Multi-axis fatigue testing clamp of high-cycle fatigue testing machine

A fatigue testing machine and high-cycle fatigue technology, applied in the field of materials and machinery, to achieve the effect of fixed reliability and guaranteed measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

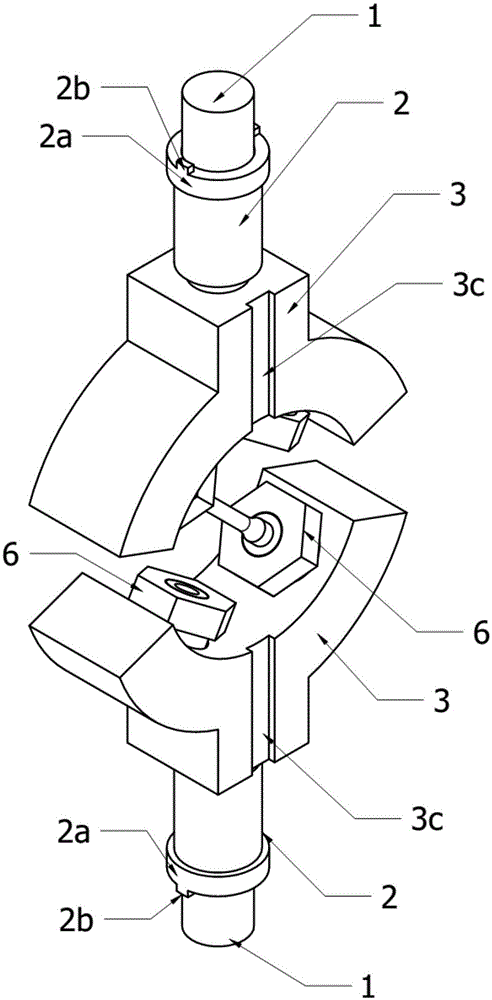

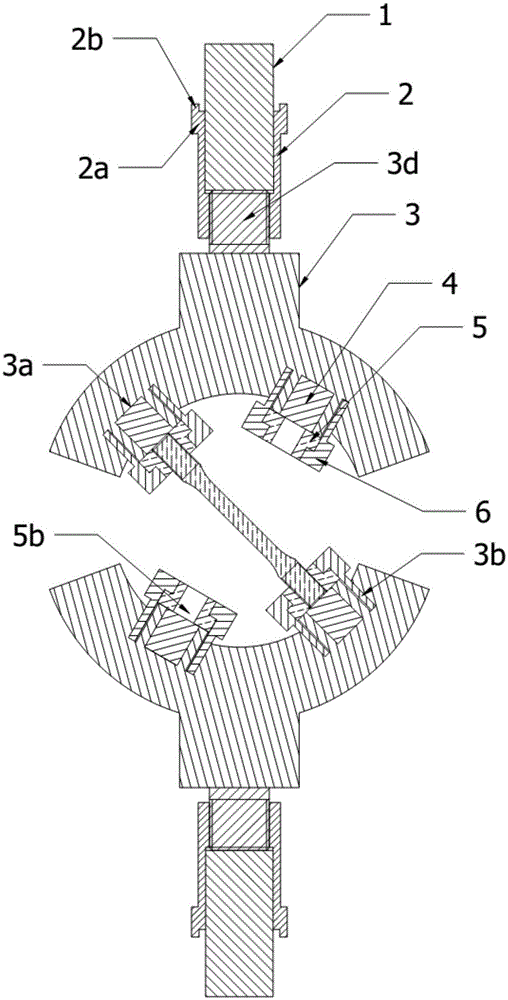

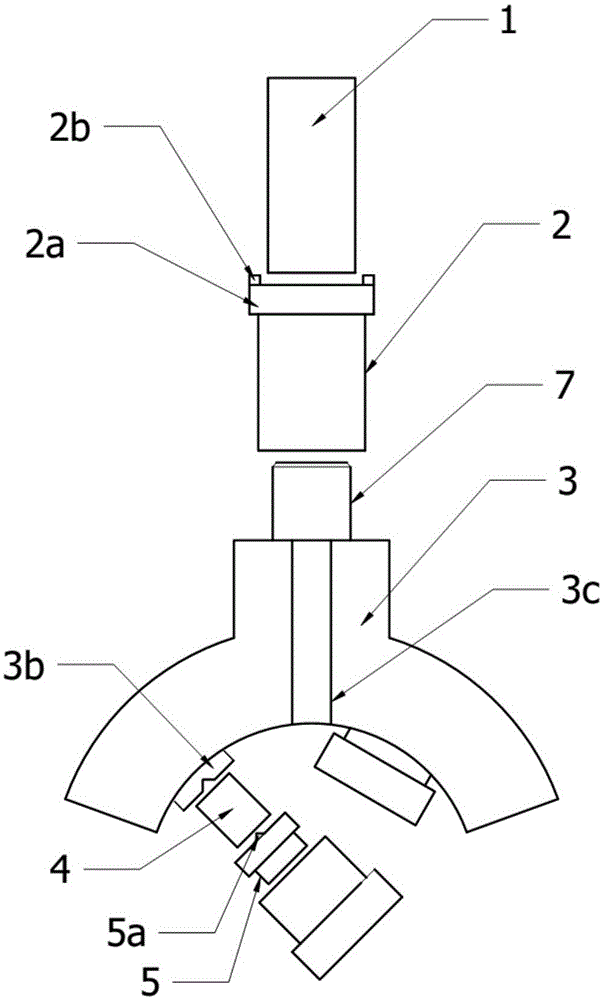

[0033] figure 1 , figure 2 and image 3As shown, a specific embodiment of the present invention is: a multi-axis fatigue test fixture of a high-cycle fatigue testing machine, including two opposite clamp bodies, and the clamping end at the rear of each clamp body is connected to the fatigue testing machine. The clamping head at the back of the clamp body is composed of an extension main shaft 1 and an extension sleeve 2 fitted outside the extension main shaft 1. The rear part of the extension sleeve 2 is provided with a The boss 2a and the limit foot 2b fixed and locked by the flange of the collet are characterized in that: the front end of the extension sleeve 2 is provided with an internal thread, and the internal thread is connected to the rear end of the arc-shaped clamp 3 The external threads at the rear of the shaft 3d cooperate; the concave surface at the front end of the arc fixture 3 is provided with a plurality of locking devices at different angles from the verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com