Sealing rod type laser liquid level gauge

A liquid level gauge and laser technology, applied in the field of liquid level gauges, can solve the problems of difficult measurement, low measurement accuracy, and high laser energy density, and achieve the effects of long service life, improved measurement accuracy, and reliable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further illustrate the present invention, below in conjunction with embodiment is described in more detail.

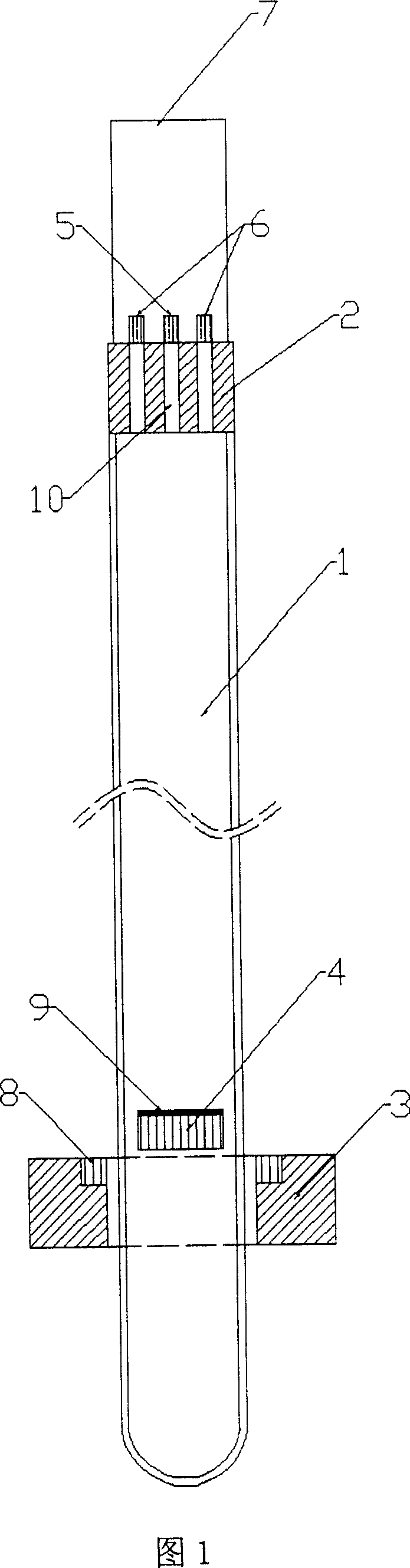

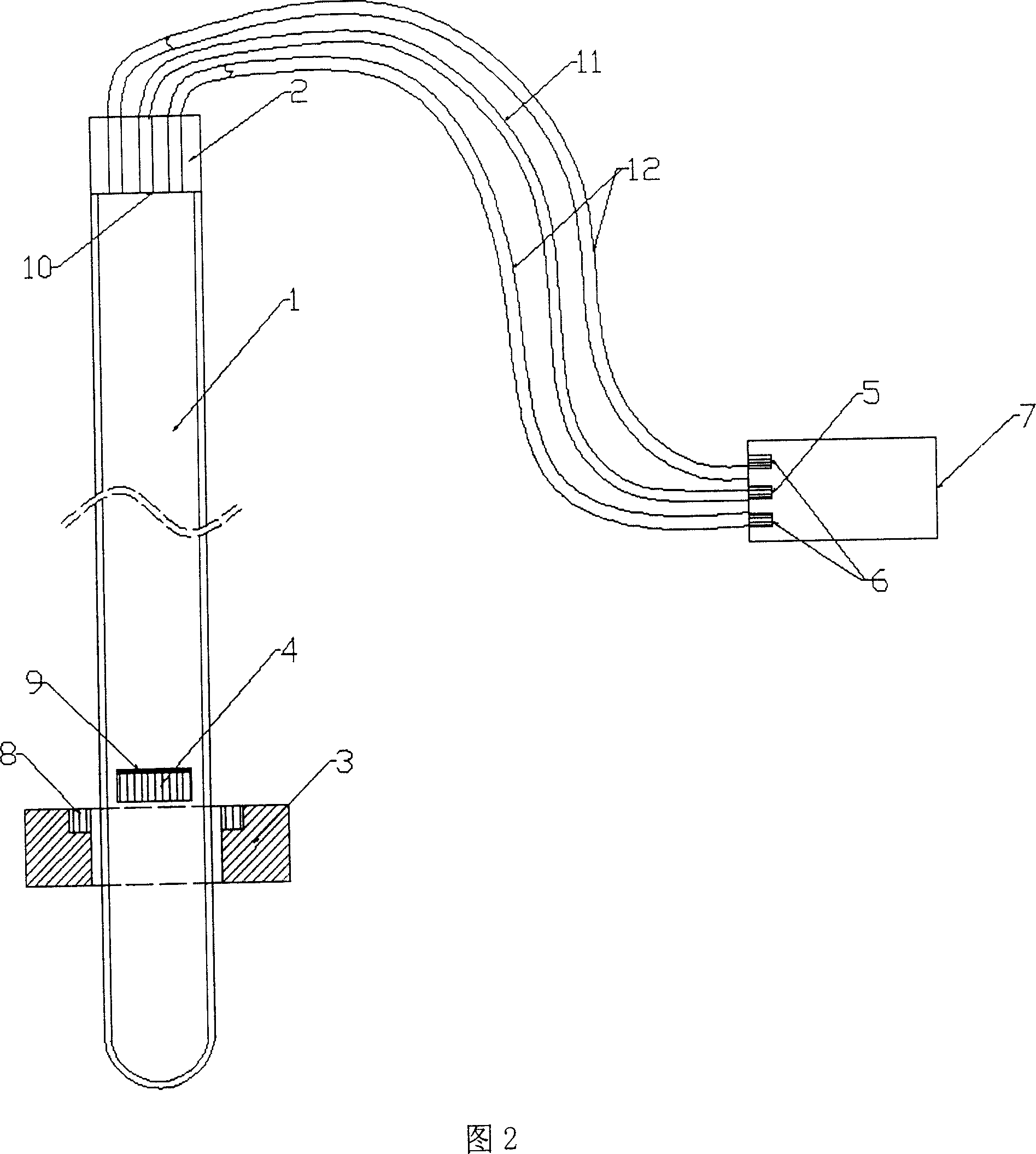

[0015] Fig. 1 is a schematic diagram of the first embodiment of the sealed rod laser liquid level gauge of the present invention. There is a magnetic float 4 inside the slender hollow detection rod 1, and there is an annular magnetic float composed of an annular float 3 and a small magnetic ring 8 outside the rod. The annular magnetic float 3 floats on the liquid surface when testing the liquid level. The diameter of the magnetic float 4 is slightly smaller than the inner diameter of the detection rod 1, and it should be ensured that it can move up and down without inversion;

[0016] The polarities of the magnetic float 4 and the annular magnetic float 3 are oppositely placed, that is, when the annular magnetic float floats on the liquid surface, the magnetic float 4 floats slightly higher than the small magnetic ring under the repulsive force of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com