pleione bulbocodioides. The tissue cultivationmethod is used to remove viruses, fungi and bacteria of most plants, so that the plant has strong growth potential, enlarged flowers, bright color, improved stress resistance, and increased number offlowers produced.

Owner:昭通芸生农业科技开发有限公司

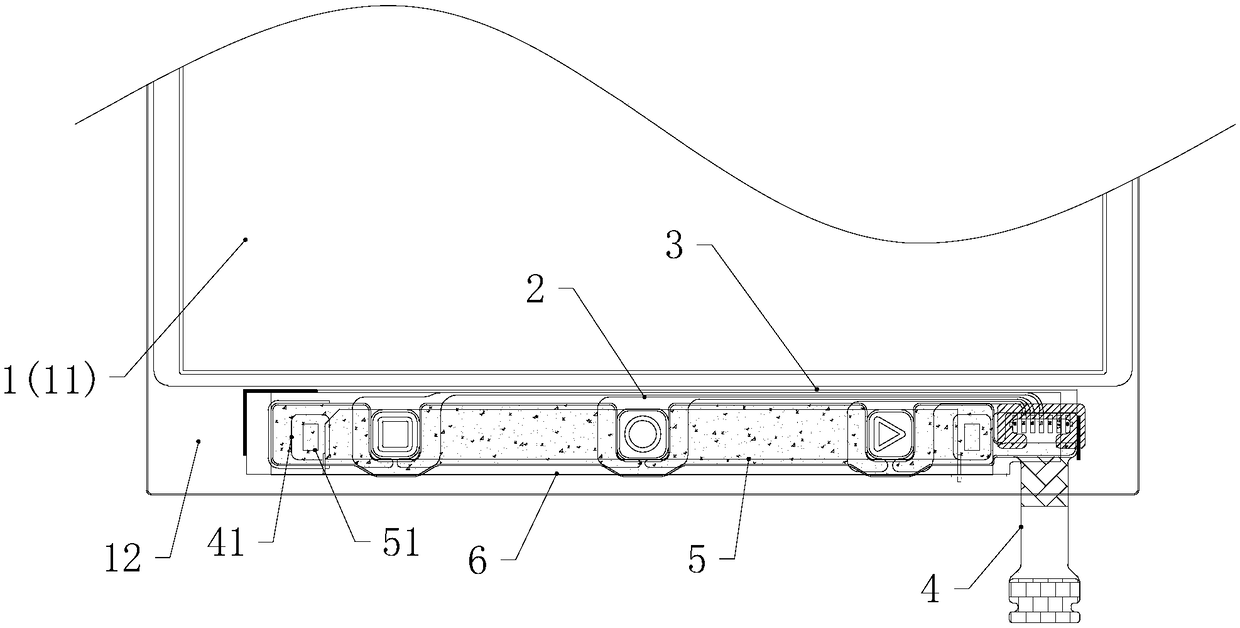

Cover plate assembly of an embedded touch screen and a manufacturing process of the cover plate assembly

PendingCN109491548AHighlight bad problems to avoidAvoid direct exposureElectrical equipmentInput/output processes for data processingSilver inkCooking & baking

The invention discloses a cover plate assembly of an embedded touch screen, which comprises a cover plate, a key circuit, an insulating layer, an FPC, a light guide film and a shading film, the key circuit is printed on an ink layer of the cover plate, the insulating layer is printed on the ink layer and covers the key circuit, and the FPC is attached to the insulating layer and electrically connected with the key circuit; the light guide film and the light shielding film are sequentially attached to the FPC, and a light shielding layer is arranged on the face, away from the insulating layer,of the FPC. The invention further discloses a manufacturing process based on the cover plate assembly, including printing silver ink on the cover plate and baking to obtain the key circuit; printing insulating ink and baking to obtain an insulating layer; laminating an FPC on the insulating layer and binding a joint of the key circuit with the FPC, wherein a copper foil at the light shielding layer is reserved when the FPC is manufactured; attaching a light guide film on the FPC; and attaching a shading film to the light guide film. The light shielding layer is laid under the light source, opposite to the light guide film, of the FPC, when the key structure is lightened, the light source is prevented from directly irradiating the cover plate, and therefore the problem of poor bright spotsappearing on the cover plate is avoided.

