Cover plate assembly of an embedded touch screen and a manufacturing process of the cover plate assembly

An in-cell touch screen and manufacturing process technology, applied in other home appliances, data processing input/output process, electronic equipment and other directions, can solve problems such as defective bright spots, increase process cost and material cost, improve utilization rate, Guaranteed effect of excellent rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

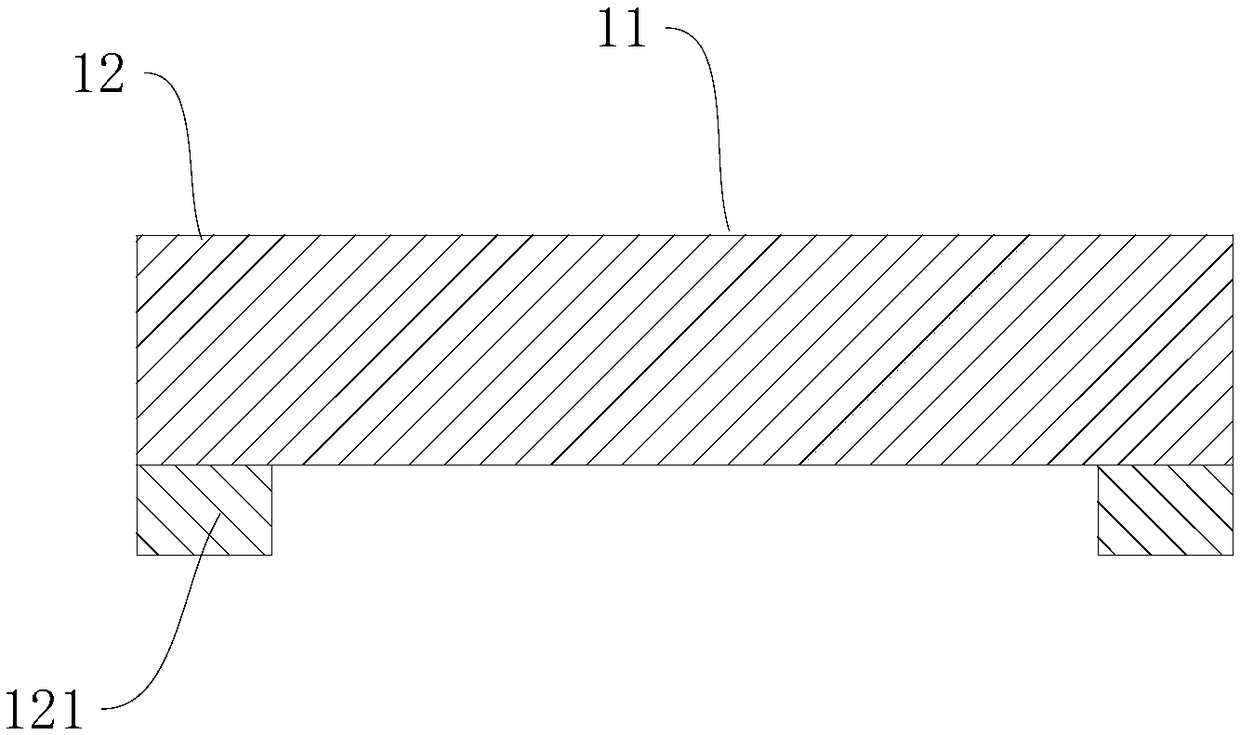

[0069] Print the silver ink on the cover plate 1, the thickness of the silver ink is 6-12μm;

[0070] Bake the silver ink, the baking temperature is 140±5℃, and the time is 60±5min;

[0071] It is beneficial to improve the adhesion of the button circuit 2 and ensure that the adhesion of the button circuit 2 on the cover plate 1 is greater than 4B.

