Clamping method for fine machining of large workpieces

A technology for fine processing and large workpieces, applied in metal processing equipment, metal processing machinery parts, clamping, etc., can solve the problems that cannot meet the requirements of people's processing speed, efficiency and precision, and achieve high-quality rate, smooth processing, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

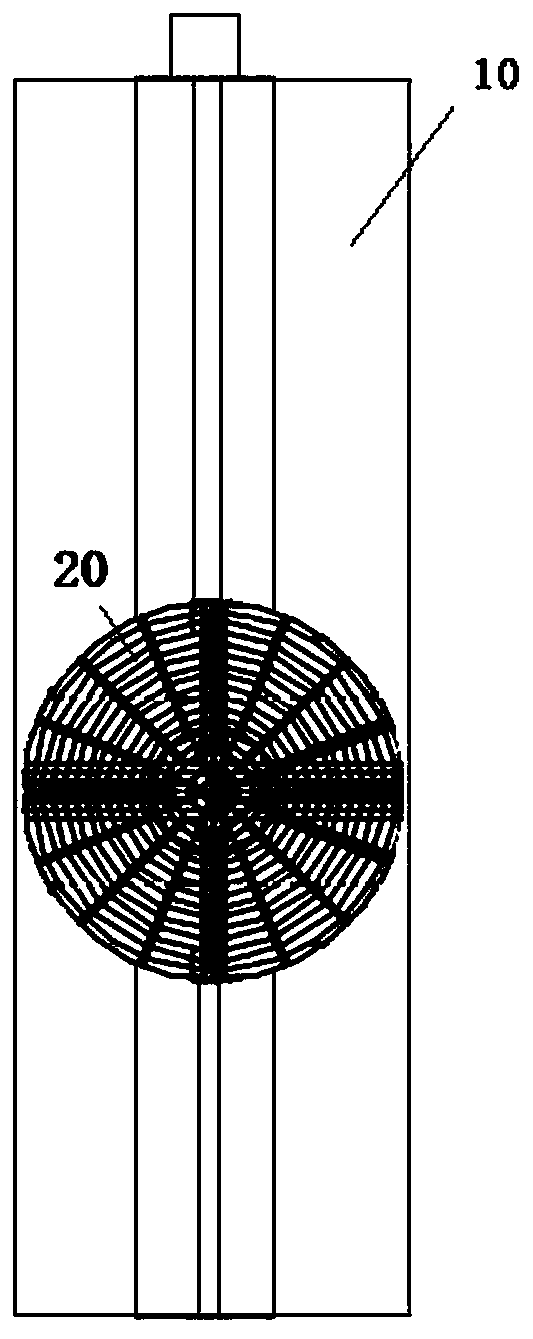

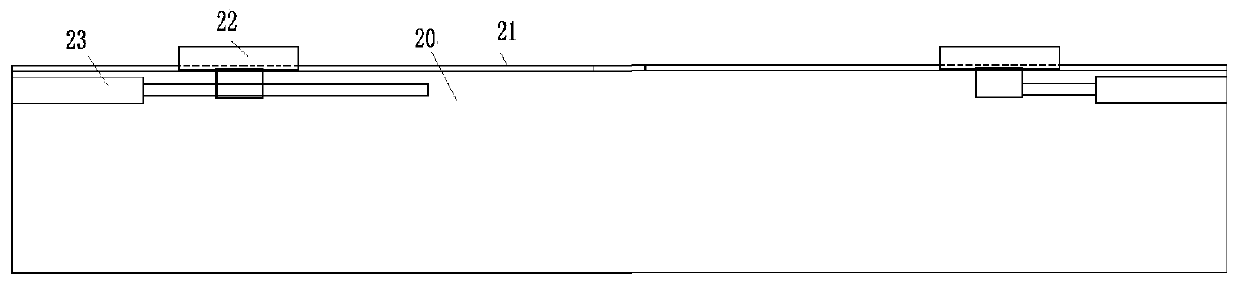

[0032] see Figure 1 to Figure 3 , shows one embodiment of the clamping system for fine machining of large workpieces of the present invention.

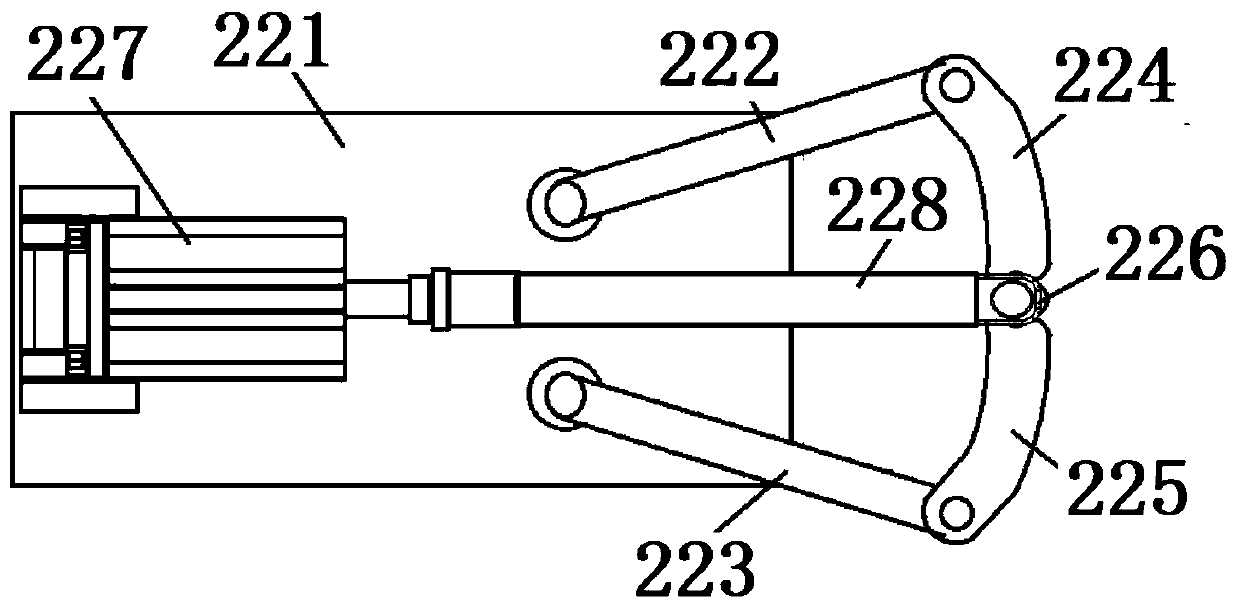

[0033] In this embodiment, the clamping system for fine machining of large workpieces includes a clamping disc 20 that can move along the workpiece table 10, and the clamping disc 20 is provided with a plurality of dovetails radiating outward from the center of the disc. Clamping slots 21, each dovetail clamping slot 21 is provided with rotating clamping blocks 22 that can be slid and fixed along the dovetail clamping slots, so that workpieces of various shapes can be clamped by sliding and fixing a plurality of rotating clamping blocks 22, optional Yes, the plurality of dovetail clamping grooves 21 are eight dovetail clamping grooves arranged at equiangular intervals. Through such an arrangement, it is possible to stably clamp various large-scale workpieces with special shapes or plastic shapes. Among them, the eight dovetail clampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com