Owner:SHENZHEN JUNDA OPTOELECTRONICS

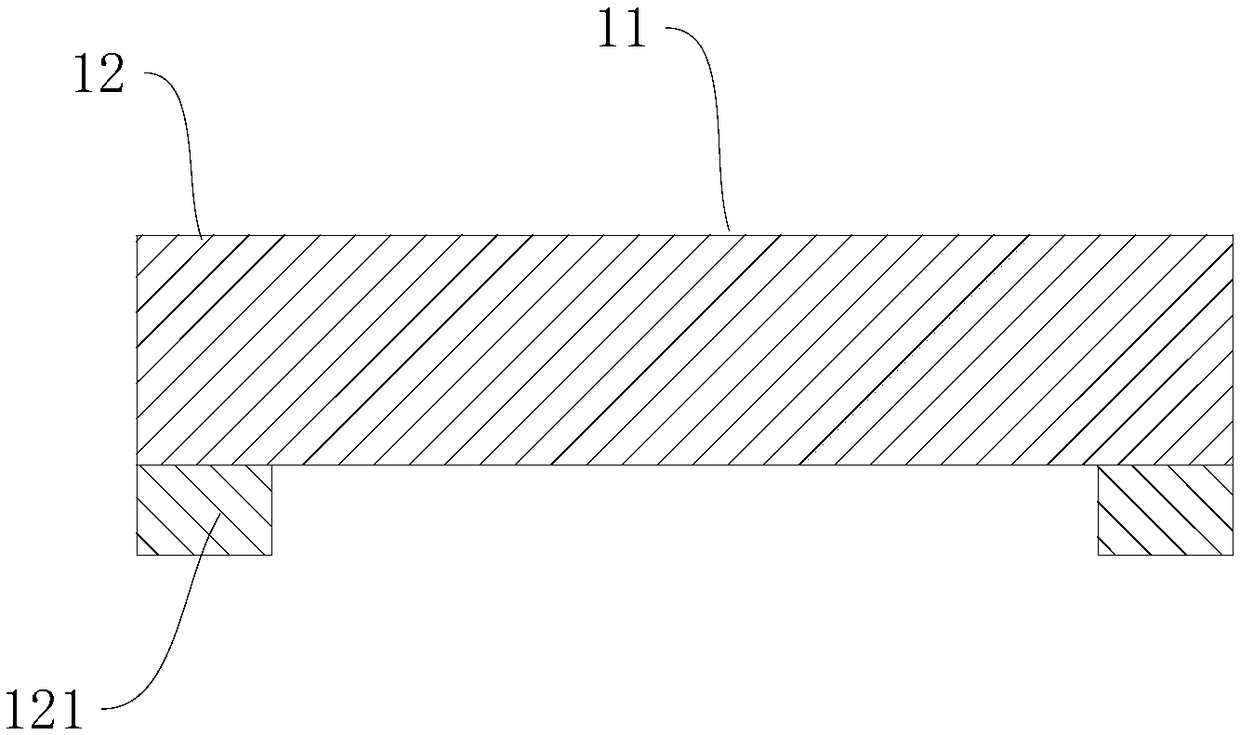

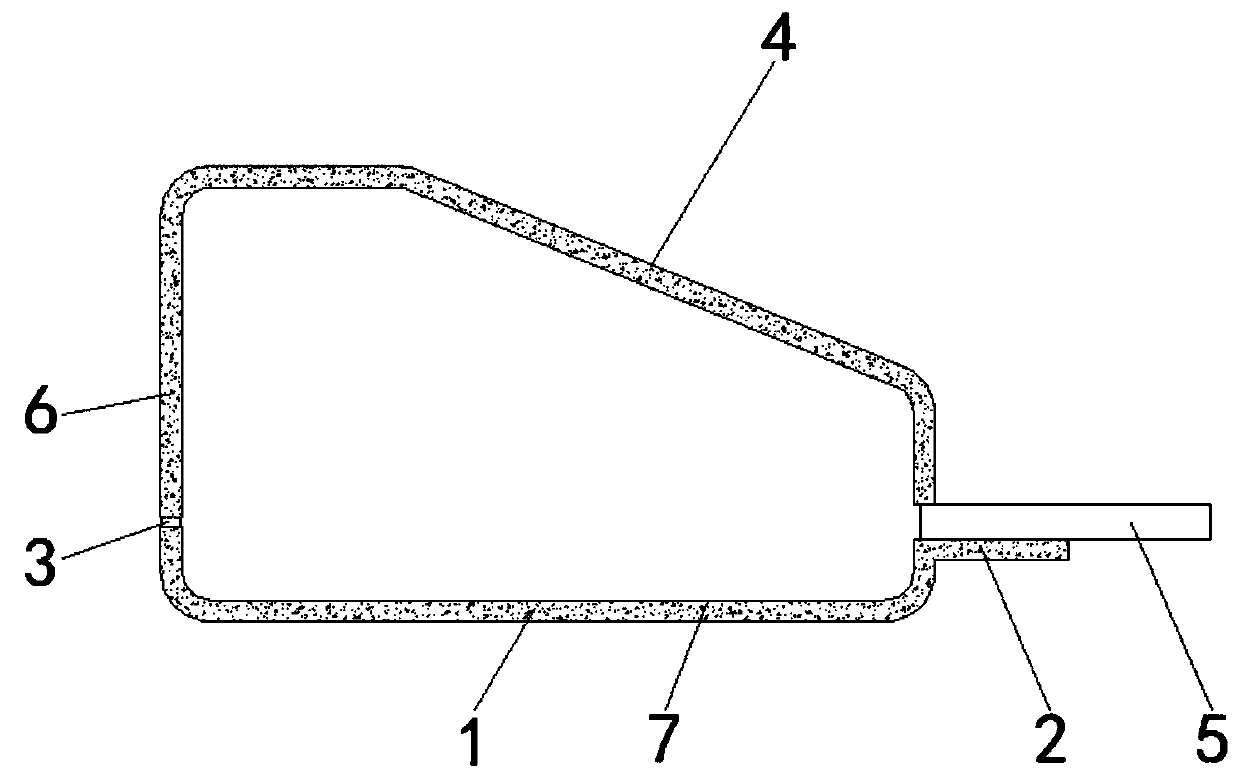

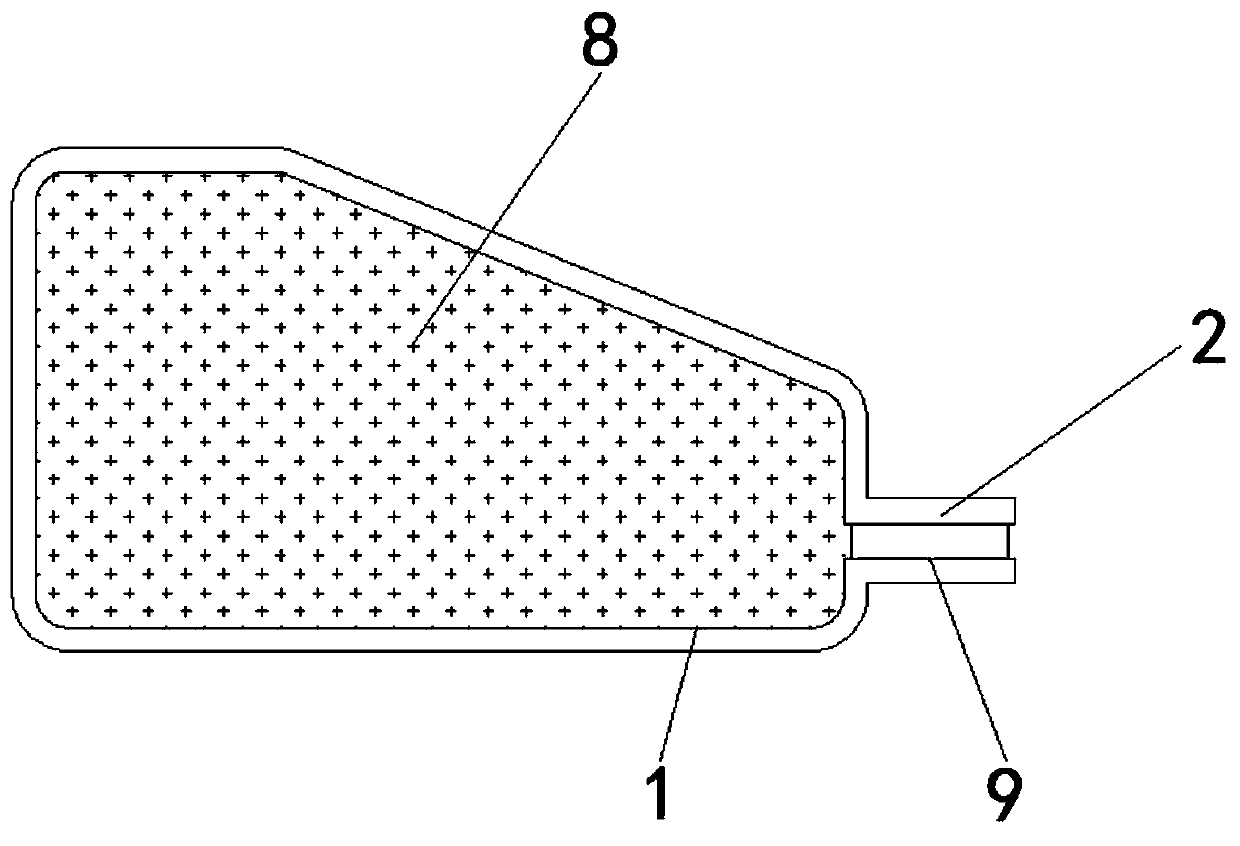

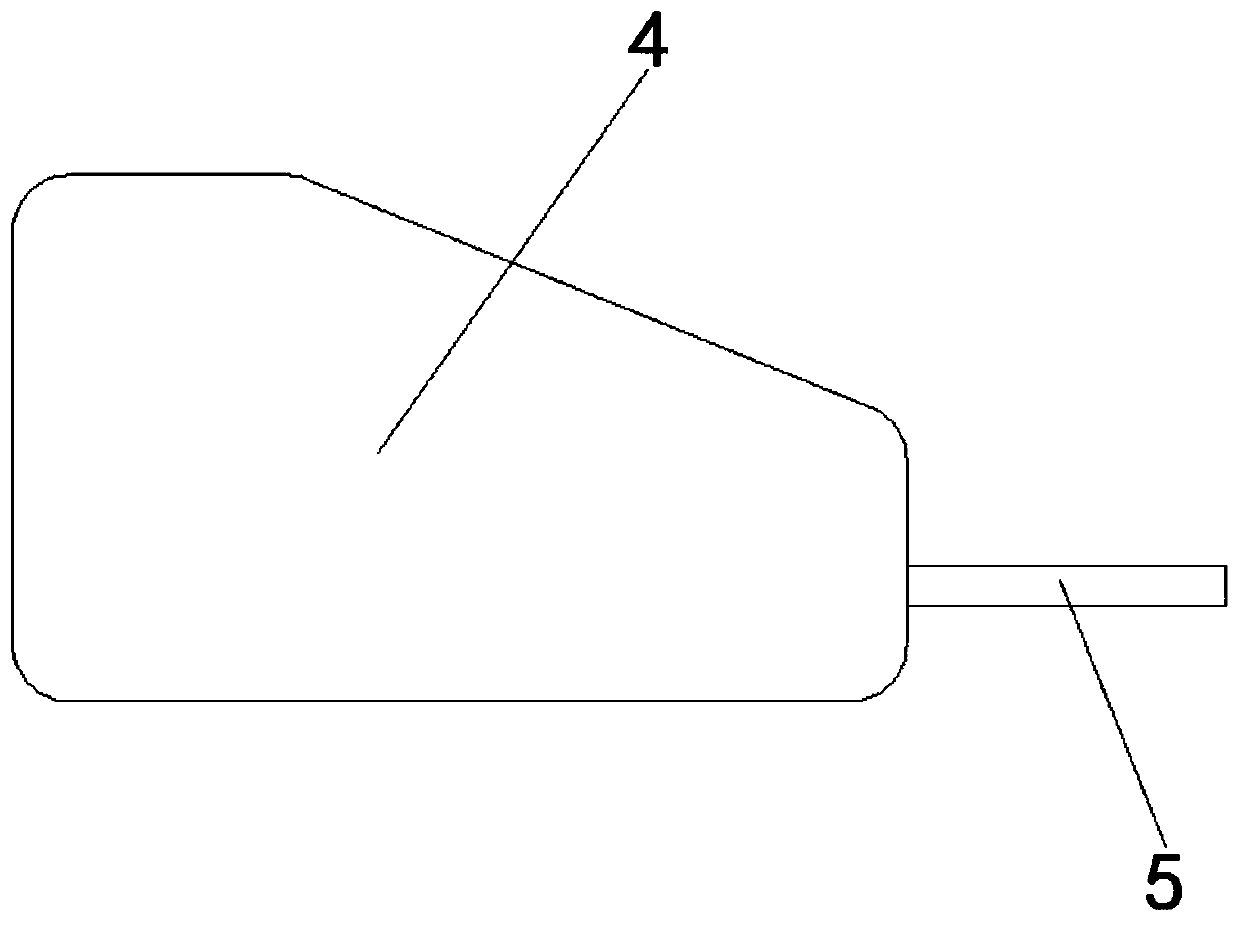

Manufacturing method of ultra-thin VC

PendingCN111504104AImprove sealingGet over the splashIndirect heat exchangersNon-electric welding apparatusManufactured materialStructural engineering

The invention relates to the technical field of vapor chambers, and discloses an ultra-thin VC. The ultra-thin VC comprises a lower cover plate. A mounting plate is fixedly mounted on the right side of the lower cover plate. The top of the lower cover plate is fixedly provided with an upper cover plate. A welding groove is formed in the left side of a joint of the lower cover plate and the upper cover plate. A liquid inlet pipe is fixedly mounted on the right side of the upper cover plate. Wool layers are fixedly mounted inside the lower cover plate and the upper cover plate. Grooves are formed in the top of the lower cover plate and the bottom of the upper cover plate. An etching layer is arranged on the inner bottom wall of the lower cover plate. A mounting groove is formed in the top ofthe mounting plate. According to a manufacturing method of the ultra-thin VC, ultrasonic metal welding is adopted, so that the quality of ultrasonic wave metal welding production is effectively improved, waste of raw materials is avoided, and the ultra-thin VC does not need to be welded little by little. The ultra-thin VC is sealed in a circle through ultrasonic wave metal welding and welding, sothat the excellence rate of ultra-thin VC production is guaranteed.

Owner:江苏明利嘉科技有限公司

Iron removing and feeding device for wood powder grinding and processing

The invention discloses an iron removing and feeding device for wood powder grinding and processing. The iron removing and feeding device comprises a bottom plate, a bracket is welded to the top of the bottom plate, and a shell is welded to the top of the bracket. Through holes are formed in the side wall of the shell, an inserting plate is movably sleeved with the through hole, and a strip-shapedgear is welded to the side wall of the inserting plate. A fixed block is welded to the side wall of the shell, a fixed rod is welded to the surface of the top of the fixed block, and a gear is movably connected to the outer side of the fixed rod in a clamped mode. The through holes are formed in the side wall of the shell, a spring is welded to the inner wall of the shell, and a sleeve rod is welded to the other end of the sleeve rod. A first screw is welded to the top of the sleeve rod, a first nut movably meshes with the outer side of the first screw, and one end of the sleeve rod passes through the side walls of the through holes. Through the iron removing and feeding device, operators can control the size of discharging flow and the manufacturing process, on the other hand, iron removing parts can also be conveniently replaced, so that the quality of products is better, the excellent rate of the products is ensured, the company image is improved, the unqualified rate of products is reduced, and the company interest is ensured.

Owner:陈苗琴

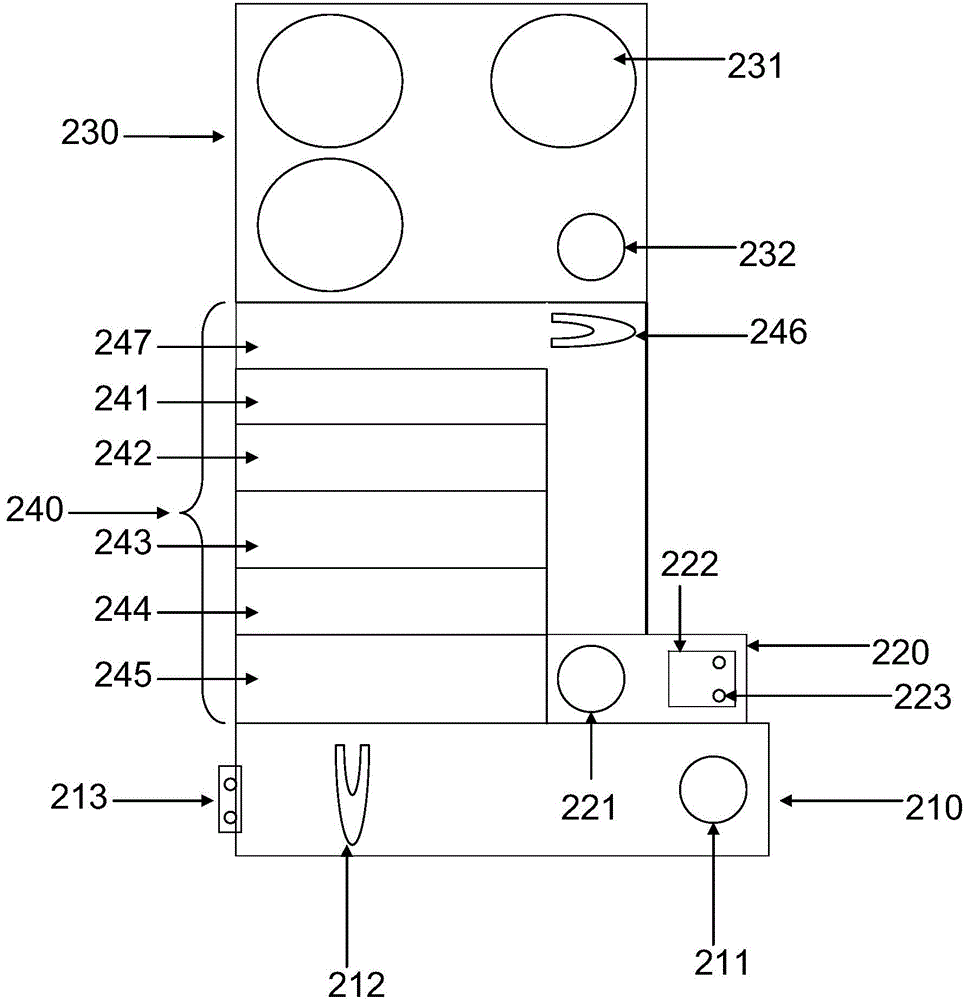

Semiconductor device and method of polishing and cleaning wafer

InactiveCN105529284AImprove reliabilityIncrease smoothnessSemiconductor/solid-state device manufacturingPower semiconductor deviceBiochemical engineering

The invention provides a semiconductor device for polishing and cleaning a wafer, which comprises a front-end module, a measurement module, a CMP (Chemical Mechanical Planarization of Microelectronic Materials) polishing module and a cleaning module, wherein an EKC cleaning unit is arranged in the cleaning module for carrying out EKC solution cleaning processing on a wafer put in the cleaning module, and through slightly corroding the partial area on the surface of the wafer, pollution components which have a complex composition and are stubbornly attached to the surface of the wafer are removed jointly, and good effects of cleaning the wafer and improving the wafer yield are achieved. In addition, the invention also provides a wafer polishing and cleaning method. The method comprises a polishing step and a cleaning step. The cleaning step comprises four procedures of megasonic cleaning, Brush cleaning, EKC cleaning and IPA drying, thereby completing each conventional cleaning procedure for the traditional cleaning process, further improving the cleaning effects through the EKC cleaning procedure and facilitating improvement of the product yield.

Owner:ACM RES SHANGHAI

Network-based enterprise service mode

InactiveCN108305140AIncrease awarenessExpand the scope of the releaseBuying/selling/leasing transactionsEnterprise servicesOperation Activity

The invention provides a network-based enterprise service platform construction mode. Information disclosure and resource sharing are carried out through a network, and the public will check related data through a service platform after supplier information is released, so the information releasing range is increased and thus marketing channels are expanded. Meanwhile, the supplier information isreleased, so the influence scope of the supplier information is expanded, the popularity of an enterprise is improved and the enterprise is urged to guarantee the yield rate of product quality. Moreover, operating activities are performed under the guidance of the platform in accordance with laws and regulations, supervision is carried out through an online supervising module, experts for evaluation and supervision are randomly selected from an expert database to guarantee fairness and excellence of a whole supervision process, and thus an entire industry production and operation environment better develops in a cyclic manner.

