Dual-drive multi-knuckle bionic gripper

A dual-drive and gripper technology, applied in the field of robots, can solve the problems of increasing time and production costs, unable to meet the problems of fragile grasping, low reliability, etc., to achieve a simplified structure, facilitate human-machine collaboration, and ensure the clamping effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

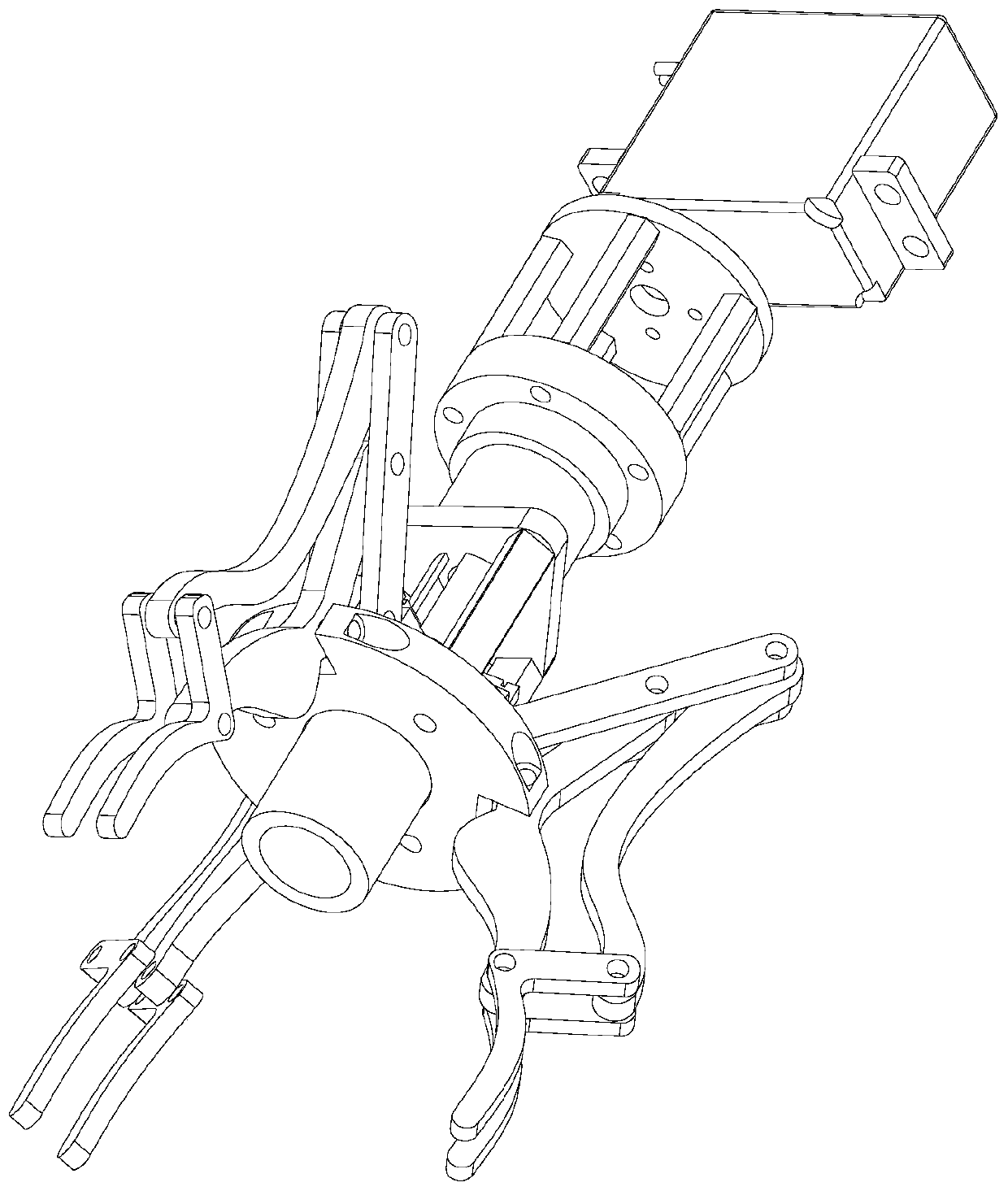