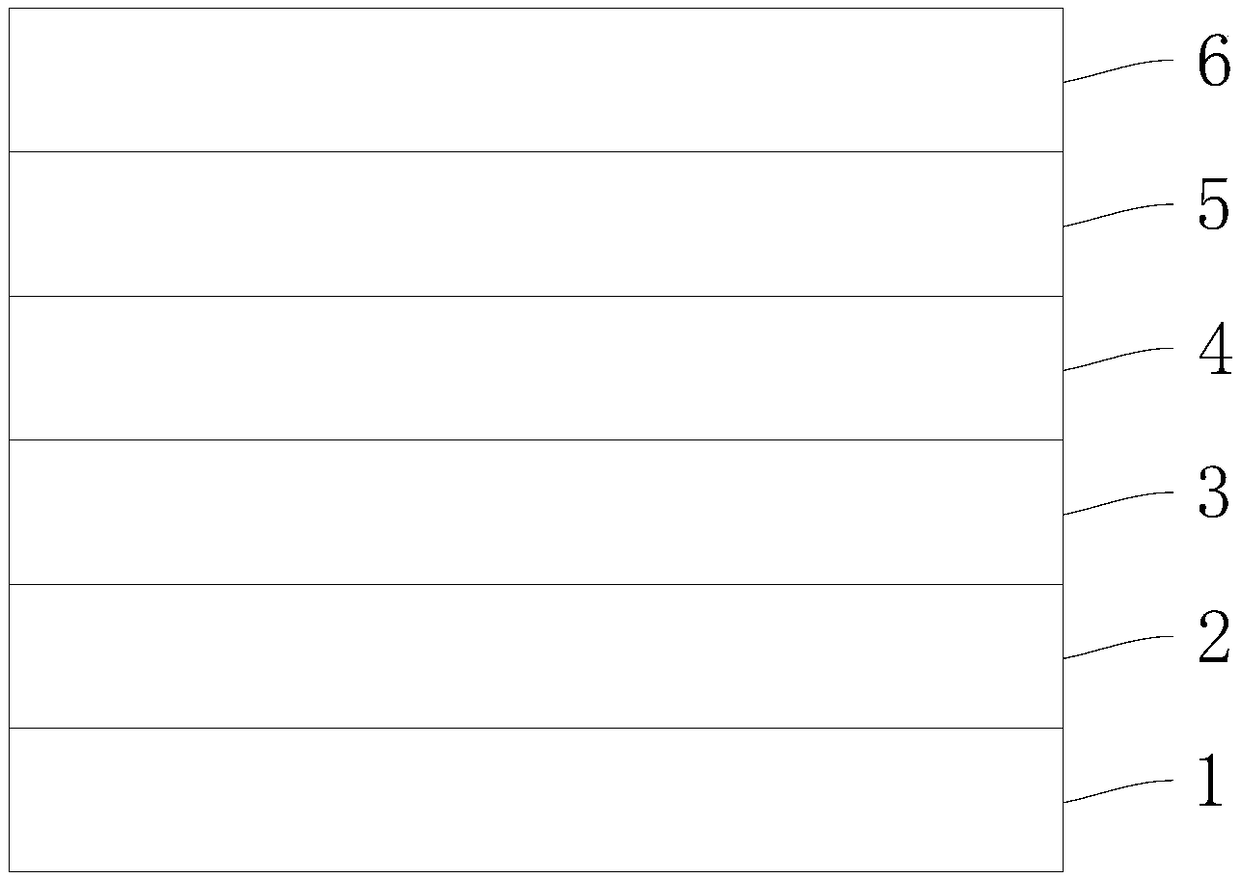

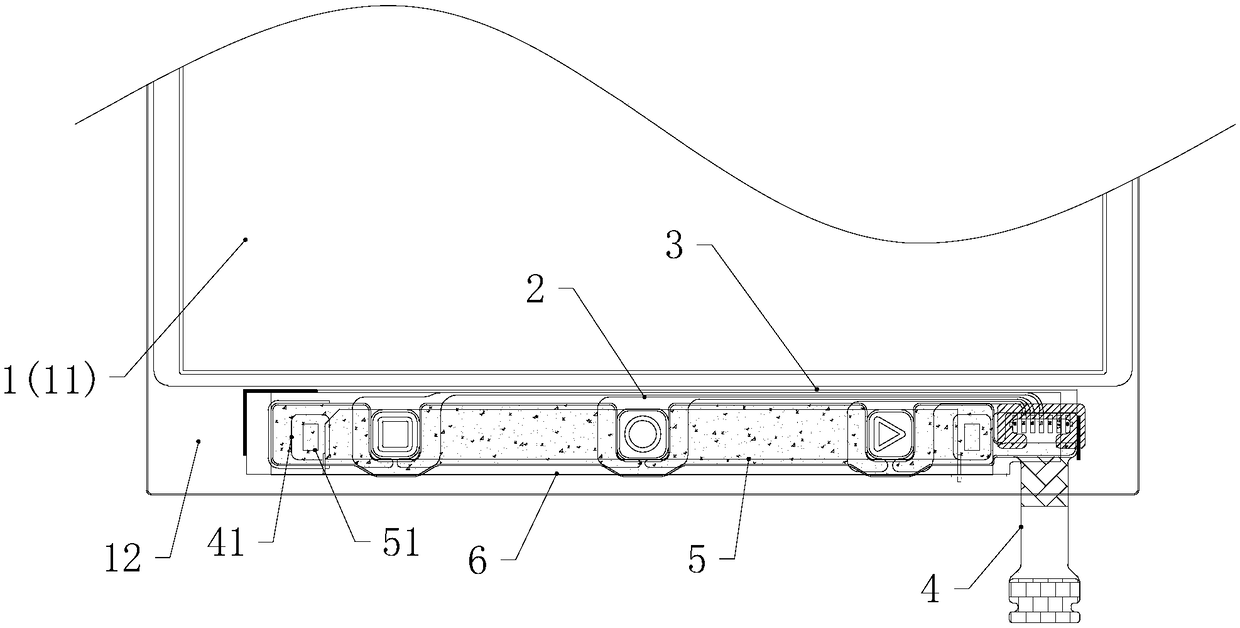

[0072] Further, as a specific embodiment of the manufacturing process of the cover plate assembly of the in-cell touch screen provided by the present invention,

[0073] The printing thickness of insulating ink is 6-18μm;

[0074] The temperature of baking the insulating ink is 120±5℃, and the time is 30±5min;

[0075] It is beneficial to improve the adhesion of the insulating layer 3 and ensure that the adhesion of the insulating layer 3 on the cover plate 1 and the ammonium bond circuit is greater than 4B.

[0076] Further, as a specific implementation of the manufacturing process of the cover assembly of the in-cell touch screen provided by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com