Owner:安宁市安航管理咨询有限公司

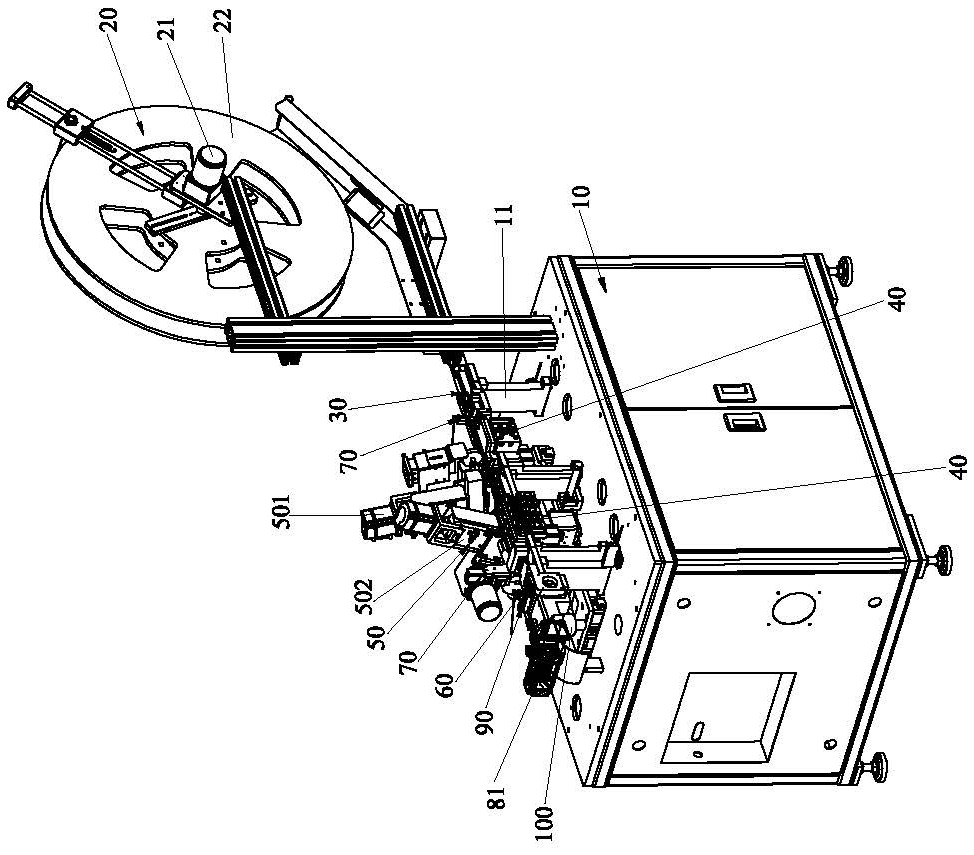

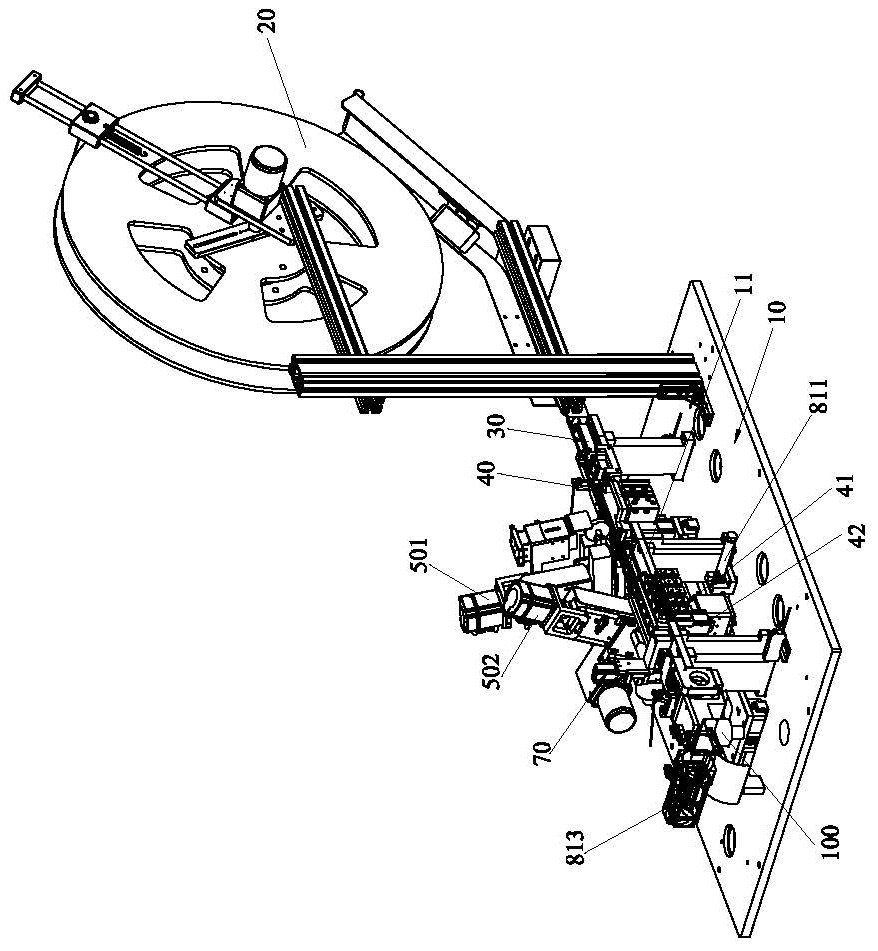

Automatic polishing machine for 5G terminal

ActiveCN111687738ARealize fully automatic actionIncrease productivityGrinding carriagesPolishing machinesPolishingEngineering

The invention discloses an automatic polishing machine for a 5G terminal. The automatic polishing machine comprises a machine frame, a placing device for placing a terminal material strip, a conveyingmechanism for conveying the terminal material strip, a pressing device for fixing and positioning the terminal material strip and a polishing device for polishing the terminal. The machine frame is provided with a workbench, the placing device is arranged on the machine frame, the conveying device is arranged on the workbench and located behind the output end of the placing device, the pressing device is arranged on the workbench and located on the side of the conveying device, and the polishing device is arranged on the machine frame and located on one side of the pressing device. Due to theintegrated design of the placing device, the conveying device, the pressing device and the polishing device, full-automatic actions of placing, conveying, positioning and polishing for the terminal material strip are realized, compared with manual polishing, the production efficiency is greatly improved, the labor cost is reduced, and the good rate of products is ensured.

Owner:SHENZHEN CHUANGYITONG TECH CO LTD

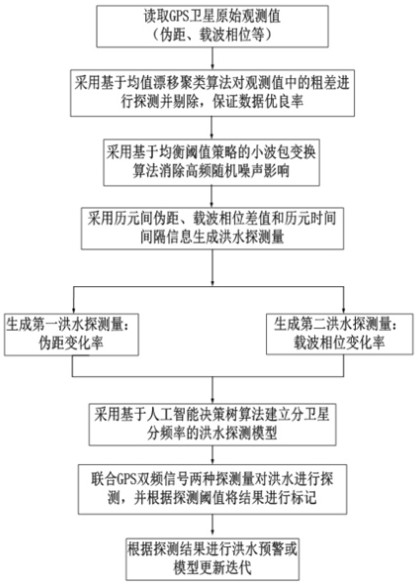

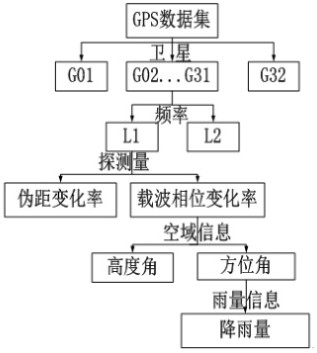

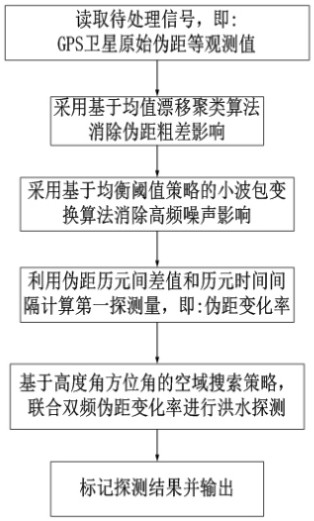

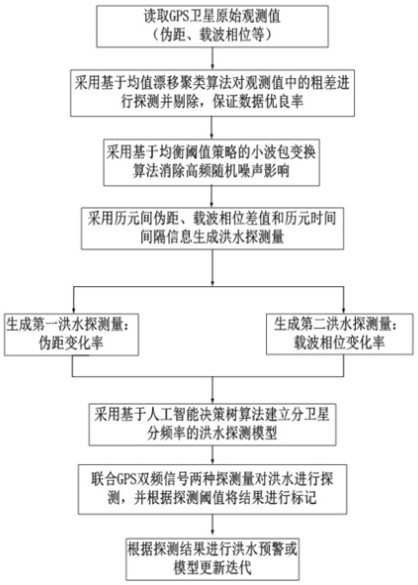

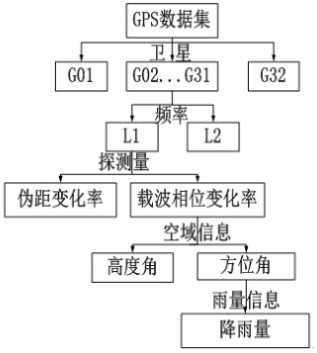

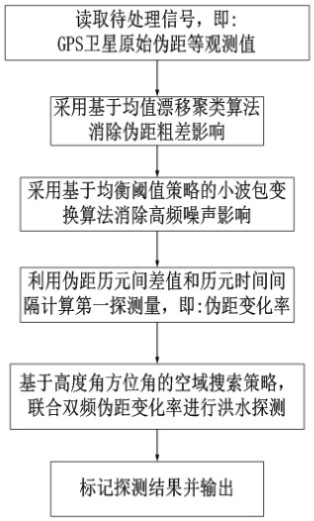

GPS remote sensing flood warning method based on artificial intelligence decision tree

ActiveCN114254568BSolve the accuracy problemProbe meetsWeather condition predictionCharacter and pattern recognitionAlgorithmCarrier signal

The invention discloses a GPS remote sensing flood prediction method based on an artificial intelligence decision tree, comprising the following steps: S1, reading the original observation value of GPS satellite; S2, preprocessing the original observation value; S3, adopting the pseudo-range between epochs The information of the difference, the carrier phase difference and the epoch time interval generates a flood detection amount, and the flood detection amount includes a first detection amount and a second detection amount; S4, using an artificial intelligence-based decision tree algorithm to establish a sub-satellite sub-frequency flood detection model; S5, combine the first detection quantity and the second detection quantity of the GPS dual-frequency signal to detect the flood, and mark the result according to the detection threshold; S6, perform flood warning according to the detection result or update and iterate the flood detection model. The artificial intelligence-based decision tree algorithm is used to establish a high-precision flood detection model, and the correlation between the detection amount and other auxiliary characteristic parameters is deeply excavated to reduce the false detection rate and ensure the accuracy and stability of flood detection.

Owner:浙江国遥地理信息技术有限公司

5g terminal automatic polishing machine

ActiveCN111687738BRealize fully automatic actionIncrease productivityGrinding carriagesPolishing machinesPolishingMachine

The invention discloses an automatic polishing machine for a 5G terminal. The automatic polishing machine comprises a machine frame, a placing device for placing a terminal material strip, a conveyingmechanism for conveying the terminal material strip, a pressing device for fixing and positioning the terminal material strip and a polishing device for polishing the terminal. The machine frame is provided with a workbench, the placing device is arranged on the machine frame, the conveying device is arranged on the workbench and located behind the output end of the placing device, the pressing device is arranged on the workbench and located on the side of the conveying device, and the polishing device is arranged on the machine frame and located on one side of the pressing device. Due to theintegrated design of the placing device, the conveying device, the pressing device and the polishing device, full-automatic actions of placing, conveying, positioning and polishing for the terminal material strip are realized, compared with manual polishing, the production efficiency is greatly improved, the labor cost is reduced, and the good rate of products is ensured.