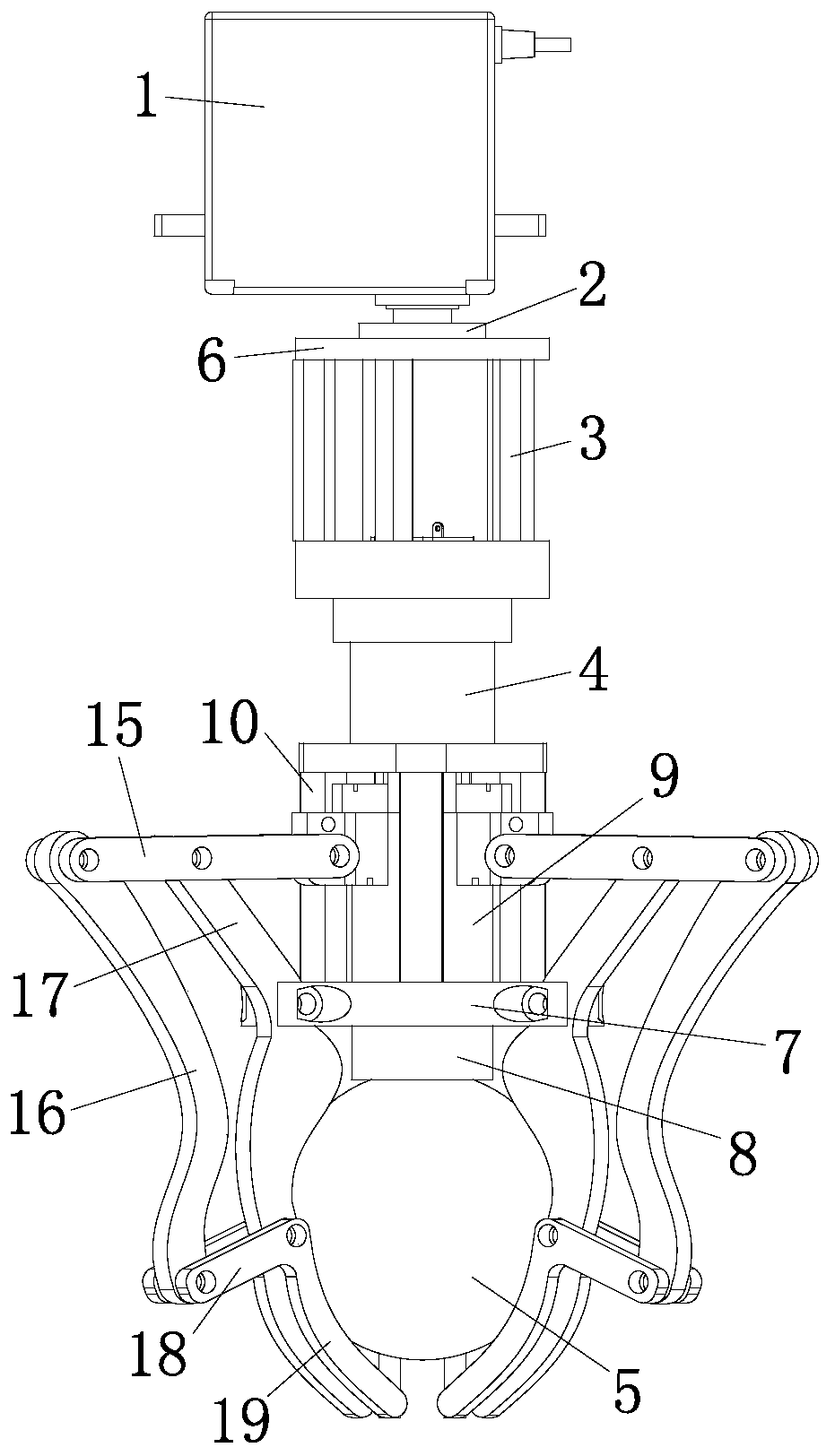

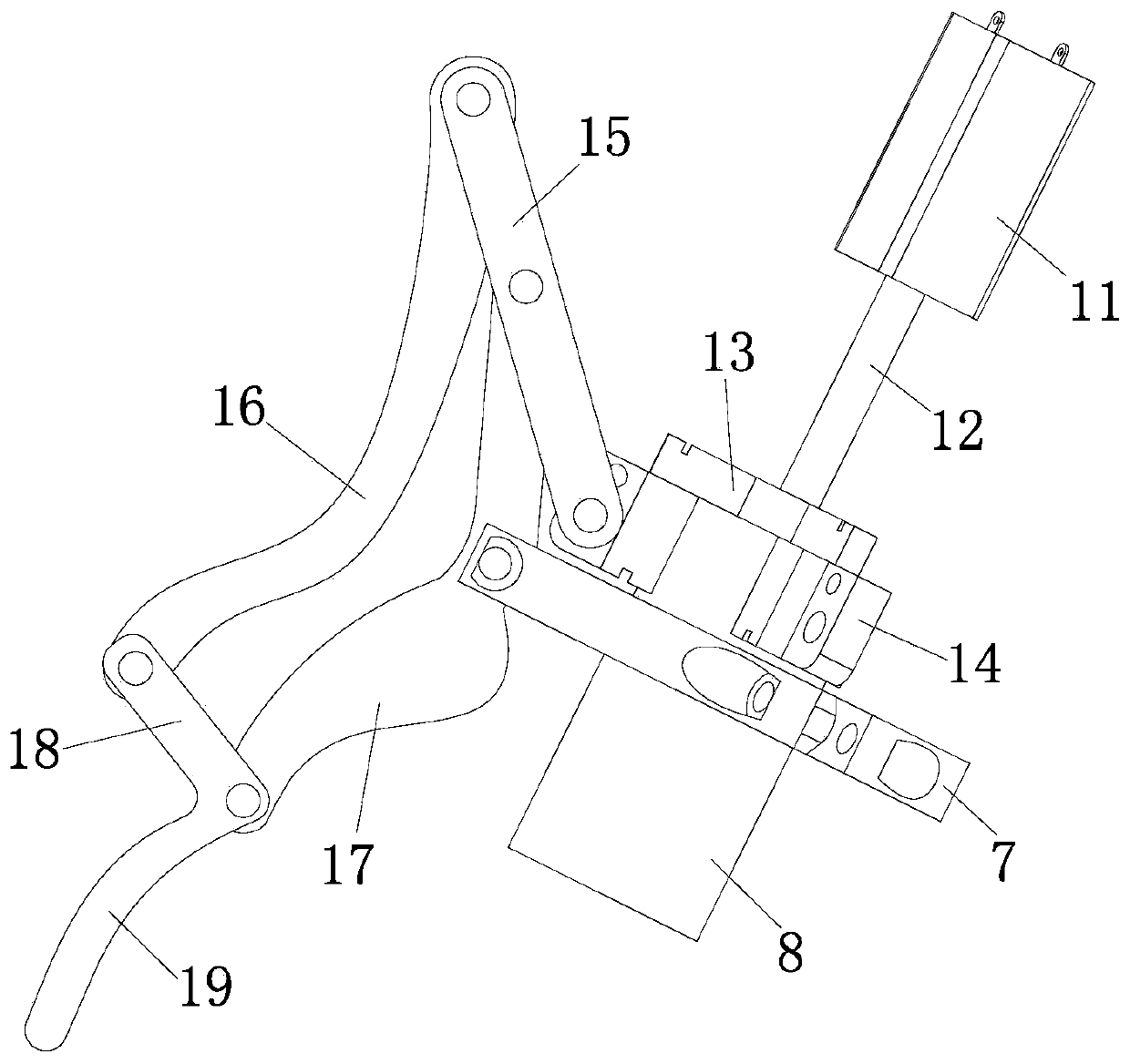

[0027] Such as figure 1 As shown, the dual-drive multi-knuckle bionic gripper includes a frame, a first motor 1, a second motor 11, a support platform 8, gripper branches and a transmission mechanism. The first motor is arranged at the rear end of the rack ( figure 2 The upper part of the middle frame), the first motor is used to drive the frame to rotate around the axis, the second motor is arranged in the frame, and the pallet is telescopically positioned at the front end of the frame ( figure 2 The lower part of the middle frame), several gripper branches are also arranged at the front end of the frame and evenly arranged around the pallet, and the transmission mechanism is used to transmit the second motor power to drive the pallet and the gripper branch to move. Three gripper branches are even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com