Deep ultraviolet light emitting diode package

A technology for light-emitting diodes and packaging structures, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as package breakage and performance degradation of bonding materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

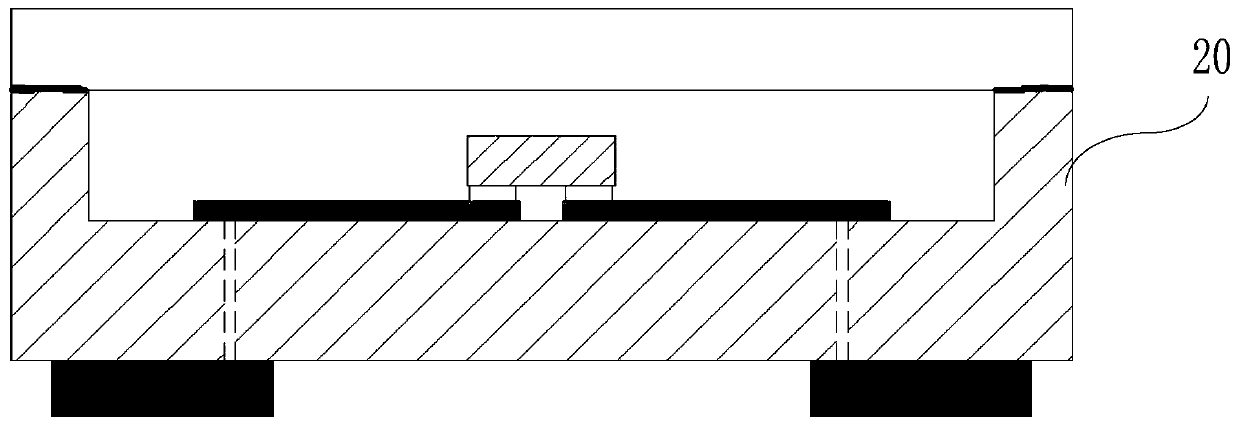

[0027] In recent years, deep ultraviolet light-emitting diodes have broad application prospects in the fields of sterilization and disinfection, polymer curing, biochemical detection, non-line-of-sight communication and special lighting. Compared with traditional ultraviolet light source mercury lamps, they are environmentally friendly, compact and portable, low power consumption, Low voltage and many other well-known advantages, the packaging structure of deep ultraviolet light-emitting diodes generally adopts an integrally formed insulating substrate and a support structure 20 composed of dams to place deep ultraviolet light-emitting diode chips, such as figure 1 As shown, in this packaging structure, the optical lens and the top of the dam are bonded together by an adhesive material or a welding material, so that a closed space is formed between the support structure 20 and the optical lens. In the current packaging structure, some inorganic packaging is used. This is becaus...