Owner:SHENZHEN CHUANGYITONG TECH CO LTD

Motor assembly riveting detection mechanism

ActiveCN111360167BNovel structureRiveting realizationMetal-working feeding devicesMetal working apparatusElectric machineControl engineering

Owner:深圳市中科创想科技有限责任公司

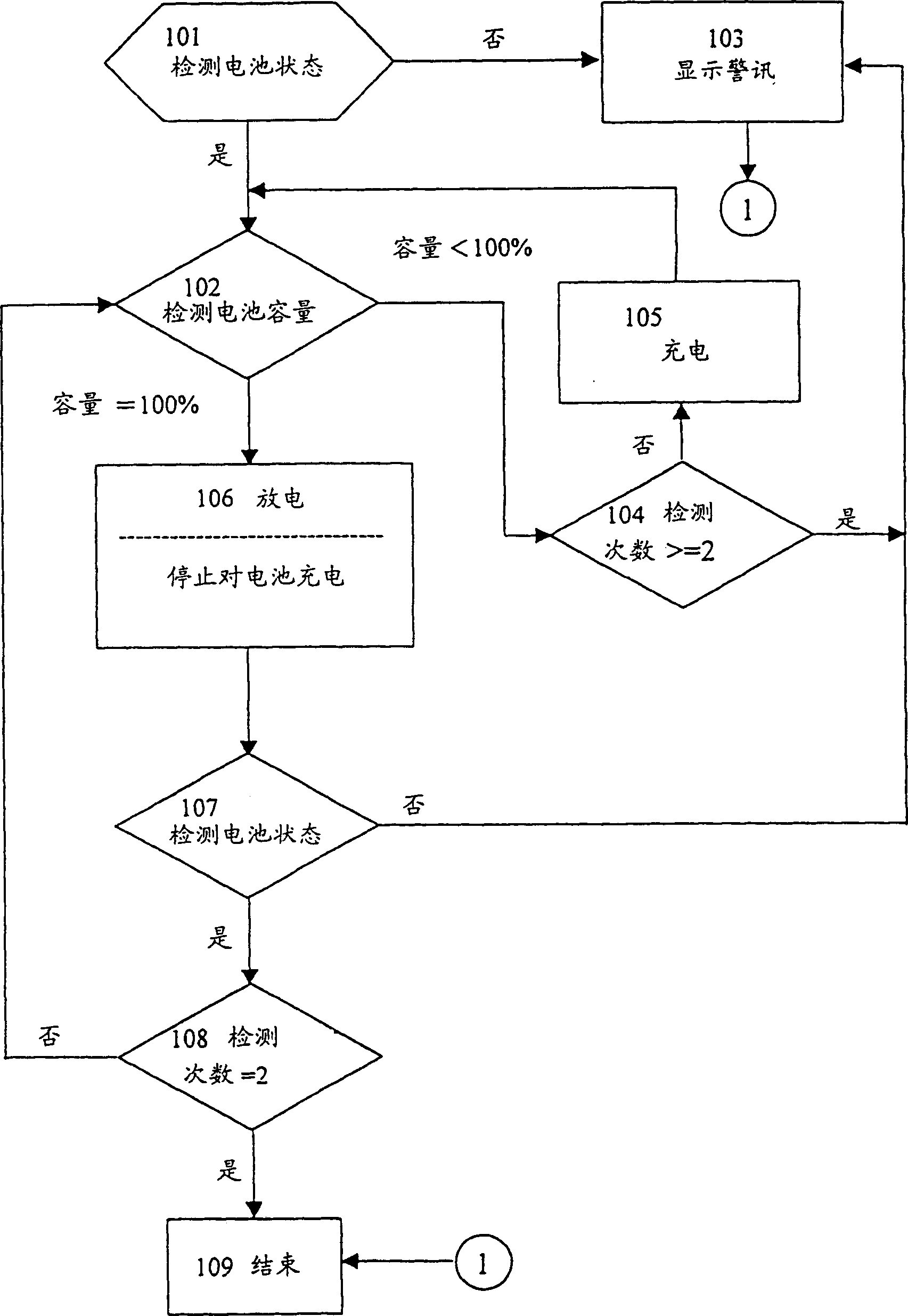

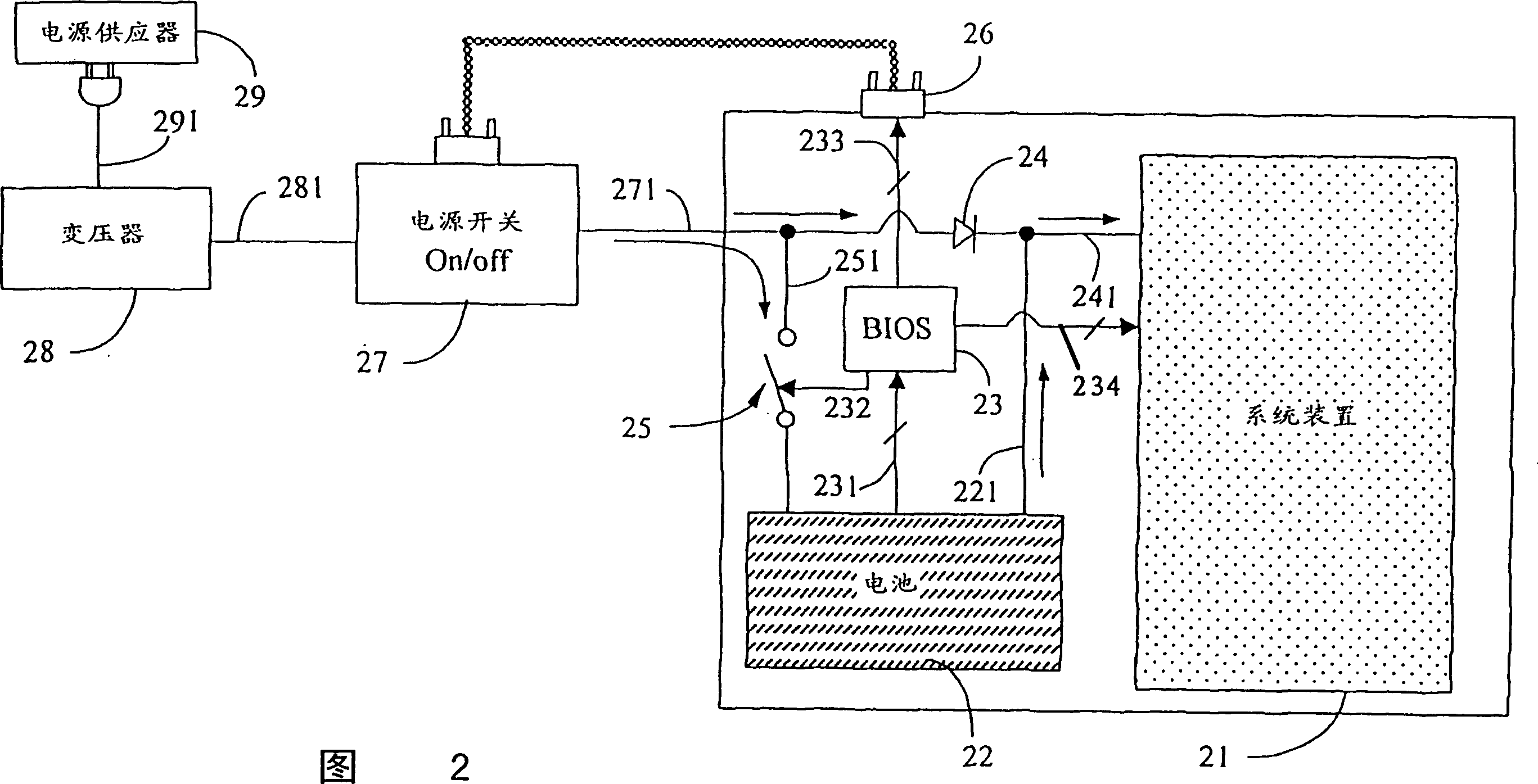

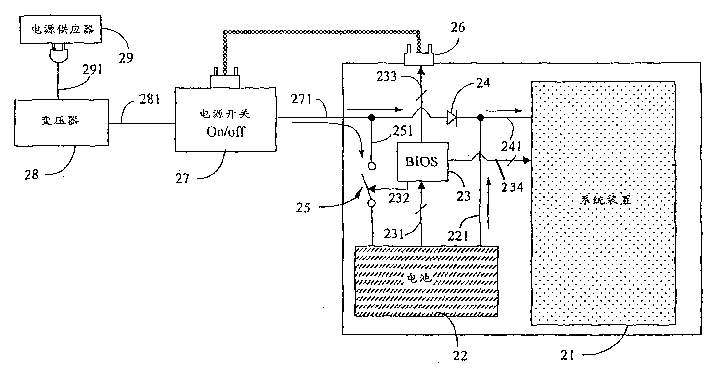

Automatic test method and device for battery

InactiveCN1174536CGuaranteed excellent rateImprove product qualityBatteries circuit arrangementsVolume/mass flow measurementElectrical batteryBIOS

A method and its device for automatically detecting the state of battery in notebook computer and controlling the charging and discharging of the said battery feature that a BIOS unit is used to control the first and the second controller for controlling the charging and discharging of battery and detecting the state and capacity of battery, so determining the performance of battery. Its advantages are instantameous detecting on-line, power supply norral operation and no need to spend time of battery detection.

Owner:GETAC TECH CORP

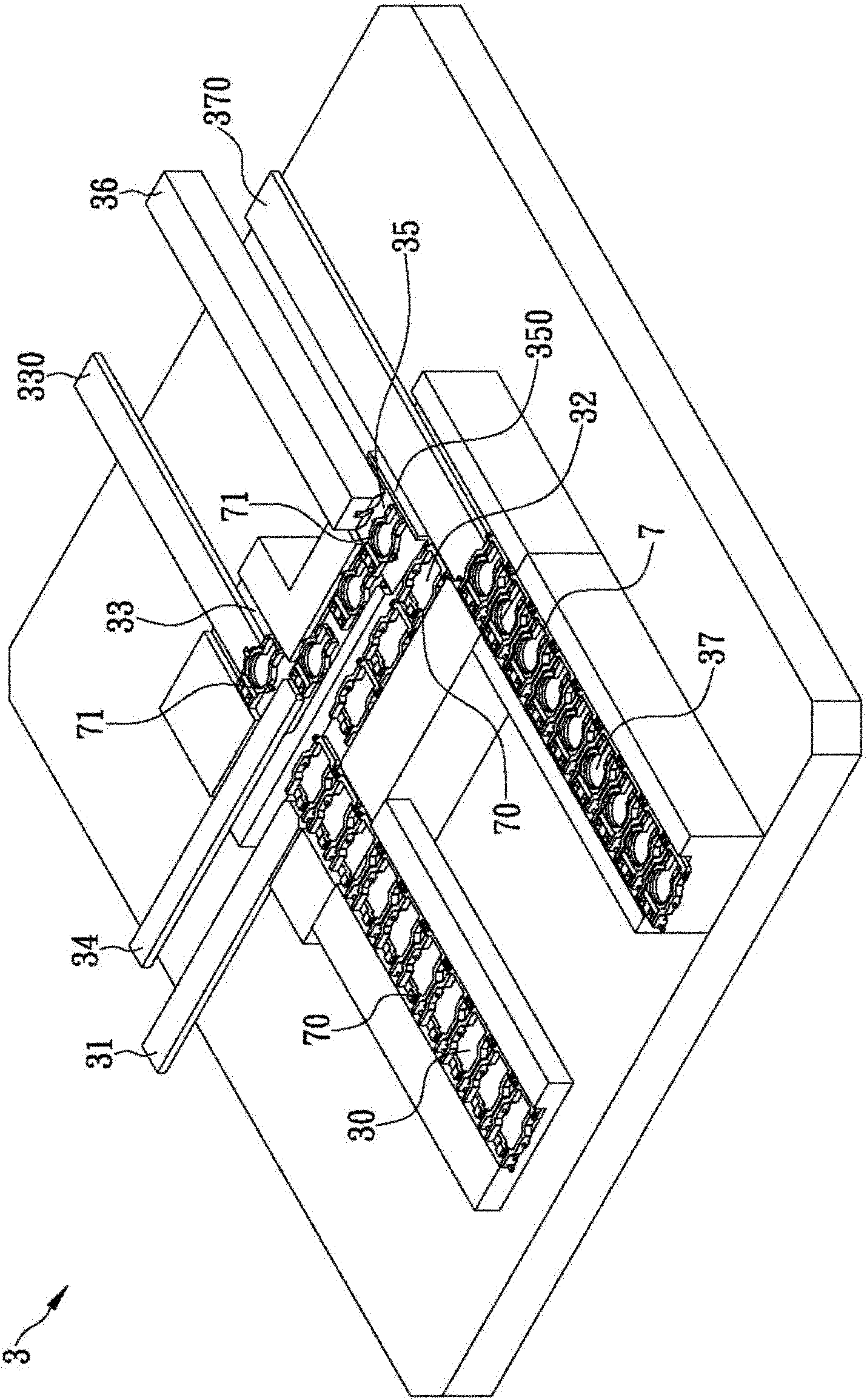

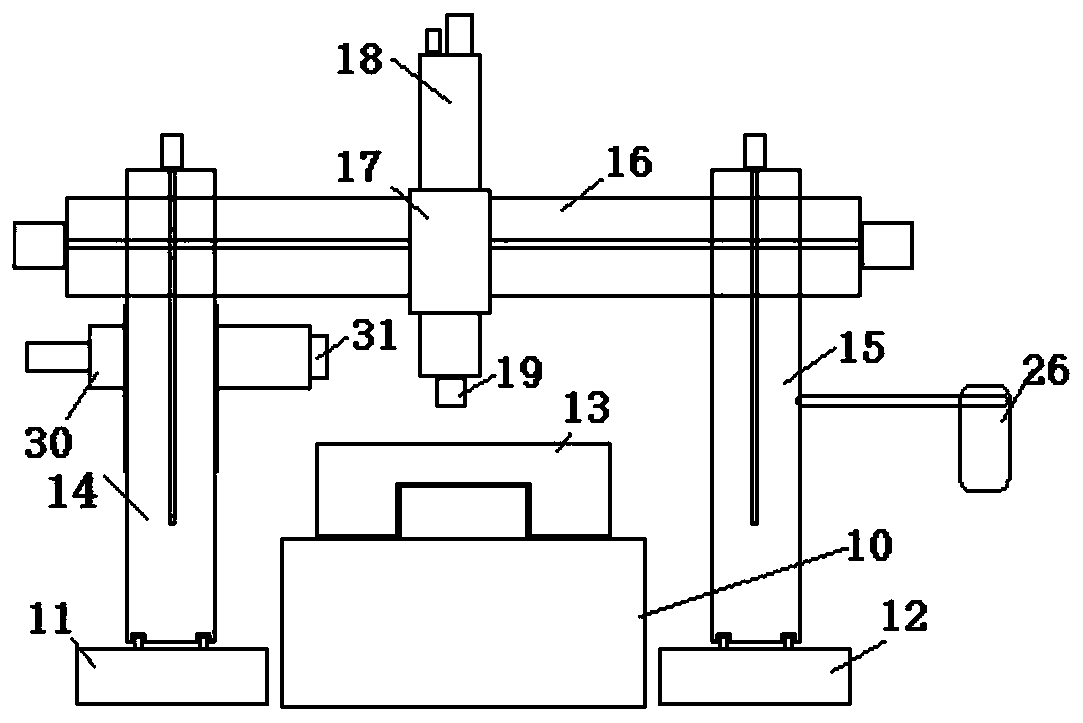

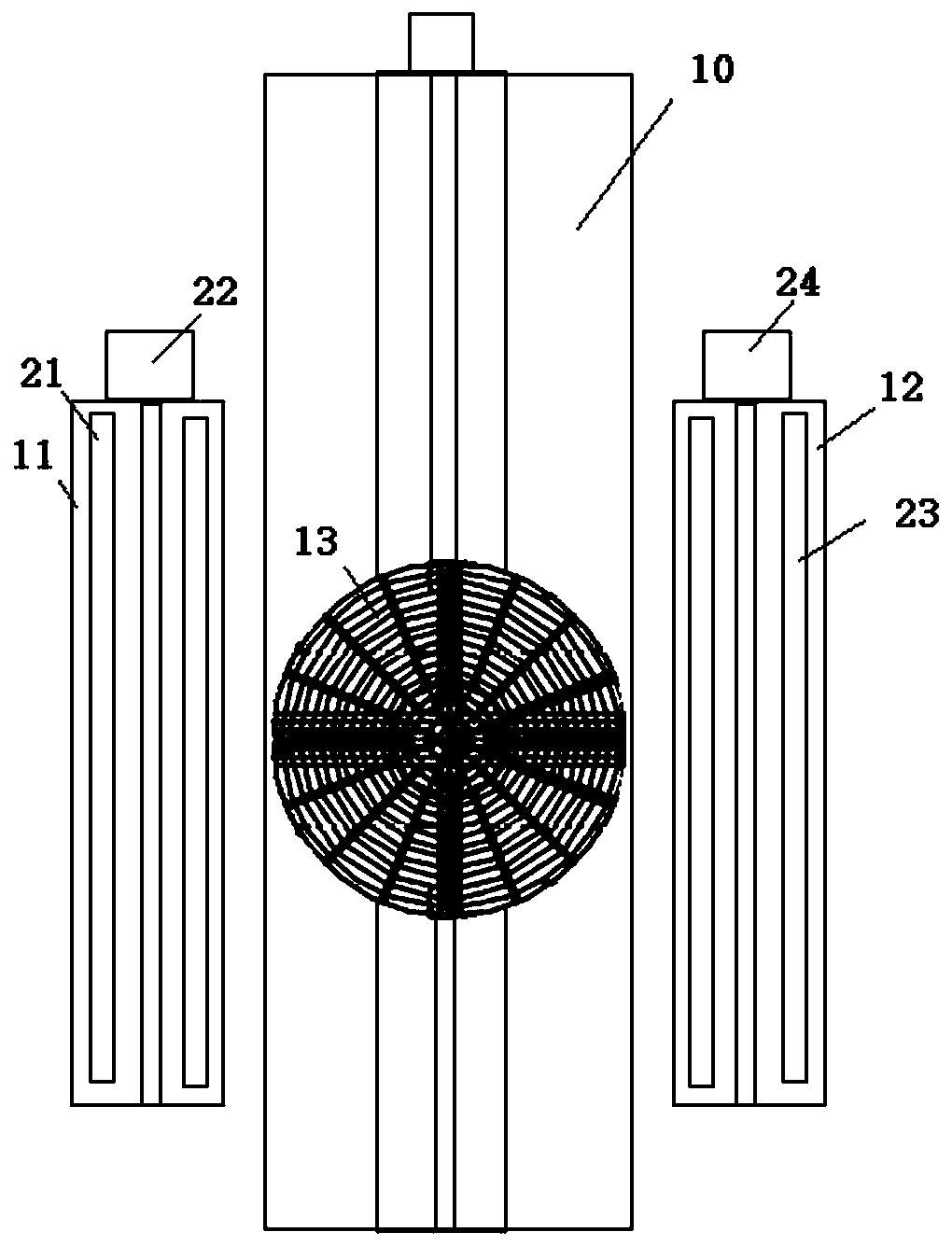

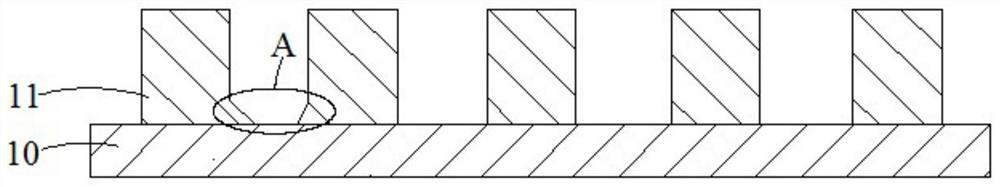

Gantry Machine Tool for Fine Machining

ActiveCN108340165BRealize fine processingImprove processing efficiencyLarge fixed membersMetal working apparatusMachine toolMachining

A gantry machine tool for elaborate machining comprises a workpiece table; the two sides of the workpiece table are provided with a left base and a right base correspondingly; a rotating clamp is arranged above the workpiece table; a left stand column capable of relatively sliding forwards and backwards is arranged on the left base; the right base is provided with a right stand column capable of relatively sliding forwards and backwards; the front sides of the left stand column and the right stand column are provided with a cross beam capable of relatively sliding up and down; a sliding tablecapable of relatively sliding leftwards and rightwards is arranged on the front side of the cross beam, and is used for a telescopic column to penetrate; a machining head for machining a workpiece isarranged at the bottom end of the telescopic column; a side machining table is further arranged on the left stand column; a containing part is arranged on the middle portion of the left stand column;the two sides of the containing part are provided with rack slide rails; the side machining table can slide up and down along the rack slide rails on the two sides; and a telescopic side machining head is arranged on the inner side of the side machining table. Thus, the gantry machine tool for elaborate machining is convenient to operate and capable of providing elaborate machining for large partsso as to meet the requirements improved day by day.

Owner:上海欧博自控技术装备有限公司

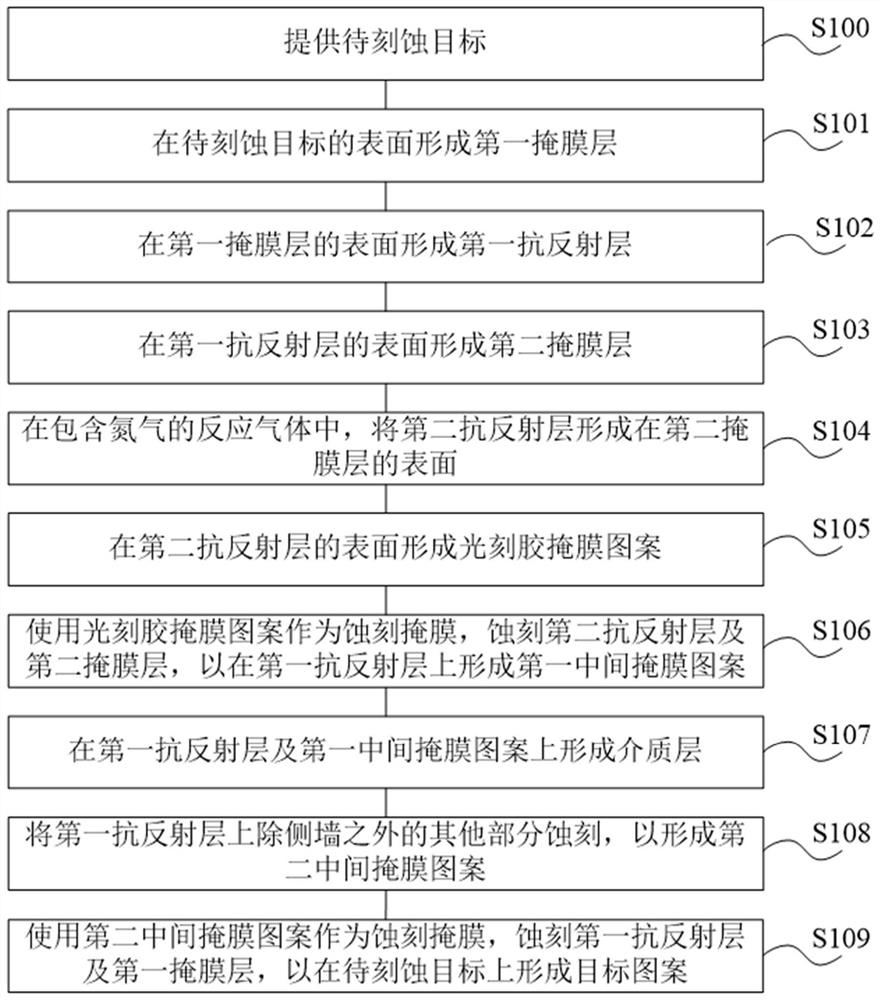

Preparation method of semiconductor device

ActiveCN110890376BGuaranteed excellent rateReduce generationSolid-state devicesSemiconductor devicesDevice materialPhysical chemistry