Embodiment 2

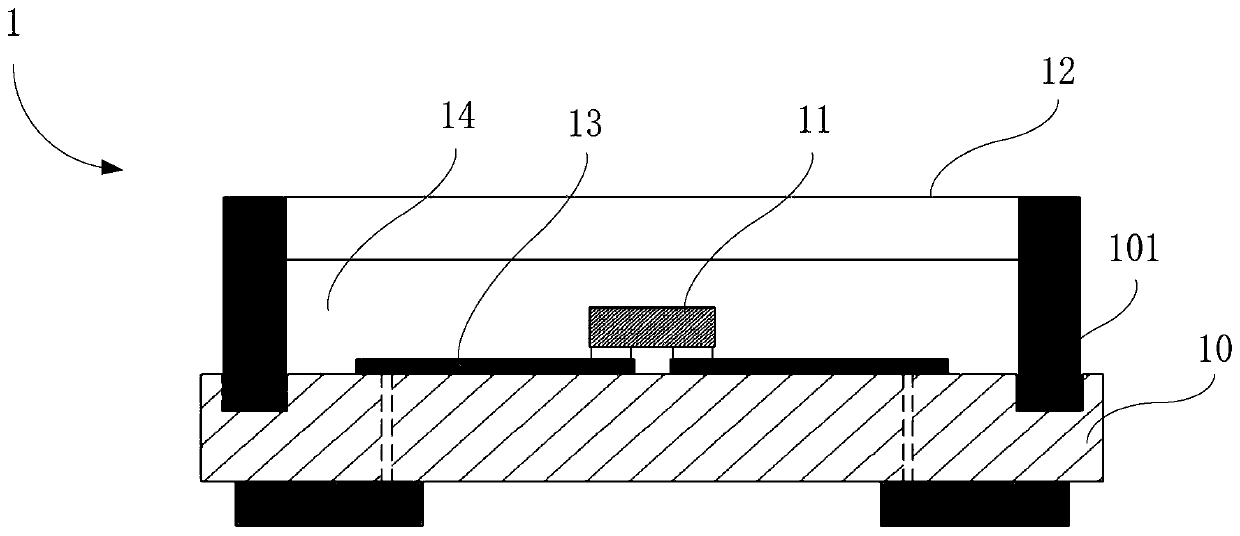

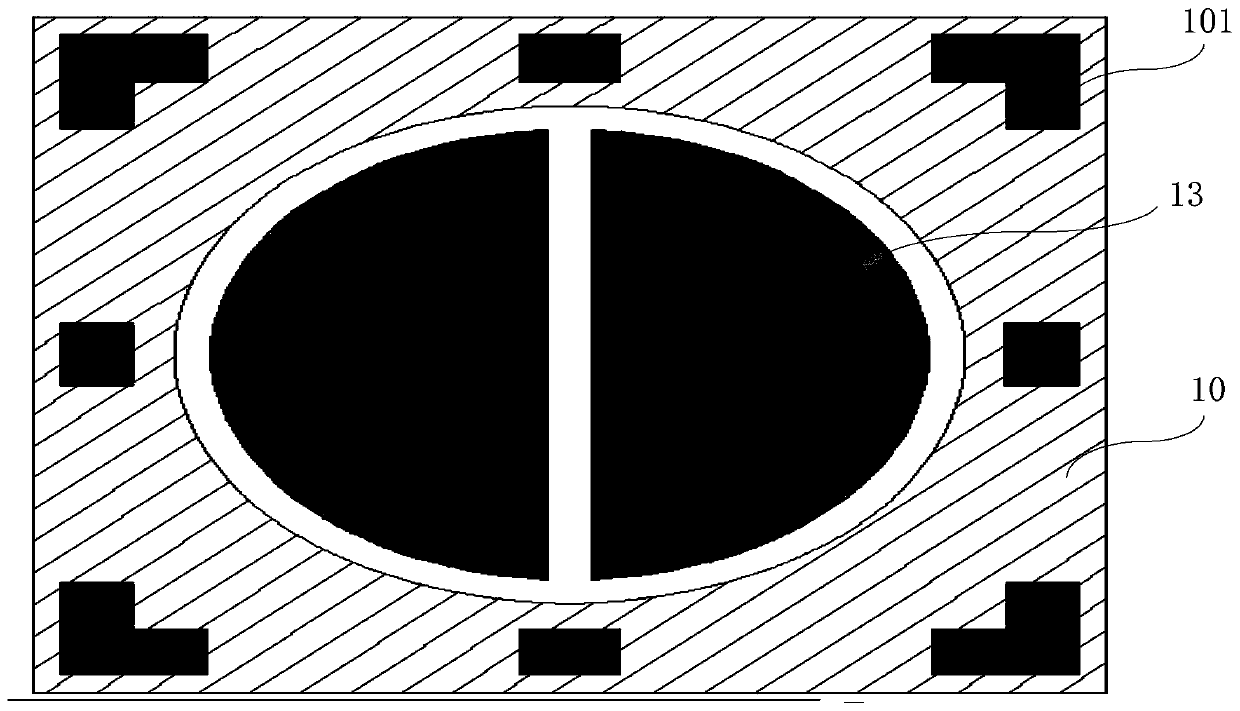

[0042] This embodiment provides a deep ultraviolet light emitting diode packaging structure 1, such as Figure 6 As shown, it includes: an insulating substrate 10, a light-emitting diode chip 11, a welding pad 13, and a light-transmitting component 12, wherein an inwardly recessed groove 101 is opened on the edge of the insulating substrate 10, and the light-transmitting component 12 is covered on the insulating substrate. 10 and the bottom end of the light-transmitting component 12 is bonded in the groove 101, the light-transmitting component 12 and the insulating substrate 10 jointly enclose a closed accommodation space 14, and the light-emitting diode chip 11 and the welding pad 13 are located in the accommodation space 14 , the welding pad 13 is arranged on the insulating substrate 10, and the light-emitting diode chip 11 is electrically connected to the welding pad 13. In the working state, the deep ultraviolet light emitted by the light-emitting diode chip 11 will fill th...

Embodiment 3

[0047] This embodiment provides a deep ultraviolet light emitting diode packaging structure 1, such as Figure 7 As shown, it includes: an insulating substrate 10, a light-emitting diode chip 11, a welding pad 13, and a light-transmitting component 12, wherein an inwardly recessed groove 101 is opened on the edge of the insulating substrate 10, and the light-transmitting component 12 is covered on the insulating substrate. 10 and the bottom end of the light-transmitting component 12 is bonded in the groove 101, the light-transmitting component 12 and the insulating substrate 10 jointly enclose a closed accommodation space 14, and the light-emitting diode chip 11 and the welding pad 13 are located in the accommodation space 14 , the welding pad 13 is arranged on the insulating substrate 10, and the light-emitting diode chip 11 is electrically connected to the welding pad 13. In the working state, the deep ultraviolet light emitted by the light-emitting diode chip 11 will fill th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com