Owner:CHANGXIN MEMORY TECH INC

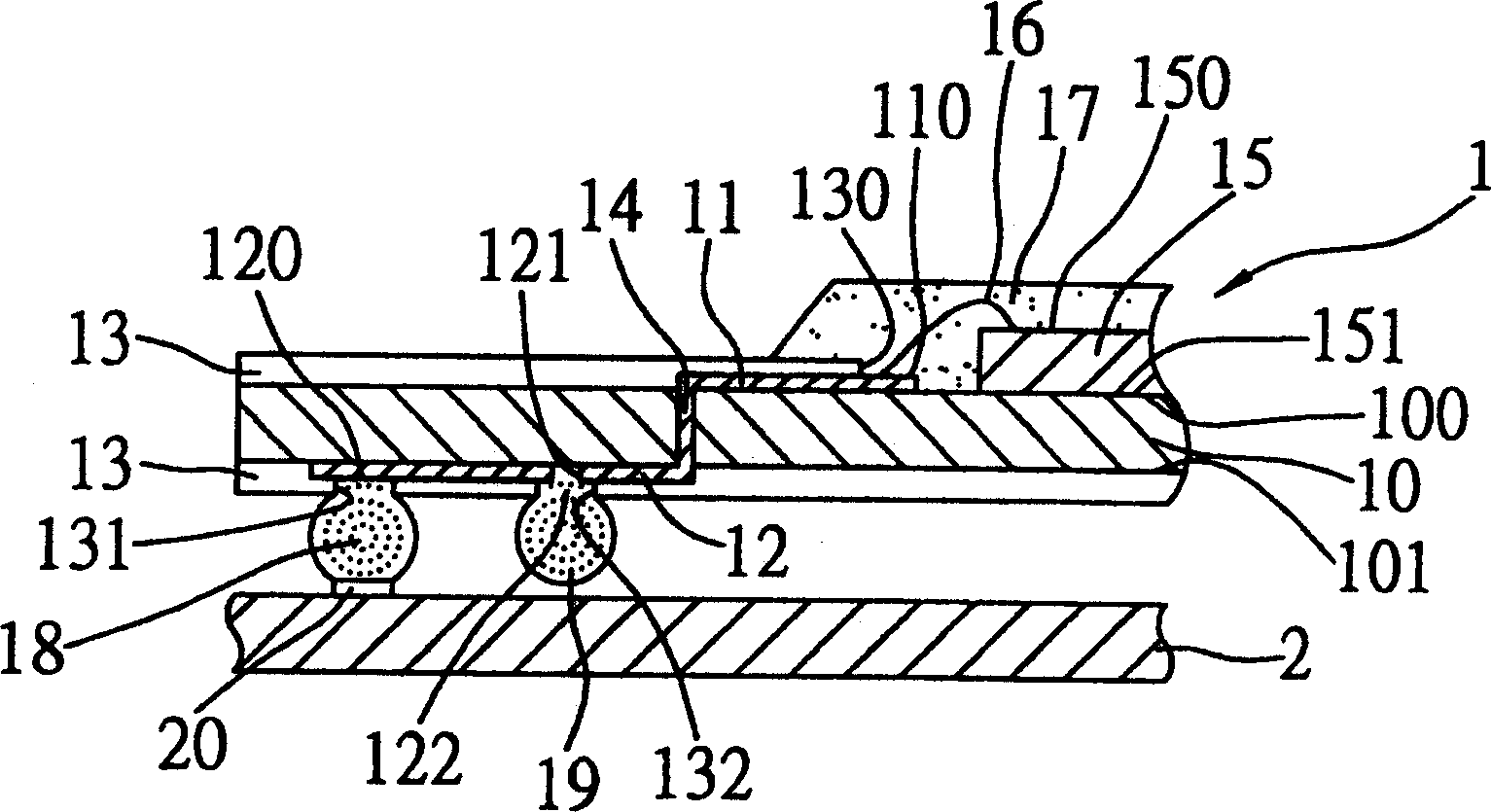

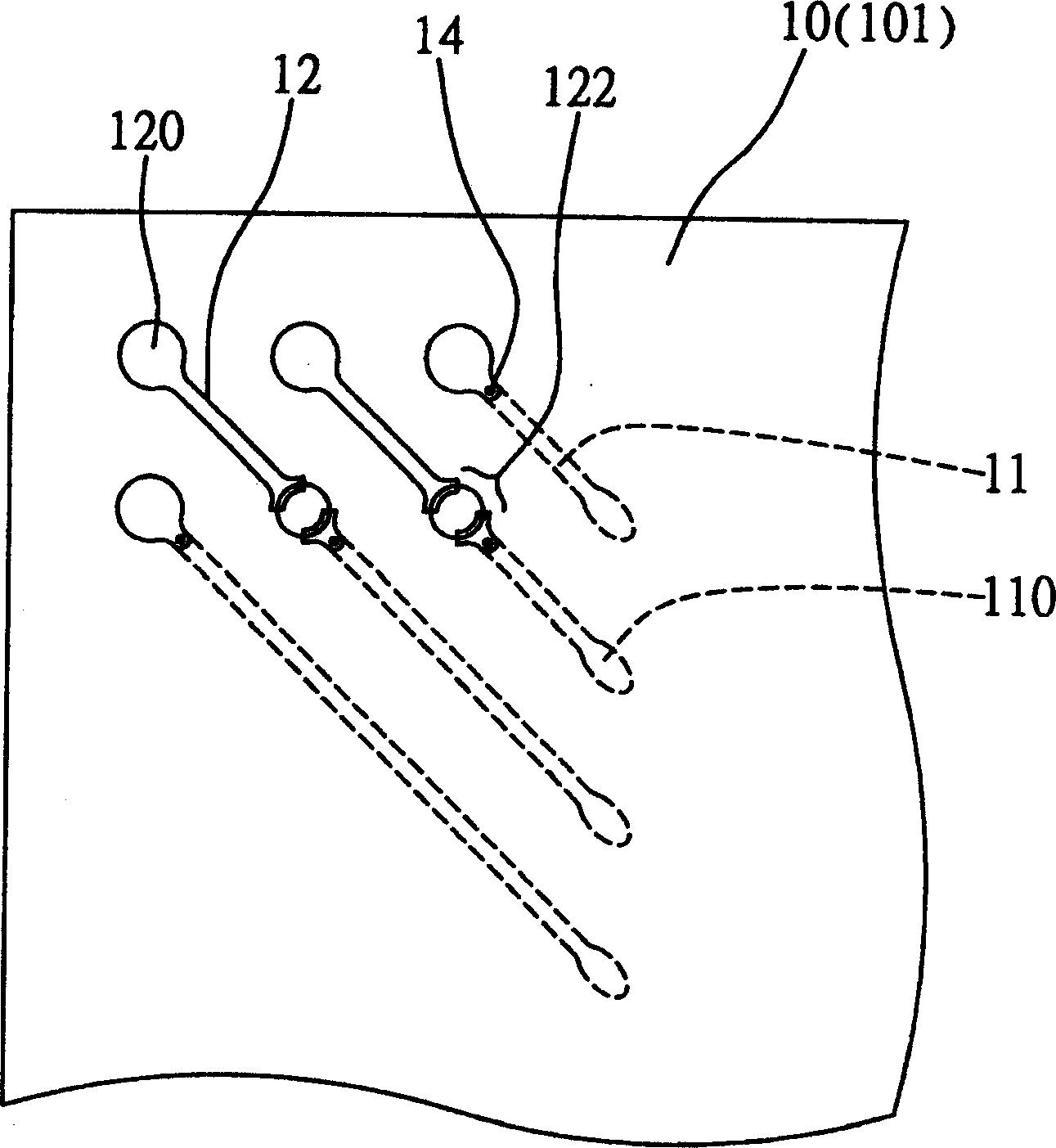

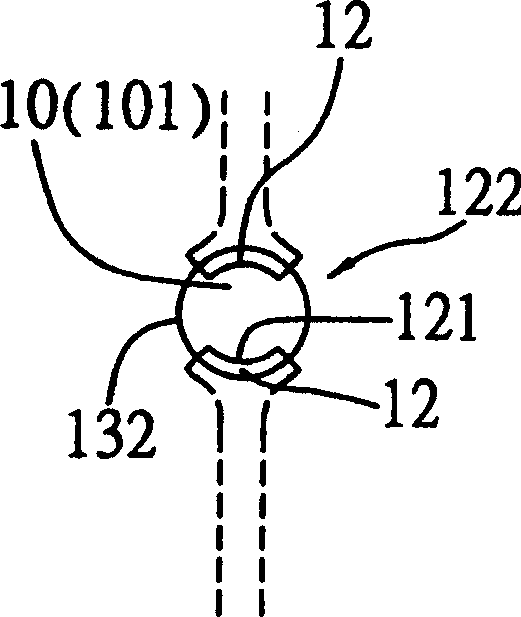

Ball grid array semiconductor package

InactiveCN1287451CGuaranteed excellent rateGuaranteed normal operationSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

The ball grid array semiconductor package is manufactured through forming discontinuous fractures in the set parts of conducting trace on the substrate to expose the soldering inhibitor in the fractures and adjacent trace parts and to form discontinuous soldering pads; and selectively implanting soldering balls onto the discontinuous soldering pads to make the conducting trace with soldering balls form conducting path. The soldering balls are jointed to the soldering pads in unstable state and may be removed easily to make the conducting trace broken; and the removed soldering balls may be re-implanted to the soldering pads to restore the electric conductivity of the conducting trace.

Owner:SILICONWARE PRECISION IND CO LTD

Clamping method for fine machining of large workpieces

ActiveCN108436538BGuaranteed clamping effectEasy to operatePositioning apparatusMetal-working holdersCircular discBall screw

Owner:江苏科挺智能装备有限公司

A Design Method for Ink Plug Hole Tool

ActiveCN106211592BGuaranteed excellent rateIncrease the bearing areaPrinted circuit manufacturePrinting inkBiomedical engineering

Owner:AOSHIKANG TECH CO LTD

GPS remote sensing flood early warning method based on artificial intelligence decision tree

ActiveCN114254568AHigh precisionImprove real-time performanceWeather condition predictionCharacter and pattern recognitionCarrier signalFalse detection

The invention discloses a GPS remote sensing flood prediction method based on an artificial intelligence decision tree. The method comprises the following steps: S1, reading an original observation value of a GPS satellite; s2, preprocessing an original observation value; s3, generating flood detection quantity by adopting information of pseudo-range difference, carrier phase difference and epoch time interval between epochs, wherein the flood detection quantity comprises first detection quantity and second detection quantity; s4, establishing a flood detection model based on satellite and frequency by adopting an artificial intelligence decision tree algorithm; s5, flood is detected by combining the first detection quantity and the second detection quantity of the GPS dual-frequency signal, and a result is marked according to a detection threshold value; and S6, performing flood early warning or updating and iterating the flood detection model according to a detection result. A high-precision flood detection model is established based on an artificial intelligence decision tree algorithm, the correlation between the detection amount and other auxiliary characteristic parameters is deeply excavated, the false detection rate is reduced, and the accuracy and stability of flood detection are ensured.

Owner:浙江国遥地理信息技术有限公司

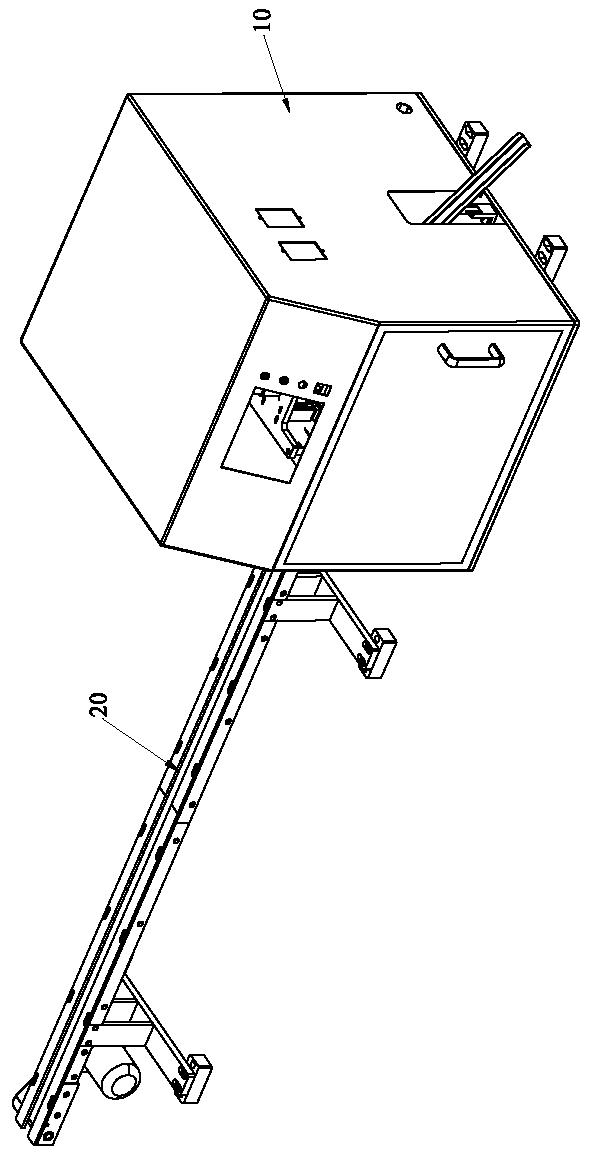

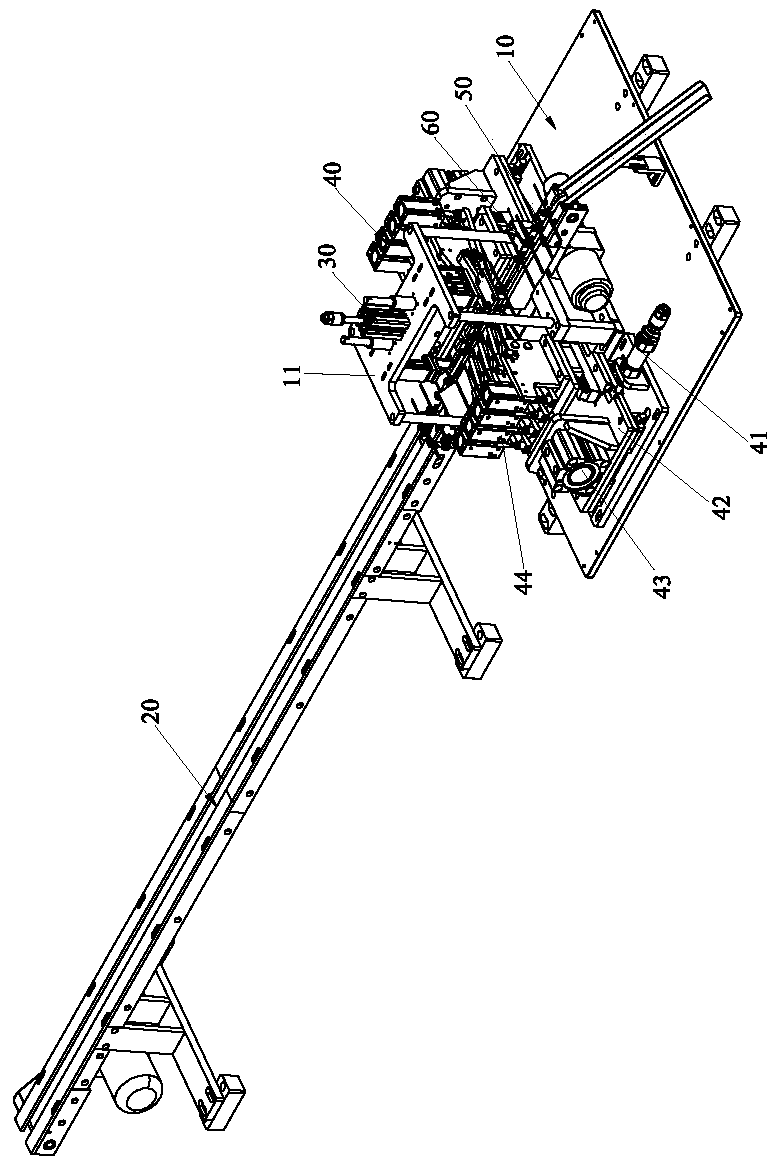

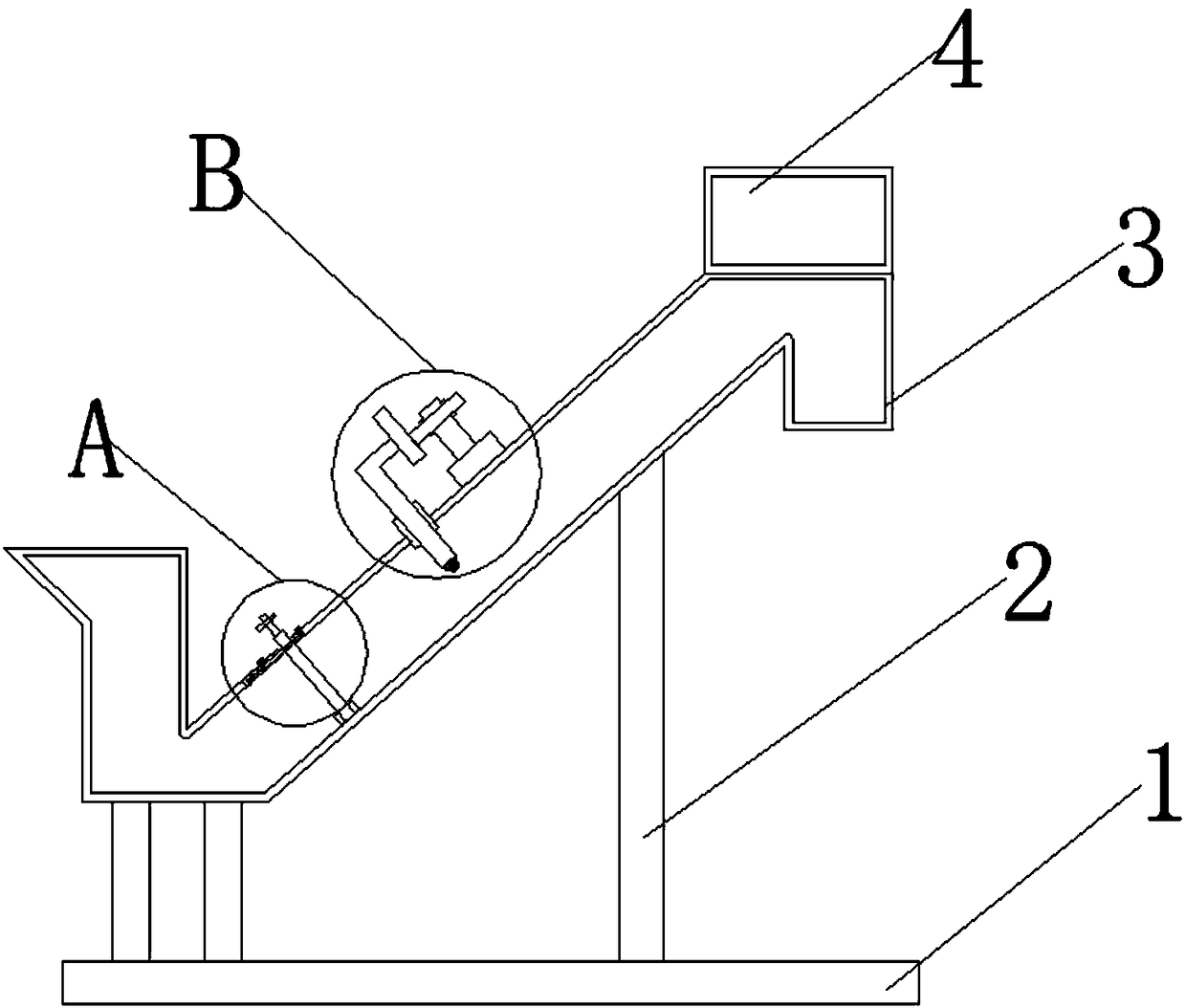

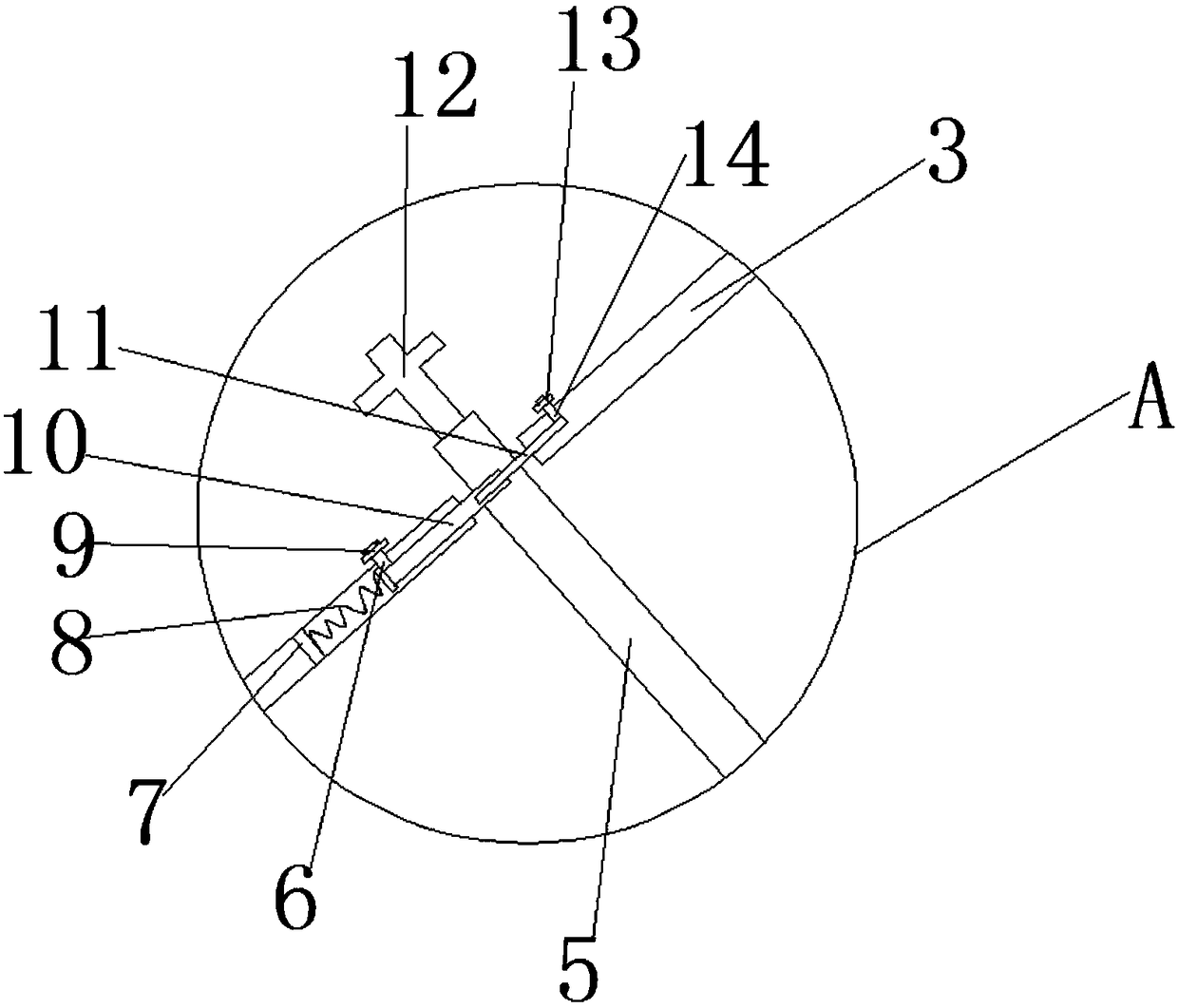

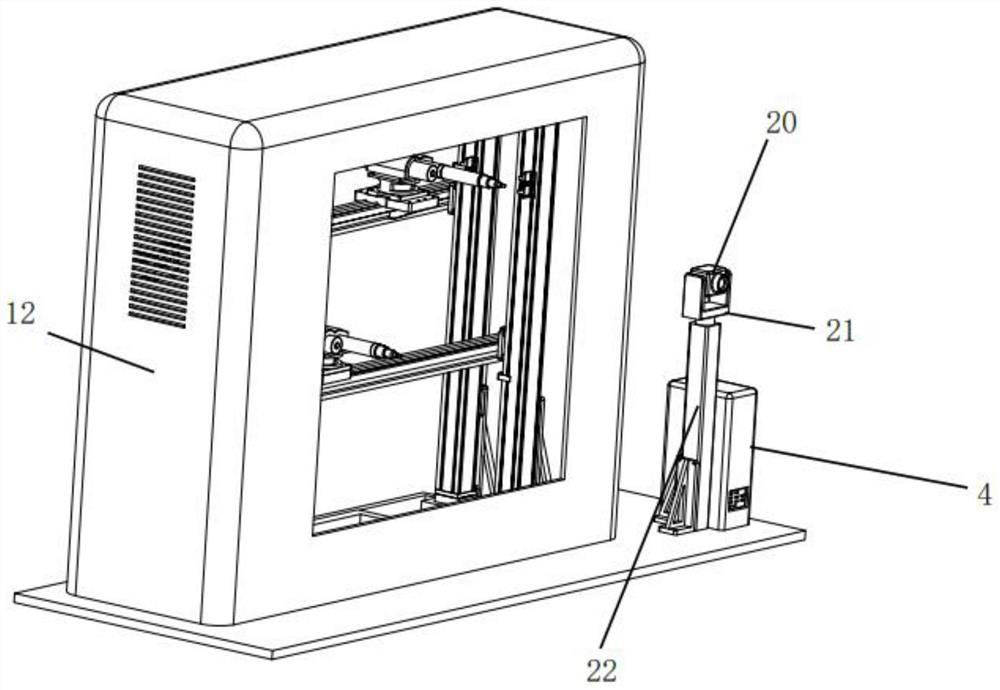

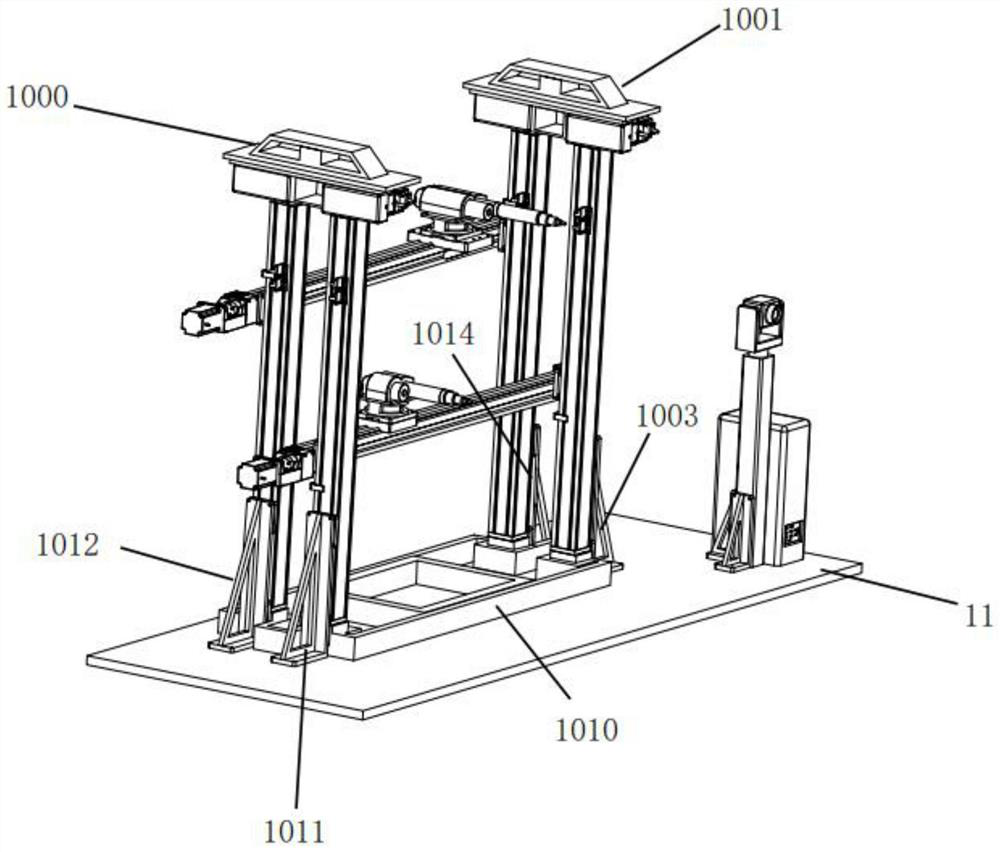

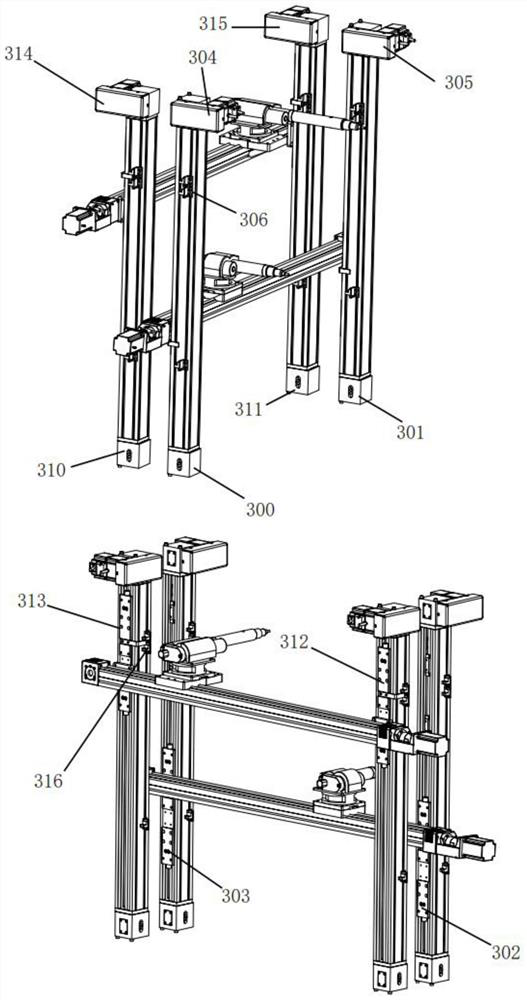

Intelligent device for detecting on-off state between wiring terminals in electric cabinet

PendingCN113267735AGuaranteed excellent rateNo manual operationContinuity testingElectric controlControl theory

The invention relates to an intelligent device for detecting and controlling the on-off state of wiring terminals in an electric cabinet. The intelligent device comprises a mainframe box, a visual positioning control mechanism, a driving mechanism for detecting whether the wiring terminals in the electric cabinet are conducted or not, and an electric control cabinet. The driving mechanism for the on-off state test and the visual positioning control mechanism are both connected with the electric control cabinet in a conducting manner. During detection, an electric cabinet box body carried by a conveyor belt is conveyed to a conduction detection station and stops, then the visual positioning control mechanism obtains position information of any two wiring terminals in the electric cabinet, and then the driving mechanism carries out conduction detection on the wiring terminals; and finally, a detection result is sent to a lower computer for a next process. Manual operation is not needed, use is convenient, detection is accurate, efficiency is high, the factory yield of products is guaranteed, and labor cost is greatly reduced.

Owner:CHANGCHUN UNIV OF TECH

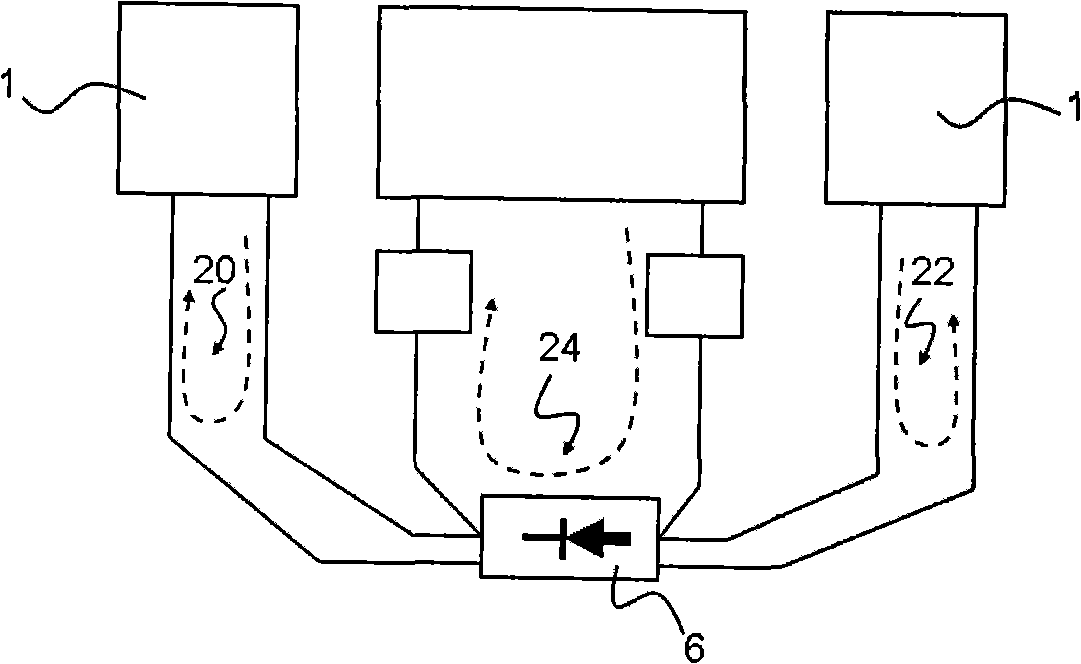

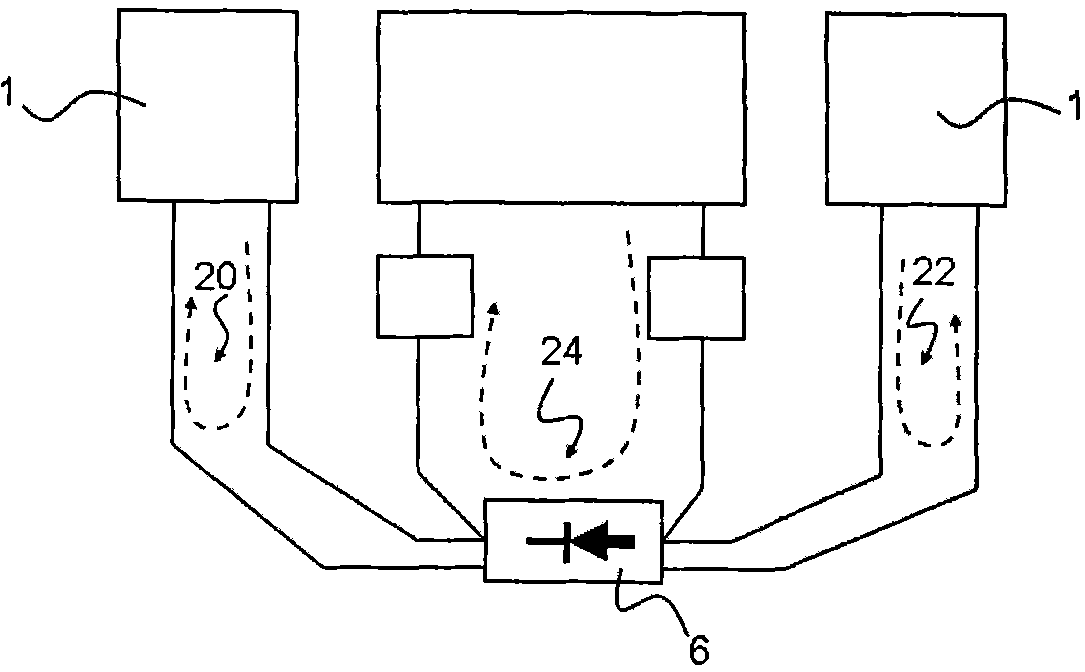

Automatic soldering equipment capable of protecting transformer PINs and soldering method

PendingCN112191970AAutomate operationsImprove the condition of poor solderingMetal working apparatusSoldering auxillary devicesTransformerEngineering

The invention discloses automatic soldering equipment capable of protecting transformer PINs and a soldering method. The automatic soldering equipment capable of protecting the transformer PINs comprises a jig transferring system, a high-temperature soldering system, a low-temperature soldering system and a soldering flux system; the jig transferring system is provided with a loading jig and a driving device for driving the loading jig to move; the high-temperature soldering system is provided with a high-temperature soldering furnace; the low-temperature soldering system is provided with a low-temperature soldering furnace; the soldering flux system is provided with a soldering flux furnace; the high-temperature soldering furnace, the low-temperature soldering furnace and the soldering flux furnace are arranged in an X-axis direction of the loading jig; and the driving device selectively drives the loading jig to the soldering flux furnace, the low-temperature soldering furnace and the high-temperature soldering furnace. Therefore, by configuring the jig transferring system, the high-temperature soldering system, the low-temperature soldering system and the soldering flux system,when soldering operation is conducted, low-temperature soldering furnace soldering can be conducted before high-temperature soldering furnace soldering on a same machine base, so that the problem of yellowing of soldered transformer PINs in traditional technologies is effectively solved, and the condition of poor soldering of transformer PINs is improved.

Owner:DONGGUAN JIALONG HAIJIE ELECTRONICS TECH CO LTD

Detection machine station with contact impedance detection device

InactiveCN101581742BImprove disadvantagesReduced risk of errorResistance/reactance/impedenceElectronic circuit testingContact impedanceTransfer switch

The invention is suitable for the technical field of circuit component tests, and provides a detection machine station with a contact impedance detection device, used for detecting a circuit component to be tested. The detection machine station comprises two pairs of pressure conduction connecting devices and electric signal supply sensing devices, the contact impedance detection device comprises a set of standard components with known electric characteristics and a set of transfer switches used for switching the pressure conduction connecting device to the standard components by electric connection, is provided for the electric signal supply sensing device to sense contact impedance of an electric circuit of the pressure conduction connecting device and the standard components.

Owner:CHROMA ELECTRONICS SHENZHEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com